light VAUXHALL MERIVA 2015.5 Repair Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015.5, Model line: MERIVA, Model: VAUXHALL MERIVA 2015.5Pages: 247, PDF Size: 7.83 MB

Page 193 of 247

Vehicle care191

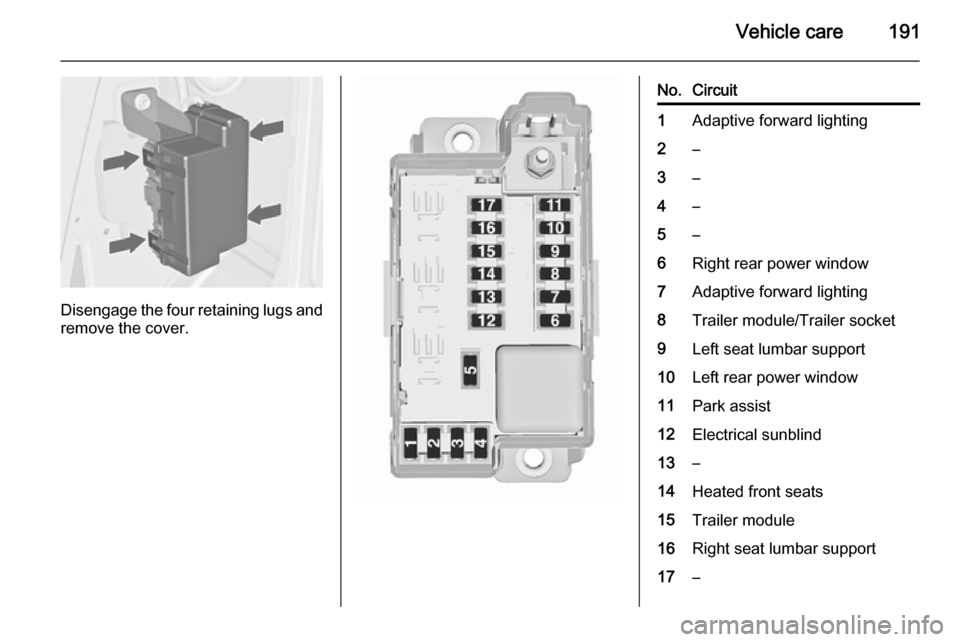

Disengage the four retaining lugs andremove the cover.

No.Circuit1Adaptive forward lighting2–3–4–5–6Right rear power window7Adaptive forward lighting8Trailer module/Trailer socket9Left seat lumbar support10Left rear power window11Park assist12Electrical sunblind13–14Heated front seats15Trailer module16Right seat lumbar support17–

Page 198 of 247

196Vehicle care

If w flashes for 60-90 seconds and

then illuminates continuously, there is a fault in the system. Consult a

workshop.

After inflating, driving may be

required to update the tyre pressure

values in the DIC. During this time w

may illuminate.

If w illuminates at lower temperatures

and extinguishes after some driving,

this could be an indicator for getting

low pressure. Check tyre pressure.

Vehicle messages 3 105.

If the tyre pressure shall be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A temporary spare wheel is not

equipped with pressure sensors. The

tyre pressure monitoring system is

not operational for these wheels.

Control indicator w illuminates. For

the further three wheels the system

remains operational.The use of commercially available

liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

External high-power radio equipment

could disrupt the tyre pressure

monitoring system.

Each time the tyres are replaced tyre

pressure monitoring system sensors

must be dismounted and serviced. For the screwed sensor: replace

valve core and sealing ring. For

clipped sensor: replace complete

valve stem.

Vehicle loading status Adjust tyre pressure to load condition according to tyre information label or

tyre pressure chart 3 233, and select

the relevant setting in the menu Tire

Load in the Driver Information Centre,

Vehicle Information Menu 3 100.

Select:

■ Light for comfort pressure up to

3 people.

■ Eco for Eco pressure up to

3 people.

■ Max for full loading.

TPMS Sensor Matching

Process

Each TPMS sensor has a unique

identification code. The identification

code must be matched to a new tyre/

wheel position after rotating the tyres

or exchanging the complete wheel set and if one or more TPMS sensorswere replaced. The TPMS sensor

Page 199 of 247

Vehicle care197

matching process should also be

performed after replacing a spare tyre with a road tyre containing the TPMS

sensor.

