length YAMAHA TTR125 2001 Betriebsanleitungen (in German)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: TTR125, Model: YAMAHA TTR125 2001Pages: 508, PDF-Größe: 16.81 MB

Page 192 of 508

3 - 21

INSP

ADJ

DRIVE CHAIN INSPECTION

EC369002

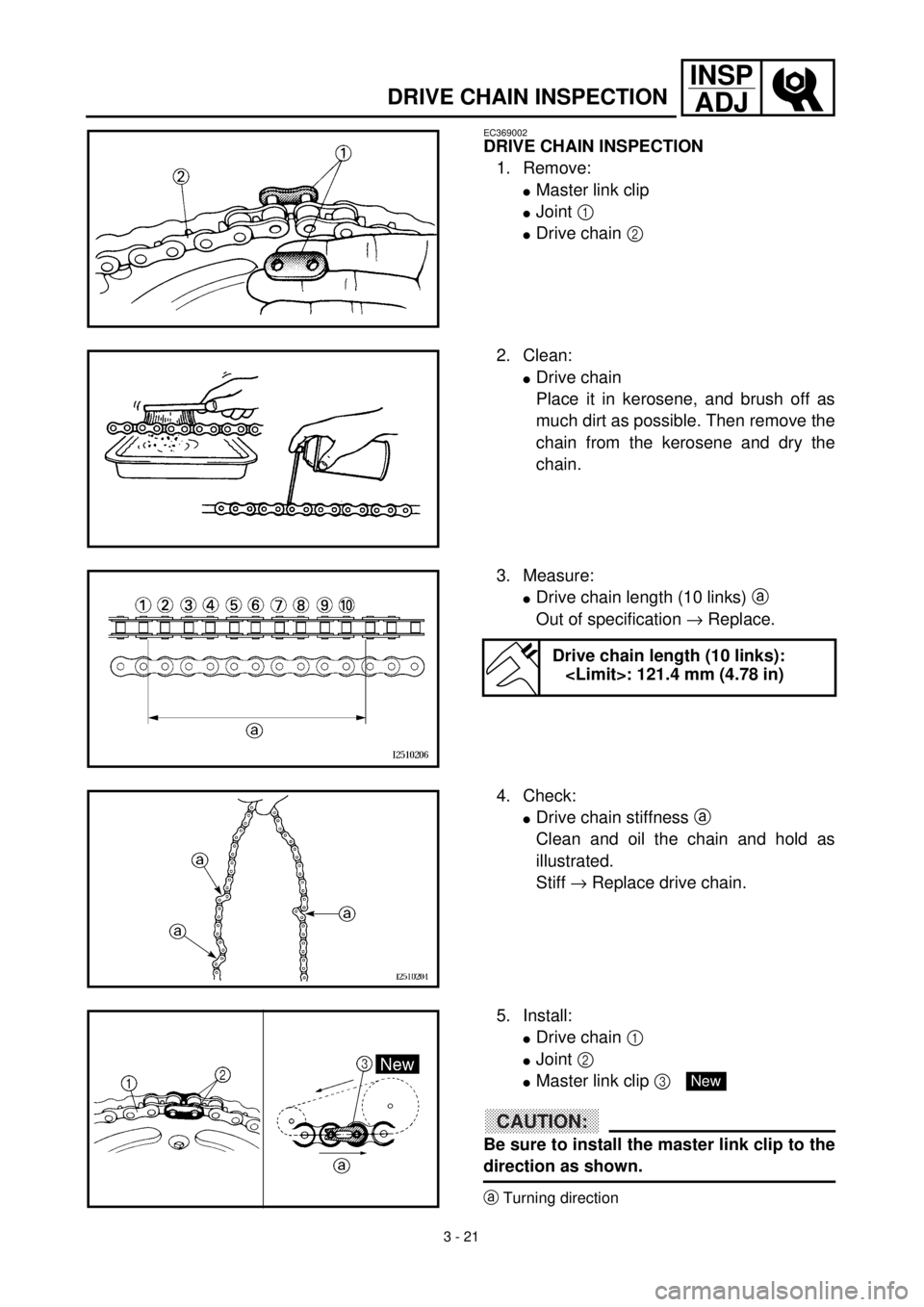

DRIVE CHAIN INSPECTION

1. Remove:

lMaster link clip

lJoint 1

lDrive chain 2

2. Clean:

lDrive chain

Place it in kerosene, and brush off as

much dirt as possible. Then remove the

chain from the kerosene and dry the

chain.

3. Measure:

lDrive chain length (10 links) a

Out of specification ® Replace.

Drive chain length (10 links):

4. Check:

lDrive chain stiffness a

Clean and oil the chain and hold as

illustrated.

Stiff ® Replace drive chain.

