wheel YAMAHA NIKEN 2018 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2018, Model line: NIKEN, Model: YAMAHA NIKEN 2018Pages: 106, PDF Size: 9.44 MB

Page 53 of 106

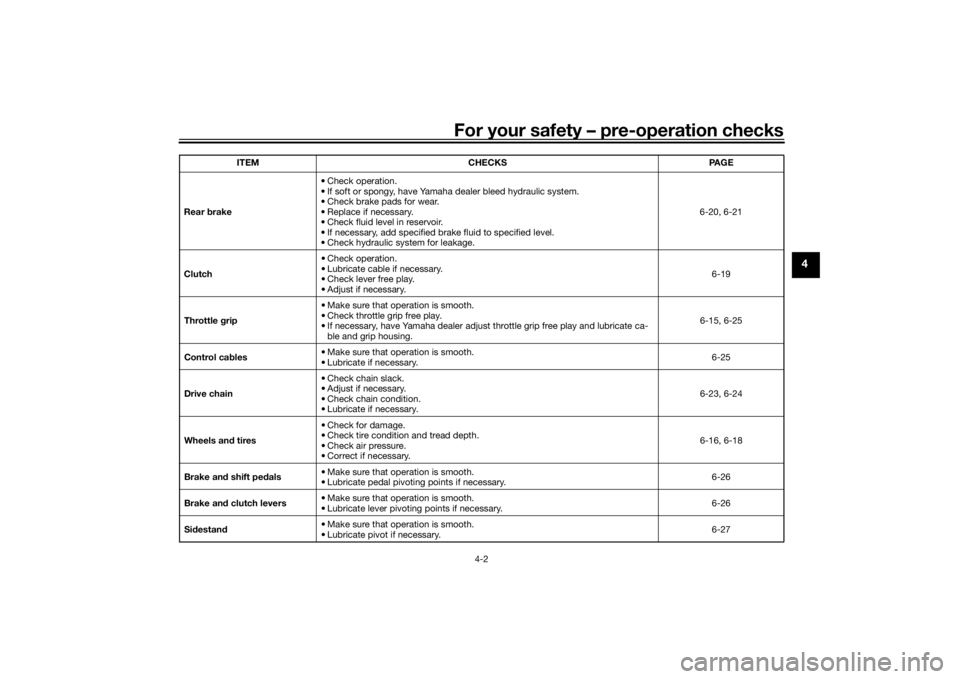

For your safety – pre-operation checks

4-2

4

Rear brake • Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic system.

• Check brake pads for wear.

• Replace if necessary.

• Check fluid level in reservoir.

• If necessary, add specified brake fluid to specified level.

• Check hydraulic system for leakage. 6-20, 6-21

Clutch • Check operation.

• Lubricate cable if necessary.

• Check lever free play.

• Adjust if necessary.

6-19

Throttle grip • Make sure that operation is smooth.

• Check throttle grip free play.

• If necessary, have Yamaha dealer adjust throttle grip free play and lubricate ca-

ble and grip housing. 6-15, 6-25

Control ca bles • Make sure that operation is smooth.

• Lubricate if necessary. 6-25

Drive chain • Check chain slack.

• Adjust if necessary.

• Check chain condition.

• Lubricate if necessary.

6-23, 6-24

Wheels an d tires • Check for damage.

• Check tire condition and tread depth.

• Check air pressure.

• Correct if necessary.

6-16, 6-18

Brake an d shift pe dals • Make sure that operation is smooth.

• Lubricate pedal pivoting points if necessary. 6-26

Brake an d clutch levers • Make sure that operation is smooth.

• Lubricate lever pivoting points if necessary.

6-26

Si destan d • Make sure that operation is smooth.

• Lubricate pivot if necessary.