The malfunction light w and the

warning message or code should go

off at the next ignition cycle. The

sensors are matched to the tyre/

wheel positions, using a TPMS

relearn tool, in the following order: left

side front tyre, right side front tyre,

right side rear tyre and left side rear

tyre. The turn light at the current

active position is illuminated until

sensor is matched.

Consult your workshop for service or

to purchase a relearn tool. There are

2 minutes to match the first tyre/wheel position, and 5 minutes overall to

match all four tyre/wheel positions. If

it takes longer, the matching process

stops and must be restarted.The TPMS sensor matching process is:

1. Apply the parking brake; on vehicles with automatic

transmission set the selector lever

to P.

2. Turn the ignition on.

3. Press MENU on the turn signal

lever to select the Vehicle

Information Menu in the Driver

Information Centre (DIC).

4. Turn the adjuster wheel to scroll to

the tyre pressure menu.

5. Press the SET/CLR button to

begin the sensor matching

process. A message requesting

acceptance of the process should

display.

6. Press the SET/CLR button again

to confirm the selection. The horn sounds twice to signal the

receiver is in relearn mode.

7. Start with the left side front tyre.

8. Place the relearn tool against the tyre sidewall, near the valve stem.Then press the button to activate

the TPMS sensor. A horn chirpconfirms that the sensor

identification code has been

matched to this tyre and wheel

position.

9. Proceed to the right side front tyre,

and repeat the procedure in Step 8.

10. Proceed to the right side rear tyre,

and repeat the procedure in

Step 8.

11. Proceed to the left side rear tyre, and repeat the procedure in

Step 8. The horn sounds twice to

indicate the sensor identification

code has been matched to the left side rear tyre, and the TPMS

sensor matching process is no

longer active.

12. Turn off the ignition.

13. Set all four tyres to the recommended air pressure level

as indicated on the tyre pressure

label.

14. Ensure the tyre loading status is set according selected pressure

3 100.

Page 205 of 247

Vehicle care203

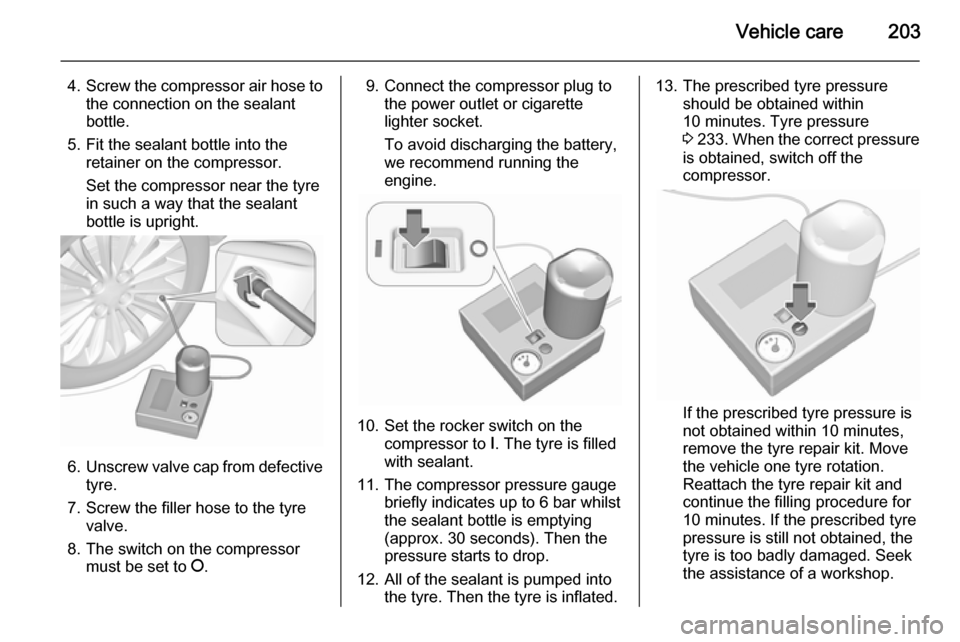

4.Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

6. Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.