5. Install:

lDrive chain 1

lJoint 2

lMaster link clip 3

CAUTION:

Be sure to install the master link clip to the

direction as shown.

aTurning direction

New

Page 196 of 508

3 - 23

INSP

ADJFRONT FORK INSPECTION/

REAR SHOCK ABSORBER ASSEMBLY INSPECTION/

REAR SHOCK ABSORBER SPRING PRELOAD ADJUSTMENT

EC36C000

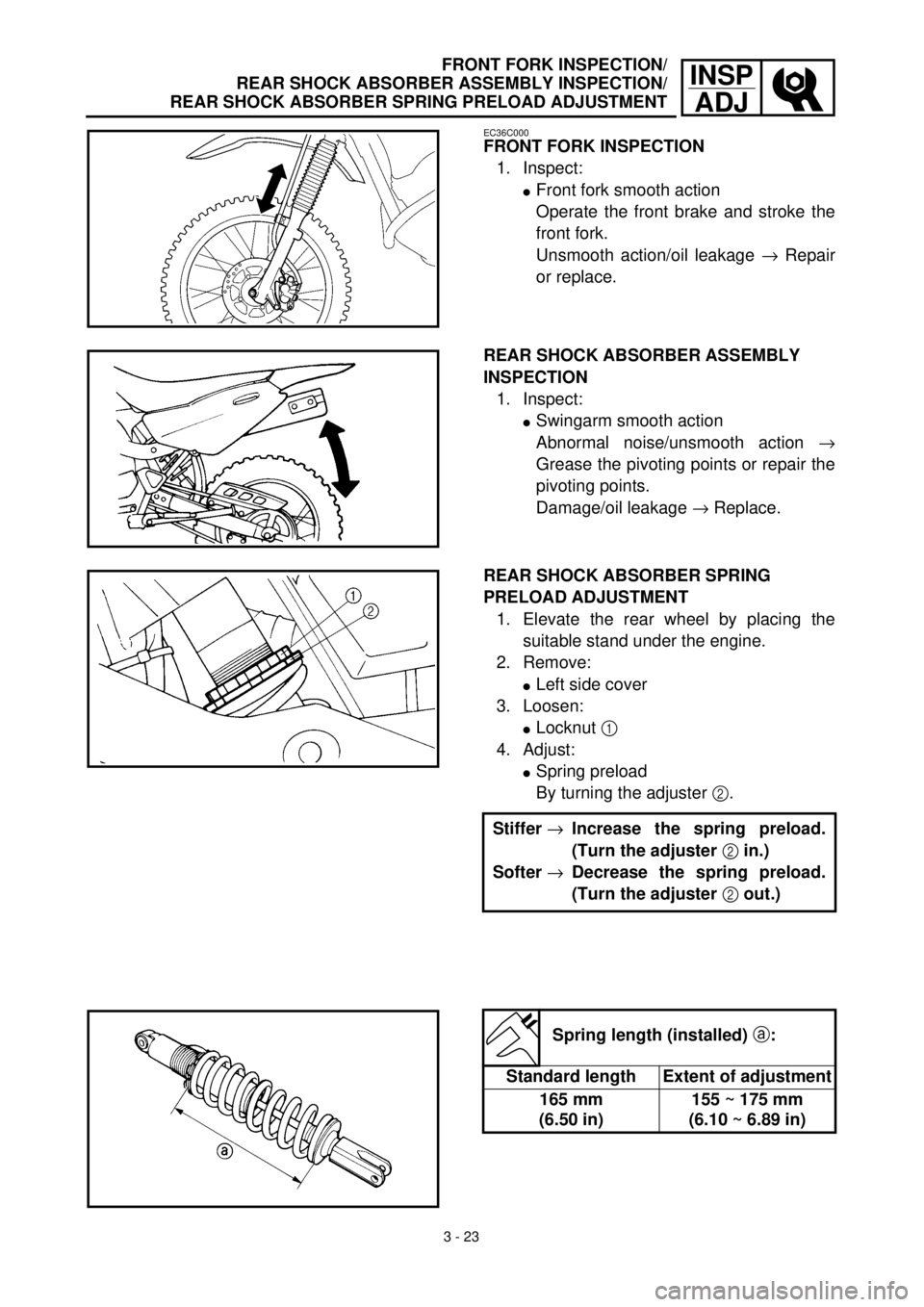

FRONT FORK INSPECTION

1. Inspect:

lFront fork smooth action

Operate the front brake and stroke the

front fork.

Unsmooth action/oil leakage ® Repair

or replace.

REAR SHOCK ABSORBER ASSEMBLY

INSPECTION

1. Inspect:

lSwingarm smooth action

Abnormal noise/unsmooth action ®

Grease the pivoting points or repair the

pivoting points.

Damage/oil leakage ® Replace.

REAR SHOCK ABSORBER SPRING

PRELOAD ADJUSTMENT

1. Elevate the rear wheel by placing the

suitable stand under the engine.

2. Remove:

lLeft side cover

3. Loosen:

lLocknut 1

4. Adjust:

lSpring preload

By turning the adjuster 2.

Stiffer ®Increase the spring preload.

(Turn the adjuster 2 in.)

Softer ®Decrease the spring preload.

