engine mechanical TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 6 of 3000

PREPARATION – 2GR-FE ENGINE MECHANICALPP–5

PP

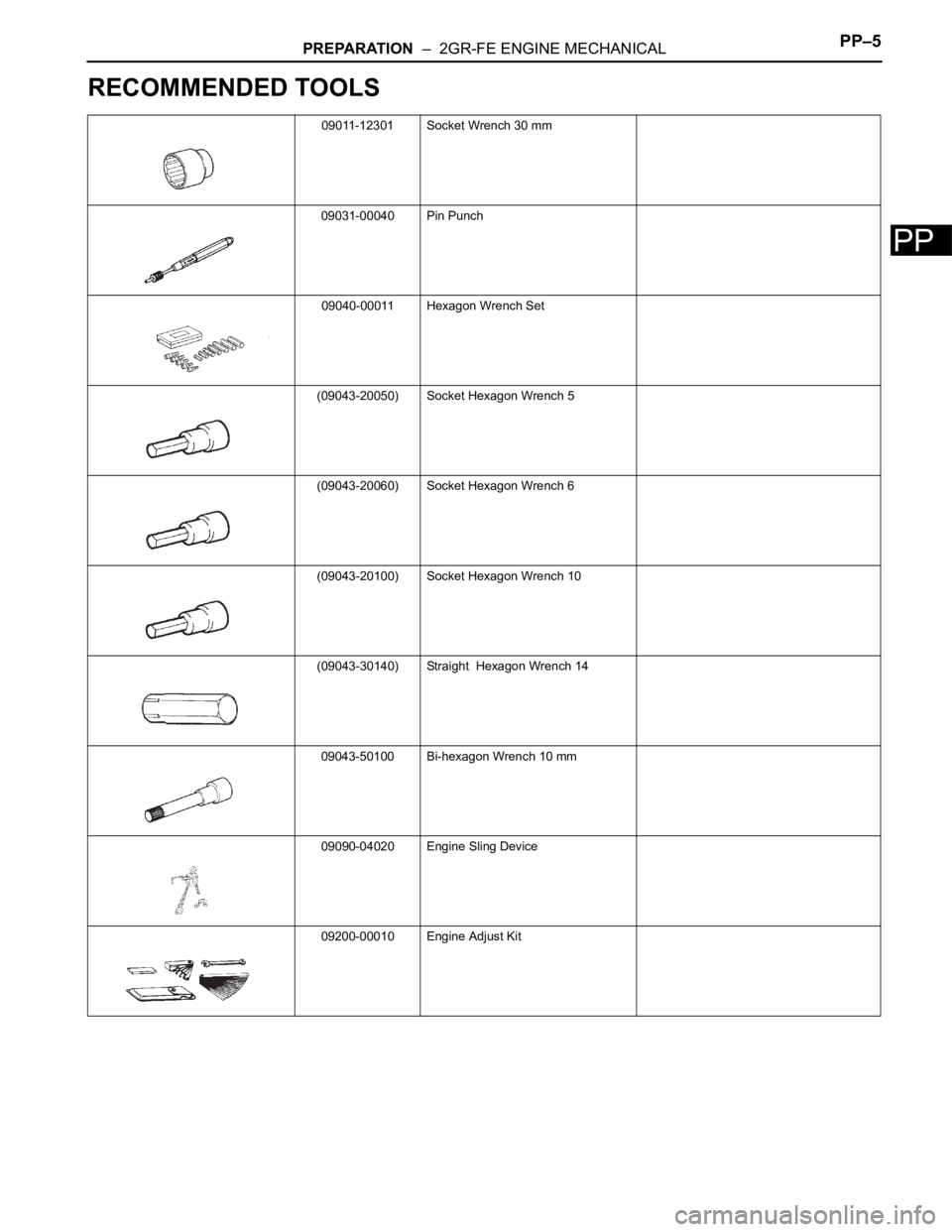

RECOMMENDED TOOLS

09011-12301 Socket Wrench 30 mm

09031-00040 Pin Punch

09040-00011 Hexagon Wrench Set

(09043-20050) Socket Hexagon Wrench 5

(09043-20060) Socket Hexagon Wrench 6

(09043-20100) Socket Hexagon Wrench 10

(09043-30140) Straight Hexagon Wrench 14

09043-50100 Bi-hexagon Wrench 10 mm

09090-04020 Engine Sling Device

09200-00010 Engine Adjust Kit

Page 7 of 3000

PP–6PREPARATION – 2GR-FE ENGINE MECHANICAL

PP

EQUIPMENT

Abrasive compound

Brush

Caliper gauge

Carbide cutter (30

)

Carbide cutter (45

)

Carbide cutter (60

)

Carbide cutter (75

)

Connecting rod aligner

Cylinder gauge

Dial indicator

Dye penetrant

Engine tune-up tester

Groove cleaning tool

Heater

Micrometer

Piston ring compressor

Piston ring expander

Plastigage

Precision straight edge

Press

Reamer (5.5 mm)

Ridge reamer

Soft brush

Solvent

Spring tester

Steel square

Thermometer

To r q u e w r e n c h

Torx socket wrench

Valve seat cutter

Valve guide bushing brush

V-block

Vernier calipers

Wire brush

Bar

Chain Block

CO/HC meter

Compression gauge

Dial indicator with magnetic base

Engine Sling Device

Feeler gauge

Radiator cap tester

Slide calipers

Tachometer

Timing light

Wooden block

Deep socket wrench

Screwdriver

Hammer

Page 8 of 3000

PREPARATION – 2GR-FE ENGINE MECHANICALPP–7

PPHINT:

Torx is registered trademark of Textron Inc.