9. Connect the compressor plug to

the power outlet or cigarette

lighter socket.

To avoid discharging the battery,

we recommend running the

engine.

10. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to 6 bar whilstthe sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is inflated.

13. The prescribed tyre pressure should be obtained within

10 minutes. Tyre pressure

3 233 . When the correct pressure

is obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within 10 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

10 minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Page 207 of 247

Vehicle care205

Make the following preparations and

observe the following information:

■ Park the vehicle on a level, firm and

non-skid surface. The front wheels

must be in the straight-ahead

position.

■ Apply the parking brake and engage first gear, reverse gear or

P .

■ Remove the spare wheel 3 208.

■ Never change more than one wheel

at once.

■ Use the jack only to change wheels

in case of puncture, not for

seasonal winter or summer tyre

change.

■ The jack is maintenance-free.

■ If the ground on which the vehicle is standing is soft, a solid board

(max. 1 cm thick) should be placed

under the jack.

■ Take heavy objects out of the vehicle before jacking up.

■ No people or animals may be in the

vehicle when it is jacked-up.■ Never crawl under a jacked-up vehicle.

■ Do not start the vehicle when it is raised on the jack.

■ Before screwing in the wheel bolts,

clean them and lightly coat the

taper of each wheel bolt with

commercially available grease.9 Warning

Do not grease the thread of the

wheel bolt.

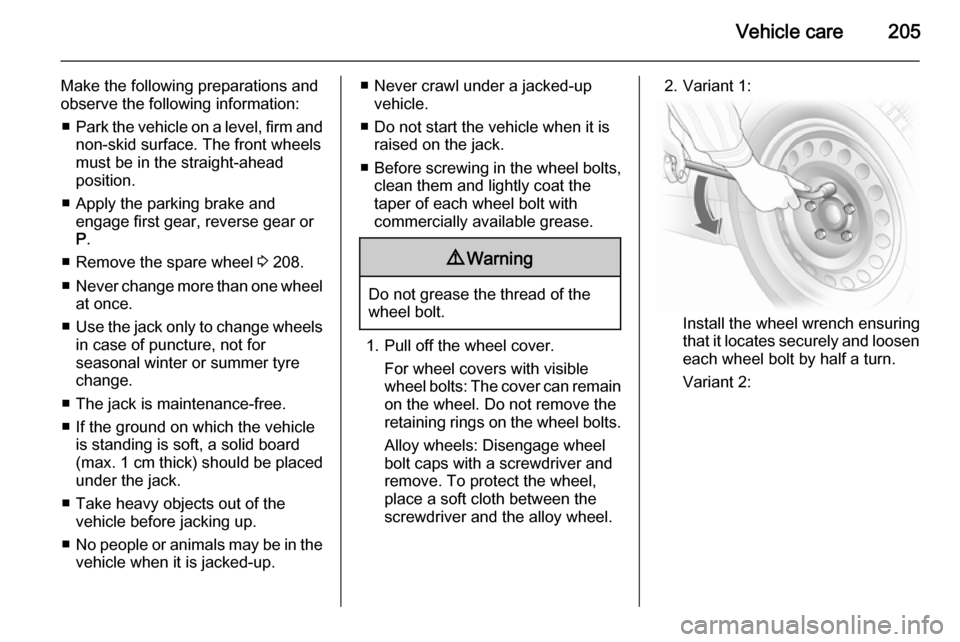

1. Pull off the wheel cover.

For wheel covers with visible

wheel bolts: The cover can remain

on the wheel. Do not remove the

retaining rings on the wheel bolts.

Alloy wheels: Disengage wheel

bolt caps with a screwdriver and

remove. To protect the wheel,

place a soft cloth between the

screwdriver and the alloy wheel.

2. Variant 1:

Install the wheel wrench ensuring

that it locates securely and loosen

each wheel bolt by half a turn.