6-27

ITEM CHECKS PAGE

UBD5E0E0.book Page 2 Wednesday, April 25, 2018 2:23 PM

Page 63 of 106

Periodic maintenance an d a djustment

6-5

6

EAU71352

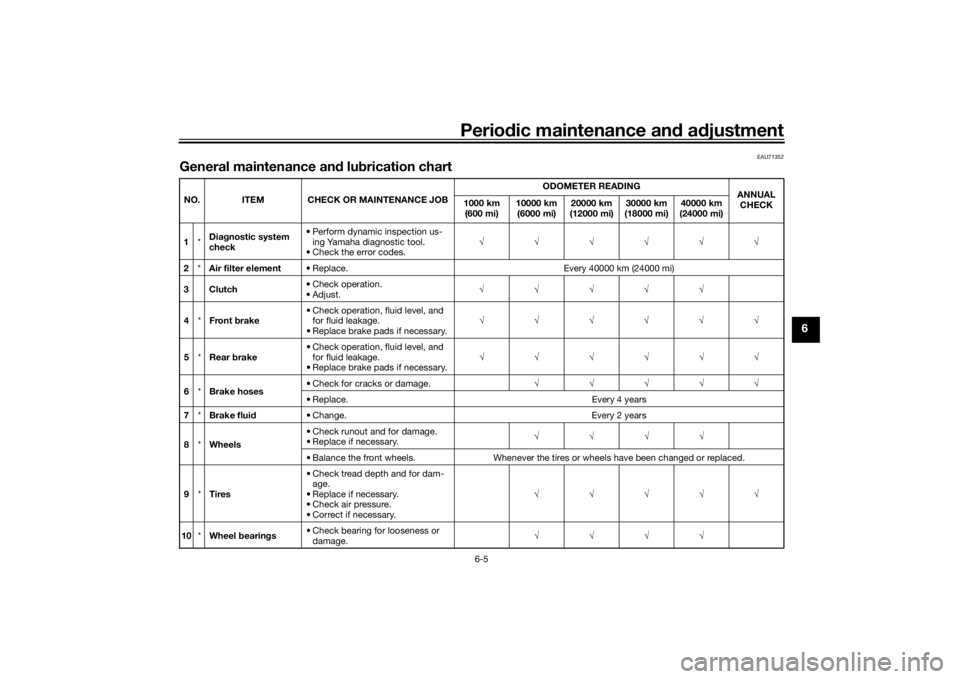

General maintenance an d lu brication chartNO. ITEM CHECK OR MAINTENANCE JOB ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

1 *Dia

gnostic system

check • Perform dynamic inspection us-

ing Yamaha diagnostic tool.

• Check the error codes. √√√√√√

2 *Air filter element • Replace. Every 40000 km (24000 mi)

3Clutch • Check operation.

•Adjust. √√√√√

4 *Front brake • Check operation, fluid level, and

for fluid leakage.

• Replace brake pads if necessary. √√√√√√

5 *Rear brake • Check operation, fluid level, and

for fluid leakage.

• Replace brake pads if necessary. √√√√√√

6 *Brake hoses • Check for cracks or damage.

√√√√√

• Replace. Every 4 years

7 *Brake flui d • Change. Every 2 years

8 *Wheels • Check runout and for damage.

• Replace if necessary.

√√√√

• Balance the front wheels. Whenever the tires or wheels have been changed or replaced.

9 *Tires • Check tread depth and for dam-

age.

• Replace if necessary.

• Check air pressure.

