ESP VAUXHALL MERIVA 2015.5 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015.5, Model line: MERIVA, Model: VAUXHALL MERIVA 2015.5Pages: 247, PDF Size: 7.83 MB

Page 197 of 247

Vehicle care195Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Notice

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

The current tyre pressures can be

shown in the Vehicle Information

Menu in the Driver Information Centre

(DIC).

The menu can be selected by the

buttons on the turn signal lever.

Press MENU to select the Vehicle

Information Menu X .

Turn the adjuster wheel to select the

tyre pressure monitoring system.

System status and pressure warnings

are displayed by a message with the

corresponding tyre flashing in the

DIC.

A detected low tyre pressure

condition is indicated by the control

indicator w 3 97.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 233.

Page 200 of 247

198Vehicle care

Temperature dependencyTyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase.

The tyre pressure value displayed in

the Driver Information Centre shows

the actual tyre pressure. Therefore it

is important to check tyre pressure

with cold tyres.

Tread depth Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons it is recommended

that the tread depth of the tyres on

one axle should not vary by more than

2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and rear wheels periodically. Ensure that

the direction of rotation of the wheels

remains the same.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel

size

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and make other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.9 Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination requirements must be used.

Page 210 of 247

208Vehicle care

Front arm position of the lifting

platform at the underbody.

Spare wheel Some vehicles are equipped with a

tyre repair kit instead of a spare

wheel.

If mounting a spare wheel, which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

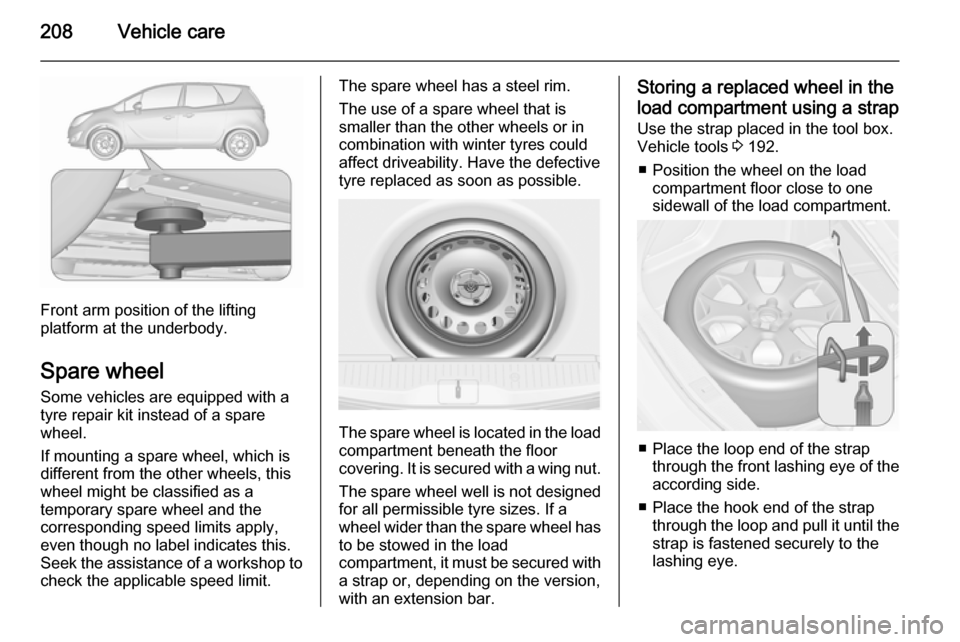

The spare wheel has a steel rim.

The use of a spare wheel that is

smaller than the other wheels or in

combination with winter tyres could

affect driveability. Have the defective

tyre replaced as soon as possible.

The spare wheel is located in the load

compartment beneath the floor

covering. It is secured with a wing nut.

The spare wheel well is not designed for all permissible tyre sizes. If a

wheel wider than the spare wheel has

to be stowed in the load

compartment, it must be secured with a strap or, depending on the version,

with an extension bar.

Storing a replaced wheel in the

load compartment using a strap

Use the strap placed in the tool box.

Vehicle tools 3 192.

■ Position the wheel on the load compartment floor close to one

sidewall of the load compartment.

■ Place the loop end of the strap through the front lashing eye of the

according side.