Variant 2:

Page 213 of 247

Vehicle care211

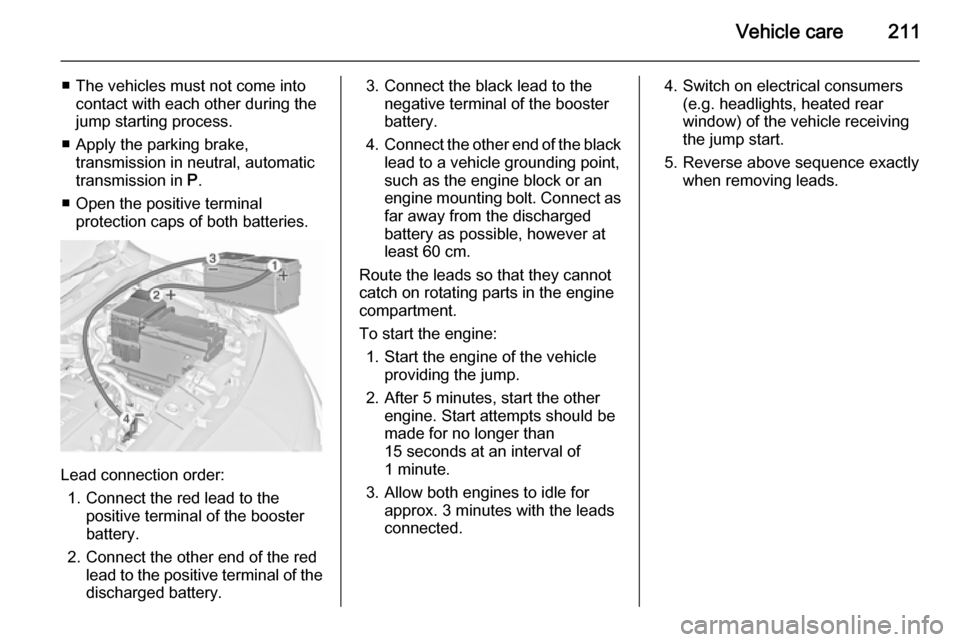

■ The vehicles must not come intocontact with each other during the

jump starting process.

■ Apply the parking brake, transmission in neutral, automatic

transmission in P.

■ Open the positive terminal protection caps of both batteries.

Lead connection order:

1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged battery.

3. Connect the black lead to the negative terminal of the booster

battery.

4. Connect the other end of the black

lead to a vehicle grounding point,

such as the engine block or an

engine mounting bolt. Connect as far away from the discharged

battery as possible, however at

least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After 5 minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

1 minute.

3. Allow both engines to idle for approx. 3 minutes with the leads

connected.4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.

Page 214 of 247

212Vehicle careTowing

Towing the vehicle

Disengage cap at bottom and remove downwards.

The towing eye is stowed with the

vehicle tools 3 192.

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

Attach a tow rope – or better still a tow

rod – to the towing eye.

The towing eye must only be used for towing and not for recovering the

vehicle.

Caution

Activate the child lock in both rear

doors if the rear seats are

occupied. Child locks 3 25.

Switch on ignition to release steering

wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Transmission in neutral.Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation and close the

windows.

Vehicles with automatic transmission: The vehicle must be towed facing

forwards, not faster than 50 mph nor further than 60 miles. In all other

cases and when the transmission is

defective, the front axle must be

raised off the ground.

Seek the assistance of a workshop. After towing, unscrew the towing eye.

Page 216 of 247

214Vehicle careAppearance care

Exterior care Locks

The locks are lubricated at the factory using a high quality lock cylinder

grease. Use de-icing agent only when absolutely necessary, as this has adegreasing effect and impairs lockfunction. After using de-icing agent,

have the locks regreased by a

workshop.

Washing

The paintwork of your vehicle is

exposed to environmental influences. Wash and wax your vehicle regularly.

When using automatic vehicle

washes, select a programme that

includes waxing.

Bird droppings, dead insects, resin,

pollen and the like should be cleaned

off immediately, as they contain

aggressive constituents which can

cause paint damage.If using a vehicle wash, comply with

the vehicle wash manufacturer's

instructions. The windscreen wiper and rear window wiper must be

switched off. Remove antenna and

external accessories such as roof

racks etc.

If you wash your vehicle by hand,

make sure that the insides of the

wheel housings are also thoroughly

rinsed out.