• Correct if necessary. √√√√√

10 *Wheel bearin gs • Check bearing for looseness or

damage. √√√√

UBD5E0E0.book Page 5 Wednesday, April 25, 2018 2:23 PM

Page 75 of 106

Periodic maintenance an d a djustment

6-17

6

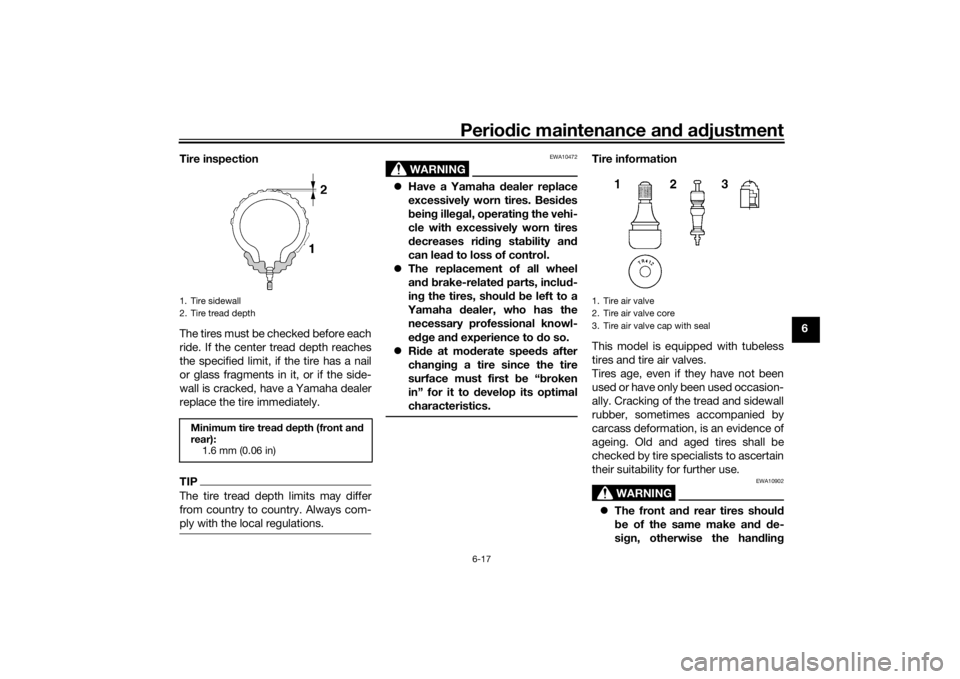

Tire inspection

The tires must be checked before each

ride. If the center tread depth reaches

the specified limit, if the tire has a nail

or glass fragments in it, or if the side-

wall is cracked, have a Yamaha dealer

replace the tire immediately.

TIPThe tire tread depth limits may differ

from country to country. Always com-

ply with the local regulations.

WARNING

EWA10472

Have a Yamaha d ealer replace

excessively worn tires. Besi des

b ein g ille gal, operatin g the vehi-

cle with excessively worn tires

d ecreases ri din g sta bility an d

can lea d to loss of control.

The replacement of all wheel

and b rake-relate d parts, inclu d-

in g the tires, shoul d b e left to a

Yamaha dealer, who has the

necessary professional knowl-

e dg e an d experience to do so.

Ride at mo derate spee ds after

chan gin g a tire since the tire

surface must first be “ broken

in” for it to d evelop its optimal

characteristics.

Tire information

This model is equipped with tubeless

tires and tire air valves.

Tires age, even if they have not been

used or have only been used occasion-

ally. Cracking of the tread and sidewall

rubber, sometimes accompanied by

carcass deformation, is an evidence of

ageing. Old and aged tires shall be

checked by tire specialists to ascertain

their suitability for further use.

WARNING

EWA10902

The front an d rear tires shoul d

b e of the same make an d d e-

si gn, otherwise the han dlin g

1. Tire sidewall

2. Tire tread depthMinimum tire trea d d epth (front an d

rear): 1.6 mm (0.06 in)

1. Tire air valve

2. Tire air valve core

3. Tire air valve cap with seal

UBD5E0E0.book Page 17 Wednesday, April 25, 2018 2:23 PM

Page 76 of 106

Periodic maintenance an d a djustment

6-18

6 characteristics of the motorcy-

cle may

be different, which

coul d lea d to an acci dent.

Always make sure that the valve

caps are securely installe d to

prevent air pressure leaka ge.

Use only the tire valves an d

valve cores listed below to

avoi d tire d eflation durin g a ri de.

