engine YAMAHA TTR90 2000 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: TTR90, Model: YAMAHA TTR90 2000Pages: 287, PDF Size: 6.77 MB

Page 28 of 287

1 - 2

GEN

INFO

MACHINE IDENTIFICATION

EC120001

MACHINE IDENTIFICATION

There are two significant reasons for knowing

the serial number of your machine:

1. When ordering parts, you can give the

number to your Yamaha dealer for positive

identification of the model you own.

2. If your machine is stolen, the authorities

will need the number to search for and

identify your machine.

EC121001

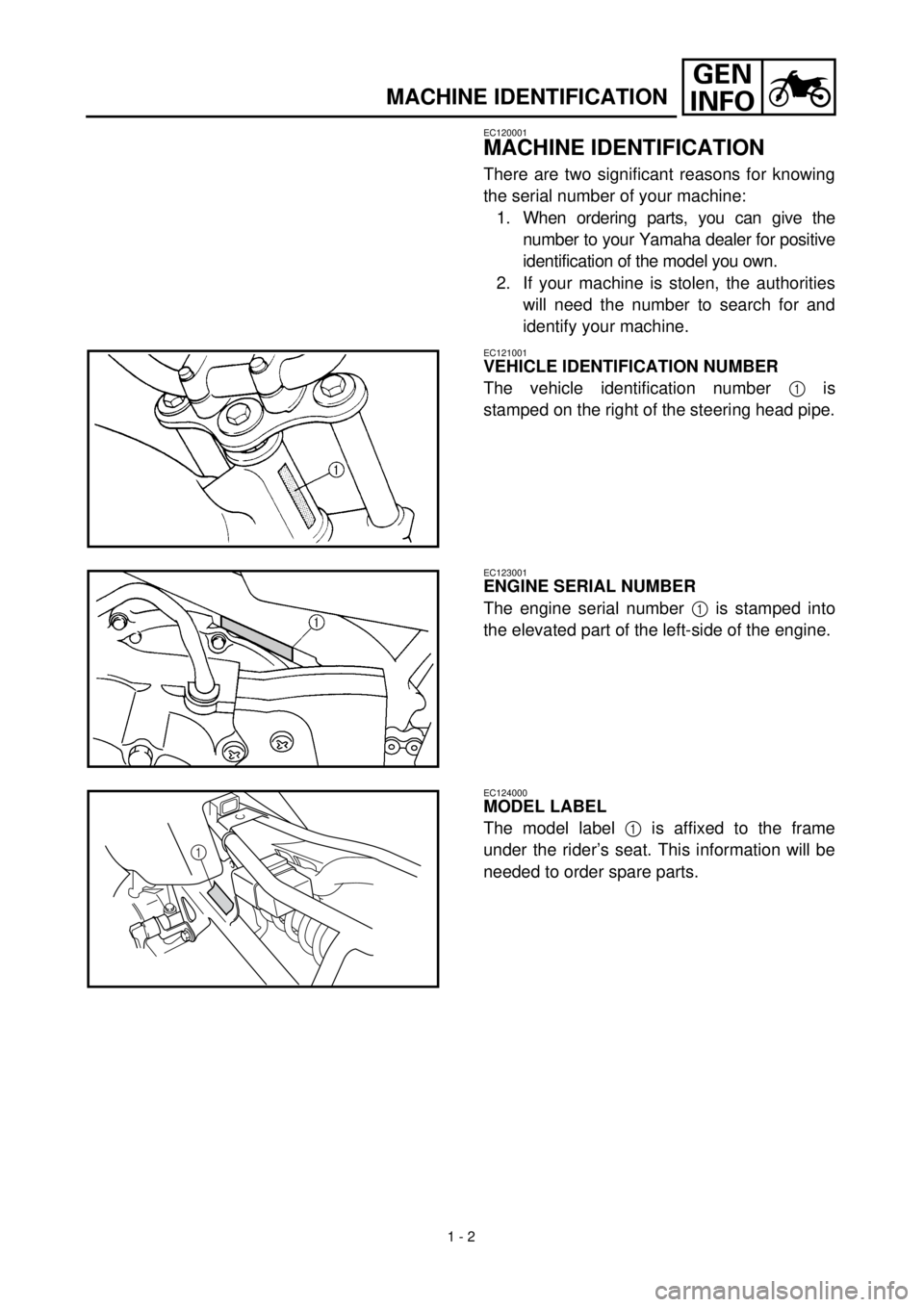

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number

1

is

stamped on the right of the steering head pipe.

EC123001

ENGINE SERIAL NUMBER

The engine serial number

1

is stamped into

the elevated part of the left-side of the engine.

EC124000

MODEL LABEL

The model label

1

is affixed to the frame

under the rider’s seat. This information will be

needed to order spare parts.

1

Page 32 of 287

1 - 4

GEN

INFO

IMPORTANT INFORMATION

EC133000

GASKETS, OIL SEALS AND O-RINGS

1. All gaskets, oil seals, and O-rings should

be replaced when an engine is over-

hauled. All gasket surfaces, oil seal lips,

and O-rings must be cleaned.

2. Properly oil all mating parts and bearings

during reassembly. Apply grease to the

oil seal lips.