(Turn the adjuster 2 out.)

Spring length (installed) a:

Standard length Extent of adjustment

165 mm

(6.50 in)155 ~ 175 mm

(6.10 ~ 6.89 in)

Page 198 of 508

3 - 24

INSP

ADJ

TIRE PRESSURE CHECK

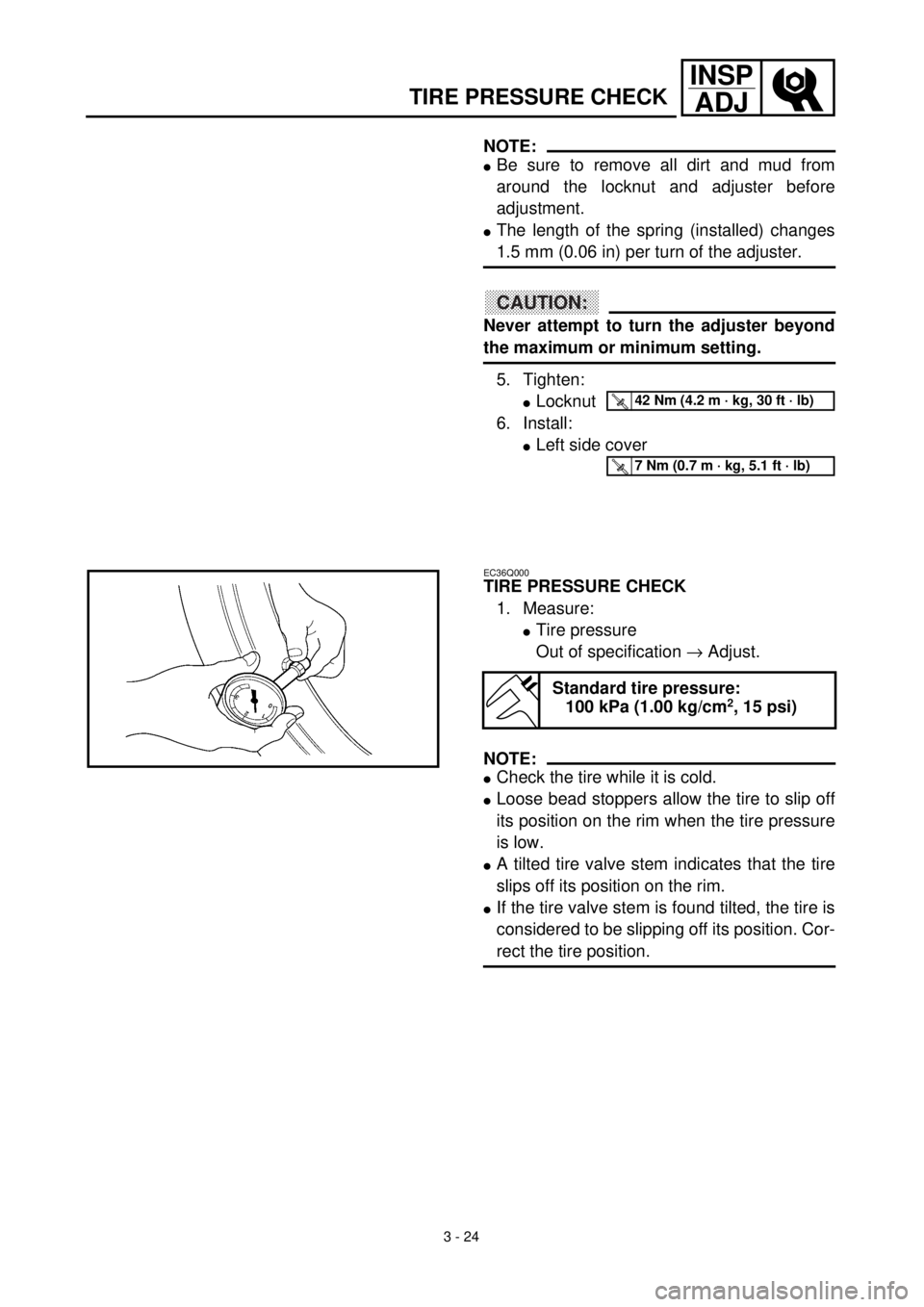

NOTE:

lBe sure to remove all dirt and mud from

around the locknut and adjuster before

adjustment.

lThe length of the spring (installed) changes

1.5 mm (0.06 in) per turn of the adjuster.

CAUTION:

Never attempt to turn the adjuster beyond

the maximum or minimum setting.

5. Tighten:

lLocknut

6. Install:

lLeft side cover

T R..42 Nm (4.2 m · kg, 30 ft · lb)

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

EC36Q000

TIRE PRESSURE CHECK

1. Measure:

lTire pressure

Out of specification ® Adjust.

NOTE:

lCheck the tire while it is cold.

lLoose bead stoppers allow the tire to slip off

its position on the rim when the tire pressure

is low.

lA tilted tire valve stem indicates that the tire

slips off its position on the rim.

lIf the tire valve stem is found tilted, the tire is

considered to be slipping off its position. Cor-

rect the tire position.