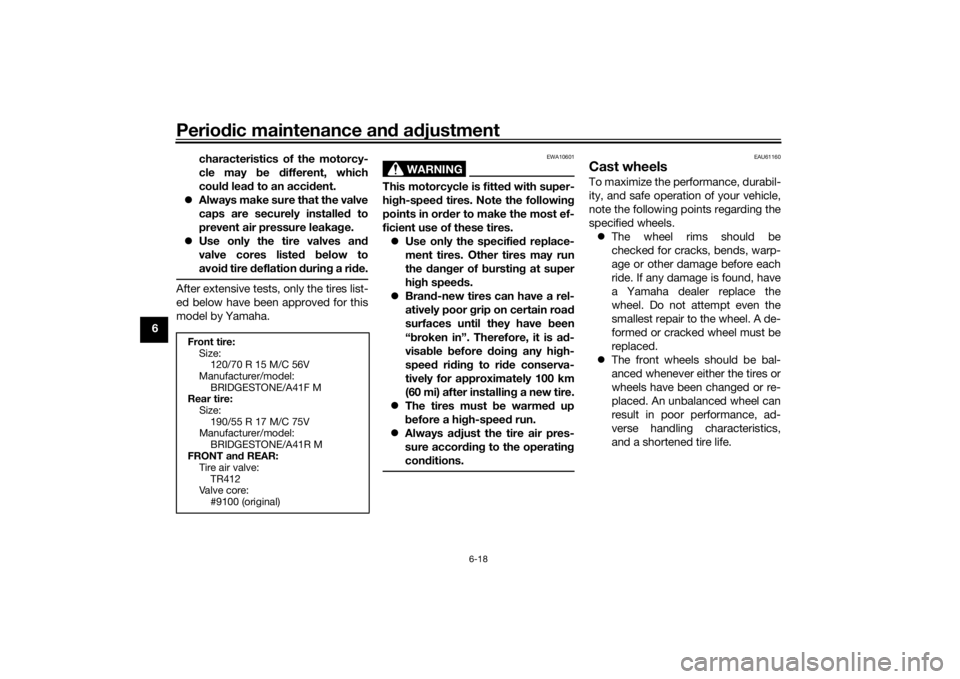

After extensive tests, only the tires list-

ed below have been approved for this

model by Yamaha.

WARNING

EWA10601

This motorcycle is fitte d with super-

hi gh-spee d tires. Note the followin g

points in or der to make the most ef-

ficient use of these tires. Use only the specified replace-

ment tires. Other tires may run

the dan ger of burstin g at super

hi gh spee ds.

Bran d-new tires can have a rel-

atively poor g rip on certain roa d

surfaces until they have been

“ b roken in”. Therefore, it is a d-

visa ble before doin g any hi gh-

speed ridin g to ri de conserva-

tively for approximately 100 km

(60 mi) after installin g a new tire.

The tires must be warme d up

b efore a hi gh-spee d run.

Always a djust the tire air pres-

sure accor din g to the operating

con ditions.

EAU61160

Cast wheelsTo maximize the performance, durabil-

ity, and safe operation of your vehicle,

note the following points regarding the

specified wheels.

The wheel rims should be

checked for cracks, bends, warp-

age or other damage before each

ride. If any damage is found, have

a Yamaha dealer replace the

wheel. Do not attempt even the

smallest repair to the wheel. A de-

formed or cracked wheel must be

replaced.

The front wheels should be bal-

anced whenever either the tires or

wheels have been changed or re-

placed. An unbalanced wheel can

result in poor performance, ad-

verse handling characteristics,

and a shortened tire life.

Front tire:

Size:120/70 R 15 M/C 56V

Manufacturer/model: BRIDGESTONE/A41F M

Rear tire:

Size:190/55 R 17 M/C 75V

Manufacturer/model:

BRIDGESTONE/A41R M

FRONT an d REAR:

Tire air valve:

TR412

Valve core: #9100 (original)