Needle-noise plier

Compressed air

Magnetic finger

Plastic hammer

Gasket scraper

Piston

Nipper

Page 25 of 3000

EM–262GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE (See page

FU-13)

2. DISCHARGE REFRIGERANT FROM

REFRIGERATION SYSTEM (See page AC-172)

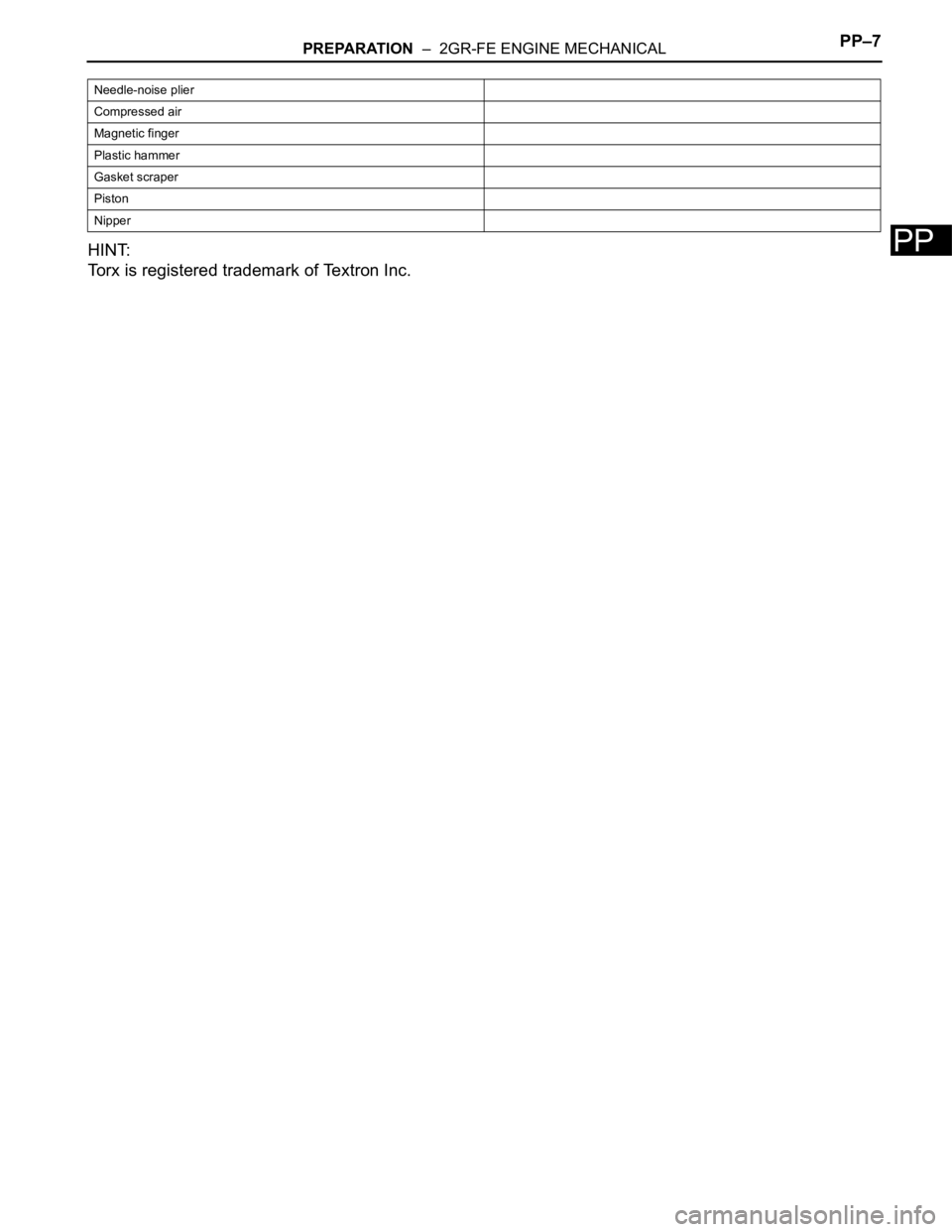

3. REMOVE BATTERY

(a) Disconnect the negative battery terminal.

(b) Disconnect the positive battery terminal.

(c) Loosen the nut, and remove the bolt and battery

clamp.

(d) Remove the battery and battery tray.

4. PLACE FRONT WHEELS FACING STRAIGHT AHEAD

5. REMOVE FRONT WHEELS

6. REMOVE NO. 1 ENGINE UNDER COVER ASSEMBLY

(a) Remove the 8 bolts, 4 clips and No. 1 engine under

cover assembly.

7. REMOVE FRONT FENDER APRON SEAL RH

(a) Remove the 2 bolts, clip and front fender apron seal

RH.

