brake fluid TOYOTA SIENNA 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 2074 of 3000

DS–20DRIVE SHAFT – FRONT DRIVE SHAFT

DS

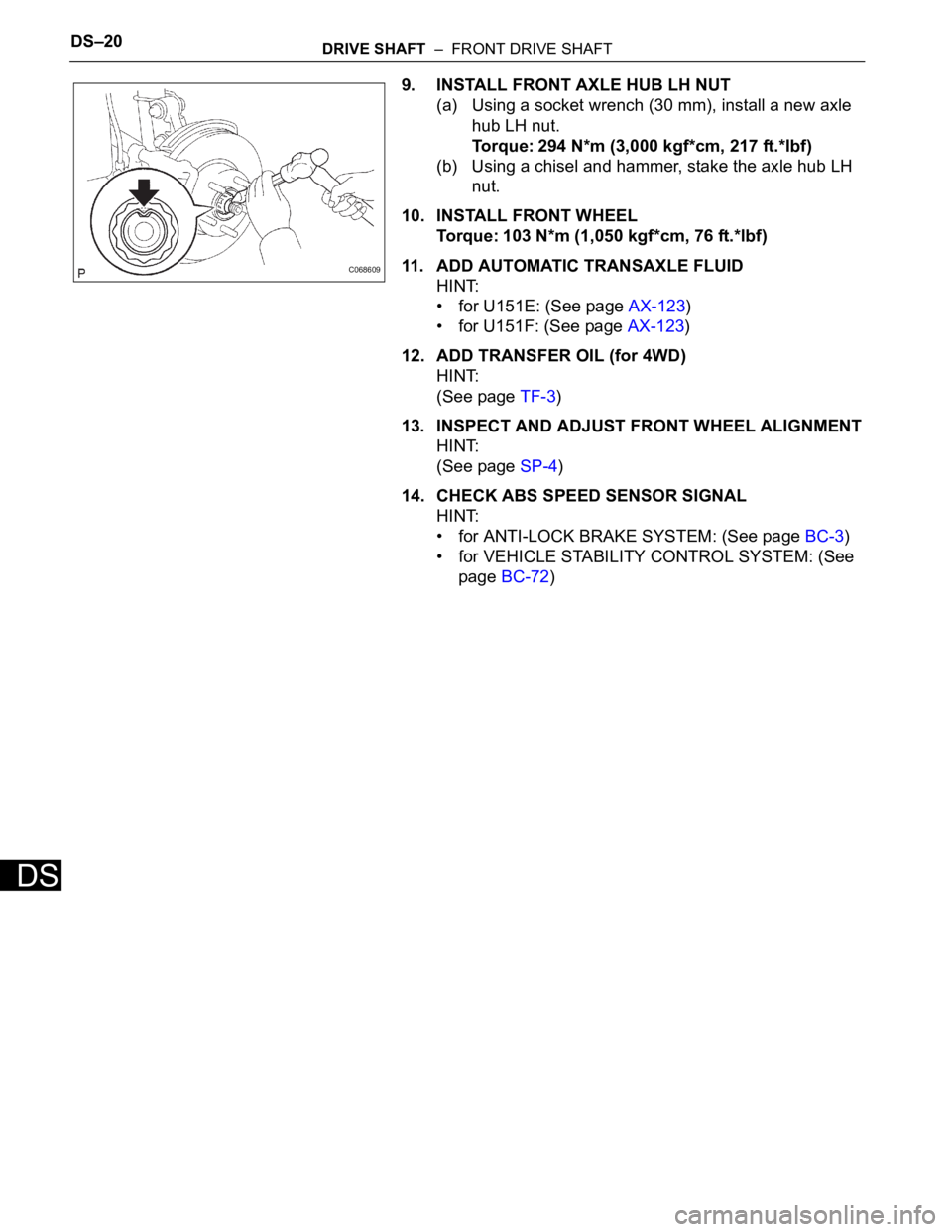

9. INSTALL FRONT AXLE HUB LH NUT

(a) Using a socket wrench (30 mm), install a new axle

hub LH nut.

Torque: 294 N*m (3,000 kgf*cm, 217 ft.*lbf)

(b) Using a chisel and hammer, stake the axle hub LH

nut.

10. INSTALL FRONT WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

11. ADD AUTOMATIC TRANSAXLE FLUID

HINT:

• for U151E: (See page AX-123)

• for U151F: (See page AX-123)

12. ADD TRANSFER OIL (for 4WD)

HINT:

(See page TF-3)

13. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

HINT:

(See page SP-4)

14. CHECK ABS SPEED SENSOR SIGNAL

HINT:

• for ANTI-LOCK BRAKE SYSTEM: (See page BC-3)

• for VEHICLE STABILITY CONTROL SYSTEM: (See

page BC-72)

C068609

Page 2080 of 3000

DRIVE SHAFT – FRONT DRIVE SHAFTDS–5

DS

REMOVAL

1. DRAIN AUTOMATIC TRANSAXLE FLUID

(a) Remove the drain plug, gasket and drain ATF.

(b) Install a new gasket and the drain plug.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

2. DRAIN TRANSFER OIL (for 4WD)

HINT:

(See page TF-8)