Standard tire pressure:

100 kPa (1.00 kg/cm2, 15 psi)

Page 250 of 508

4 - 21

ENG

CAMSHAFT AND ROCKER ARMS

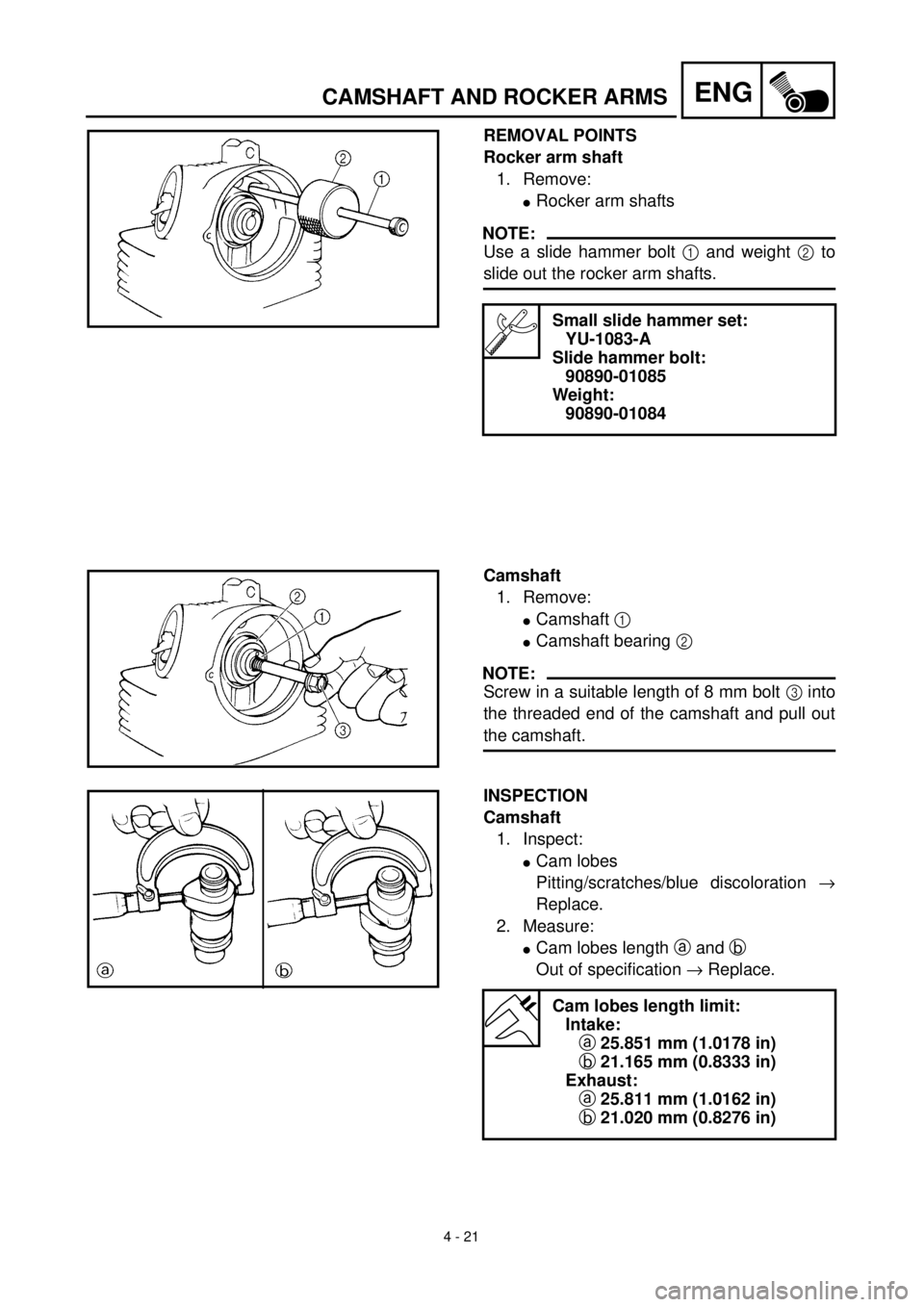

REMOVAL POINTS

Rocker arm shaft

1. Remove:

l

Rocker arm shafts

NOTE:

Use a slide hammer bolt

1

and weight

2

to

slide out the rocker arm shafts.

Small slide hammer set:

YU-1083-A

Slide hammer bolt:

90890-01085

Weight:

90890-01084

Camshaft

1. Remove:

l

Camshaft

1

l

Camshaft bearing

2

NOTE:

Screw in a suitable length of 8 mm bolt

3

into

the threaded end of the camshaft and pull out

the camshaft.

INSPECTION

Camshaft

1. Inspect:

l

Cam lobes

Pitting/scratches/blue discoloration

®

Replace.

2. Measure:

l

Cam lobes length

a

and

b

Out of specification

®

Replace.

