battery YAMAHA WR 250F 2011 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2011, Model line: WR 250F, Model: YAMAHA WR 250F 2011Pages: 232, PDF Size: 14.29 MB

Page 88 of 232

3-29

ELECTRICAL

ELECTRICAL

CHECKING THE SPARK PLUG

1. Remove:

• Spark plug

2. Inspect:

• Electrode "1"

Wear/damage→Replace.

• Insulator color "2"

Normal condition is a medium to

light tan color.

Distinctly different color→Check

the engine condition.

When the engine runs for many hours

at low speeds, the spark plug insula-

tor will become sooty, even if the en-

gine and carburetor are in good

operating condition.

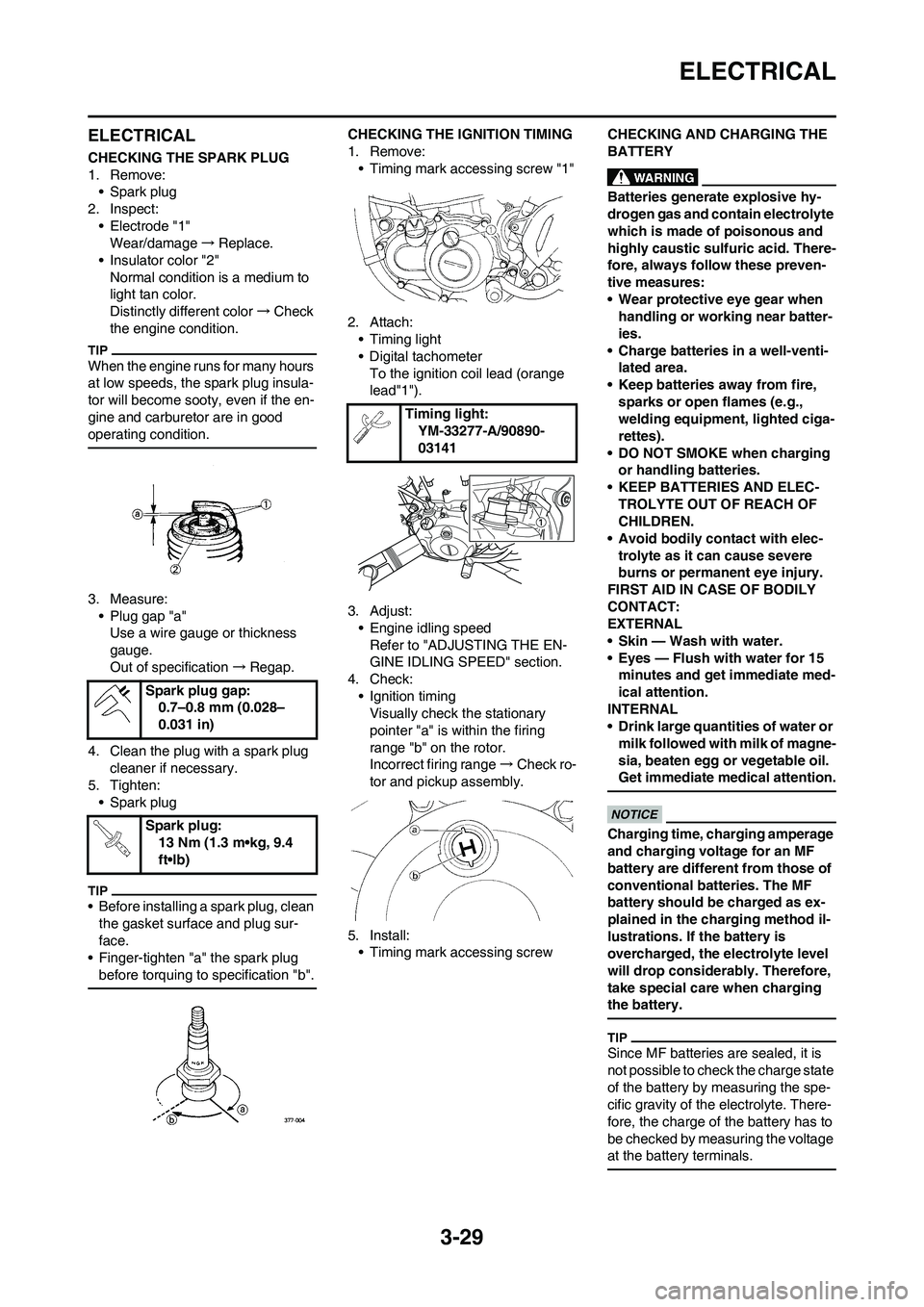

3. Measure:

• Plug gap "a"

Use a wire gauge or thickness

gauge.

Out of specification→Regap.

4. Clean the plug with a spark plug

cleaner if necessary.

5. Tighten:

• Spark plug

• Before installing a spark plug, clean

the gasket surface and plug sur-

face.

• Finger-tighten "a" the spark plug

before torquing to specification "b".