3. REMOVE FRONT WHEEL

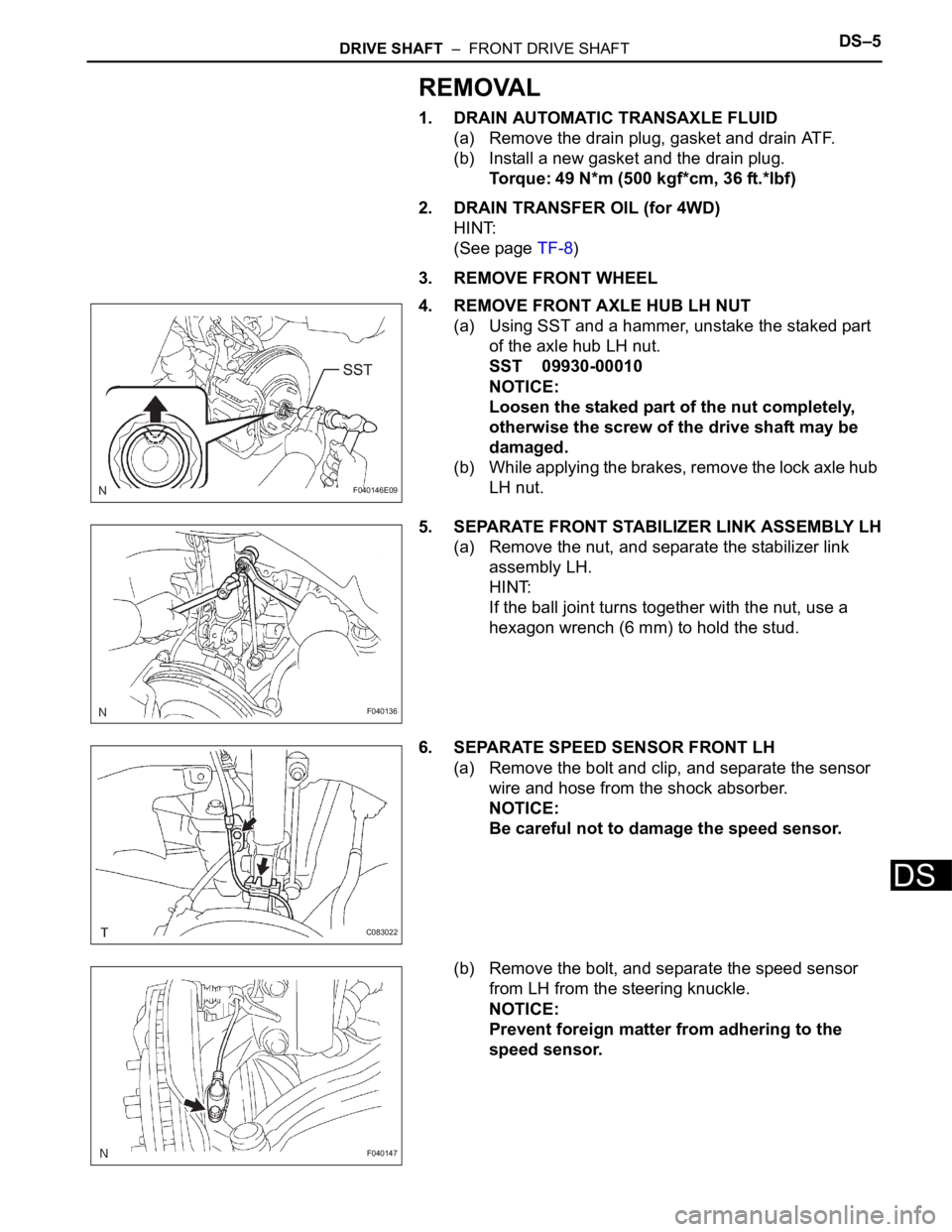

4. REMOVE FRONT AXLE HUB LH NUT

(a) Using SST and a hammer, unstake the staked part

of the axle hub LH nut.

SST 09930-00010

NOTICE:

Loosen the staked part of the nut completely,

otherwise the screw of the drive shaft may be

damaged.

(b) While applying the brakes, remove the lock axle hub

LH nut.

5. SEPARATE FRONT STABILIZER LINK ASSEMBLY LH

(a) Remove the nut, and separate the stabilizer link

assembly LH.

HINT:

If the ball joint turns together with the nut, use a

hexagon wrench (6 mm) to hold the stud.

6. SEPARATE SPEED SENSOR FRONT LH

(a) Remove the bolt and clip, and separate the sensor

wire and hose from the shock absorber.

NOTICE:

Be careful not to damage the speed sensor.

(b) Remove the bolt, and separate the speed sensor

from LH from the steering knuckle.

NOTICE:

Prevent foreign matter from adhering to the

speed sensor.