Cam lobes length limit:

Intake:

a

25.851 mm (1.0178 in)

b

21.165 mm (0.8333 in)

Exhaust:

a

25.811 mm (1.0162 in)

b

21.020 mm (0.8276 in)

Page 266 of 508

4 - 29

ENGVALVES AND VALVE SPRINGS

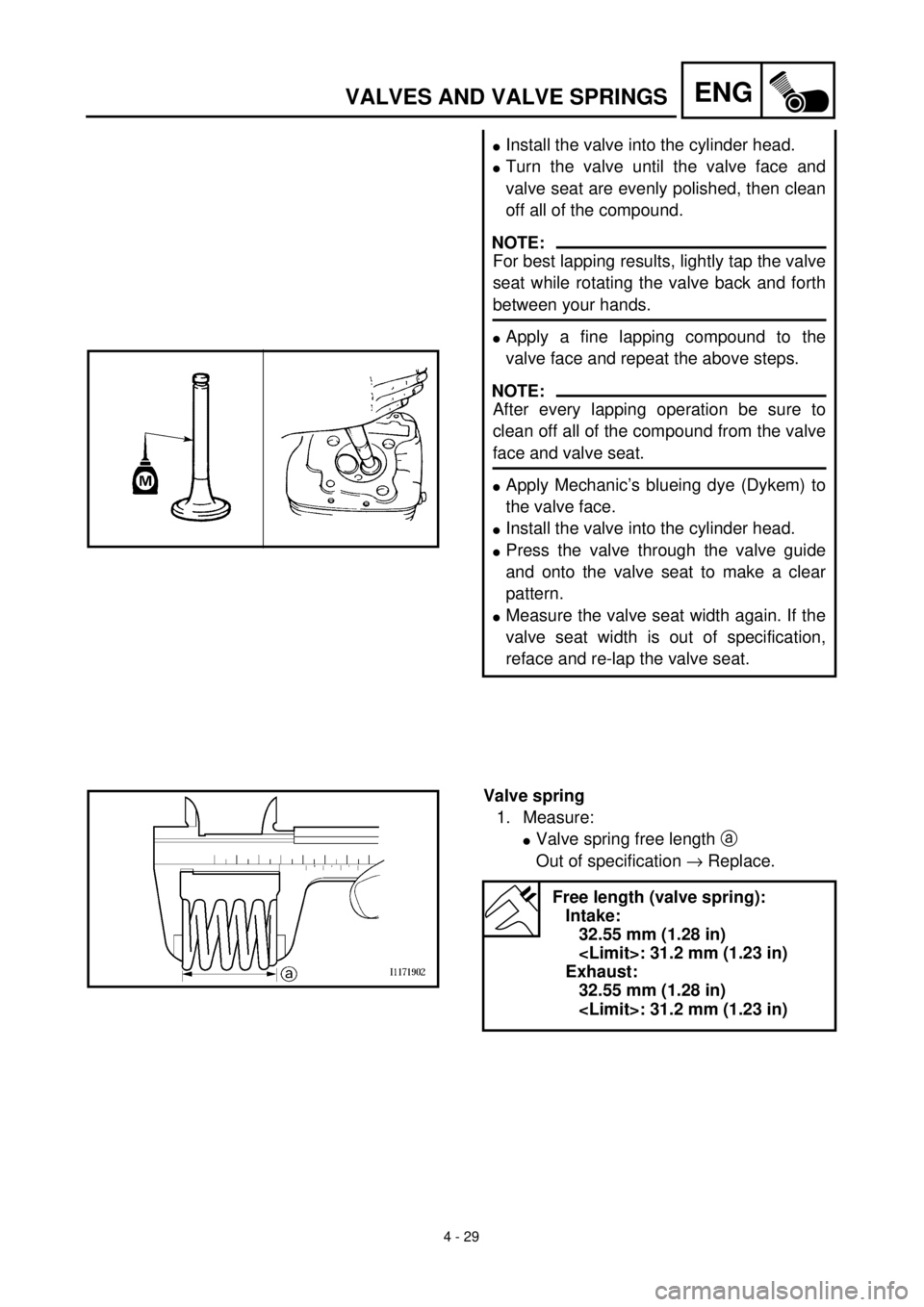

lInstall the valve into the cylinder head.

lTurn the valve until the valve face and

valve seat are evenly polished, then clean

off all of the compound.

NOTE:

For best lapping results, lightly tap the valve

seat while rotating the valve back and forth

between your hands.

lApply a fine lapping compound to the

valve face and repeat the above steps.

NOTE:

After every lapping operation be sure to

clean off all of the compound from the valve

face and valve seat.

lApply Mechanic’s blueing dye (Dykem) to

the valve face.

lInstall the valve into the cylinder head.

lPress the valve through the valve guide

and onto the valve seat to make a clear

pattern.

lMeasure the valve seat width again. If the

valve seat width is out of specification,

reface and re-lap the valve seat.