CHECKING THE IGNITION TIMING

1. Remove:

• Timing mark accessing screw "1"

2. Attach:

• Timing light

• Digital tachometer

To the ignition coil lead (orange

lead"1").

3. Adjust:

• Engine idling speed

Refer to "ADJUSTING THE EN-

GINE IDLING SPEED" section.

4. Check:

• Ignition timing

Visually check the stationary

pointer "a" is within the firing

range "b" on the rotor.

Incorrect firing range→Check ro-

tor and pickup assembly.

5. Install:

• Timing mark accessing screwCHECKING AND CHARGING THE

BATTERY

Batteries generate explosive hy-

drogen gas and contain electrolyte

which is made of poisonous and

highly caustic sulfuric acid. There-

fore, always follow these preven-

tive measures:

• Wear protective eye gear when

handling or working near batter-

ies.

• Charge batteries in a well-venti-

lated area.

• Keep batteries away from fire,

sparks or open flames (e.g.,

welding equipment, lighted ciga-

rettes).

• DO NOT SMOKE when charging

or handling batteries.

• KEEP BATTERIES AND ELEC-

TROLYTE OUT OF REACH OF

CHILDREN.

• Avoid bodily contact with elec-

trolyte as it can cause severe

burns or permanent eye injury.

FIRST AID IN CASE OF BODILY

CONTACT:

EXTERNAL

• Skin — Wash with water.

• Eyes — Flush with water for 15

minutes and get immediate med-

ical attention.

INTERNAL

• Drink large quantities of water or

milk followed with milk of magne-

sia, beaten egg or vegetable oil.

Get immediate medical attention.

Charging time, charging amperage

and charging voltage for an MF

battery are different from those of

conventional batteries. The MF

battery should be charged as ex-

plained in the charging method il-

lustrations. If the battery is

overcharged, the electrolyte level

will drop considerably. Therefore,

take special care when charging

the battery.

Since MF batteries are sealed, it is

not possible to check the charge state

of the battery by measuring the spe-

cific gravity of the electrolyte. There-

fore, the charge of the battery has to

be checked by measuring the voltage

at the battery terminals.

Spark plug gap:

0.7–0.8 mm (0.028–

0.031 in)

Spark plug:

13 Nm (1.3 m•kg, 9.4

ft•lb)

Timing light:

YM-33277-A/90890-

03141

Page 89 of 232

3-30

ELECTRICAL

1. Remove:

• Seat

2. Disconnect:

• Battery leads

(from the battery terminals)

First, disconnect the negative bat-

tery lead "1", and then the positive

battery lead "2".