F040146E09

F040136

C083022

F040147

Page 2095 of 3000

DS–20DRIVE SHAFT – FRONT DRIVE SHAFT

DS

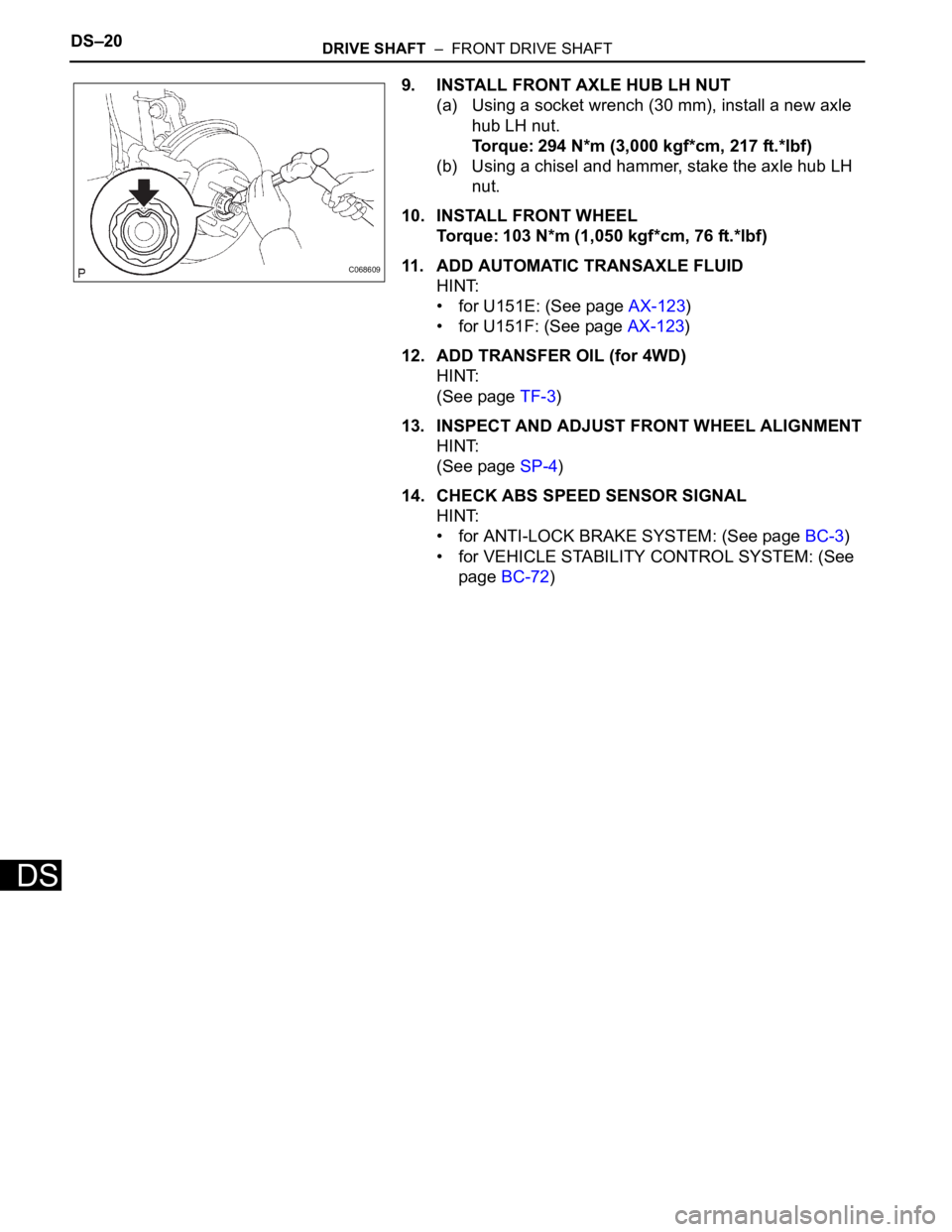

9. INSTALL FRONT AXLE HUB LH NUT

(a) Using a socket wrench (30 mm), install a new axle

hub LH nut.

Torque: 294 N*m (3,000 kgf*cm, 217 ft.*lbf)

(b) Using a chisel and hammer, stake the axle hub LH

nut.

10. INSTALL FRONT WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

11. ADD AUTOMATIC TRANSAXLE FLUID

HINT:

• for U151E: (See page AX-123)

• for U151F: (See page AX-123)

12. ADD TRANSFER OIL (for 4WD)

HINT:

(See page TF-3)

13. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

HINT:

(See page SP-4)

14. CHECK ABS SPEED SENSOR SIGNAL

HINT:

• for ANTI-LOCK BRAKE SYSTEM: (See page BC-3)

• for VEHICLE STABILITY CONTROL SYSTEM: (See

page BC-72)

C068609

Page 2225 of 3000

SP–42SUSPENSION – REAR COIL SPRING

SP

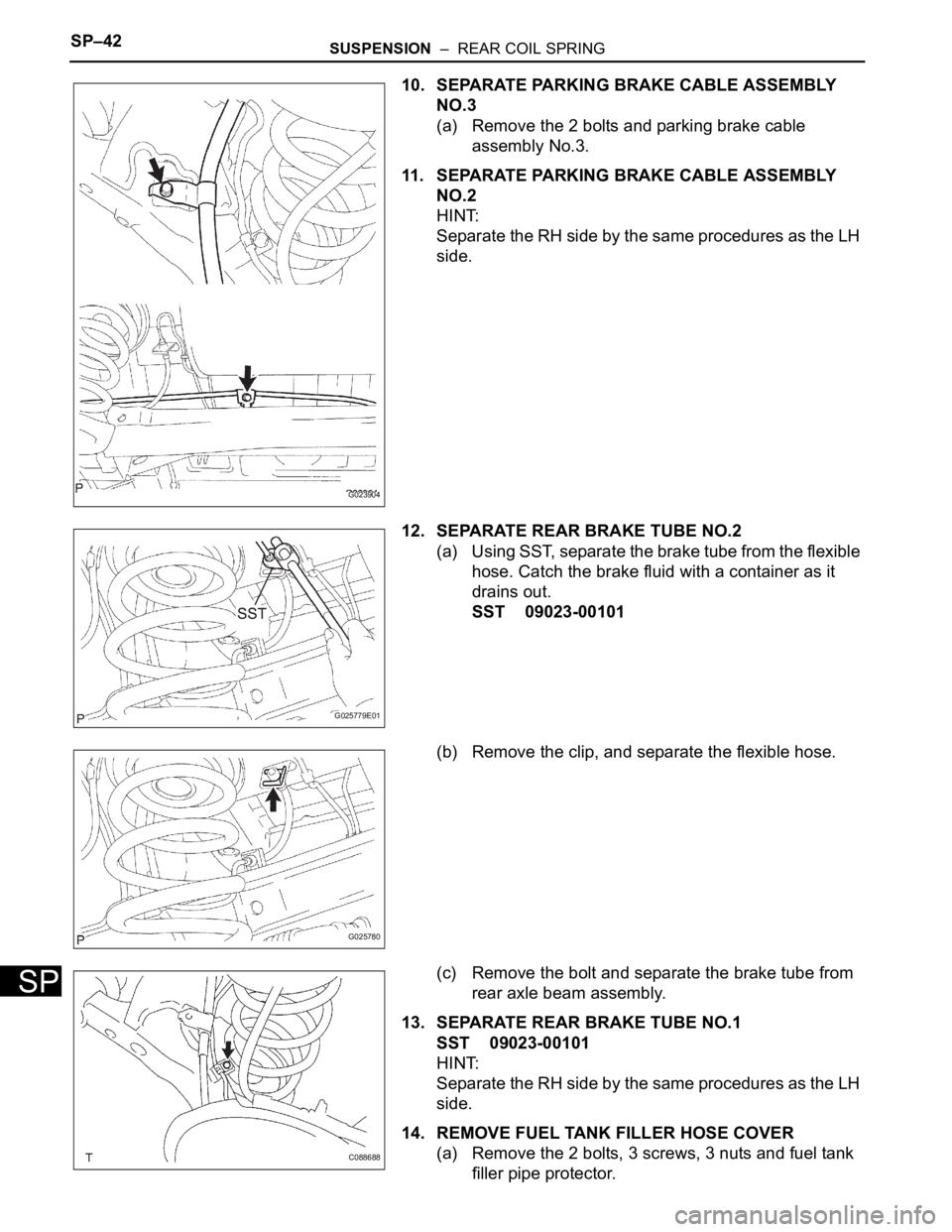

10. SEPARATE PARKING BRAKE CABLE ASSEMBLY

NO.3

(a) Remove the 2 bolts and parking brake cable

assembly No.3.

