battery YAMAHA WR 250F 2010 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2010, Model line: WR 250F, Model: YAMAHA WR 250F 2010Pages: 232, PDF Size: 13.94 MB

Page 215 of 232

7-6

ELECTRIC STARTING SYSTEM

INSPECTION STEPS

If the starter motor will not operate, use the following inspection steps.

*1 marked: Refer to "CHECKING TH E FUSE" section in the CHAPTER 3.

*2 marked: Refer to "CHECKING AND CHARGIN G THE BATTERY" section in the CHAPTER 3.

*3 marked: Refer to "CHECKING THE MAIN SWITCH" section.

*4 marked: Refer to "CHECKING THE NEUTRAL SWITCH" section.

• Remove the following parts before inspection.

1. Seat

2. Rear fender

• Use 12 V battery in this inspection.

• Use the following special tools in this inspection.

*1 Check fuse. No good→Replace fuse and check wire harness.

OK ↓

*2 Check battery. No good→Recharge or replace.

OK ↓

Check each coupler and wire connection. No good →Repair or replace.

OK ↓

*3 Check main switch. No good→Replace.

OK ↓

Check starter motor operation. No good→Repair or replace.

OK ↓

Check starting circuit cut-off relay. No good→Replace.

OK ↓

Check starter relay. No good→Replace.

OK ↓

*4 Check neutral switch. No good→Replace.

OK ↓

Check clutch switch. No good→Replace.

OK ↓

Check diode. No good→Replace.

OK ↓

Check start switch. No good→Replace.

Pocket tester:

YU-3112-C/90890-03112

Page 216 of 232

7-7

ELECTRIC STARTING SYSTEM

CHECKING THE COUPLERS AND

LEADS CONNECTION

1. Check:• Couplers and leads connection

Rust/dust/looseness/short-circuit

→ Repair or replace.