■ Place the hook end of the strap through the loop and pull it until thestrap is fastened securely to the

lashing eye.

Page 211 of 247

Vehicle care209

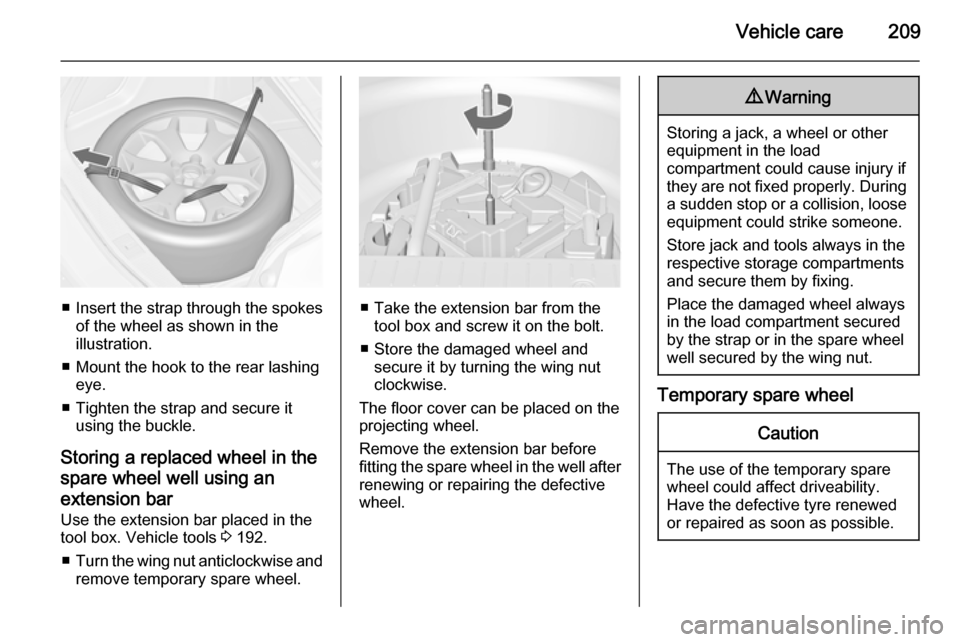

■Insert the strap through the spokes

of the wheel as shown in the

illustration.

■ Mount the hook to the rear lashing eye.

■ Tighten the strap and secure it using the buckle.

Storing a replaced wheel in the

spare wheel well using an

extension bar Use the extension bar placed in the

tool box. Vehicle tools 3 192.

■ Turn the wing nut anticlockwise and

remove temporary spare wheel.■ Take the extension bar from the tool box and screw it on the bolt.

■ Store the damaged wheel and secure it by turning the wing nut

clockwise.

The floor cover can be placed on the

projecting wheel.

Remove the extension bar before

fitting the spare wheel in the well after

renewing or repairing the defective

wheel.

9 Warning

Storing a jack, a wheel or other

equipment in the load

compartment could cause injury if they are not fixed properly. During a sudden stop or a collision, looseequipment could strike someone.

Store jack and tools always in the

respective storage compartments

and secure them by fixing.

Place the damaged wheel always

in the load compartment secured

by the strap or in the spare wheel

well secured by the wing nut.

Temporary spare wheel

Caution

The use of the temporary spare

wheel could affect driveability.

Have the defective tyre renewed

or repaired as soon as possible.

Page 218 of 247

216Vehicle care

Towing equipment

Do not clean the coupling ball bar with a steam-jet or high-pressure jet

cleaner.

Rear carrier system

Clean the rear carrier system with a

steam-jet or high-pressure jet cleaner

at least once a year.

Operate the rear carrier system

periodically if not in regular use, in

particular during winter.

Interior careInterior and upholsteryOnly clean the vehicle interior,

including the instrument panel fascia

and panelling, with a dry cloth or

interior cleaner.

Clean the leather upholstery with

clear water and a soft cloth. In case of

heavy soiling, use leather care.

The instrument cluster and the

displays should only be cleaned using

a soft damp cloth. If necessary use a

weak soap solution.Clean fabric upholstery with a

vacuum cleaner and brush. Remove

stains with an upholstery cleaner.