UBD5E0E0.book Page 18 Wednesday, April 25, 2018 2:23 PM

Page 82 of 106

Periodic maintenance an d a djustment

6-24

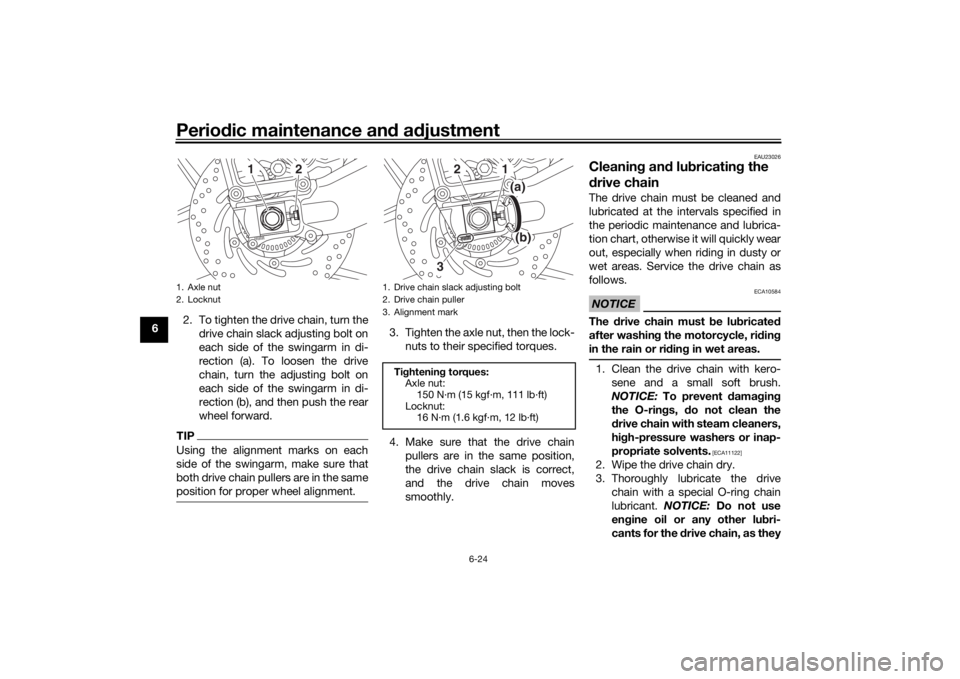

6 2. To tighten the drive chain, turn the

drive chain slack adjusting bolt on

each side of the swingarm in di-

rection (a). To loosen the drive

chain, turn the adjusting bolt on

each side of the swingarm in di-

rection (b), and then push the rear

wheel forward.

TIPUsing the alignment marks on each

side of the swingarm, make sure that

both drive chain pullers are in the same

position for proper wheel alignment.

3. Tighten the axle nut, then the lock-nuts to their specified torques.

4. Make sure that the drive chain pullers are in the same position,

the drive chain slack is correct,

and the drive chain moves

smoothly.

EAU23026

Cleanin g an d lu bricatin g the

d rive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must be lu bricated

after washin g the motorcycle, ri din g

in the rain or ri din g in wet areas.1. Clean the drive chain with kero-

sene and a small soft brush.

NOTICE: To prevent d amaging

the O-ring s, do not clean the

d rive chain with steam cleaners,

hi gh-pressure washers or inap-

propriate solvents.

[ECA11122]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

en gine oil or any other lu bri-

cants for the drive chain, as they

1. Axle nut

2. Locknut

2

1

1. Drive chain slack adjusting bolt

2. Drive chain puller

3. Alignment markTi ghtenin g torques:

Axle nut:

150 N·m (15 kgf·m, 111 lb·ft)

Locknut: 16 N·m (1.6 kgf·m, 12 lb·ft)

(a)(b)

1

2

3

UBD5E0E0.book Page 24 Wednesday, April 25, 2018 2:23 PM

Page 87 of 106

Periodic maintenance an d a djustment

6-29

6

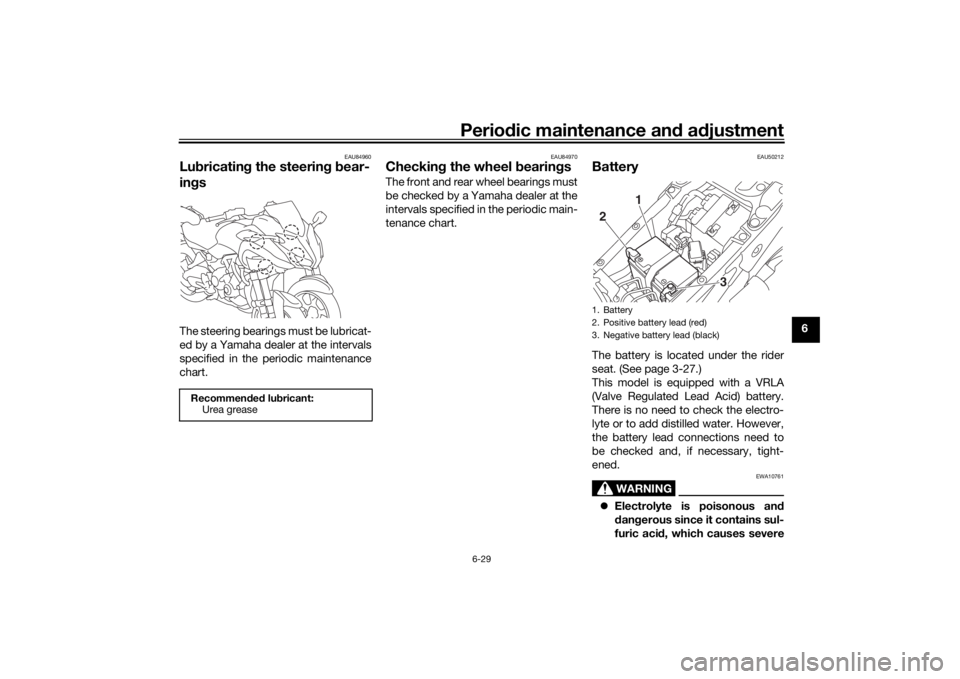

EAU84960

Lu bricatin g the steerin g b ear-

in gsThe steering bearings must be lubricat-

ed by a Yamaha dealer at the intervals

specified in the periodic maintenance

chart.