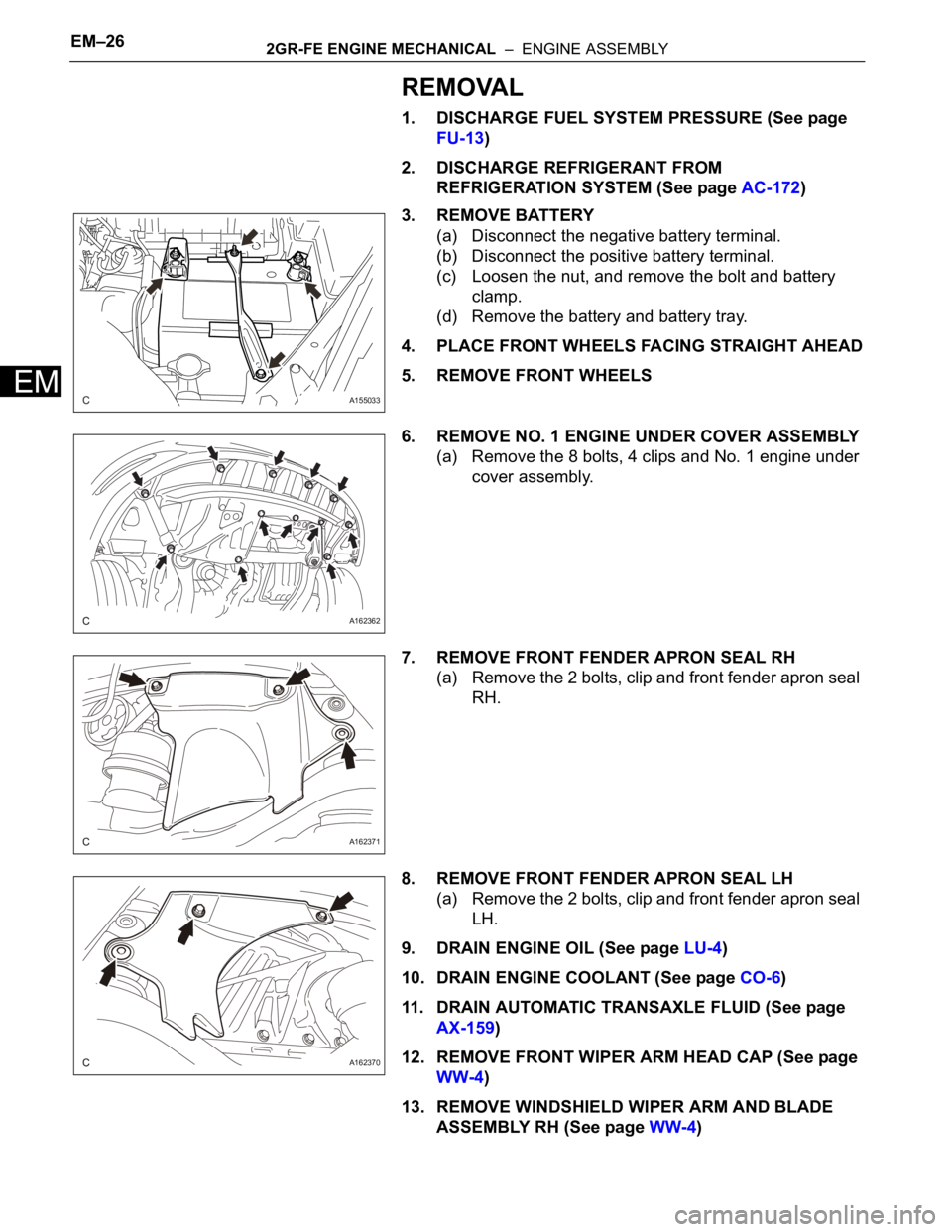

8. REMOVE FRONT FENDER APRON SEAL LH

(a) Remove the 2 bolts, clip and front fender apron seal

LH.

9. DRAIN ENGINE OIL (See page LU-4)

10. DRAIN ENGINE COOLANT (See page CO-6)

11. DRAIN AUTOMATIC TRANSAXLE FLUID (See page

AX-159)

12. REMOVE FRONT WIPER ARM HEAD CAP (See page

WW-4)

13. REMOVE WINDSHIELD WIPER ARM AND BLADE

ASSEMBLY RH (See page WW-4)

A155033

A162362

A162371

A162370

Page 26 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–27

EM

14. REMOVE WINDSHIELD WIPER ARM AND BLADE

ASSEMBLY LH (See page WW-4)

15. REMOVE COWL TOP VENTILATOR LOUVER SUB-

ASSEMBLY (See page WW-4)

16. REMOVE FRONT WIPER MOTOR AND LINK

ASSEMBLY (See page WW-4)