3. Remove:

• Battery band

•Battery

4. Measure:

• Battery charge

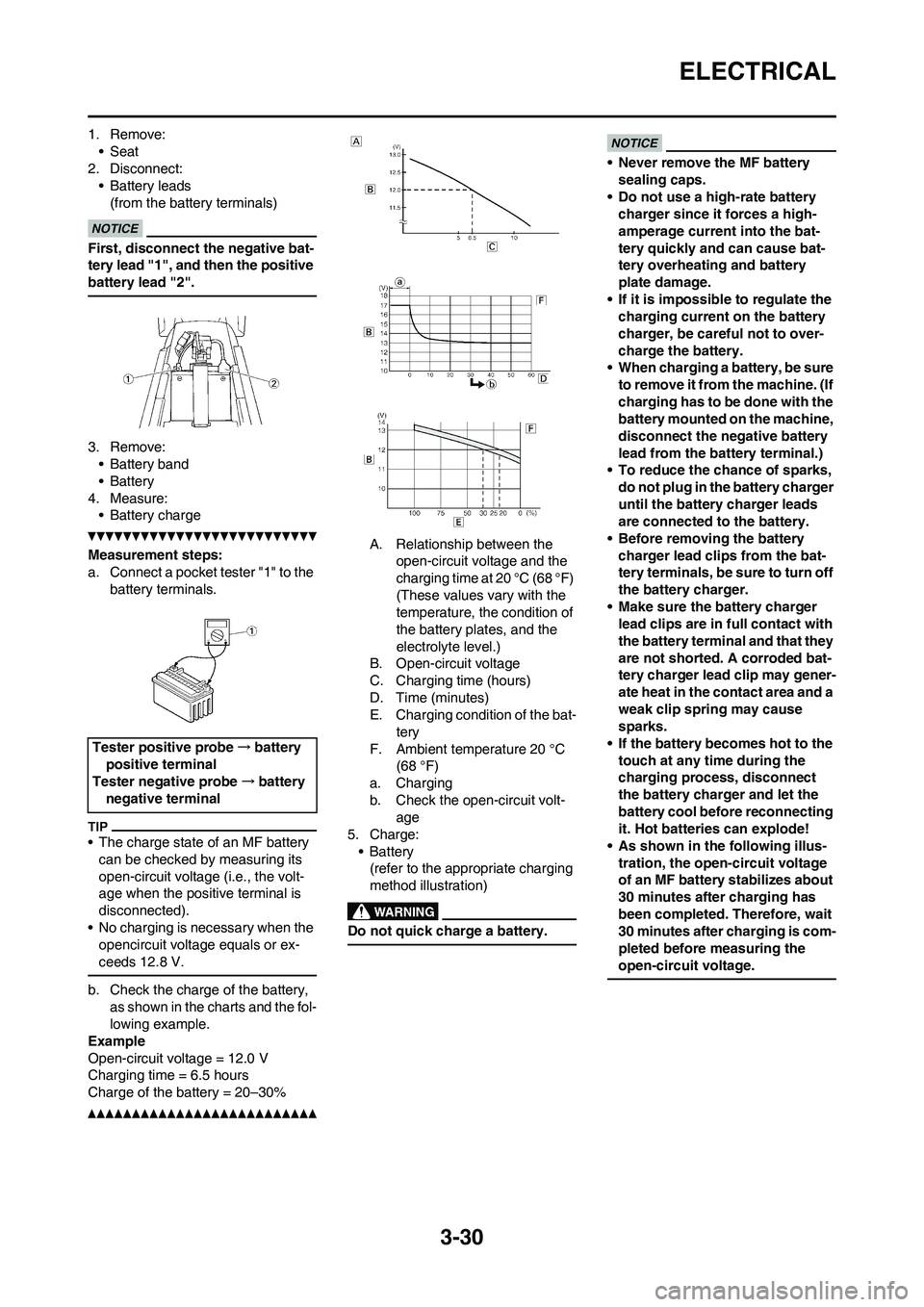

Measurement steps:

a. Connect a pocket tester "1" to the

battery terminals.

• The charge state of an MF battery

can be checked by measuring its

open-circuit voltage (i.e., the volt-

age when the positive terminal is

disconnected).

• No charging is necessary when the

opencircuit voltage equals or ex-

ceeds 12.8 V.

b. Check the charge of the battery,

as shown in the charts and the fol-

lowing example.

Example

Open-circuit voltage = 12.0 V

Charging time = 6.5 hours

Charge of the battery = 20–30%

A. Relationship between the

open-circuit voltage and the

charging time at 20 °C (68 °F)

(These values vary with the

temperature, the condition of

the battery plates, and the

electrolyte level.)

B. Open-circuit voltage

C. Charging time (hours)

D. Time (minutes)

E. Charging condition of the bat-

tery

F. Ambient temperature 20 °C

(68 °F)

a. Charging

b. Check the open-circuit volt-

age

5. Charge:

•Battery

(refer to the appropriate charging

method illustration)

Do not quick charge a battery.

• Never remove the MF battery

sealing caps.

• Do not use a high-rate battery

charger since it forces a high-

amperage current into the bat-

tery quickly and can cause bat-

tery overheating and battery

plate damage.

• If it is impossible to regulate the

charging current on the battery

charger, be careful not to over-

charge the battery.

• When charging a battery, be sure

to remove it from the machine. (If

charging has to be done with the

battery mounted on the machine,

disconnect the negative battery

lead from the battery terminal.)

• To reduce the chance of sparks,

do not plug in the battery charger

until the battery charger leads

are connected to the battery.

• Before removing the battery

charger lead clips from the bat-

tery terminals, be sure to turn off

the battery charger.

• Make sure the battery charger

lead clips are in full contact with

the battery terminal and that they

are not shorted. A corroded bat-

tery charger lead clip may gener-

ate heat in the contact area and a

weak clip spring may cause

sparks.

• If the battery becomes hot to the

touch at any time during the

charging process, disconnect

the battery charger and let the

battery cool before reconnecting

it. Hot batteries can explode!

• As shown in the following illus-

tration, the open-circuit voltage

of an MF battery stabilizes about

30 minutes after charging has

been completed. Therefore, wait

30 minutes after charging is com-

pleted before measuring the

open-circuit voltage.

Tester positive probe→battery

positive terminal

Tester negative probe→battery

negative terminal

Page 92 of 232

3-33

ELECTRICAL

6. Install:

•Battery

• Battery band

7. Connect:

• Battery leads

(to the battery terminals)

First, connect the positive lead "1",

then the negative lead "2".

8. Check:

• Battery terminals

Dirt→Clean with a wire brush.

Loose connection→Connect

properly.