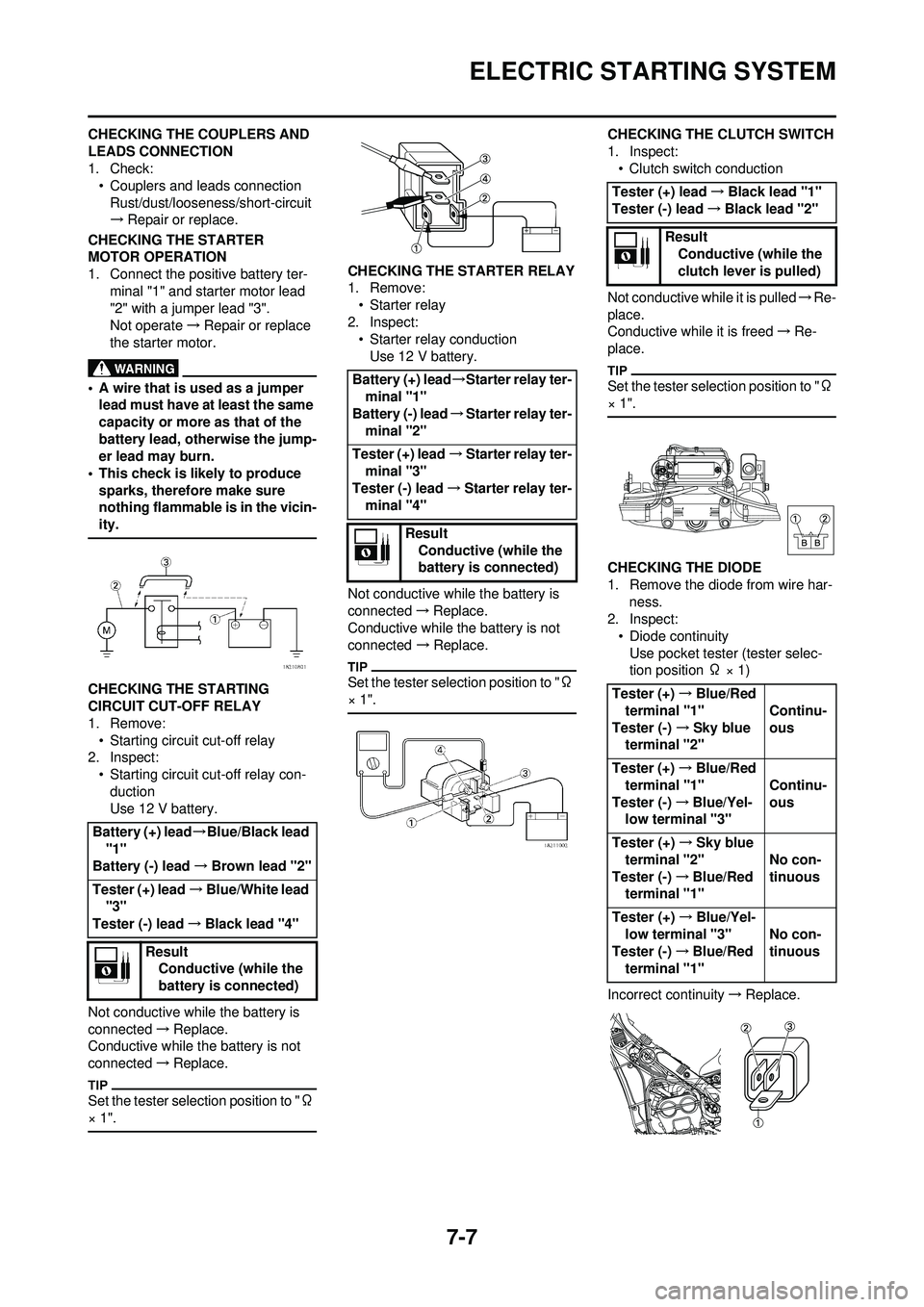

CHECKING THE STARTER

MOTOR OPERATION

1. Connect the posi tive battery ter-

minal "1" and starter motor lead

"2" with a jumper lead "3".

Not operate →Repair or replace

the starter motor.

• A wire that is used as a jumper lead must have at least the same

capacity or more as that of the

battery lead, otherwise the jump-

er lead may burn.

• This check is likely to produce

sparks, therefore make sure

nothing flammable is in the vicin-

ity.

CHECKING THE STARTING

CIRCUIT CUT-OFF RELAY

1. Remove:• Starting circuit cut-off relay

2. Inspect:

• Starting circuit cut-off relay con-duction

Use 12 V battery.

Not conductive while the battery is

connected →Replace.

Conductive while the battery is not

connected →Replace.

Set the tester selection position to " Ω

× 1".

CHECKING THE STARTER RELAY

1. Remove:

• Starter relay

2. Inspect: • Starter relay conduction

Use 12 V battery.

Not conductive while the battery is

connected →Replace.

Conductive while the battery is not

connected →Replace.

Set the tester selection position to " Ω

× 1".

CHECKING THE CLUTCH SWITCH

1. Inspect: • Clutch switch conduction

Not conductive while it is pulled →Re-

place.

Conductive while it is freed →Re-

place.

Set the tester selection position to " Ω

× 1".

CHECKING THE DIODE

1. Remove the diode from wire har- ness.

2. Inspect: • Diode continuity

Use pocket tester (tester selec-

tion position Ω × 1)

Incorrect continuity →Replace.