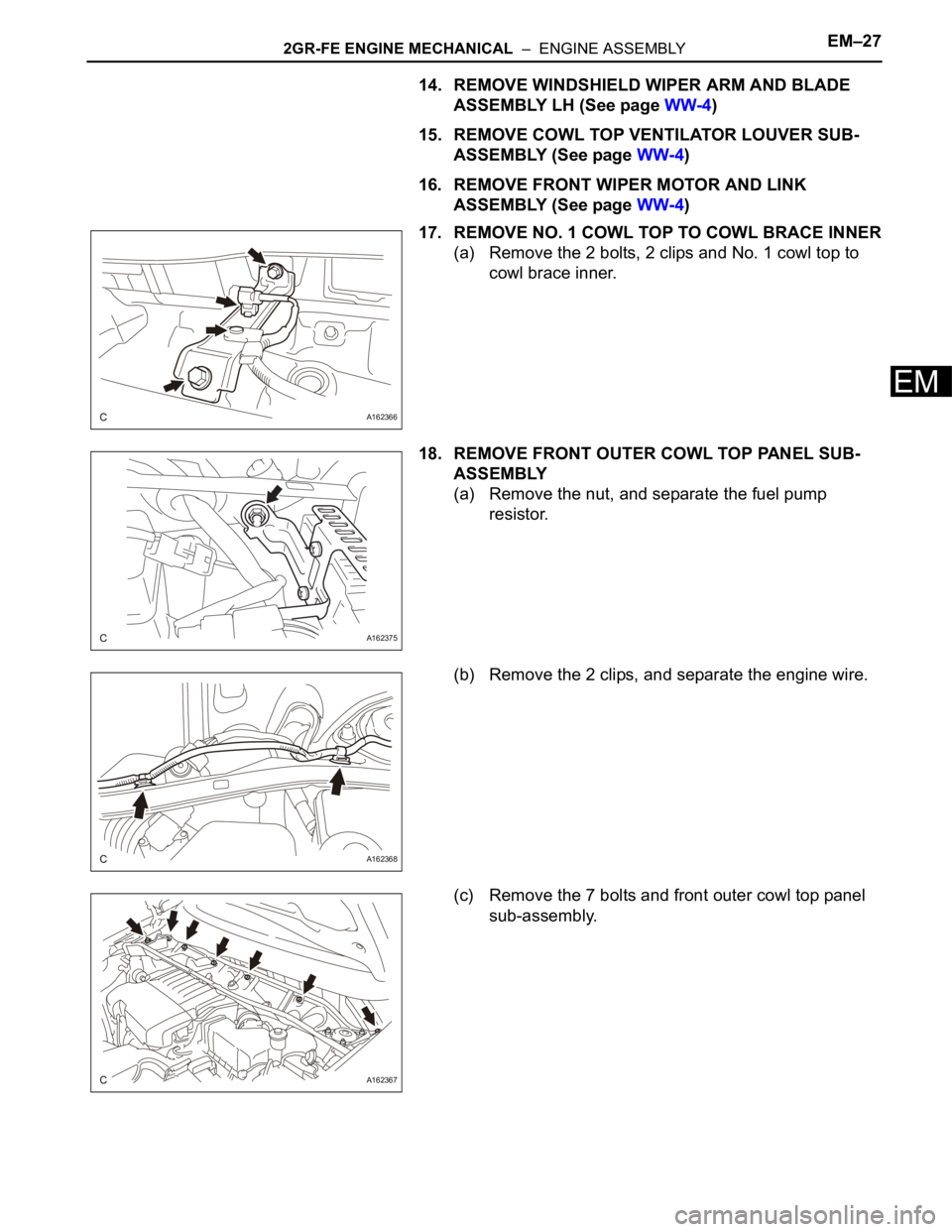

17. REMOVE NO. 1 COWL TOP TO COWL BRACE INNER

(a) Remove the 2 bolts, 2 clips and No. 1 cowl top to

cowl brace inner.