9. Lubricate:

• Battery terminal

10. Install:

• Seat

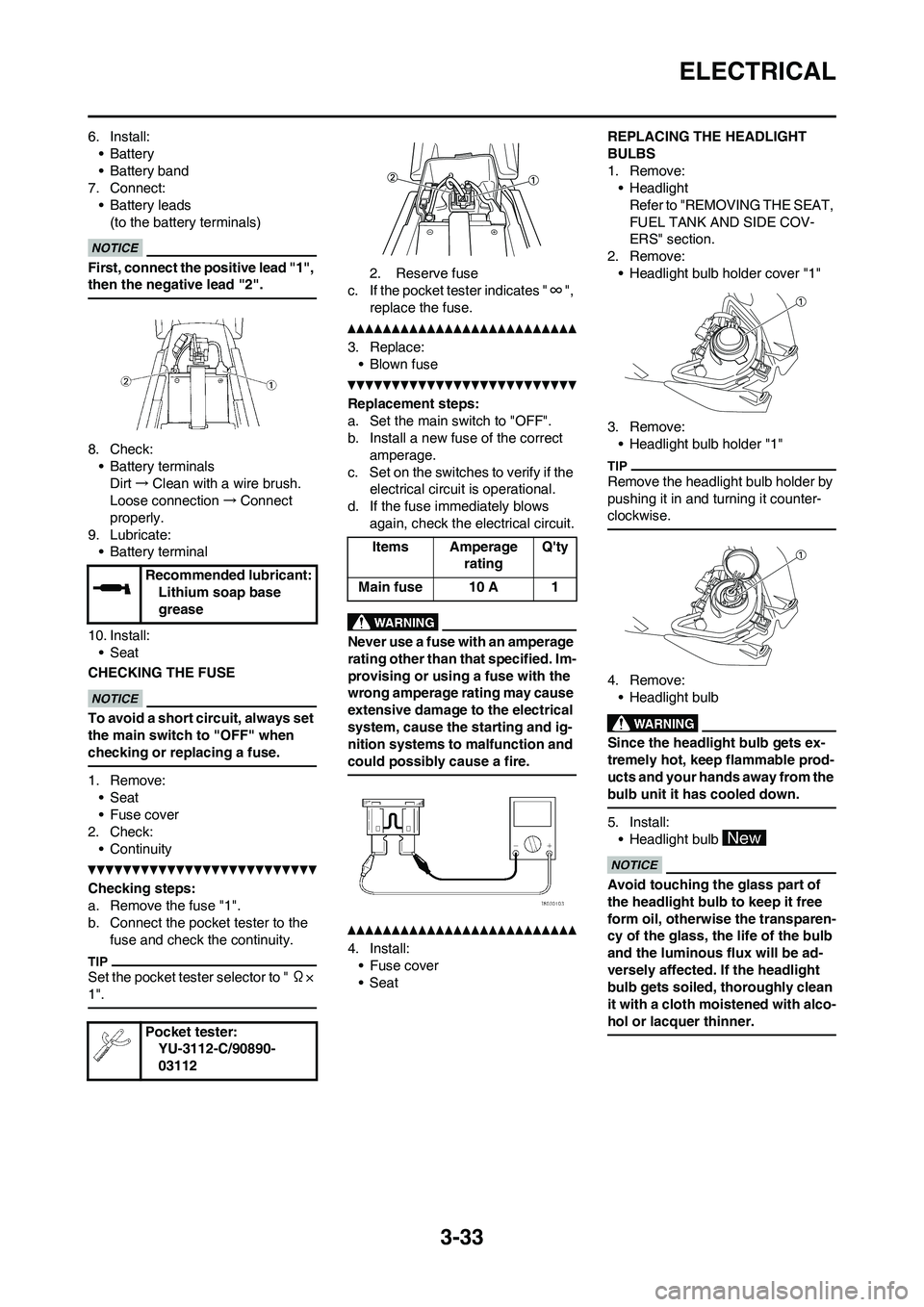

CHECKING THE FUSE

To avoid a short circuit, always set

the main switch to "OFF" when

checking or replacing a fuse.

1. Remove:

• Seat

• Fuse cover

2. Check:

• Continuity

Checking steps:

a. Remove the fuse "1".

b. Connect the pocket tester to the

fuse and check the continuity.

Set the pocket tester selector to " Ω×

1".

2. Reserve fuse

c. If the pocket tester indicates "∞",

replace the fuse.

3. Replace:

• Blown fuse

Replacement steps:

a. Set the main switch to "OFF".

b. Install a new fuse of the correct

amperage.

c. Set on the switches to verify if the

electrical circuit is operational.

d. If the fuse immediately blows

again, check the electrical circuit.

Never use a fuse with an amperage

rating other than that specified. Im-

provising or using a fuse with the

wrong amperage rating may cause

extensive damage to the electrical

system, cause the starting and ig-

nition systems to malfunction and

could possibly cause a fire.

4. Install:

• Fuse cover

•SeatREPLACING THE HEADLIGHT

BULBS

1. Remove:

• Headlight

Refer to "REMOVING THE SEAT,

FUEL TANK AND SIDE COV-

ERS" section.

2. Remove:

• Headlight bulb holder cover "1"

3. Remove:

• Headlight bulb holder "1"

Remove the headlight bulb holder by

pushing it in and turning it counter-

clockwise.

4. Remove:

• Headlight bulb

Since the headlight bulb gets ex-

tremely hot, keep flammable prod-

ucts and your hands away from the

bulb unit it has cooled down.