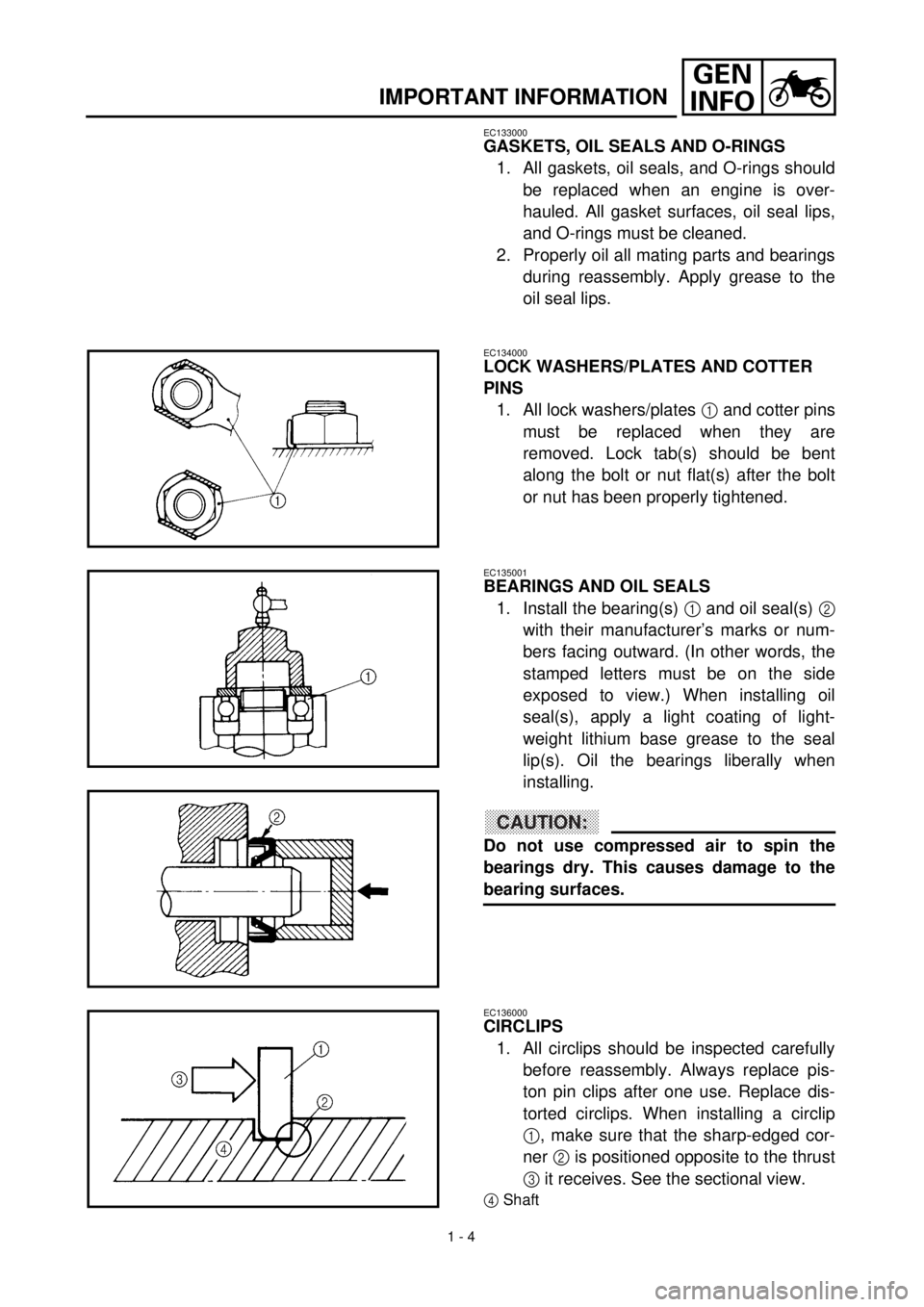

EC134000

LOCK WASHERS/PLATES AND COTTER

PINS

1. All lock washers/plates

1

and cotter pins

must be replaced when they are

removed. Lock tab(s) should be bent

along the bolt or nut flat(s) after the bolt

or nut has been properly tightened.

EC135001

BEARINGS AND OIL SEALS

1. Install the bearing(s)

1

and oil seal(s)

2

with their manufacturer’s marks or num-

bers facing outward. (In other words, the

stamped letters must be on the side

exposed to view.) When installing oil

seal(s), apply a light coating of light-

weight lithium base grease to the seal

lip(s). Oil the bearings liberally when

installing.

CAUTION:

Do not use compressed air to spin the

bearings dry. This causes damage to the

bearing surfaces.

EC136000

CIRCLIPS

1. All circlips should be inspected carefully

before reassembly. Always replace pis-

ton pin clips after one use. Replace dis-

torted circlips. When installing a circlip

1

, make sure that the sharp-edged cor-

ner

2

is positioned opposite to the thrust

3

it receives. See the sectional view.