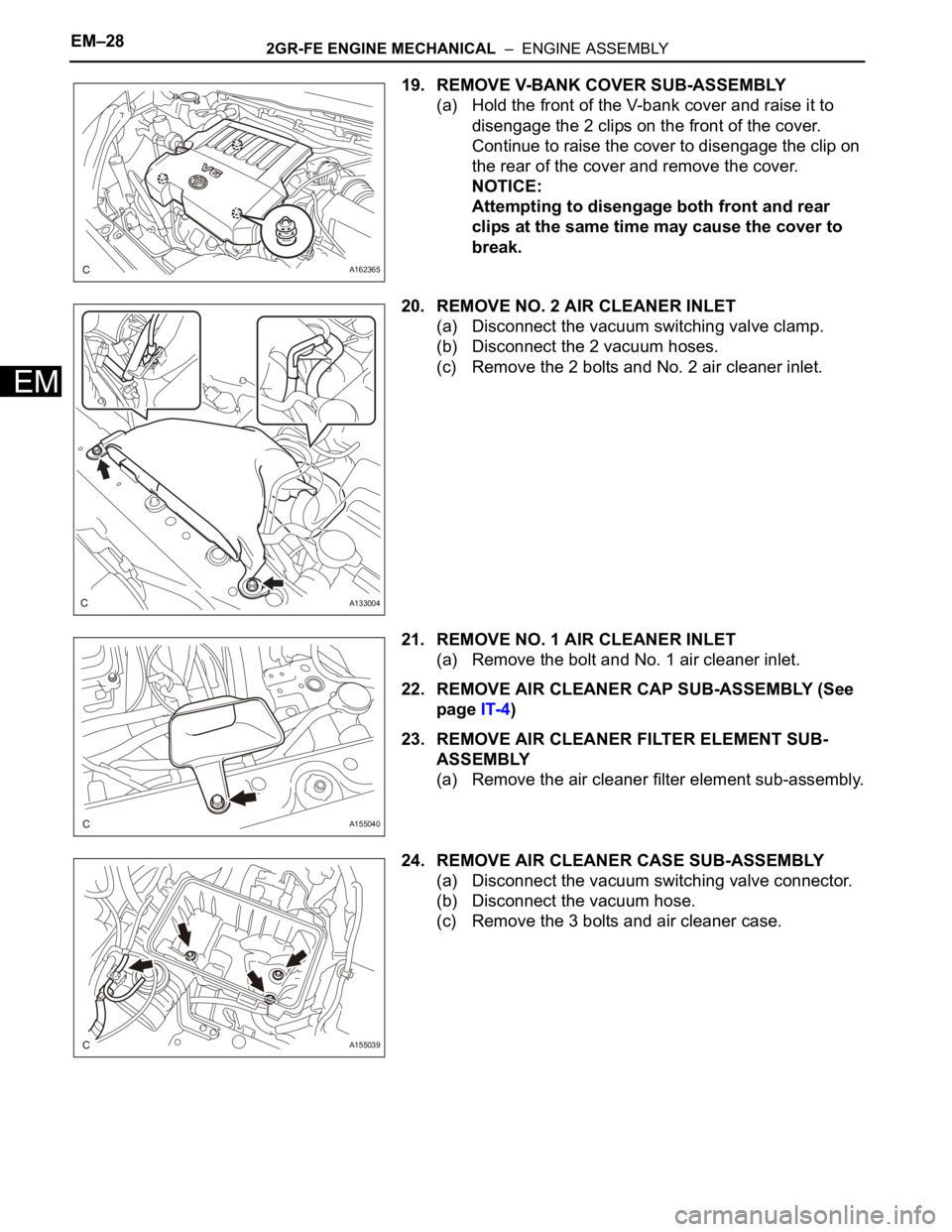

18. REMOVE FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY

(a) Remove the nut, and separate the fuel pump

resistor.

(b) Remove the 2 clips, and separate the engine wire.

(c) Remove the 7 bolts and front outer cowl top panel

sub-assembly.

A162366

A162375

A162368

A162367

Page 27 of 3000

EM–282GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

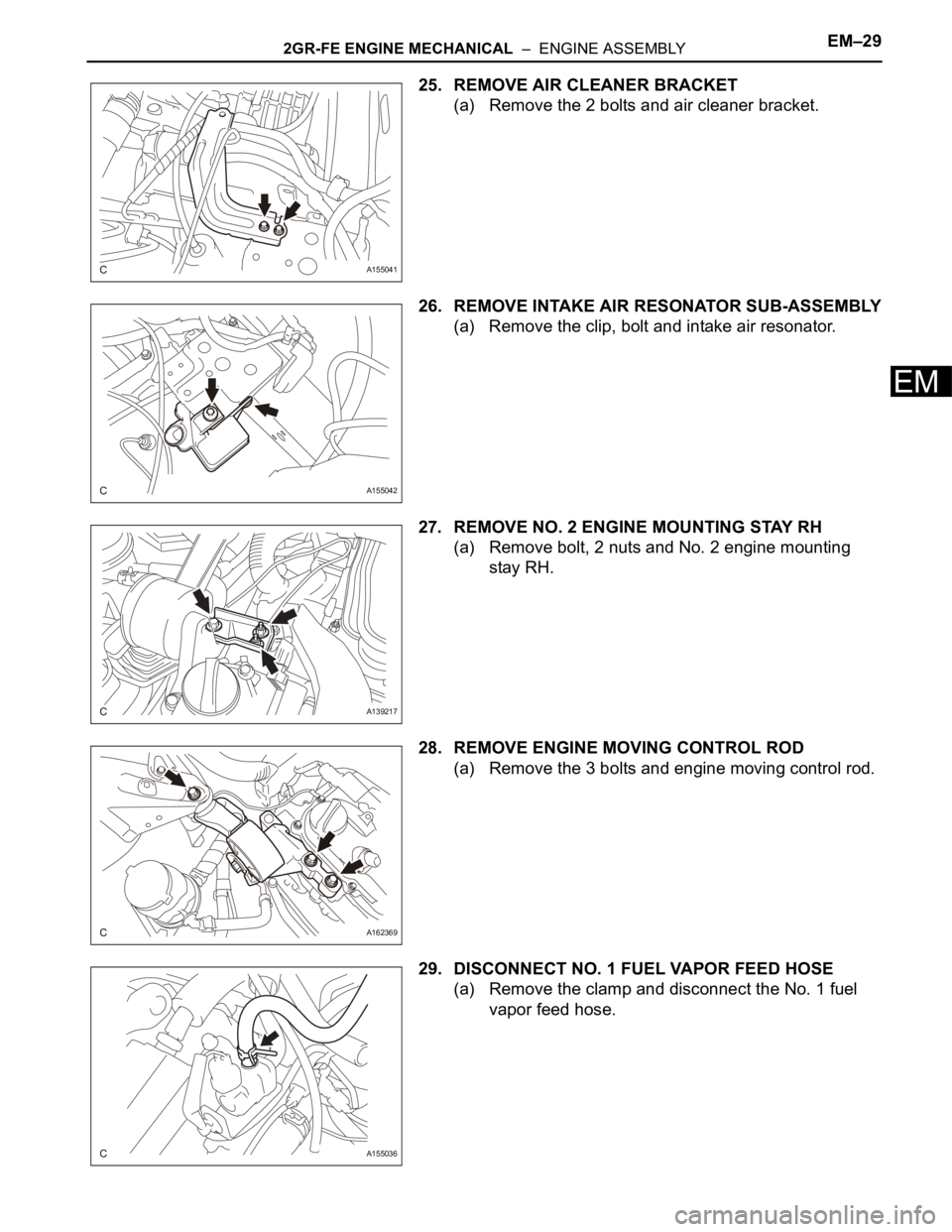

19. REMOVE V-BANK COVER SUB-ASSEMBLY

(a) Hold the front of the V-bank cover and raise it to

disengage the 2 clips on the front of the cover.