5. Install:

• Headlight bulb

Avoid touching the glass part of

the headlight bulb to keep it free

form oil, otherwise the transparen-

cy of the glass, the life of the bulb

and the luminous flux will be ad-

versely affected. If the headlight

bulb gets soiled, thoroughly clean

it with a cloth moistened with alco-

hol or lacquer thinner.

Recommended lubricant:

Lithium soap base

grease

Pocket tester:

YU-3112-C/90890-

03112

Items Amperage

ratingQ'ty

Main fuse 10 A 1

Page 158 of 232

5-55

ENGINE REMOVAL

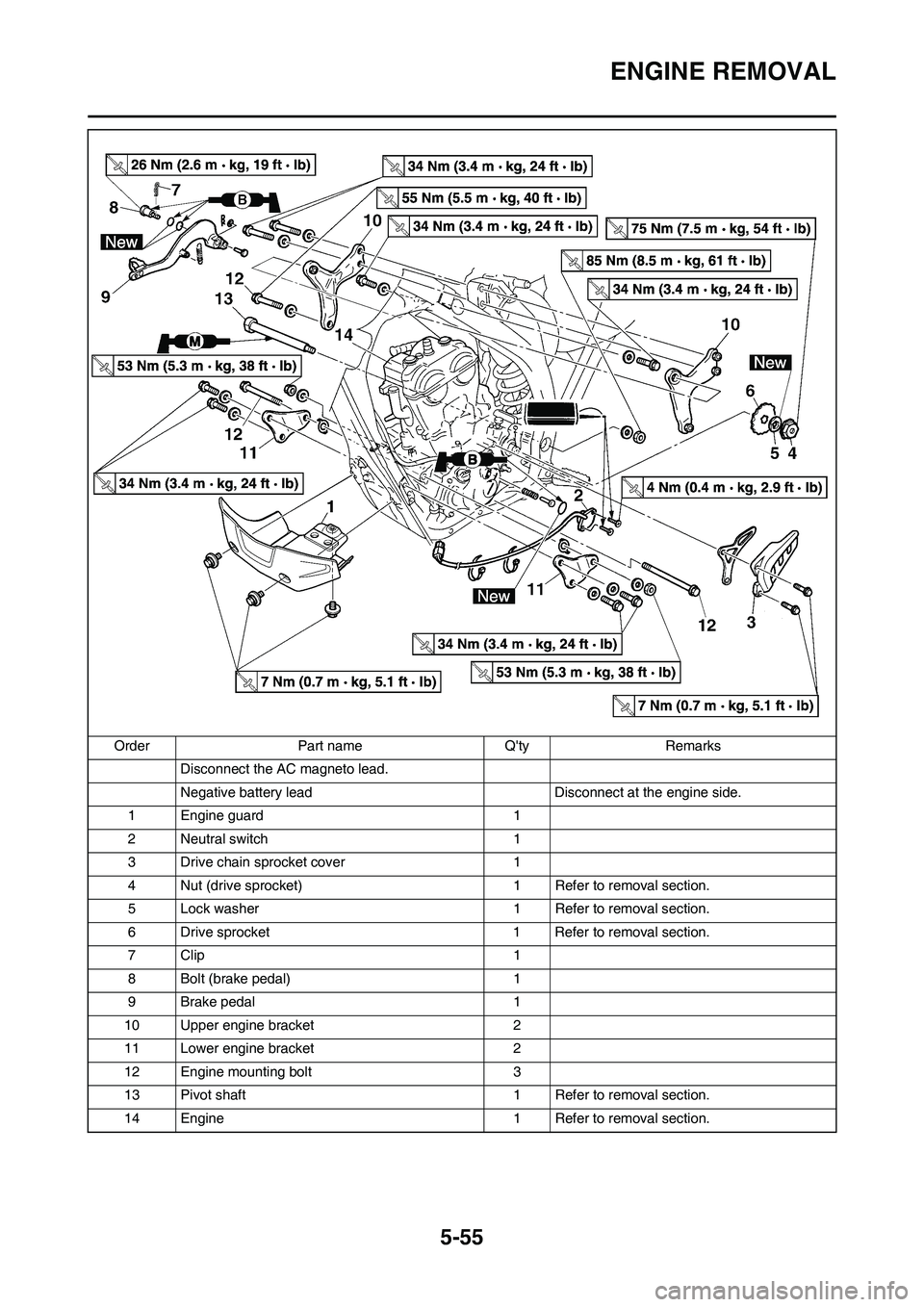

Disconnect the AC magneto lead.

Negative battery lead Disconnect at the engine side.