4

Shaft

Page 36 of 287

GEN

INFO

1 - 6

SPECIAL TOOLS

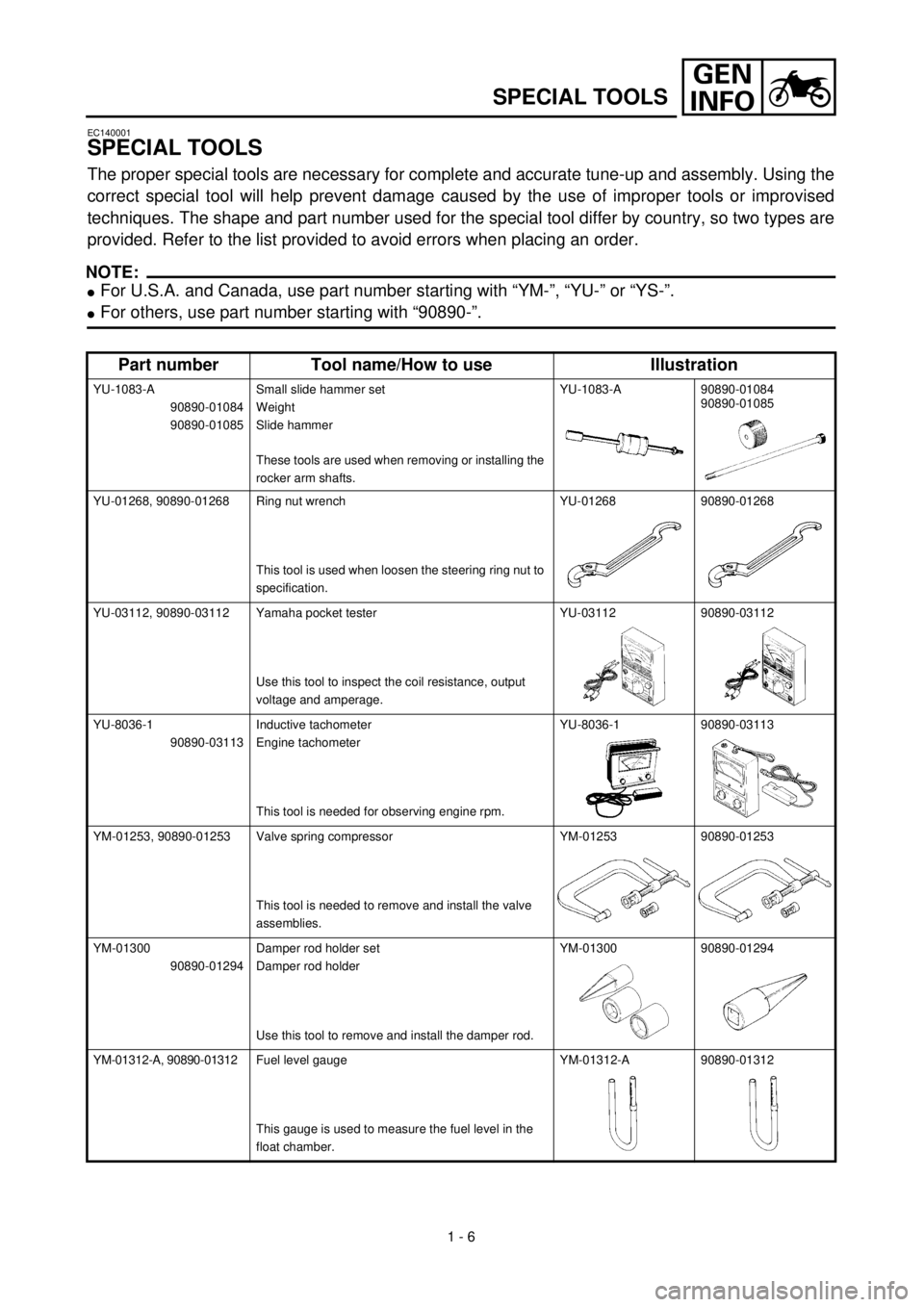

EC140001

SPECIAL TOOLS

The proper special tools are necessary for complete and accurate tune-up and assembly. Using the

correct special tool will help prevent damage caused by the use of improper tools or improvised

techniques. The shape and part number used for the special tool differ by country, so two types are

provided. Refer to the list provided to avoid errors when placing an order.

NOTE:

l

For U.S.A. and Canada, use part number starting with “YM-”, “YU-” or “YS-”.

lFor others, use part number starting with “90890-”.