Clothing fabrics may not be

colourfast. This could cause visible

discolourations, especially on light-

coloured upholstery. Removable

stains and discolourations should be

cleaned as soon as possible.

Clean seat belts with lukewarm water or interior cleaner.Caution

Close Velcro fasteners as open

Velcro fasteners on clothing could

damage seat upholstery.

The same applies to clothing with

sharp-edged objects, like zips or

belts or studded jeans.

Plastic and rubber parts

Plastic and rubber parts can be

cleaned with the same cleaner as

used to clean the body. Use interior cleaner if necessary. Do not use any

other agent. Avoid solvents and petrol in particular. Do not use high-

pressure jet cleaners.

Page 223 of 247

Technical data221Identification plate

The identification plate is located on

the rear or front right door frame.

Information on identification label:1=manufacturer2=type approval number3=vehicle identification number4=permissible gross vehicle weight rating in kg5=permissible gross train weight in

kg6=maximum permissible front axle

load in kg7=maximum permissible rear axle

load in kg8=vehicle-specific or country- specific data

The combined total of front and rear

axle loads must not exceed the

permissible gross vehicle weight. For

example, if the front axle is bearing its

maximum permissible load, the rear

axle can only bear a load that is equal

to the gross vehicle weight minus the front axle load.

The technical data is determined in

accordance with European

Community standards. We reserve

the right to make modifications.

Specifications in the vehicle

documents always have priority over

those given in this manual.

Engine identification The technical data tables show the

engine identifier code. Engine data

3 225.

To identify the respective engine,

refer to the engine power in the EEC

Certificate of Conformity provided

with your vehicle or other national

registration documents.

Page 224 of 247

222Technical dataVehicle dataRecommended fluids and lubricantsEuropean service schedule

Required engine oil qualityAll European countries

(except Belarus, Moldova, Russia, Turkey)

Only Israel

Engine oil qualityPetrol engines

(including CNG, LPG, E85)Diesel enginesPetrol engines

(including CNG, LPG, E85)Diesel enginesdexos 1––✔–dexos 2✔✔–✔

In case dexos quality is unavailable you may use max. 1 litre engine oil quality ACEA C3 for topping up once between each oil change.

Engine oil viscosity grades

All European countries and Israel

(except Belarus, Moldova, Russia, Turkey)Ambient temperaturePetrol and diesel enginesdown to -25 °CSAE 5W-30 or SAE 5W-40below -25 °CSAE 0W-30 or SAE 0W-40

Page 225 of 247

Technical data223

International service scheduleRequired engine oil qualityAll countries outside Europe except Israel

Only Belarus, Moldova, Russia, Turkey

Engine oil qualityPetrol engines

(including CNG, LPG, E85)Diesel enginesPetrol engines

(including CNG, LPG, E85)Diesel enginesdexos 1✔–––dexos 2–✔✔✔

In case dexos quality is unavailable you may use the oil qualities listed below:

All countries outside Europe except Israel

Only Belarus, Moldova, Russia, Turkey

Engine oil qualityPetrol engines

(including CNG, LPG, E85)Diesel enginesPetrol engines

(including CNG, LPG, E85)Diesel enginesGM-LL-A-025✔–✔–GM-LL-B-025–✔–✔

Page 226 of 247

224Technical data

All countries outside Europeexcept Israel

Only Belarus, Moldova, Russia, Turkey

Engine oil qualityPetrol engines

(including CNG, LPG, E85)Diesel enginesPetrol engines

(including CNG, LPG, E85)Diesel enginesACEA A3/B3✔–✔–ACEA A3/B4✔✔✔✔ACEA C3✔✔✔✔API SM✔–✔–API SN resource conserving✔–✔–

Engine oil viscosity grades

All countries outside Europe (except Israel),

including Belarus, Moldova, Russia, TurkeyAmbient temperaturePetrol and diesel enginesdown to -25 °CSAE 5W-30 or SAE 5W-40below -25 °CSAE 0W-30 or SAE 0W-40down to -20 °CSAE 10W-30 1)

or SAE 10W-40 1)1)

Permitted, but use of SAE 5W-30 or SAE 5W-40 with dexos quality is recommended.