Valve spring

1. Measure:

lValve spring free length a

Out of specification ® Replace.

Free length (valve spring):

Intake:

32.55 mm (1.28 in)

Exhaust:

32.55 mm (1.28 in)

Page 268 of 508

4 - 30

ENGVALVES AND VALVE SPRINGS

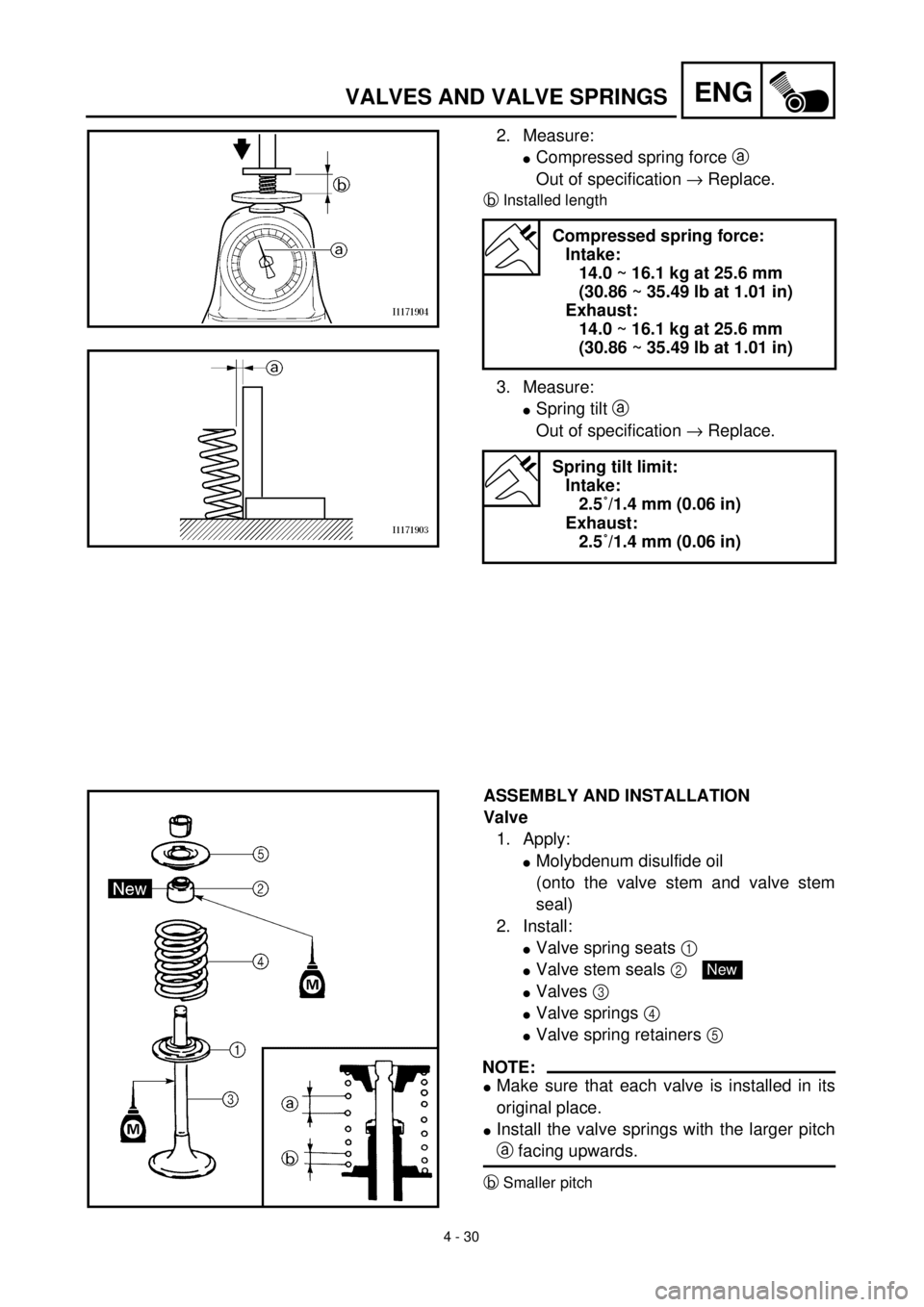

2. Measure:

lCompressed spring force a

Out of specification ® Replace.

bInstalled length

3. Measure:

lSpring tilt a

Out of specification ® Replace.