Continue to raise the cover to disengage the clip on

the rear of the cover and remove the cover.

NOTICE:

Attempting to disengage both front and rear

clips at the same time may cause the cover to

break.

20. REMOVE NO. 2 AIR CLEANER INLET

(a) Disconnect the vacuum switching valve clamp.

(b) Disconnect the 2 vacuum hoses.

(c) Remove the 2 bolts and No. 2 air cleaner inlet.

21. REMOVE NO. 1 AIR CLEANER INLET

(a) Remove the bolt and No. 1 air cleaner inlet.

22. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page IT-4)

23. REMOVE AIR CLEANER FILTER ELEMENT SUB-

ASSEMBLY

(a) Remove the air cleaner filter element sub-assembly.

24. REMOVE AIR CLEANER CASE SUB-ASSEMBLY

(a) Disconnect the vacuum switching valve connector.

(b) Disconnect the vacuum hose.

(c) Remove the 3 bolts and air cleaner case.

A162365

A133004

A155040

A155039

Page 28 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–29

EM

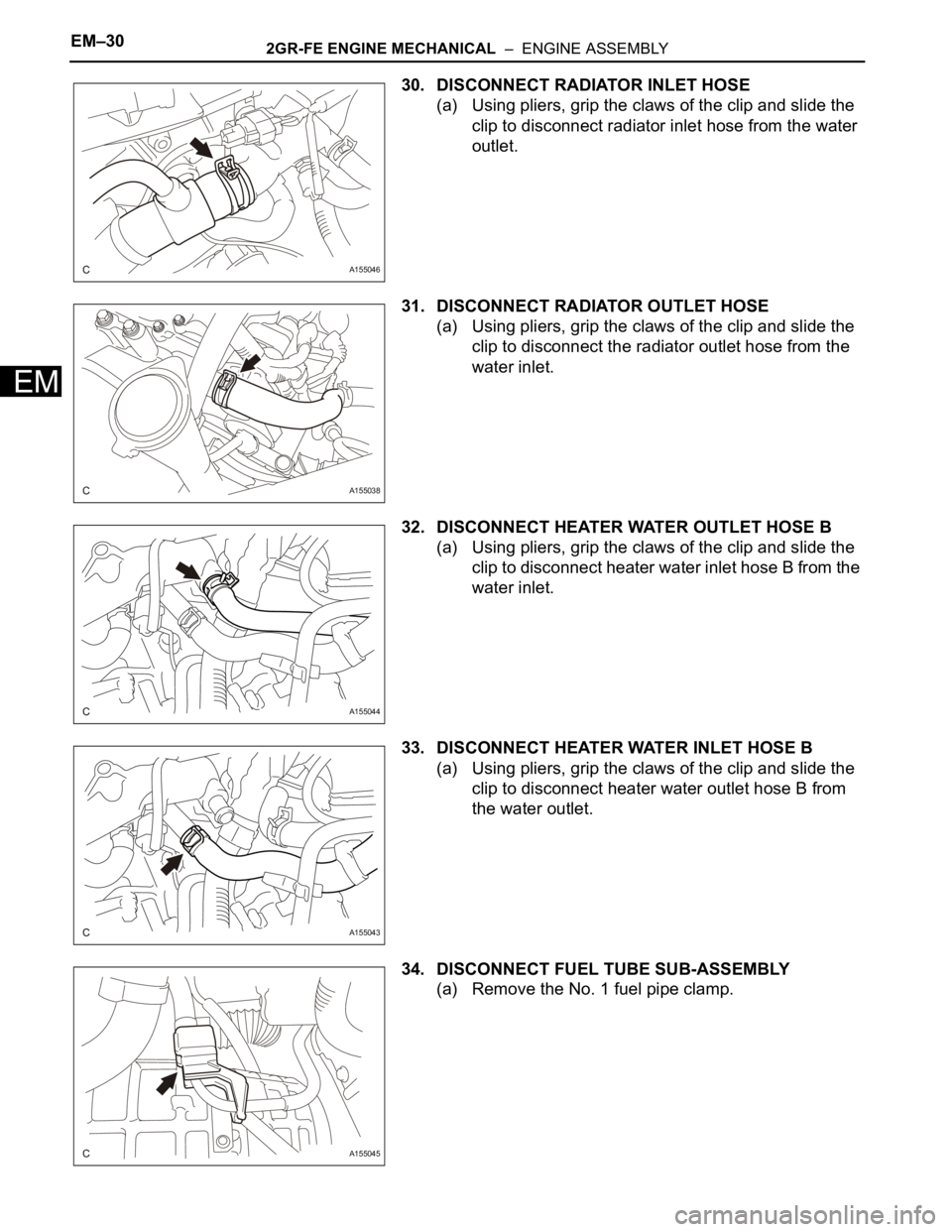

25. REMOVE AIR CLEANER BRACKET

(a) Remove the 2 bolts and air cleaner bracket.

26. REMOVE INTAKE AIR RESONATOR SUB-ASSEMBLY

(a) Remove the clip, bolt and intake air resonator.

27. REMOVE NO. 2 ENGINE MOUNTING STAY RH

(a) Remove bolt, 2 nuts and No. 2 engine mounting

stay RH.

28. REMOVE ENGINE MOVING CONTROL ROD

(a) Remove the 3 bolts and engine moving control rod.

29. DISCONNECT NO. 1 FUEL VAPOR FEED HOSE

(a) Remove the clamp and disconnect the No. 1 fuel

vapor feed hose.