EAU84970

Checkin g the wheel bearin gsThe front and rear wheel bearings must

be checked by a Yamaha dealer at the

intervals specified in the periodic main-

tenance chart.

EAU50212

BatteryThe battery is located under the rider

seat. (See page 3-27.)

This model is equipped with a VRLA

(Valve Regulated Lead Acid) battery.

There is no need to check the electro-

lyte or to add distilled water. However,

the battery lead connections need to

be checked and, if necessary, tight-

ened.

WARNING

EWA10761

Electrolyte is poisonous an d

d an gerous since it contains sul-

furic aci d, which causes severe

Recommen ded lu bricant:

Urea grease

1. Battery

2. Positive battery lead (red)

3. Negative battery lead (black)2 1

3

UBD5E0E0.book Page 29 Wednesday, April 25, 2018 2:23 PM

Page 95 of 106

Motorcycle care and stora ge

7-1

7

EAU37834

Matte color cautionNOTICE

ECA15193

Some mo dels are equipped with

matte colored finished parts. Be

sure to consult a Yamaha dealer for

a d vice on what prod ucts to use be-

fore cleanin g the vehicle. Usin g a

b rush, harsh chemical pro ducts or

cleanin g compoun ds when cleanin g

these parts will scratch or damag e

their surface. Wax also shoul d not

b e applie d to any matte colored fin-

ishe d parts.

EAU83443

CareFrequent, thorough cleaning of the ve-

hicle will not only enhance its appear-

ance but also will improve its general

performance and extend the useful life

of many components. Washing, clean-

ing, and polishing will also give you a

chance to inspect the condition of the

vehicle more frequently. Be sure to

wash the vehicle after riding in the rain

or near the sea, because salt is corro-

sive to metals.TIP The roads of heavy snowfall areas

may be sprayed with salt as a de-

icing method. This salt can stay on

the roads well into spring, so be

sure to wash the underside and

chassis parts after riding in such

areas.

Genuine Yamaha care and main-

tenance products are sold under

the YAMALUBE brand in many

markets worldwide.

See your Yamaha dealer for addi-

tional cleaning tips.

NOTICE

ECA26280

Improper cleanin g can cause cos-

metic an d mechanical damag e. Do

not use: high-pressure washers or

steam-jet cleaners. Excessive

water pressure may cause wa-

ter seepag e and d eterioration of

wheel bearin gs, brakes, trans-

mission seals an d electrical de-

vices. Avoi d hi gh-pressure

d eter gent applications such as

those availa ble in coin-operate d

car washers.

harsh chemicals, inclu din g

stron g aci dic wheel cleaners,

especially on spoke or ma gne-

sium wheels.

harsh chemicals, a brasive

cleanin g compoun ds, or wax on

matte-finishe d parts. Brushes

can scratch an d damag e the

matte-finish, use soft spon ge or

towel only.

towels, spon ges, or brushes

contaminate d with a brasive

cleanin g prod ucts or stron g

UBD5E0E0.book Page 1 Wednesday, April 25, 2018 2:23 PM

Page 96 of 106

Motorcycle care and stora ge

7-2

7 chemicals such as, solvents,

g

asoline, rust removers, brake

flui d, or antifreeze, etc.

Before washin g

1. Park the vehicle out of direct sun- light and allow it to cool. This will

help avoid water spots.

2. Make sure all caps, covers, elec- trical couplers and connectors are

tightly installed.

3. Cover the muffler end with a plas- tic bag and a strong rubber band.

4. Pre-soak stubborn stains like in- sects or bird droppings with a wet

towel for a few minutes.

5. Remove road grime and oil stains with a quality degreasing agent

and a plastic-bristle brush or

sponge. NOTICE: Do not use

d eg reasin g a gent on areas re-

quirin g lu brication such as

seals, gaskets, an d wheel axles.

Follow prod uct instructions.

[ECA26290]

Washing

1. Rinse off any degreaser and spray down the vehicle with a garden

hose. Use only enough pressure

to do the job. Avoid spraying wa-

ter directly into the muffler, instru-

ment panel, air inlet, or other inner

areas such as underseat storage

compartments.

