ESP VAUXHALL MOKKA 2015.5 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015.5, Model line: MOKKA, Model: VAUXHALL MOKKA 2015.5Pages: 229, PDF Size: 6.45 MB

Page 177 of 229

Vehicle care175Interior lightsCourtesy lights 1. To remove it, prise the opposite side of the light switch using a flat-blade screwdriver.

2. Remove the bulb.

3. Replace the bulb.

4. Reinstall the light assembly.

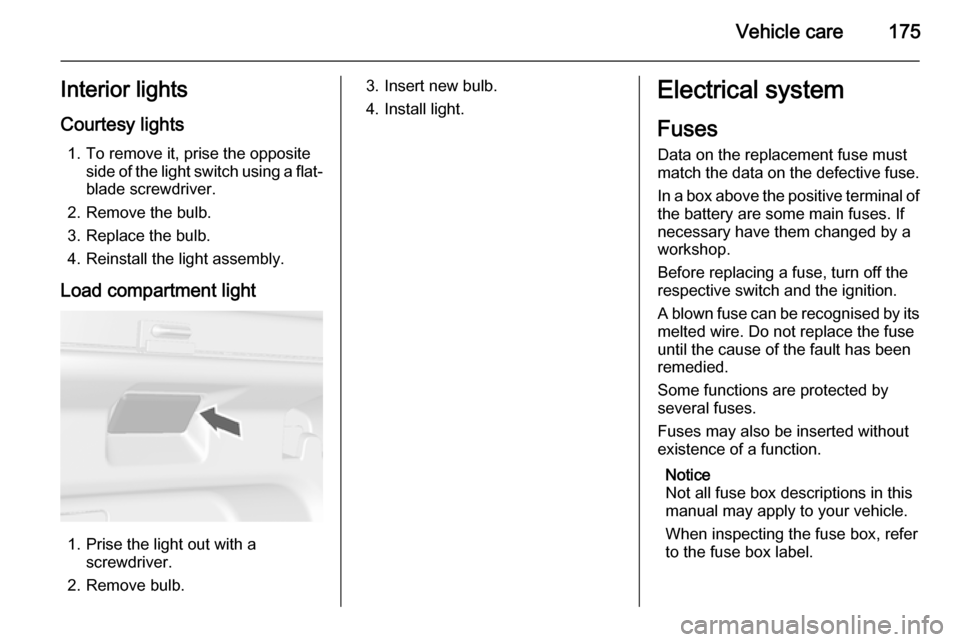

Load compartment light

1. Prise the light out with a screwdriver.

2. Remove bulb.

3. Insert new bulb.

4. Install light.Electrical system

Fuses

Data on the replacement fuse must

match the data on the defective fuse.

In a box above the positive terminal of the battery are some main fuses. If

necessary have them changed by a

workshop.

Before replacing a fuse, turn off the

respective switch and the ignition.

A blown fuse can be recognised by its

melted wire. Do not replace the fuse

until the cause of the fault has been

remedied.

Some functions are protected by

several fuses.

Fuses may also be inserted without

existence of a function.

Notice

Not all fuse box descriptions in this

manual may apply to your vehicle.

When inspecting the fuse box, refer

to the fuse box label.

Page 184 of 229

182Vehicle careTyre pressureCheck the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

Unscrew the valve cap.

Tyre pressure 3 215.

The tyre pressure information label

on the left or right door frame

indicates the original equipment tyres

and the correspondent tyre

pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 210.

2. Identify the respective tyre.

The tyre pressure tables show all possible tyre combinations 3 215.

For the tyres approved for your

vehicle, refer to the EEC Certificate of

Conformity provided with your vehicle

or other national registration

documents.The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

Tyre pressure monitoring

system

The tyre pressure monitoring system

(TPMS) checks the pressure of all

four wheels once a minute when

vehicle speed exceeds a certain limit.

Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

Page 185 of 229

Vehicle care183

All wheels must be equipped with

pressure sensors and the tyres must

have the prescribed pressure.

Notice

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

The current tyre pressures can be

shown in the Vehicle Information

Menu in the Driver Information Centre

(DIC).

The menu can be selected by the

buttons on the turn signal lever.Press MENU to select the Vehicle

Information Menu X .

Turn the adjuster wheel to select the

tyre pressure monitoring system.

System status and pressure warnings

are displayed by a message with the

corresponding tyre flashing in the

DIC.

A detected low tyre pressure

condition is indicated by the control

indicator w 3 87.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 215.

If w flashes for 60-90 seconds and

then illuminates continuously, there is a fault in the system. Consult a

workshop.

After inflating, driving may be

required to update the tyre pressure

values in the DIC. During this time w

may illuminate.

Page 188 of 229

186Vehicle care

For safety reasons it is recommended

that the tread depth of the tyres on

one axle should not vary by more than 2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and rear wheels. Ensure that the direction

of rotation of the wheels is the same

as before.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel

size

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

speedometer as well as the nominal tyre pressure and make other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.9 Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel covers

Wheel covers and tyres that are

factory-approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory-approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Vehicles with alloy wheels: When

mounting steel wheels with alloy

wheel nuts, e.g. when changing to

winter tyres, the wheel covers cannot

be attached to the steel wheels.

Page 194 of 229

192Vehicle care

10. Align the valve hole in the wheelcover with the tyre valve before

installing.

Install wheel nut caps.

Install centre cap on alloy wheels.