Part number Tool name/How to use Illustration

YU-1083-A

90890-01084

90890-01085Small slide hammer set

Weight

Slide hammer

These tools are used when removing or installing the

rocker arm shafts.YU-1083-A 90890-01084

90890-01085

YU-01268, 90890-01268 Ring nut wrench

This tool is used when loosen the steering ring nut to

specification.YU-01268 90890-01268

YU-03112, 90890-03112 Yamaha pocket tester

Use this tool to inspect the coil resistance, output

voltage and amperage.YU-03112 90890-03112

YU-8036-1

90890-03113Inductive tachometer

Engine tachometer

This tool is needed for observing engine rpm.YU-8036-1 90890-03113

YM-01253, 90890-01253 Valve spring compressor

This tool is needed to remove and install the valve

assemblies.YM-01253 90890-01253

YM-01300

90890-01294Damper rod holder set

Damper rod holder

Use this tool to remove and install the damper rod.YM-01300 90890-01294

YM-01312-A, 90890-01312Fuel level gauge

This gauge is used to measure the fuel level in the

float chamber.YM-01312-A 90890-01312

Page 46 of 287

1 - 9

GEN

INFO

CONTROL FUNCTIONS

EC150000

CONTROL FUNCTIONS

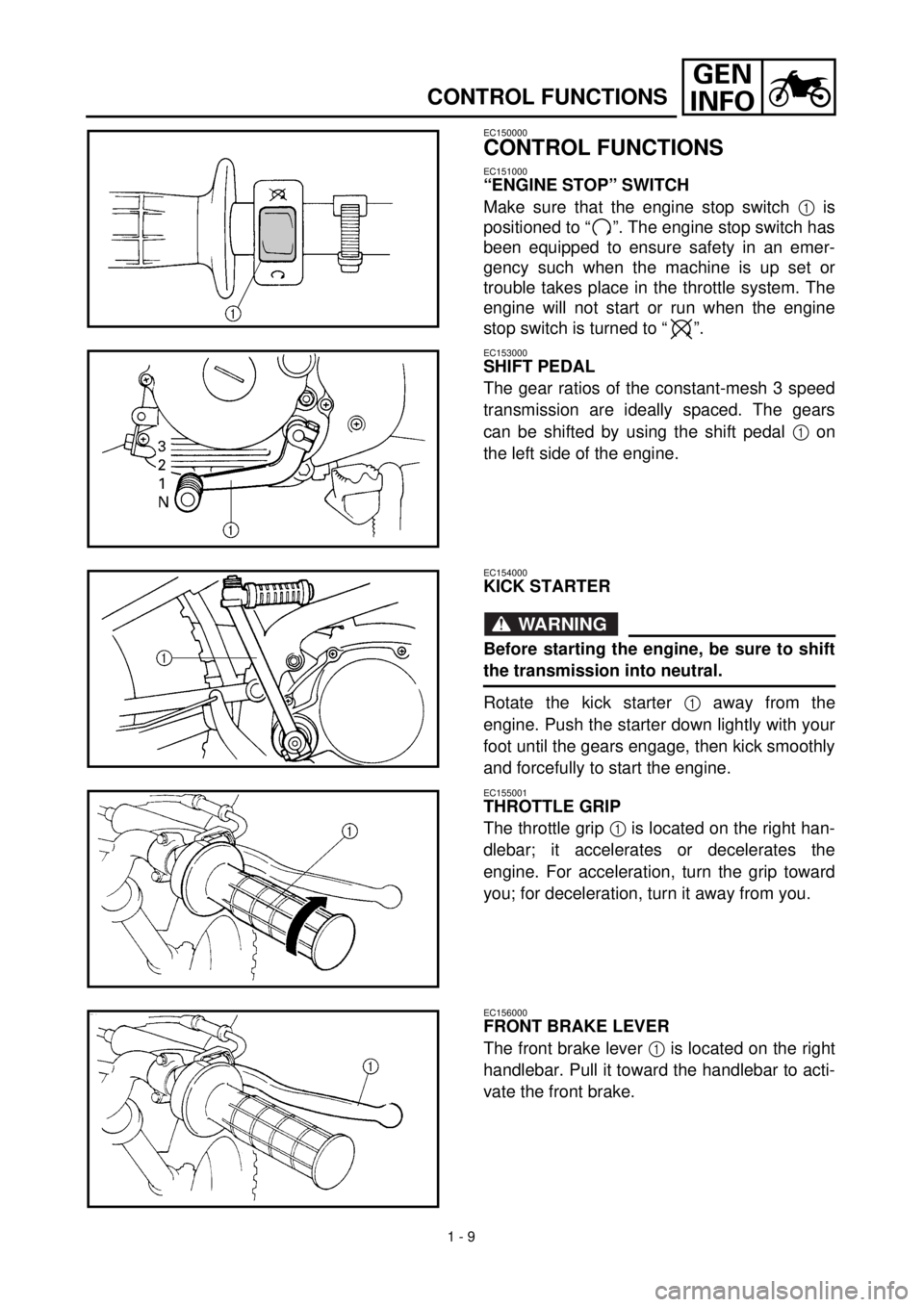

EC151000

“ENGINE STOP” SWITCH

Make sure that the engine stop switch 1 is

positioned to “ ”. The engine stop switch has

been equipped to ensure safety in an emer-

gency such when the machine is up set or

trouble takes place in the throttle system. The

engine will not start or run when the engine

stop switch is turned to “ ”.

EC153000

SHIFT PEDAL

The gear ratios of the constant-mesh 3 speed

transmission are ideally spaced. The gears

can be shifted by using the shift pedal 1 on

the left side of the engine.

EC154000

KICK STARTER

WARNING

Before starting the engine, be sure to shift

the transmission into neutral.

Rotate the kick starter 1 away from the

engine. Push the starter down lightly with your

foot until the gears engage, then kick smoothly

and forcefully to start the engine.

EC155001

THROTTLE GRIP

The throttle grip 1 is located on the right han-

dlebar; it accelerates or decelerates the

engine. For acceleration, turn the grip toward

you; for deceleration, turn it away from you.

EC156000

FRONT BRAKE LEVER

The front brake lever 1 is located on the right

handlebar. Pull it toward the handlebar to acti-

vate the front brake.

Page 48 of 287

1 - 10

GEN

INFO

CONTROL FUNCTIONS

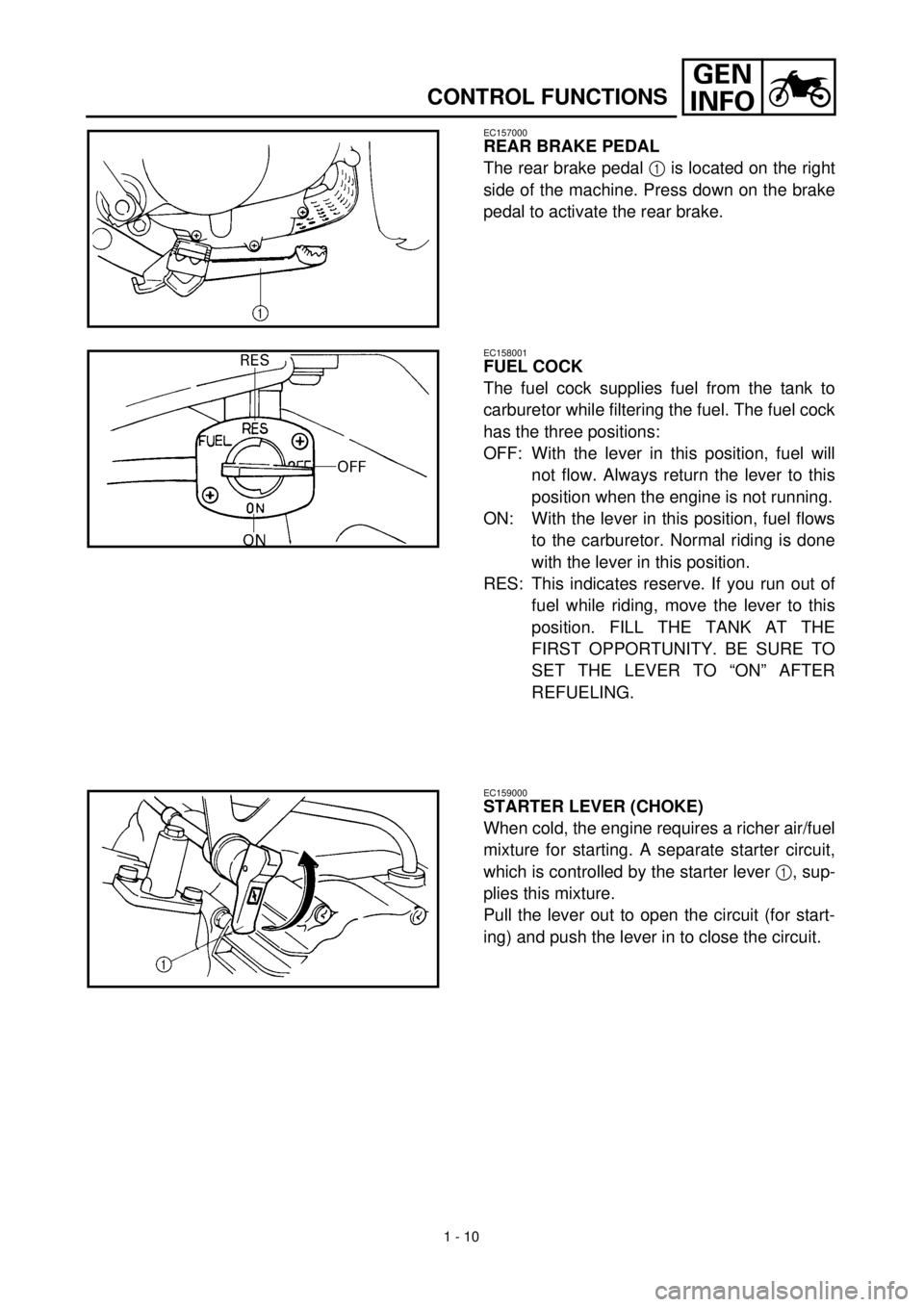

EC157000

REAR BRAKE PEDAL

The rear brake pedal 1 is located on the right

side of the machine. Press down on the brake

pedal to activate the rear brake.