1 Engine guard 1

2 Neutral switch 1

3 Drive chain sprocket cover 1

4 Nut (drive sprocket) 1 Refer to removal section.

5 Lock washer 1 Refer to removal section.

6 Drive sprocket 1 Refer to removal section.

7Clip 1

8 Bolt (brake pedal) 1

9 Brake pedal 1

10 Upper engine bracket 2

11 Lower engine bracket 2

12 Engine mounting bolt 3

13 Pivot shaft 1 Refer to removal section.

14 Engine 1 Refer to removal section. Order Part name Q'ty Remarks

Page 205 of 232

6-36

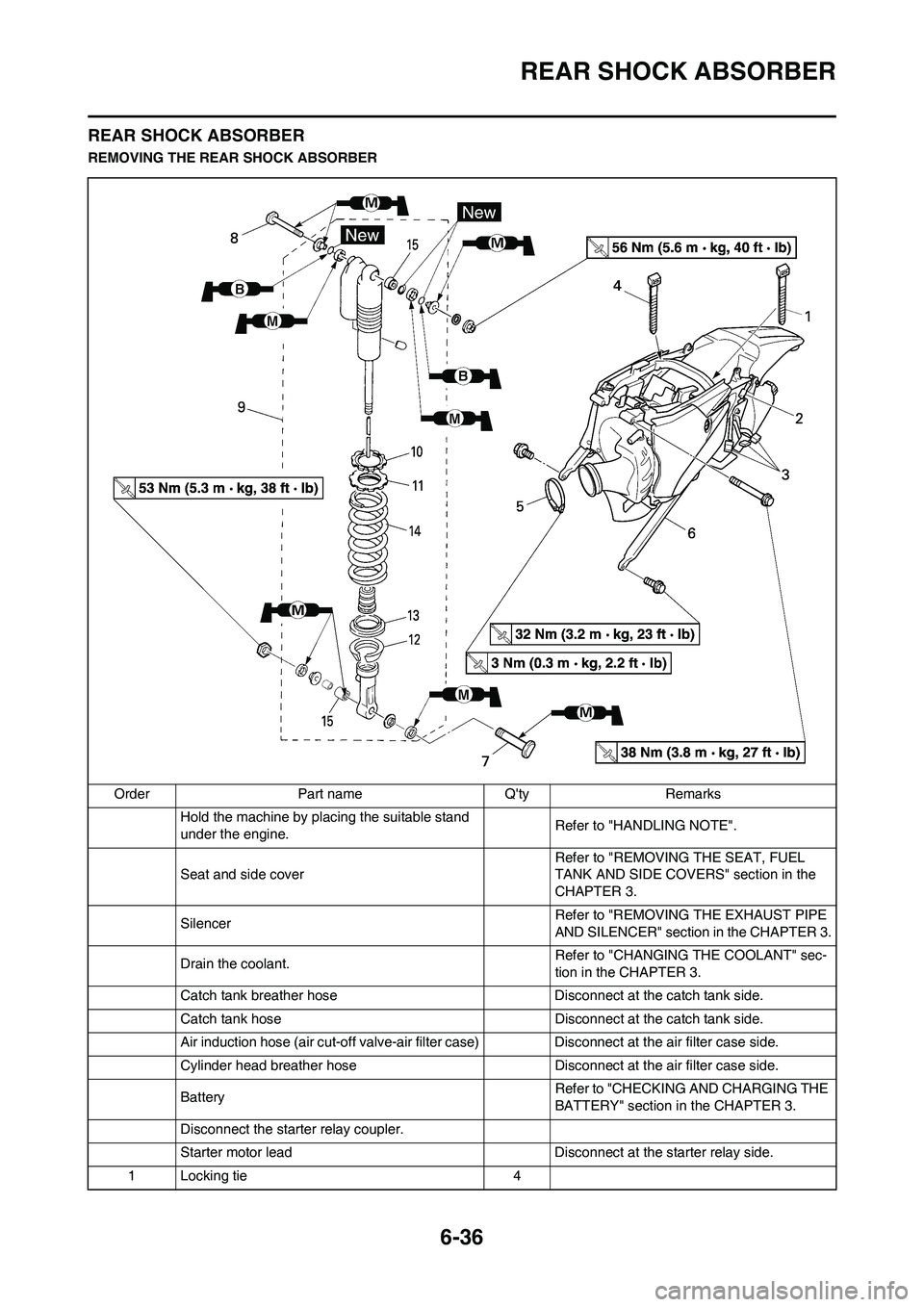

REAR SHOCK ABSORBER

REAR SHOCK ABSORBER

REMOVING THE REAR SHOCK ABSORBER

Order Part name Q'ty Remarks

Hold the machine by placing the suitable stand

under the engine.Refer to "HANDLING NOTE".

Seat and side cover Refer to "REMOVING THE SEAT, FUEL

TANK AND SIDE COVERS" section in the

CHAPTER 3.

Silencer Refer to "REMOVING THE EXHAUST PIPE

AND SILENCER" section in the CHAPTER 3.

Drain the coolant.Refer to "CHANGING THE COOLANT" sec-

tion in the CHAPTER 3.

Catch tank breather hose Disconnect at the catch tank side.

Catch tank hose Disconnect at the catch tank side.

Air induction hose (air cut-off valve-air filter case) Disconnect at the air filter case side.

Cylinder head breather hose Disconnect at the air filter case side.

BatteryRefer to "CHECKING AND CHARGING THE

BATTERY" section in the CHAPTER 3.