11. SEPARATE PARKING BRAKE CABLE ASSEMBLY

NO.2

HINT:

Separate the RH side by the same procedures as the LH

side.

12. SEPARATE REAR BRAKE TUBE NO.2

(a) Using SST, separate the brake tube from the flexible

hose. Catch the brake fluid with a container as it

drains out.

SST 09023-00101

(b) Remove the clip, and separate the flexible hose.

(c) Remove the bolt and separate the brake tube from

rear axle beam assembly.

13. SEPARATE REAR BRAKE TUBE NO.1

SST 09023-00101

HINT:

Separate the RH side by the same procedures as the LH

side.

14. REMOVE FUEL TANK FILLER HOSE COVER

(a) Remove the 2 bolts, 3 screws, 3 nuts and fuel tank

filler pipe protector.

G023904

G025779E01

G025780

C088688

Page 2230 of 3000

SUSPENSION – REAR COIL SPRINGSP–47

SP

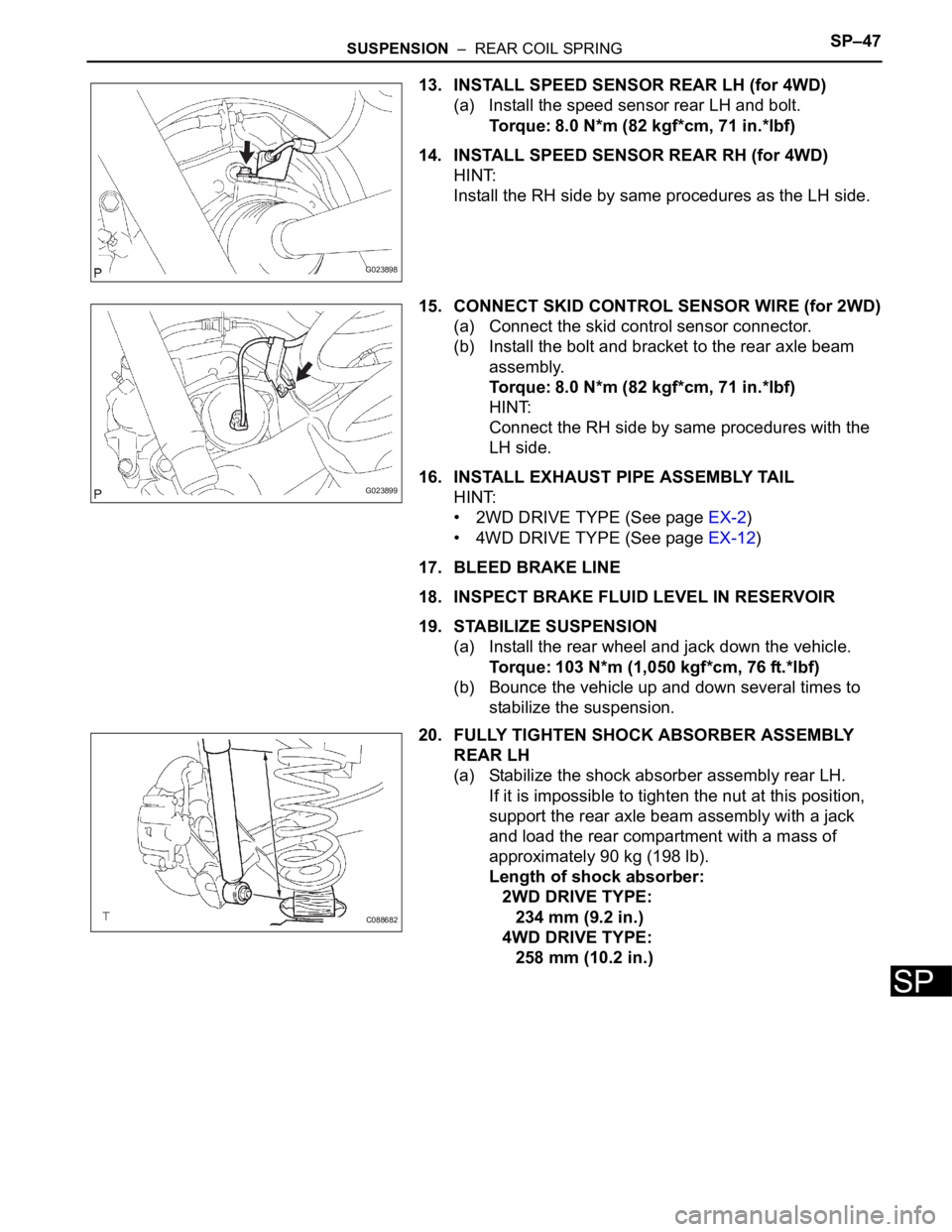

13. INSTALL SPEED SENSOR REAR LH (for 4WD)

(a) Install the speed sensor rear LH and bolt.

Torque: 8.0 N*m (82 kgf*cm, 71 in.*lbf)

14. INSTALL SPEED SENSOR REAR RH (for 4WD)

HINT:

Install the RH side by same procedures as the LH side.