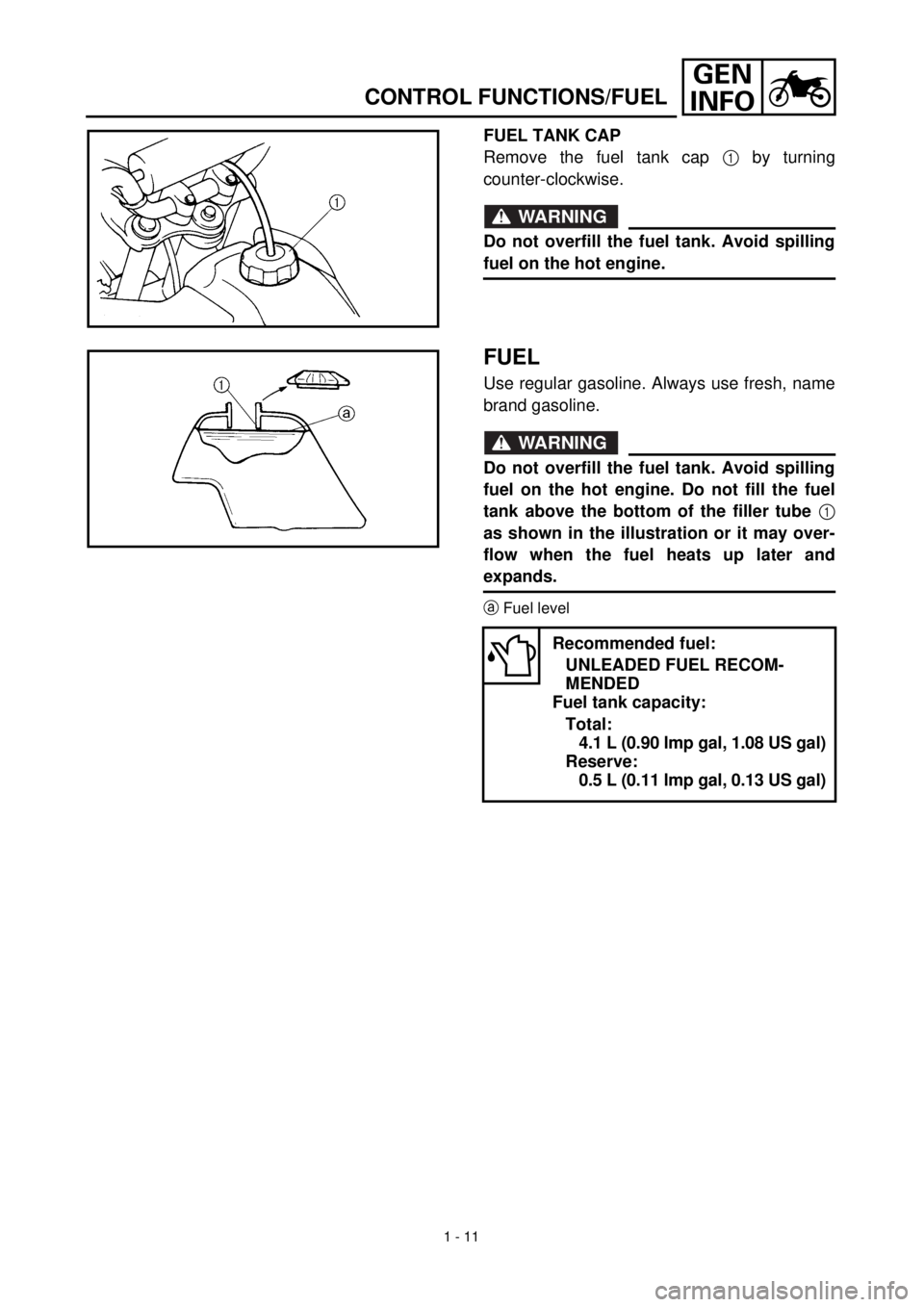

EC158001

FUEL COCK

The fuel cock supplies fuel from the tank to

carburetor while filtering the fuel. The fuel cock

has the three positions:

OFF: With the lever in this position, fuel will

not flow. Always return the lever to this

position when the engine is not running.

ON: With the lever in this position, fuel flows

to the carburetor. Normal riding is done

with the lever in this position.

RES: This indicates reserve. If you run out of

fuel while riding, move the lever to this

position. FILL THE TANK AT THE

FIRST OPPORTUNITY. BE SURE TO

SET THE LEVER TO “ON” AFTER

REFUELING.

EC159000

STARTER LEVER (CHOKE)

When cold, the engine requires a richer air/fuel

mixture for starting. A separate starter circuit,

which is controlled by the starter lever 1, sup-

plies this mixture.

Pull the lever out to open the circuit (for start-

ing) and push the lever in to close the circuit.

Page 50 of 287

1 - 11

GEN

INFO

CONTROL FUNCTIONS/FUEL

FUEL TANK CAP

Remove the fuel tank cap 1 by turning

counter-clockwise.

WARNING

Do not overfill the fuel tank. Avoid spilling

fuel on the hot engine.

FUEL

Use regular gasoline. Always use fresh, name

brand gasoline.

WARNING

Do not overfill the fuel tank. Avoid spilling

fuel on the hot engine. Do not fill the fuel

tank above the bottom of the filler tube 1

as shown in the illustration or it may over-

flow when the fuel heats up later and

expands.

aFuel level

Recommended fuel:

UNLEADED FUEL RECOM-

MENDED

Fuel tank capacity:

Total:

4.1 L (0.90 lmp gal, 1.08 US gal)

Reserve:

0.5 L (0.11 lmp gal, 0.13 US gal)

Page 52 of 287

GEN

INFO

1 - 12

STARTING AND OPERATION

STARTING AND OPERATION

CAUTION:

Prior to operating the machine, perform

steps listed in pre-operation check list.

WARNING

Never start your engine or let it run for any

length of time in a closed area. The exhaust

fumes are poisonous and can cause loss of

consciousness and death within a short

time. Always operate your machine in an

area with adequate ventilation.

STARTING A COLD ENGINE

WARNING

Before starting the engine, be sure to shift

the transmission into neutral.

1. Turn the fuel cock to “ON”.

2. Operate the starter (choke) and com-

pletely close the throttle grip.

3. Slide the “ENGINE STOP” switch to the

“”.

4. Kick the kick starter with full strength to

start the engine.

5. After the engine starts, warm up for one

or two minutes. Make sure the stater

(choke) is returned to the original position

before riding.

STARTING A WARM ENGINE

To start a warm engine, refer to the “Starting a

cold engine” section. The starter (choke)

should not be used. The throttle should be

opened slightly.