Disconnect the starter relay coupler.

Starter motor lead Disconnect at the starter relay side.

1 Locking tie 4

Page 210 of 232

7-1

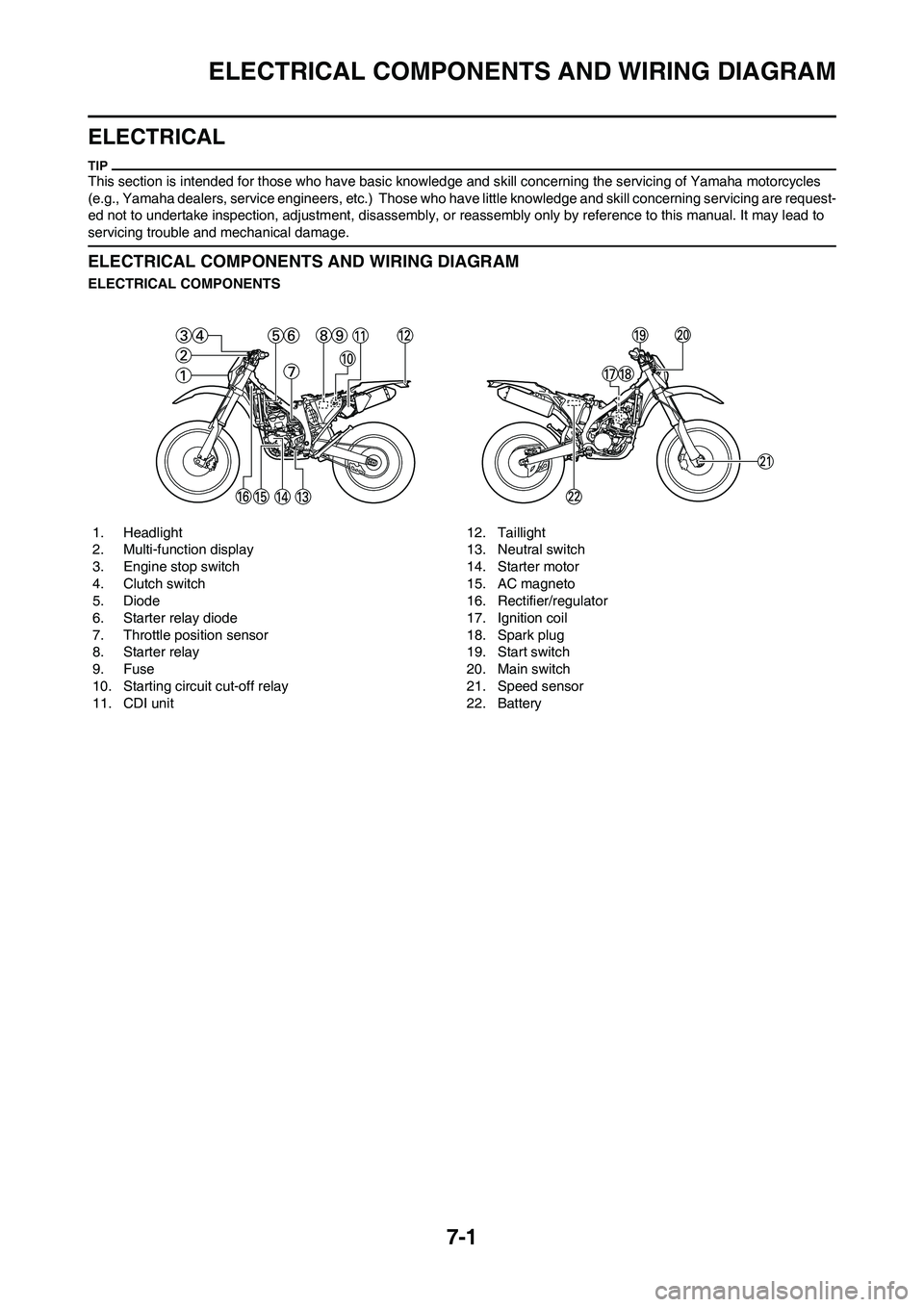

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

ELECTRICAL

This section is intended for those who have basic knowledge and skill concerning the servicing of Yamaha motorcycles

(e.g., Yamaha dealers, service engineers, etc.) Those who have little knowledge and skill concerning servicing are request-

ed not to undertake inspection, adjustment, disassembly, or reassembly only by reference to this manual. It may lead to

servicing trouble and mechanical damage.