A155041

A155042

A139217

A162369

A155036

Page 29 of 3000

EM–302GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

30. DISCONNECT RADIATOR INLET HOSE

(a) Using pliers, grip the claws of the clip and slide the

clip to disconnect radiator inlet hose from the water

outlet.

31. DISCONNECT RADIATOR OUTLET HOSE

(a) Using pliers, grip the claws of the clip and slide the

clip to disconnect the radiator outlet hose from the

water inlet.

32. DISCONNECT HEATER WATER OUTLET HOSE B

(a) Using pliers, grip the claws of the clip and slide the

clip to disconnect heater water inlet hose B from the

water inlet.

33. DISCONNECT HEATER WATER INLET HOSE B

(a) Using pliers, grip the claws of the clip and slide the

clip to disconnect heater water outlet hose B from

the water outlet.

34. DISCONNECT FUEL TUBE SUB-ASSEMBLY

(a) Remove the No. 1 fuel pipe clamp.

A155046

A155038

A155044

A155043

A155045

Page 30 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–31

EM

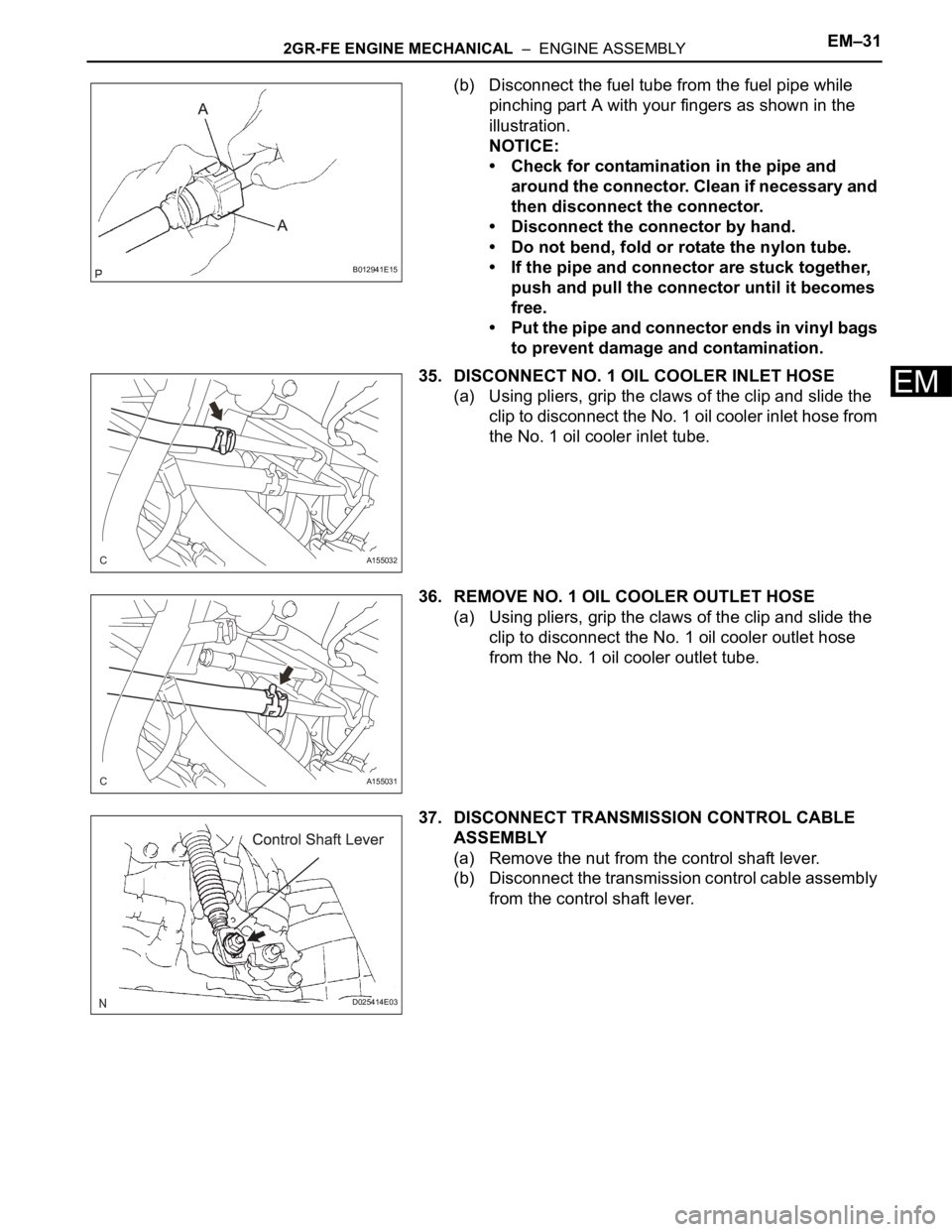

(b) Disconnect the fuel tube from the fuel pipe while

pinching part A with your fingers as shown in the

illustration.

NOTICE:

• Check for contamination in the pipe and

around the connector. Clean if necessary and

then disconnect the connector.

• Disconnect the connector by hand.

• Do not bend, fold or rotate the nylon tube.

• If the pipe and connector are stuck together,

push and pull the connector until it becomes

free.

• Put the pipe and connector ends in vinyl bags

to prevent damage and contamination.