CAUTION:

See “Break-in Section” prior to operating

engine for the first time.WARMING UP

To get maximum engine life, always “warm-up”

the engine before starting off. Never acceler-

ate hard with a cold engine! To see whether or

not the engine is warm, see if it responds to

throttle normally with the stater (choke) turned

off.

WARNING

Before starting off, be sure to turn up or

remove the side stand.

Failure to retract the side stand completely

can result in a serious accident when you

try to turn a corner.

ENGINE BREAK-IN

1. Prior to starting, fill fuel tank with gasoline

and oil tank with specified oil.

2. Allow engine to warm up. Check engine

idling speed. Check operating controls

and engine stop switch operation.

3. Operate machine in lower gears at mod-

erate throttle setting for 3 ~ 5 minutes.

Check spark plug condition.

4. Allow engine to cool. Repeat procedure,

running for 5 minutes. Very briefly, shift to

higher gears and check full throttle

response. Check spark plug condition.

5. Allow engine to cool. Repeat procedure,

running for 5 minutes. Full throttle and

higher gears may be used, but avoid sus-

tained full throttle operation. Check spark

plug condition.

6. Allow engine to cool. Remove top end and

inspect. Remove “high” spots on piston

with No.600 grit, wet sandpaper.

Clean, and carefully reassemble.

7. Check entire unit for loose or misadjusted

fittings/controls/fasteners.

8. Re-start engine and check through entire

operating range thoroughly. Stop. Check

spark plug condition. Re-start. After 10 ~

15 minutes operation, machine is ready

to ride.

CAUTION:

After the break-in period, check every fit-

ting and fastener for looseness.

If any loose is found, retighten it securely.

Page 56 of 287

SPEC

2 - 1

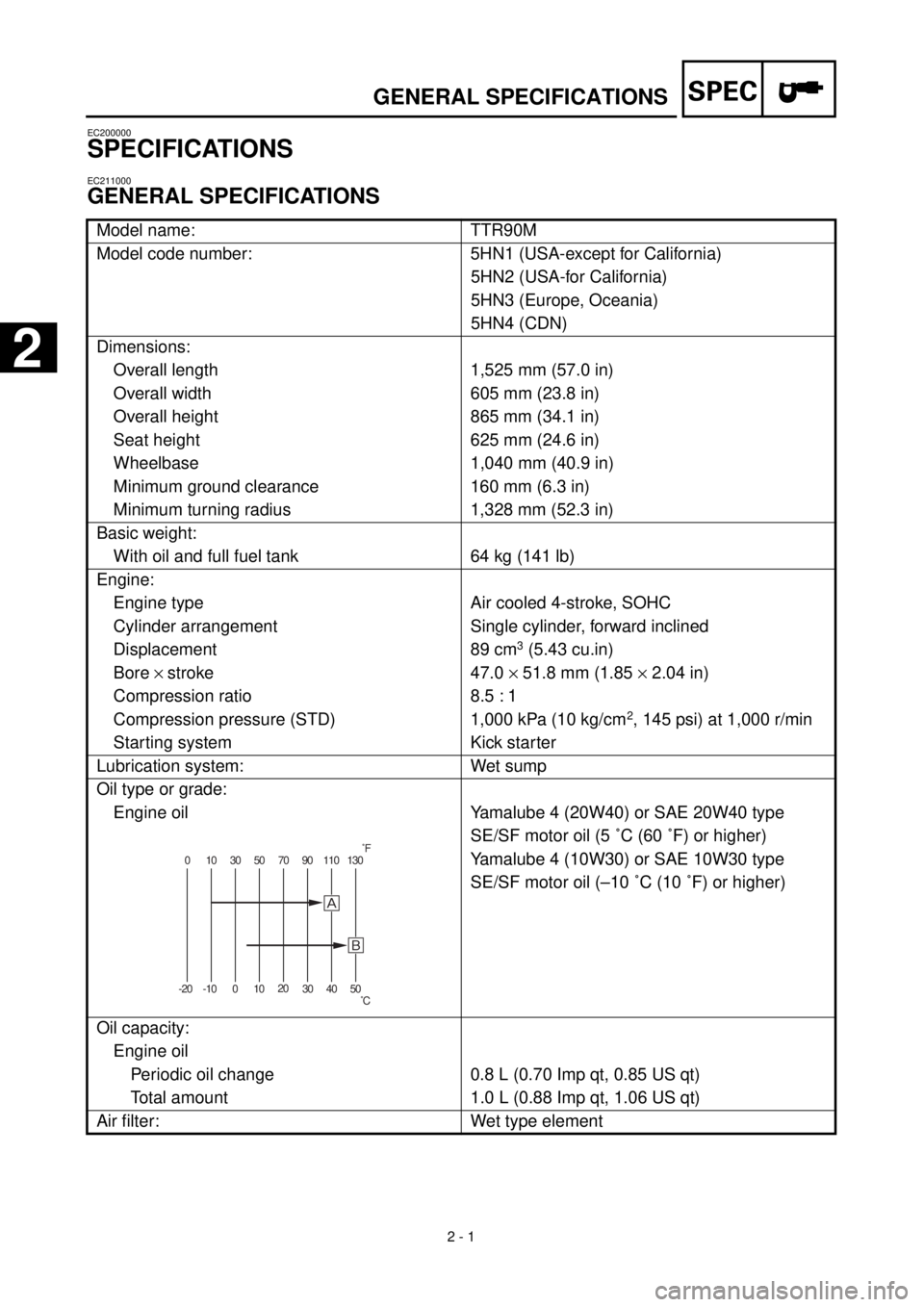

EC200000

SPECIFICATIONS

EC211000

GENERAL SPECIFICATIONS

Model name: TTR90M

Model code number: 5HN1 (USA-except for California)

5HN2 (USA-for California)

5HN3 (Europe, Oceania)

5HN4 (CDN)

Dimensions:

Overall length 1,525 mm (57.0 in)

Overall width 605 mm (23.8 in)

Overall height 865 mm (34.1 in)

Seat height 625 mm (24.6 in)

Wheelbase 1,040 mm (40.9 in)

Minimum ground clearance 160 mm (6.3 in)

Minimum turning radius 1,328 mm (52.3 in)

Basic weight:

With oil and full fuel tank 64 kg (141 lb)

Engine:

Engine type Air cooled 4-stroke, SOHC

Cylinder arrangement Single cylinder, forward inclined

Displacement 89 cm

3

(5.43 cu.in)

Bore

´

stroke 47.0

´

51.8 mm (1.85

´

2.04 in)

Compression ratio 8.5 : 1

Compression pressure (STD) 1,000 kPa (10 kg/cm

2

, 145 psi) at 1,000 r/min

Starting system Kick starter

Lubrication system: Wet sump

Oil type or grade:

Engine oil

Yamalube 4 (20W40) or SAE 20W40 type

SE/SF motor oil (5 ˚C (60 ˚F) or higher)

Yamalube 4 (10W30) or SAE 10W30 type

SE/SF motor oil (–10 ˚C (10 ˚F) or higher)

Oil capacity:

Engine oil

Periodic oil change 0.8 L (0.70 Imp qt, 0.85 US qt)

Total amount 1.0 L (0.88 Imp qt, 1.06 US qt)

Air filter: Wet type element

0 10 30 50 70 90 110 130

-20 -10 01020

30 40 50

õ

˚F

˚C

GENERAL SPECIFICATIONS

2

Page 59 of 287

SPEC

2 - 4

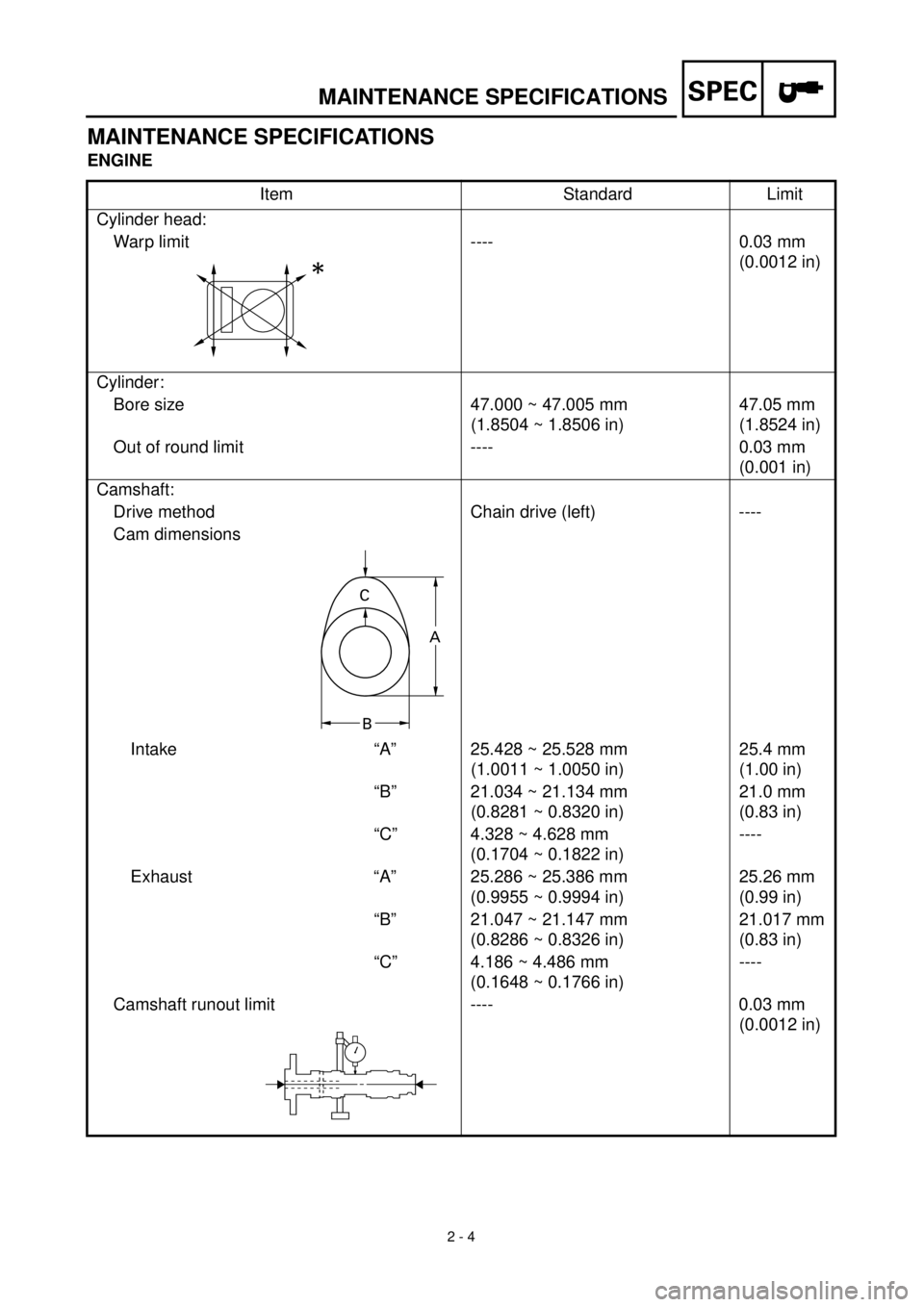

MAINTENANCE SPECIFICATIONS

ENGINE

Item Standard Limit

Cylinder head:

Warp limit ---- 0.03 mm

(0.0012 in)

Cylinder:

Bore size 47.000 ~ 47.005 mm

(1.8504 ~ 1.8506 in)47.05 mm

(1.8524 in)

Out of round limit ---- 0.03 mm

(0.001 in)

Camshaft:

Drive method Chain drive (left) ----

Cam dimensions

Intake “A” 25.428 ~ 25.528 mm

(1.0011 ~ 1.0050 in)25.4 mm

(1.00 in)

“B” 21.034 ~ 21.134 mm

(0.8281 ~ 0.8320 in)21.0 mm

(0.83 in)

“C” 4.328 ~ 4.628 mm

(0.1704 ~ 0.1822 in)----

Exhaust “A” 25.286 ~ 25.386 mm

(0.9955 ~ 0.9994 in)25.26 mm

(0.99 in)

“B” 21.047 ~ 21.147 mm

(0.8286 ~ 0.8326 in)21.017 mm

(0.83 in)

“C” 4.186 ~ 4.486 mm

(0.1648 ~ 0.1766 in)----

Camshaft runout limit ---- 0.03 mm

(0.0012 in)