Battery (+) lead

→Blue/Black lead

"1"

Battery (-) lead →Brown lead "2"

Tester (+) lead →Blue/White lead

"3"

Tester (-) lead →Black lead "4"

Result Conductive (while the

battery is connected)

Battery (+) lead →Starter relay ter-

minal "1"

Battery (-) lead →Starter relay ter-

minal "2"

Tester (+) lead →Starter relay ter-

minal "3"

Tester (-) lead →Starter relay ter-

minal "4"

ResultConductive (while the

battery is connected)

Tester (+) lead →Black lead "1"

Tester (-) lead →Black lead "2"

Result Conductive (while the

clutch lever is pulled)

Tester (+) →Blue/Red

terminal "1"

Tester (-) →Sky blue

terminal "2" Continu-

ous

Tester (+) →Blue/Red

terminal "1"

Tester (-) →Blue/Yel-

low terminal "3" Continu-

ous

Tester (+) →Sky blue

terminal "2"

Tester (-) →Blue/Red

terminal "1" No con-

tinuous

Tester (+) →Blue/Yel-

low terminal "3"

Tester (-) →Blue/Red

terminal "1" No con-

tinuous

Page 222 of 232

7-13

CHARGING SYSTEM

CHARGING SYSTEM

INSPECTION STEPS

If the battery is not charged, use the following inspection steps.

*1 marked: Refer to "CHECKING TH E FUSE" section in the CHAPTER 3.

*2 marked: Refer to "CHECKING AND CHARGIN G THE BATTERY" section in the CHAPTER 3.

• Remove the following parts before inspection.

1. Seat

2. Fuel tank

• Use the following special tools in this inspection.

*1 Check fuse. No good→Replace fuse and check wire harness.

OK ↓

*2 Check battery. No good→Recharge or replace.

OK ↓

Check each coupler and wire connection. No good →Repair or replace.

OK ↓

Check charging voltage. OK→ Charging system is good.

No good ↓

Check AC magneto. (Charging coil) No good→Replace.

OK ↓

Replace rectifier/regulator.