35. DISCONNECT NO. 1 OIL COOLER INLET HOSE

(a) Using pliers, grip the claws of the clip and slide the

clip to disconnect the No. 1 oil cooler inlet hose from

the No. 1 oil cooler inlet tube.

36. REMOVE NO. 1 OIL COOLER OUTLET HOSE

(a) Using pliers, grip the claws of the clip and slide the

clip to disconnect the No. 1 oil cooler outlet hose

from the No. 1 oil cooler outlet tube.

37. DISCONNECT TRANSMISSION CONTROL CABLE

ASSEMBLY

(a) Remove the nut from the control shaft lever.

(b) Disconnect the transmission control cable assembly

from the control shaft lever.

B012941E15

A155032

A155031

D025414E03

Page 31 of 3000

EM–322GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

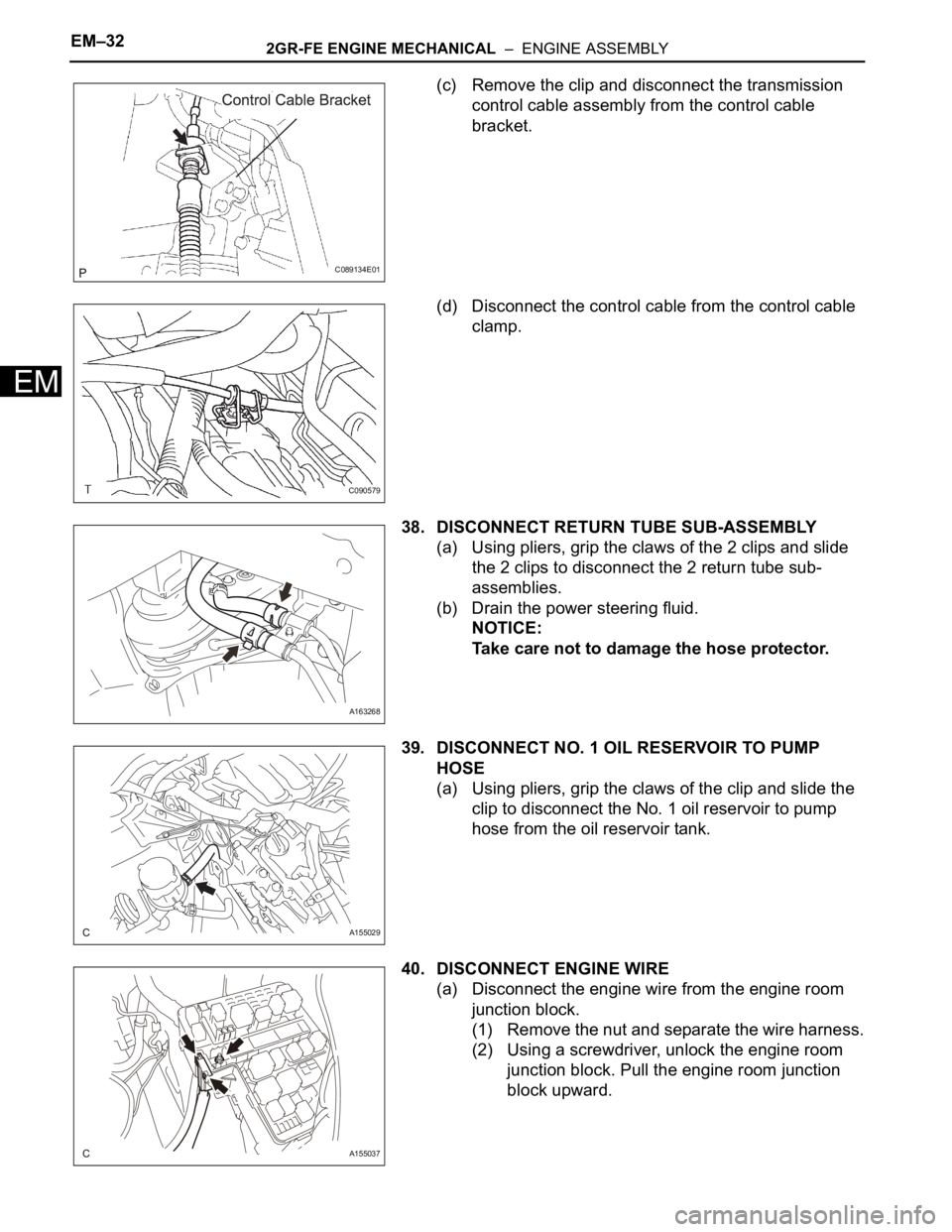

(c) Remove the clip and disconnect the transmission

control cable assembly from the control cable

bracket.

(d) Disconnect the control cable from the control cable

clamp.

38. DISCONNECT RETURN TUBE SUB-ASSEMBLY

(a) Using pliers, grip the claws of the 2 clips and slide

the 2 clips to disconnect the 2 return tube sub-

assemblies.

(b) Drain the power steering fluid.

NOTICE:

Take care not to damage the hose protector.

39. DISCONNECT NO. 1 OIL RESERVOIR TO PUMP

HOSE

(a) Using pliers, grip the claws of the clip and slide the

clip to disconnect the No. 1 oil reservoir to pump

hose from the oil reservoir tank.

40. DISCONNECT ENGINE WIRE

(a) Disconnect the engine wire from the engine room

junction block.

(1) Remove the nut and separate the wire harness.

(2) Using a screwdriver, unlock the engine room

junction block. Pull the engine room junction

block upward.

C089134E01

C090579

A163268

A155029

A155037