Clean edges and folds on opened

doors and the bonnet as well as the

areas they cover.Caution

Always use a cleaning agent with

a pH value of 4 to 9.

Do not use cleaning agents on hot surfaces.

Have the door hinges of all doors

greased by a workshop.

Do not clean the engine compartment with a steam-jet or high-pressure jet

cleaner.

Thoroughly rinse and leather-off the vehicle. Rinse leather frequently. Use

separate leathers for painted and

glass surfaces: remnants of wax on

the windows will impair vision.

Exterior lights

Headlight and other light covers are

made of plastic. Do not use any

abrasive or caustic agents, do not use an ice scraper, and do not clean them

dry.

Polishing and waxing Wax the vehicle regularly (at the

latest when water no longer beads).

Otherwise, the paintwork will dry out.

Polishing is necessary only if the paint

has become dull or if solid deposits

have become attached to it.

Paintwork polish with silicone forms a

protective film, making waxing

unnecessary.

Plastic body parts must not be treated with wax or polishing agents.

Page 218 of 247

216Vehicle care

Towing equipment

Do not clean the coupling ball bar with a steam-jet or high-pressure jet

cleaner.

Rear carrier system

Clean the rear carrier system with a

steam-jet or high-pressure jet cleaner

at least once a year.

Operate the rear carrier system

periodically if not in regular use, in

particular during winter.

Interior careInterior and upholsteryOnly clean the vehicle interior,

including the instrument panel fascia

and panelling, with a dry cloth or

interior cleaner.

Clean the leather upholstery with

clear water and a soft cloth. In case of

heavy soiling, use leather care.

The instrument cluster and the

displays should only be cleaned using

a soft damp cloth. If necessary use a

weak soap solution.Clean fabric upholstery with a

vacuum cleaner and brush. Remove

stains with an upholstery cleaner.

Clothing fabrics may not be

colourfast. This could cause visible

discolourations, especially on light-

coloured upholstery. Removable

stains and discolourations should be

cleaned as soon as possible.

Clean seat belts with lukewarm water or interior cleaner.Caution

Close Velcro fasteners as open

Velcro fasteners on clothing could

damage seat upholstery.

The same applies to clothing with

sharp-edged objects, like zips or

belts or studded jeans.

Plastic and rubber parts

Plastic and rubber parts can be

cleaned with the same cleaner as

used to clean the body. Use interior cleaner if necessary. Do not use any

other agent. Avoid solvents and petrol in particular. Do not use high-

pressure jet cleaners.

Page 242 of 247

240IndexAAccessories and vehicle modifications .......................... 168

Active head restraints ..................35

Adaptive brake light ....................146

Adaptive forward lighting ..........

.................................. 99, 119, 179

Adjustable air vents ...................132

Airbag and belt tensioners ...........94

Airbag deactivation ................53, 95

Airbag label................................... 48 Airbag system .............................. 48

Air conditioning regular operation ................................ 133

Air conditioning system .............. 126

Air intake .................................... 133

Air vents...................................... 132

Alert ............................................ 108

Antifreeze ................................... 171

Antilock brake system ................ 146

Antilock brake system (ABS) .......96

Anti-theft alarm system ................27

Anti-theft locking system .............. 27 Appearance care ........................214

Armrest ................................... 39, 42

Armrest storage ........................... 63

Ashtrays ....................................... 89

Automatic anti-dazzle ..................30

Automatic light control ...............117Automatic locking ..................24, 99

Automatic transmission .............142

Auxiliary heater .......................... 132

B Battery discharge protection ......124

Battery voltage ........................... 108

Belts.............................................. 44 Bicycle rack .................................. 64

Bonnet ....................................... 170

Brake and clutch fluid .................218

Brake and clutch system .............96

Brake assist ............................... 148

Brake fluid .................................. 173

Brakes ............................... 146, 173

Breakdown.................................. 212

Bulb replacement ....................... 176

C Capacities .................................. 232

Car Pass ...................................... 19

Catalytic converter .....................142

Central locking system ................21

Centre console lighting ..............123

Changing tyre and wheel size ...198

Charging system .......................... 95

Child locks ................................... 25

Child restraint installation locations ................................... 57

Child restraints.............................. 54