Compressed spring force:

Intake:

14.0 ~ 16.1 kg at 25.6 mm

(30.86 ~ 35.49 lb at 1.01 in)

Exhaust:

14.0 ~ 16.1 kg at 25.6 mm

(30.86 ~ 35.49 lb at 1.01 in)

Spring tilt limit:

Intake:

2.5˚/1.4 mm (0.06 in)

Exhaust:

2.5˚/1.4 mm (0.06 in)

ASSEMBLY AND INSTALLATION

Valve

1. Apply:

lMolybdenum disulfide oil

(onto the valve stem and valve stem

seal)

2. Install:

lValve spring seats 1

lValve stem seals 2

lValves 3

lValve springs 4

lValve spring retainers 5

NOTE:

lMake sure that each valve is installed in its

original place.

lInstall the valve springs with the larger pitch

a facing upwards.

bSmaller pitch

New

Page 296 of 508

4 - 44

ENG

CLUTCH AND PRIMARY DRIVEN GEAR

EC484400

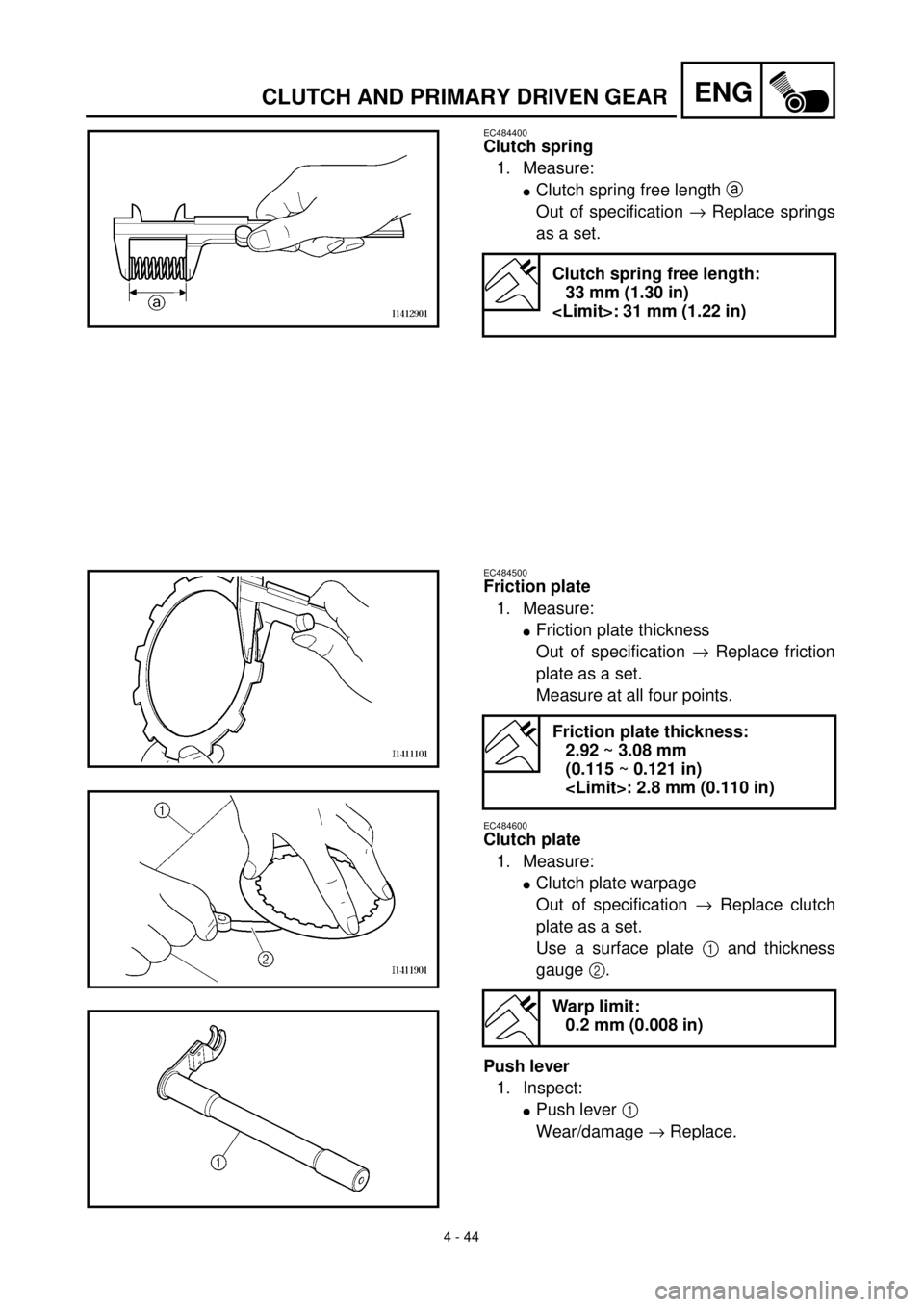

Clutch spring

1. Measure:

l

Clutch spring free length

a

Out of specification

®

Replace springs

as a set.

Clutch spring free length:

33 mm (1.30 in)

EC484500

Friction plate

1. Measure:

l

Friction plate thickness

Out of specification

®

Replace friction

plate as a set.

Measure at all four points.

EC484600

Clutch plate

1. Measure:

l

Clutch plate warpage

Out of specification

®

Replace clutch

plate as a set.

Use a surface plate

1

and thickness

gauge

2

.

Push lever

1. Inspect:

l

Push lever

1

Wear/damage

®

Replace.