11. Install vehicle jacking point cover on versions with sill panelling.

12. Stow the replaced wheel 3 192

and the vehicle tools 3 180.

13. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.

Have the defective tyre renewed or

repaired as soon as possible.Jacking position for lifting

platform

Rear arm position of the lifting

platform centrically under the recess

of the sill.

Front arm position of the lifting

platform at the underbody.

Spare wheel Some vehicles are equipped with a

tyre repair kit instead of a spare

wheel.

If mounting a spare wheel, which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

Page 202 of 229

200Vehicle care

Wheels and tyres

Do not use high-pressure jet

cleaners.

Clean rims with a pH-neutral wheel

cleaner.

Rims are painted and can be treated

with the same agents as the body.

Paintwork damage Rectify minor paintwork damage with

a touch-up pen before rust forms.

Have more extensive damage or rust areas repaired by a workshop.

Underbody Some areas of the vehicle underbody

have a PVC undercoating while other

critical areas have a durable

protective wax coating.

After the underbody is washed, check the underbody and have it waxed if

necessary.

Bitumen/rubber materials could

damage the PVC coating. Have

underbody work carried out by a

workshop.Before and after winter, wash the

underbody and have the protective

wax coating checked.

Liquid gas system9 Danger

Liquid gas is heavier than air and

can collect in sink points.

Take care when performing work

at the underbody in a pit.

For painting work and when using a

drying booth at a temperature above

60 °C, the liquid gas system must be

completely evacuated.

Do not make any modifications to the

liquid gas system.

Towing equipment Do not clean the coupling ball bar with

a steam-jet or high-pressure jet

cleaner.

Rear carrier system Clean the rear carrier system with a

steam-jet or high-pressure jet cleaner

at least once a year.

Operate the rear carrier system

periodically if not in regular use, in

particular during winter.

Interior care

Interior and upholstery Only clean the vehicle interior,

including the instrument panel fascia

and panelling, with a dry cloth or

interior cleaner.

Clean the leather upholstery with

clear water and a soft cloth. In case of heavy soiling, use leather care.

The instrument cluster and the

displays should only be cleaned using

a soft damp cloth. If necessary use a

weak soap solution.

Clean fabric upholstery with a

vacuum cleaner and brush. Remove

stains with an upholstery cleaner.

Clothing fabrics may not be

colourfast. This could cause visible

discolourations, especially on light- coloured upholstery. Removable

stains and discolourations should be

cleaned as soon as possible.

Page 208 of 229

206Technical data

Information on identification label:1=manufacturer2=type approval number3=vehicle Identification Number4=permissible gross vehicle weight

rating in kg5=permissible gross train weight

in kg6=maximum permissible front axle

load in kg7=maximum permissible rear axle

load in kg

Engine identification

The technical data tables show the

engine identifier code. Engine data

3 210.

To identify the respective engine,

refer to the engine power in the EEC

Certificate of Conformity provided

with your vehicle or other national

registration documents.

Page 209 of 229

Technical data207Vehicle dataRecommended fluids and lubricantsEuropean service scheduleRequired engine oil qualityAll European countries

(except Belarus, Moldova, Russia, Turkey)

Only Israel

Engine oil qualityPetrol engines

(including CNG, LPG, E85)Diesel enginesPetrol engines

(including CNG, LPG, E85)Diesel enginesdexos 1––✔–dexos 2✔✔–✔

In case dexos quality is unavailable you may use max. 1 litre engine oil quality ACEA C3 for topping up once between each oil change.

Engine oil viscosity grades

All European countries and Israel

(except Belarus, Moldova, Russia, Turkey)Ambient temperaturePetrol and diesel enginesdown to -25 °CSAE 5W-30 or SAE 5W-40below -25 °CSAE 0W-30 or SAE 0W-40

Page 210 of 229

208Technical data

International service scheduleRequired engine oil qualityAll countries outside Europe except Israel

Only Belarus, Moldova, Russia, Turkey

Engine oil qualityPetrol engines

(including CNG, LPG, E85)Diesel enginesPetrol engines

(including CNG, LPG, E85)Diesel enginesdexos 1✔–––dexos 2–✔✔✔

In case dexos quality is unavailable you may use the oil qualities listed below:

All countries outside Europe except Israel

Only Belarus, Moldova, Russia, Turkey

Engine oil qualityPetrol engines

(including CNG, LPG, E85)Diesel enginesPetrol engines

(including CNG, LPG, E85)Diesel enginesGM-LL-A-025✔–✔–GM-LL-B-025–✔–✔

Page 211 of 229

Technical data209

All countries outside Europeexcept Israel

Only Belarus, Moldova, Russia, Turkey

Engine oil qualityPetrol engines

(including CNG, LPG, E85)Diesel enginesPetrol engines

(including CNG, LPG, E85)Diesel enginesACEA A3/B3✔–✔–ACEA A3/B4✔✔✔✔ACEA C3✔✔✔✔API SM✔–✔–API SN resource conserving✔–✔–

Engine oil viscosity grades

All countries outside Europe (except Israel),

including Belarus, Moldova, Russia, TurkeyAmbient temperaturePetrol and diesel enginesdown to -25 °CSAE 5W-30 or SAE 5W-40below -25 °CSAE 0W-30 or SAE 0W-40down to -20 °CSAE 10W-30 1)

or SAE 10W-40 1)1)

Permitted, but usage of SAE 5W-30 or SAE 5W-40 with dexos quality is recommended.