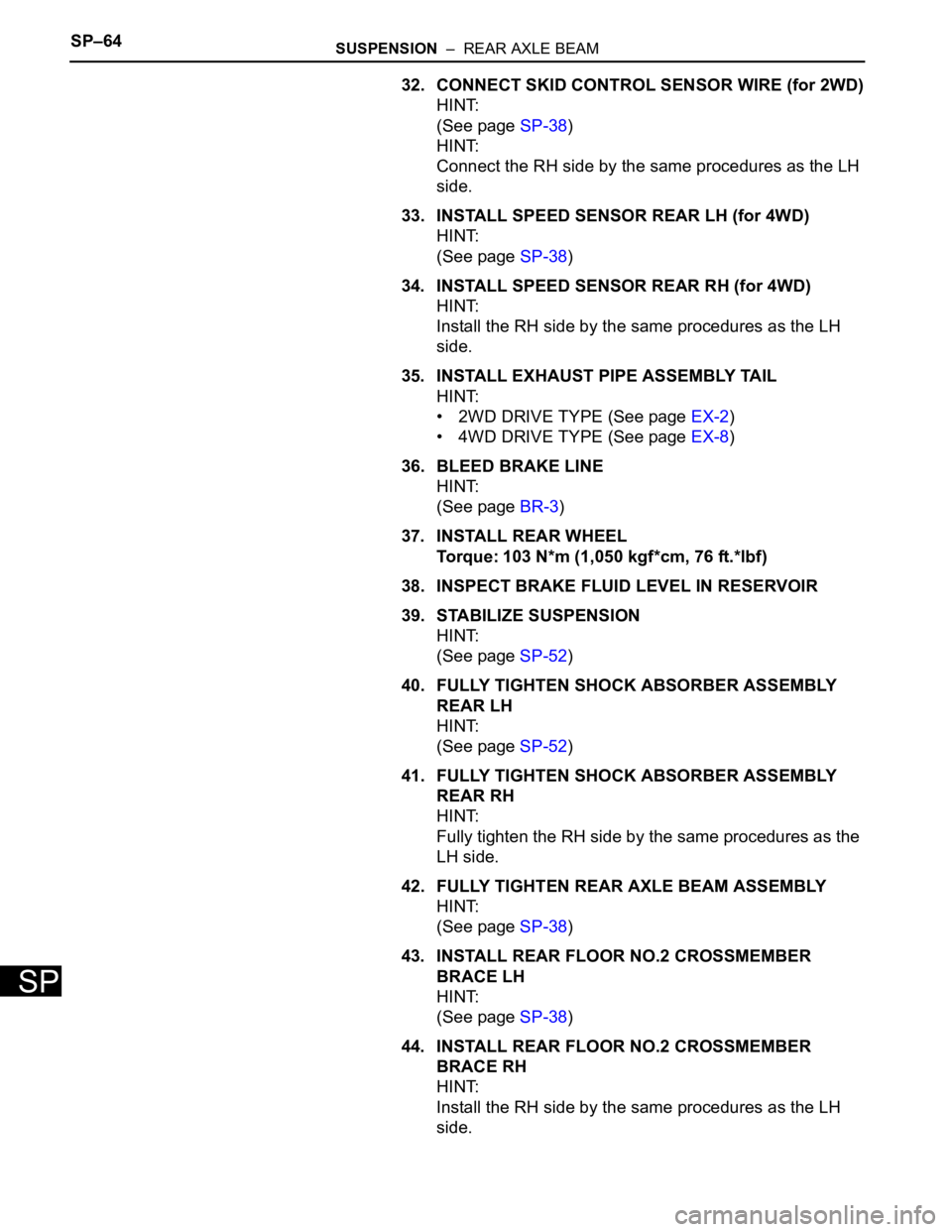

15. CONNECT SKID CONTROL SENSOR WIRE (for 2WD)

(a) Connect the skid control sensor connector.

(b) Install the bolt and bracket to the rear axle beam

assembly.

Torque: 8.0 N*m (82 kgf*cm, 71 in.*lbf)

HINT:

Connect the RH side by same procedures with the

LH side.

16. INSTALL EXHAUST PIPE ASSEMBLY TAIL

HINT:

• 2WD DRIVE TYPE (See page EX-2)

• 4WD DRIVE TYPE (See page EX-12)

17. BLEED BRAKE LINE

18. INSPECT BRAKE FLUID LEVEL IN RESERVOIR

19. STABILIZE SUSPENSION

(a) Install the rear wheel and jack down the vehicle.

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

(b) Bounce the vehicle up and down several times to

stabilize the suspension.