Friction plate thickness:

2.92 ~ 3.08 mm

(0.115 ~ 0.121 in)

Warp limit:

0.2 mm (0.008 in)

Page 434 of 508

5 - 35

CHASFRONT FORK

Damper rod holder:

YM-1300/90890-01294

T-handle:

YM-01326/90890-01326

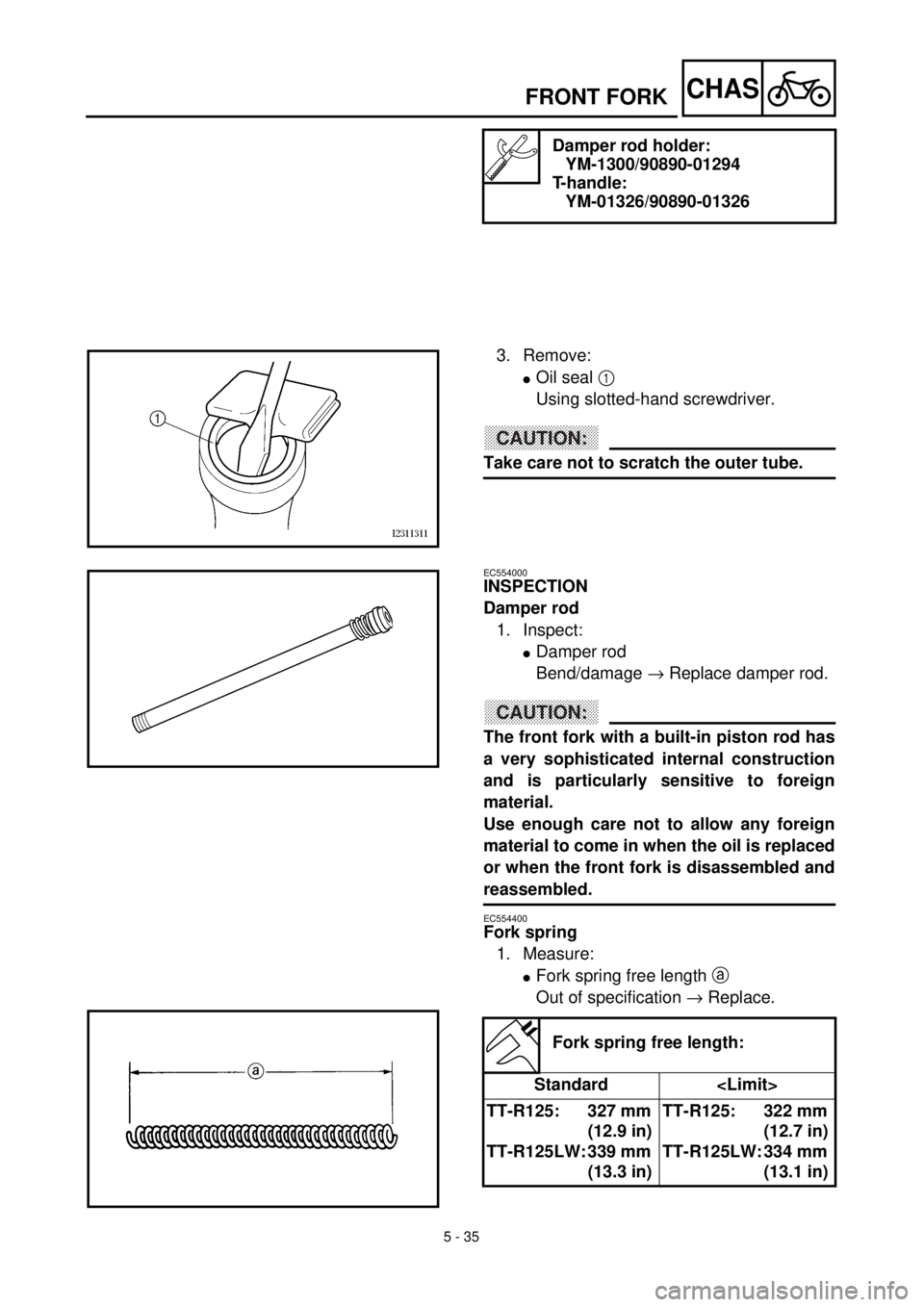

3. Remove:

lOil seal 1

Using slotted-hand screwdriver.

CAUTION:

Take care not to scratch the outer tube.

EC554000

INSPECTION

Damper rod

1. Inspect:

lDamper rod

Bend/damage ® Replace damper rod.

CAUTION:

The front fork with a built-in piston rod has

a very sophisticated internal construction

and is particularly sensitive to foreign

material.

Use enough care not to allow any foreign

material to come in when the oil is replaced

or when the front fork is disassembled and

reassembled.

EC554400

Fork spring

1. Measure:

lFork spring free length a

Out of specification ® Replace.

Fork spring free length:

Standard

TT-R125: 327 mm

(12.9 in)

TT-R125LW: 339 mm

(13.3 in)TT-R125: 322 mm

(12.7 in)

TT-R125LW: 334 mm

(13.1 in)