C

A

B

MAINTENANCE SPECIFICATIONS

Page 63 of 287

SPEC

2 - 8

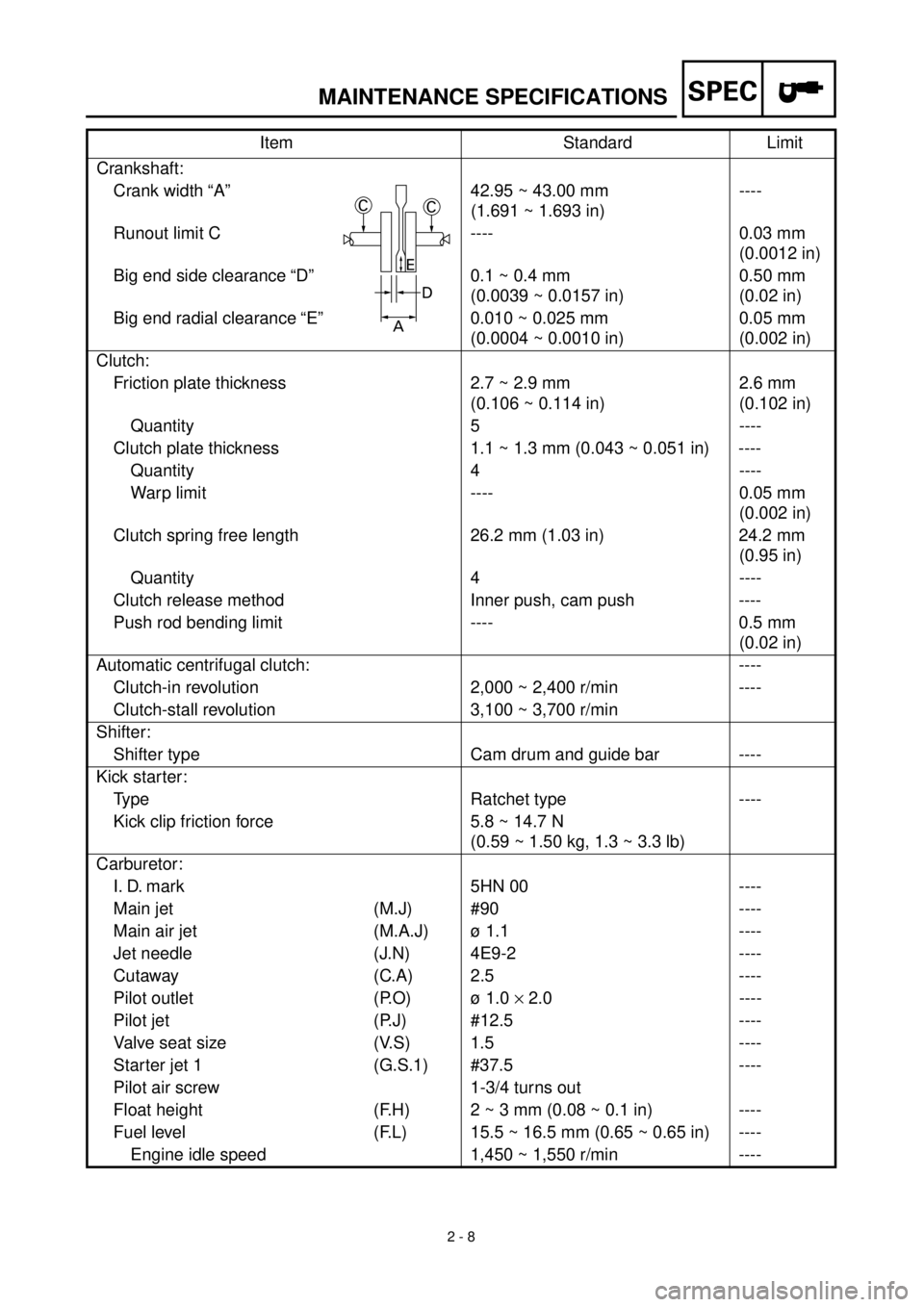

Crankshaft:

Crank width “A” 42.95 ~ 43.00 mm

(1.691 ~ 1.693 in)----

Runout limit C ---- 0.03 mm

(0.0012 in)

Big end side clearance “D” 0.1 ~ 0.4 mm

(0.0039 ~ 0.0157 in)0.50 mm

(0.02 in)

Big end radial clearance “E” 0.010 ~ 0.025 mm

(0.0004 ~ 0.0010 in)0.05 mm

(0.002 in)

Clutch:

Friction plate thickness 2.7 ~ 2.9 mm

(0.106 ~ 0.114 in)2.6 mm

(0.102 in)

Quantity 5 ----

Clutch plate thickness 1.1 ~ 1.3 mm (0.043 ~ 0.051 in) ----

Quantity 4 ----

Warp limit ---- 0.05 mm

(0.002 in)

Clutch spring free length 26.2 mm (1.03 in) 24.2 mm

(0.95 in)

Quantity 4 ----

Clutch release method Inner push, cam push ----

Push rod bending limit ---- 0.5 mm

(0.02 in)

Automatic centrifugal clutch: ----

Clutch-in revolution 2,000 ~ 2,400 r/min ----

Clutch-stall revolution 3,100 ~ 3,700 r/min

Shifter:

Shifter type Cam drum and guide bar ----

Kick starter:

Type Ratchet type ----

Kick clip friction force 5.8 ~ 14.7 N

(0.59 ~ 1.50 kg, 1.3 ~ 3.3 lb)

Carburetor:

I. D. mark 5HN 00 ----

Main jet (M.J) #90 ----

Main air jet (M.A.J) ø 1.1 ----

Jet needle (J.N) 4E9-2 ----

Cutaway (C.A) 2.5 ----

Pilot outlet (P.O) ø 1.0

´

2.0 ----

Pilot jet (P.J) #12.5 ----

Valve seat size (V.S) 1.5 ----

Starter jet 1 (G.S.1) #37.5 ----

Pilot air screw 1-3/4 turns out

Float height (F.H) 2 ~ 3 mm (0.08 ~ 0.1 in) ----

Fuel level (F.L) 15.5 ~ 16.5 mm (0.65 ~ 0.65 in) ----

Engine idle speed 1,450 ~ 1,550 r/min ----Item Standard Limit

MAINTENANCE SPECIFICATIONS

CC

D

A

E