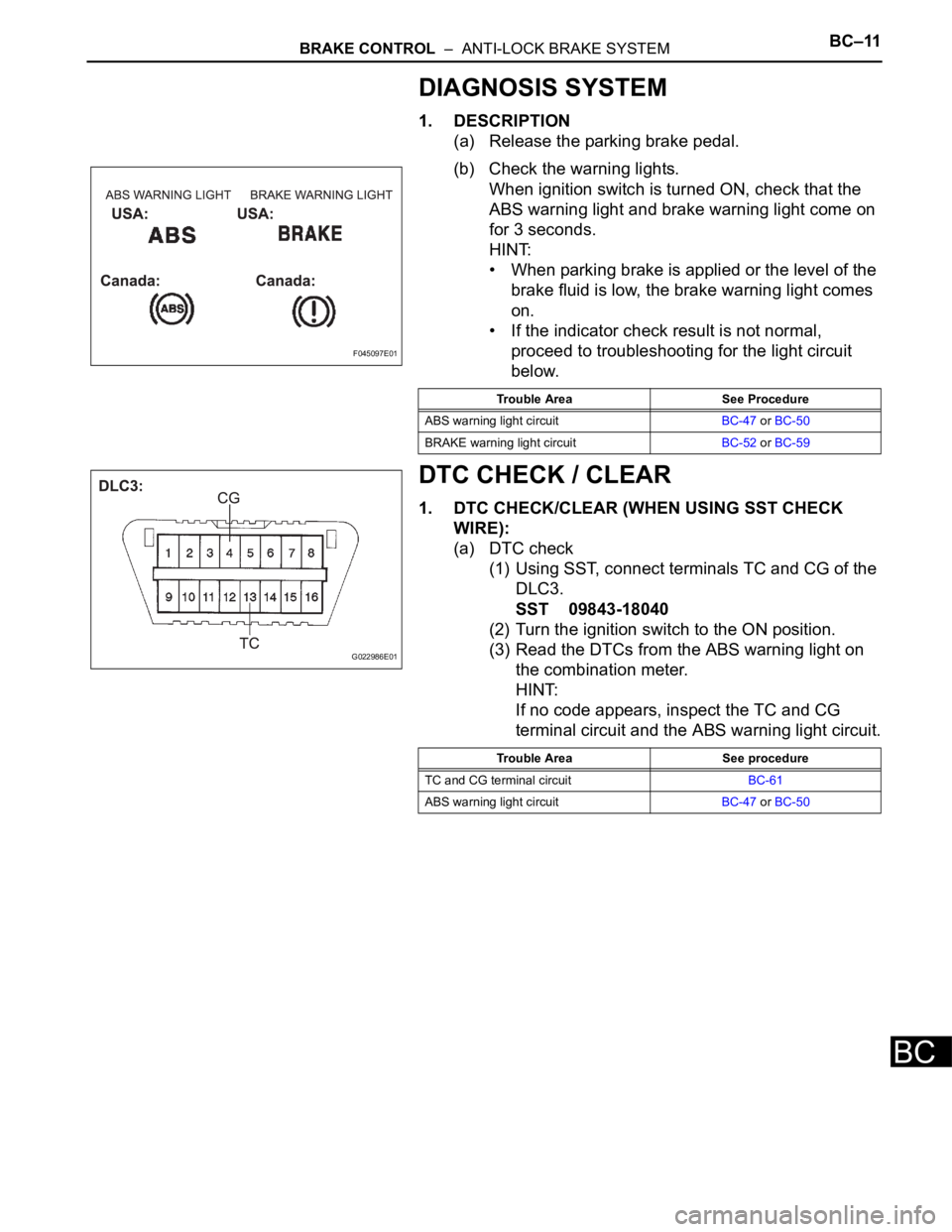

20. FULLY TIGHTEN SHOCK ABSORBER ASSEMBLY

REAR LH

(a) Stabilize the shock absorber assembly rear LH.

If it is impossible to tighten the nut at this position,

support the rear axle beam assembly with a jack

and load the rear compartment with a mass of

approximately 90 kg (198 lb).

Length of shock absorber:

2WD DRIVE TYPE:

234 mm (9.2 in.)

4WD DRIVE TYPE:

258 mm (10.2 in.)

G023898

G023899

C088682

Page 2246 of 3000

SP–64SUSPENSION – REAR AXLE BEAM

SP

32. CONNECT SKID CONTROL SENSOR WIRE (for 2WD)

HINT:

(See page SP-38)

HINT:

Connect the RH side by the same procedures as the LH

side.

33. INSTALL SPEED SENSOR REAR LH (for 4WD)

HINT:

(See page SP-38)

34. INSTALL SPEED SENSOR REAR RH (for 4WD)

HINT:

Install the RH side by the same procedures as the LH

side.

35. INSTALL EXHAUST PIPE ASSEMBLY TAIL

HINT:

• 2WD DRIVE TYPE (See page EX-2)

• 4WD DRIVE TYPE (See page EX-8)

36. BLEED BRAKE LINE

HINT:

(See page BR-3)

37. INSTALL REAR WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

38. INSPECT BRAKE FLUID LEVEL IN RESERVOIR

39. STABILIZE SUSPENSION

HINT:

(See page SP-52)

40. FULLY TIGHTEN SHOCK ABSORBER ASSEMBLY

REAR LH

HINT:

(See page SP-52)

41. FULLY TIGHTEN SHOCK ABSORBER ASSEMBLY

REAR RH

HINT:

Fully tighten the RH side by the same procedures as the

LH side.

42. FULLY TIGHTEN REAR AXLE BEAM ASSEMBLY

HINT:

(See page SP-38)

43. INSTALL REAR FLOOR NO.2 CROSSMEMBER

BRACE LH

HINT:

(See page SP-38)

44. INSTALL REAR FLOOR NO.2 CROSSMEMBER

BRACE RH

HINT:

Install the RH side by the same procedures as the LH

side.