Pocket tester: YU-3112-C/90890-03112

Page 228 of 232

7-19

LIGHTING SYSTEM

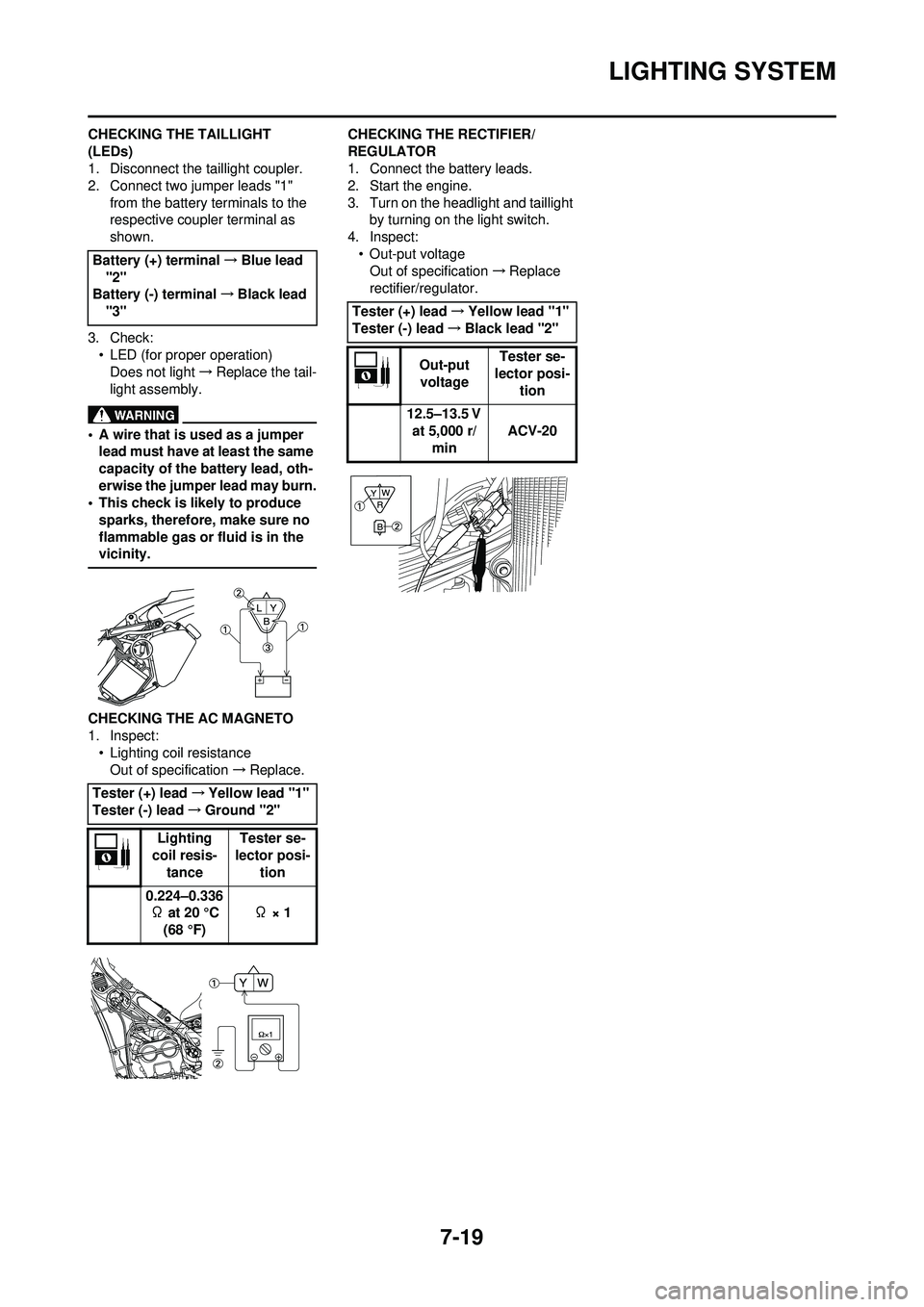

CHECKING THE TAILLIGHT

(LEDs)

1. Disconnect the taillight coupler.

2. Connect two jumper leads "1" from the battery terminals to the

respective coupler terminal as

shown.

3. Check: • LED (for proper operation)Does not light →Replace the tail-

light assembly.

• A wire that is used as a jumper lead must have at least the same

capacity of the battery lead, oth-

erwise the jumper lead may burn.

• This check is likely to produce sparks, therefore, make sure no

flammable gas or fluid is in the

vicinity.

CHECKING THE AC MAGNETO

1. Inspect:• Lighting coil resistance

Out of specification →Replace. CHECKING THE RECTIFIER/

REGULATOR

1. Connect the battery leads.

2. Start the engine.

3. Turn on the headlight and taillight

by turning on the light switch.

4. Inspect:

• Out-put voltageOut of specification →Replace

rectifier/regulator.

Battery (+) terminal

→Blue lead

"2"

Battery (-) terminal →Black lead

"3"

Tester (+) lead →Yellow lead "1"

Tester (-) lead →Ground "2"

Lighting

coil resis-

tance Tester se-

lector posi-

tion

0.224–0.336 Ω at 20 °C (68 °F) Ω × 1

Tester (+) lead

→Yellow lead "1"

Tester (-) lead →Black lead "2"