2. Wash the vehicle with a quality au- tomotive-type detergent mixed

with cool water and a soft, clean

towel or sponge. Use an old tooth-

brush or plastic-bristle brush for

for hard-to-reach places.

NOTICE: Use col d water if the

vehicle has b een exposed to

salt. Warm water will increase

salt’s corrosive properties.

[ECA26301]

3. For windshield-equipped vehicles: Clean the windshield with a soft

towel or sponge dampened with

water and a pH neutral detergent.

If necessary, use a high-quality

windshield cleaner or polish for

motorcycles. NOTICE: Never use

any stron g chemicals to clean

the win dshiel d. A dditionally, some cleanin

g compoun ds for

plastic may scratch the win d-

shiel d, so b e sure to test all

cleanin g prod ucts before gen-

eral application.

[ECA26310]

4. Rinse off thoroughly with clean water. Be sure to remove all deter-

gent residues, as they can be

harmful to plastic parts.

After washin g

1. Dry the vehicle with a chamois or absorbent towel, preferably mi-

crofiber terrycloth.

2. For drive chain-equipped models: Dry and then lubricate the drive

chain to prevent rust.

3. Use a chrome polish to shine chrome, aluminum, and stainless

steel parts. Often the thermally in-

duced discoloring of stainless

steel exhaust systems can be re-

moved through polishing.

4. Apply a corrosion protection spray on all metal parts including

chrome or nickel-plated surfaces.

WARNING! Do not apply sili-

cone or oil spray to seats, han d

g rips, ru bber foot peg s or tire

UBD5E0E0.book Page 2 Wednesday, April 25, 2018 2:23 PM

Page 98 of 106

Motorcycle care and stora ge

7-4

7 1. Make all necessary repairs and

perform any outstanding mainte-

nance.

2. Follow all instructions in the Care section of this chapter.

3. Fill up the fuel tank, adding fuel stabilizer according to product in-

structions. Run the engine for 5

minutes to distribute treated fuel

through the fuel system.

4. For vehicles equipped with a fuel cock: Turn the fuel cock lever to

the off position.

5. For vehicles with a carburetor: To prevent fuel deposits from build-

ing up, drain the fuel in the carbu-

retor float chamber into a clean

container. Retighten the drain bolt

and pour the fuel back into the fuel

tank.

6. Use a quality engine fogging oil according to product instructions

to protect internal engine compo-

nents from corrosion. If engine

fogging oil is not available, per-

form the following steps for each

cylinder:a. Remove the spark plug cap and spark plug. b. Pour a teaspoonful of engine

oil into the spark plug bore.

c. Install the spark plug cap onto the spark plug, and then place

the spark plug on the cylinder

head so that the electrodes are

grounded. (This will limit spark-

ing during the next step.)

d. Turn the engine over several times with the starter. (This will

coat the cylinder wall with oil.)

WARNING! To prevent d am-

a g e or injury from sparkin g,

make sure to groun d the

spark plu g electro des while

turnin g the en gine over.

[EWA10952]

e. Remove the spark plug cap

from the spark plug, and then

install the spark plug and the

spark plug cap.

7. Lubricate all control cables, piv- ots, levers and pedals, as well as

the sidestand and centerstand (if

equipped).

8. Check and correct the tire air pressure, and then lift the vehicle

so that all wheels are off the

ground. Otherwise, turn the wheels a little once a month in or-

der to prevent the tires from be-

coming degraded in one spot.

9. Cover the muffler outlet with a plastic bag to prevent moisture

from entering it.

10. Remove the battery and fully charge it, or attach a maintenance

charger to keep the battery opti-

mally charged. NOTICE: Confirm

that the battery an d its char ger

are compati ble. Do not char ge a

VRLA battery with a convention-

al char ger.

[ECA26330]

TIP If the battery will be removed,

charge it once a month and store

it in a temperate location between

0-30 °C (32-90 °F).

See page 6-29 for more informa-

tion on charging and storing the

battery.