Page 2362 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–11

BC

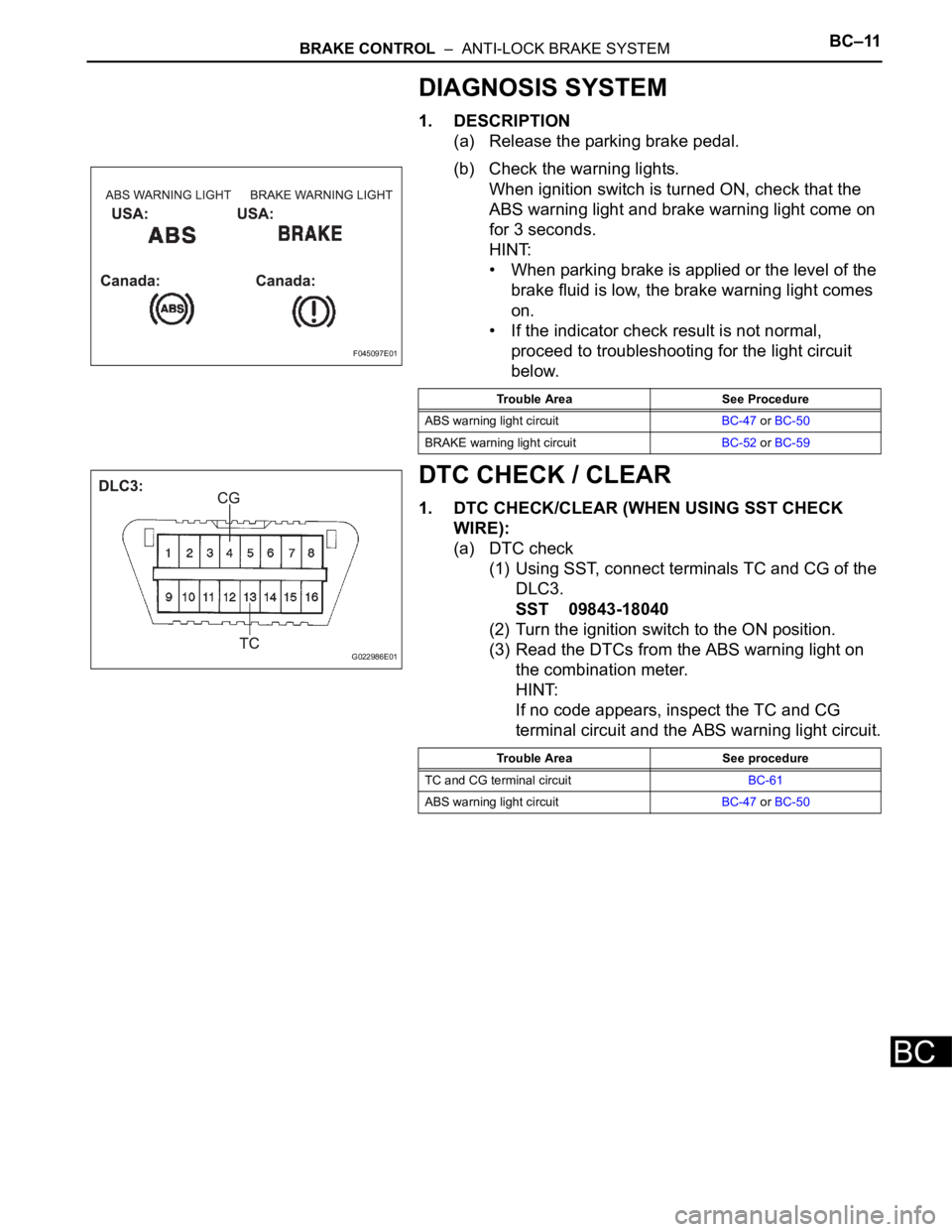

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) Release the parking brake pedal.

(b) Check the warning lights.

When ignition switch is turned ON, check that the

ABS warning light and brake warning light come on

for 3 seconds.

HINT:

• When parking brake is applied or the level of the

brake fluid is low, the brake warning light comes

on.

• If the indicator check result is not normal,

proceed to troubleshooting for the light circuit

below.

DTC CHECK / CLEAR

1. DTC CHECK/CLEAR (WHEN USING SST CHECK

WIRE):

(a) DTC check

(1) Using SST, connect terminals TC and CG of the

DLC3.

SST 09843-18040

(2) Turn the ignition switch to the ON position.

(3) Read the DTCs from the ABS warning light on

the combination meter.

HINT:

If no code appears, inspect the TC and CG

terminal circuit and the ABS warning light circuit.

F045097E01

Trouble Area See Procedure

ABS warning light circuitBC-47 or BC-50

BRAKE warning light circuitBC-52 or BC-59

G022986E01

Trouble Area See procedure

TC and CG terminal circuitBC-61

ABS warning light circuitBC-47 or BC-50

Page 2381 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–11

BC

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) Release the parking brake pedal.

(b) Check the warning lights.

When ignition switch is turned ON, check that the

ABS warning light and brake warning light come on

for 3 seconds.

HINT:

• When parking brake is applied or the level of the

brake fluid is low, the brake warning light comes

on.

• If the indicator check result is not normal,

proceed to troubleshooting for the light circuit

below.

DTC CHECK / CLEAR

1. DTC CHECK/CLEAR (WHEN USING SST CHECK

WIRE):

(a) DTC check

(1) Using SST, connect terminals TC and CG of the

DLC3.

SST 09843-18040

(2) Turn the ignition switch to the ON position.

(3) Read the DTCs from the ABS warning light on

the combination meter.

HINT:

If no code appears, inspect the TC and CG

terminal circuit and the ABS warning light circuit.