Out-put voltage Tester se-

lector posi- tion

12.5–13.5 V at 5,000 r/ min ACV-20

Page 229 of 232

7-20

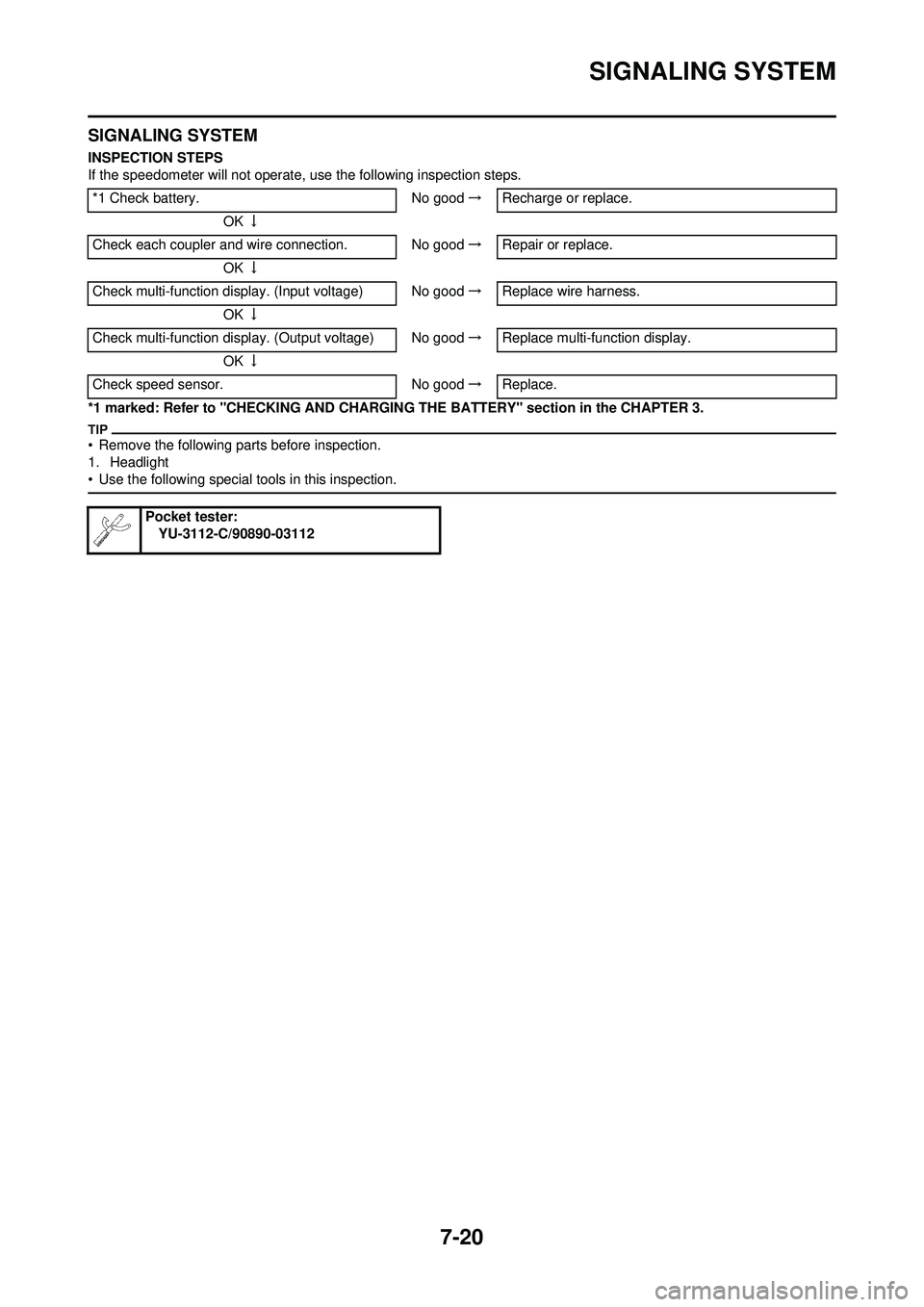

SIGNALING SYSTEM

SIGNALING SYSTEM

INSPECTION STEPS

If the speedometer will not operate, use the following inspection steps.

*1 marked: Refer to "CHECKING AND CHARGIN G THE BATTERY" section in the CHAPTER 3.

• Remove the following parts before inspection.

1. Headlight

• Use the following special tools in this inspection.

*1 Check battery. No good→Recharge or replace.

OK ↓

Check each coupler and wire connection. No good →Repair or replace.

OK ↓

Check multi-function display. (Input voltage) No good →Replace wire harness.

OK ↓

Check multi-function displa y. (Output voltage) No good →Replace multi-function display.

OK ↓

Check speed sensor. No good→Replace.

Pocket tester:

YU-3112-C/90890-03112