UBD5E0E0.book Page 4 Wednesday, April 25, 2018 2:23 PM

Page 99 of 106

Specifications

8-1

8

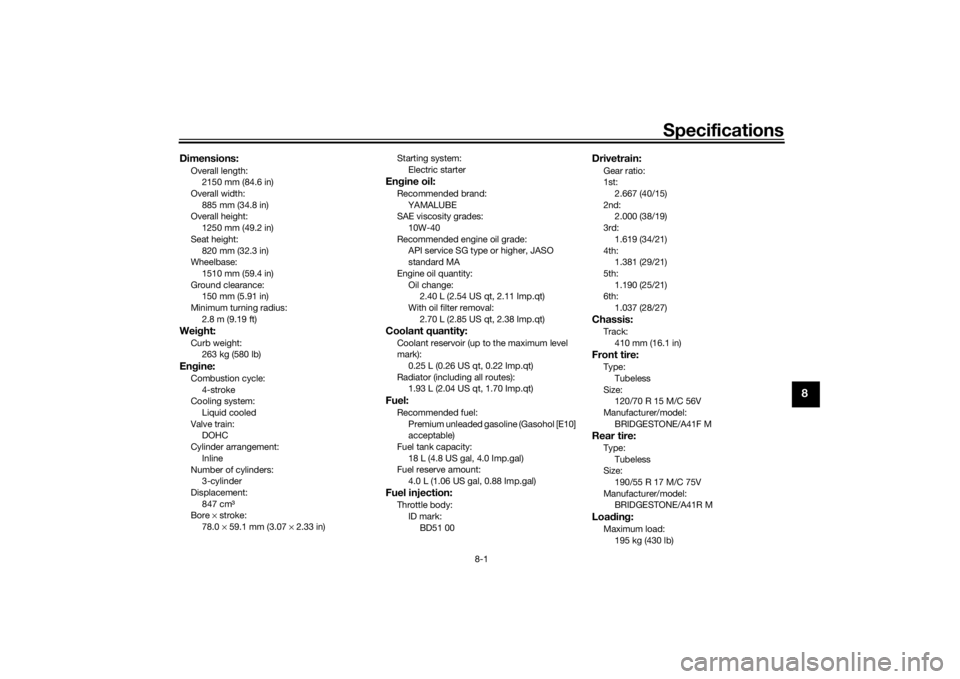

Dimensions:Overall length:2150 mm (84.6 in)

Overall width:

885 mm (34.8 in)

Overall height: 1250 mm (49.2 in)

Seat height: 820 mm (32.3 in)

Wheelbase:

1510 mm (59.4 in)

Ground clearance: 150 mm (5.91 in)

Minimum turning radius: 2.8 m (9.19 ft)Wei ght:Curb weight:

263 kg (580 lb)Engine:Combustion cycle:

4-stroke

Cooling system: Liquid cooled

Valve train: DOHC

Cylinder arrangement:

Inline

Number of cylinders: 3-cylinder

Displacement: 847 cm³

Bore × stroke:

78.0 × 59.1 mm (3.07 × 2.33 in) Starting system:

Electric starter

Engine oil:Recommended brand:

YAMALUBE

SAE viscosity grades: 10W-40

Recommended engine oil grade: API service SG type or higher, JASO

standard MA

Engine oil quantity: Oil change:2.40 L (2.54 US qt, 2.11 Imp.qt)

With oil filter removal: 2.70 L (2.85 US qt, 2.38 Imp.qt)Coolant quantity:Coolant reservoir (up to the maximum level

mark):

0.25 L (0.26 US qt, 0.22 Imp.qt)

Radiator (including all routes): 1.93 L (2.04 US qt, 1.70 Imp.qt)Fuel:Recommended fuel:

Premium unleaded gasoline (Gasohol [E10]

acceptable)

Fuel tank capacity:

18 L (4.8 US gal, 4.0 Imp.gal)

Fuel reserve amount: 4.0 L (1.06 US gal, 0.88 Imp.gal)Fuel injection:Throttle body:

ID mark:BD51 00

Drivetrain:Gear ratio:

1st:2.667 (40/15)

2nd: 2.000 (38/19)

3rd:

1.619 (34/21)

4th: 1.381 (29/21)

5th: 1.190 (25/21)

6th:

1.037 (28/27)Chassis:Track:410 mm (16.1 in)Front tire:Type:Tubeless

Size: 120/70 R 15 M/C 56V

Manufacturer/model:

BRIDGESTONE/A41F MRear tire:Type: Tubeless

Size:

190/55 R 17 M/C 75V

Manufacturer/model: BRIDGESTONE/A41R MLoa din g:Maximum load:

195 kg (430 lb)

UBD5E0E0.book Page 1 Wednesday, April 25, 2018 2:23 PM