F045097E01

Trouble Area See Procedure

ABS warning light circuitBC-47 or BC-50

BRAKE warning light circuitBC-52 or BC-59

G022986E01

Trouble Area See procedure

TC and CG terminal circuitBC-61

ABS warning light circuitBC-47 or BC-50

Page 2418 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–57

BC

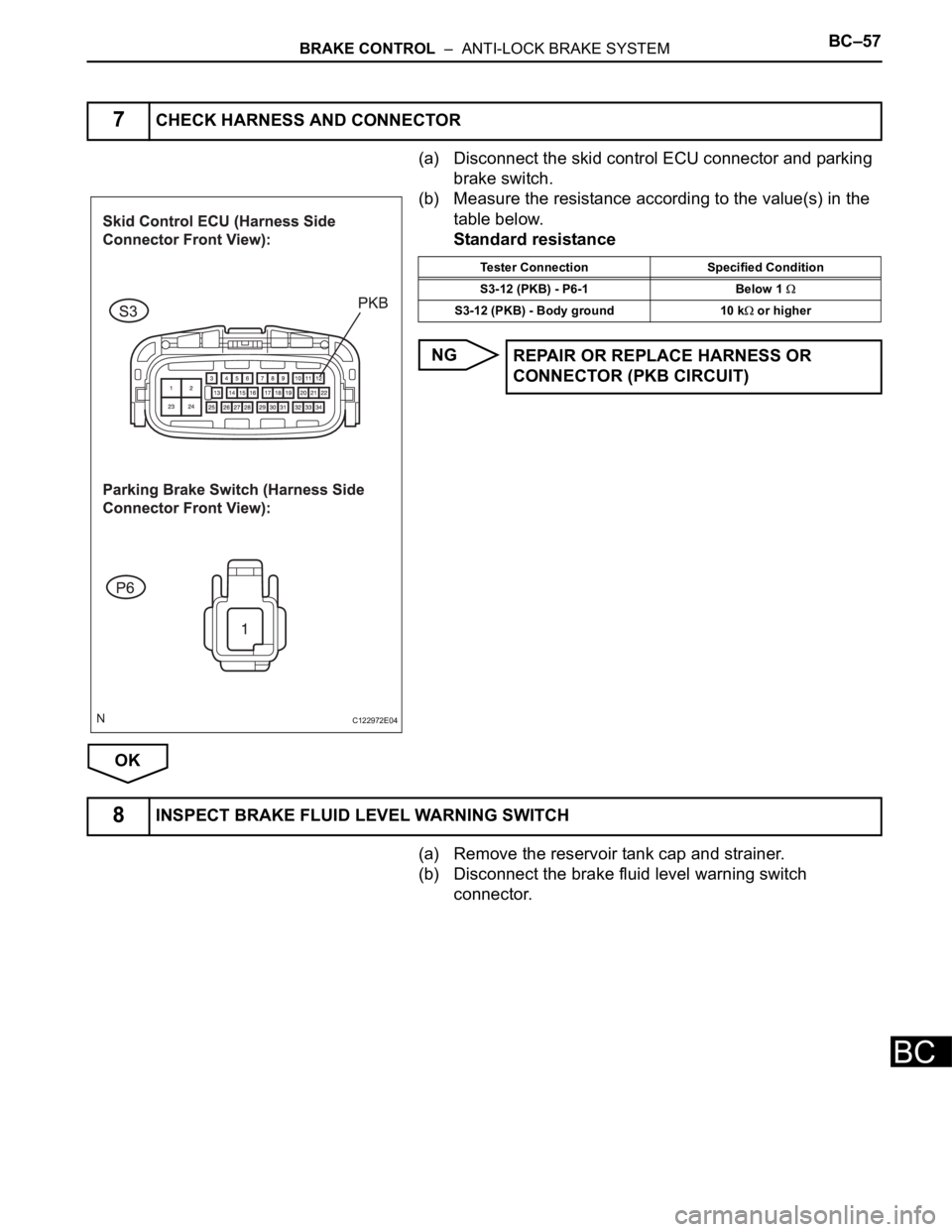

(a) Disconnect the skid control ECU connector and parking

brake switch.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

(a) Remove the reservoir tank cap and strainer.

(b) Disconnect the brake fluid level warning switch

connector.

7CHECK HARNESS AND CONNECTOR

C122972E04

Tester Connection Specified Condition

S3-12 (PKB) - P6-1 Below 1

S3-12 (PKB) - Body ground 10 k or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (PKB CIRCUIT)

8INSPECT BRAKE FLUID LEVEL WARNING SWITCH

Page 2419 of 3000

BC–58BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

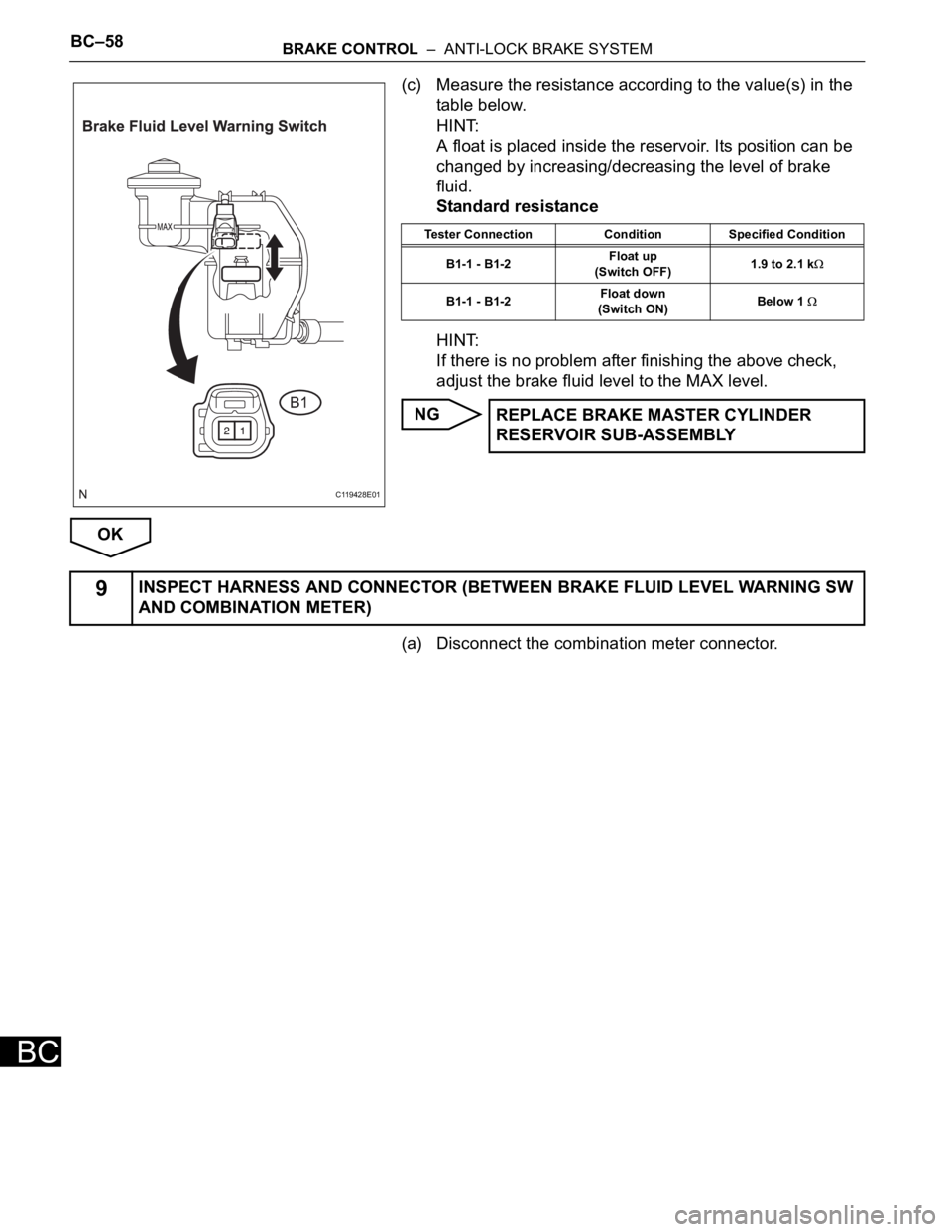

(c) Measure the resistance according to the value(s) in the

table below.

HINT:

A float is placed inside the reservoir. Its position can be

changed by increasing/decreasing the level of brake

fluid.

Standard resistance

HINT:

If there is no problem after finishing the above check,

adjust the brake fluid level to the MAX level.

NG

OK

(a) Disconnect the combination meter connector.

C119428E01

Tester Connection Condition Specified Condition

B1-1 - B1-2Float up

(Switch OFF)1.9 to 2.1 k

B1-1 - B1-2Float down

(Switch ON)Below 1

REPLACE BRAKE MASTER CYLINDER

RESERVOIR SUB-ASSEMBLY

9INSPECT HARNESS AND CONNECTOR (BETWEEN BRAKE FLUID LEVEL WARNING SW

AND COMBINATION METER)