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

ELECTRICAL COMPONENTS

1. Headlight

2. Multi-function display

3. Engine stop switch

4. Clutch switch

5. Diode

6. Starter relay diode

7. Throttle position sensor

8. Starter relay

9. Fuse

10. Starting circuit cut-off relay

11. CDI unit 12. Taillight

13. Neutral switch

14. Starter motor

15. AC magneto

16. Rectifier/regulator

17. Ignition coil

18. Spark plug

19. Start switch

20. Main switch

21. Speed sensor

22. Battery

Page 211 of 232

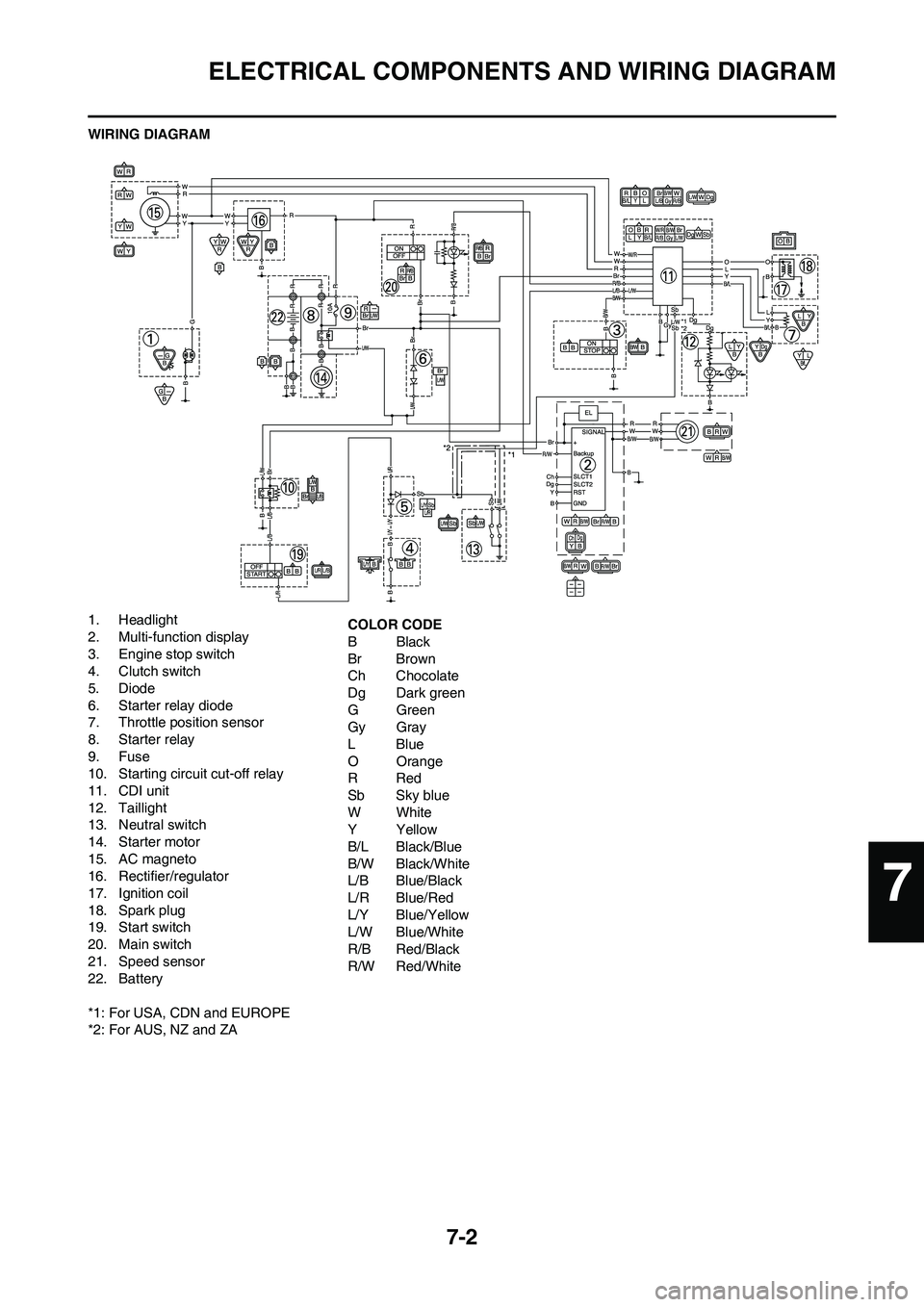

7-2

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

WIRING DIAGRAM

1. Headlight

2. Multi-function display

3. Engine stop switch

4. Clutch switch

5. Diode

6. Starter relay diode

7. Throttle position sensor

8. Starter relay

9. Fuse

10. Starting circuit cut-off relay

11. CDI unit

12. Taillight

13. Neutral switch

14. Starter motor

15. AC magneto

16. Rectifier/regulator

17. Ignition coil

18. Spark plug

19. Start switch

20. Main switch

21. Speed sensor

22. Battery

*1: For USA, CDN and EUROPE

*2: For AUS, NZ and ZACOLOR CODE

BBlack

Br Brown

Ch Chocolate

Dg Dark green

GGreen

Gy Gray

LBlue

O Orange

RRed

Sb Sky blue

WWhite

YYellow

B/L Black/Blue

B/W Black/White

L/B Blue/Black

L/R Blue/Red

L/Y Blue/Yellow

L/W Blue/White

R/B Red/Black

R/W Red/White

7

Page 212 of 232

7-3

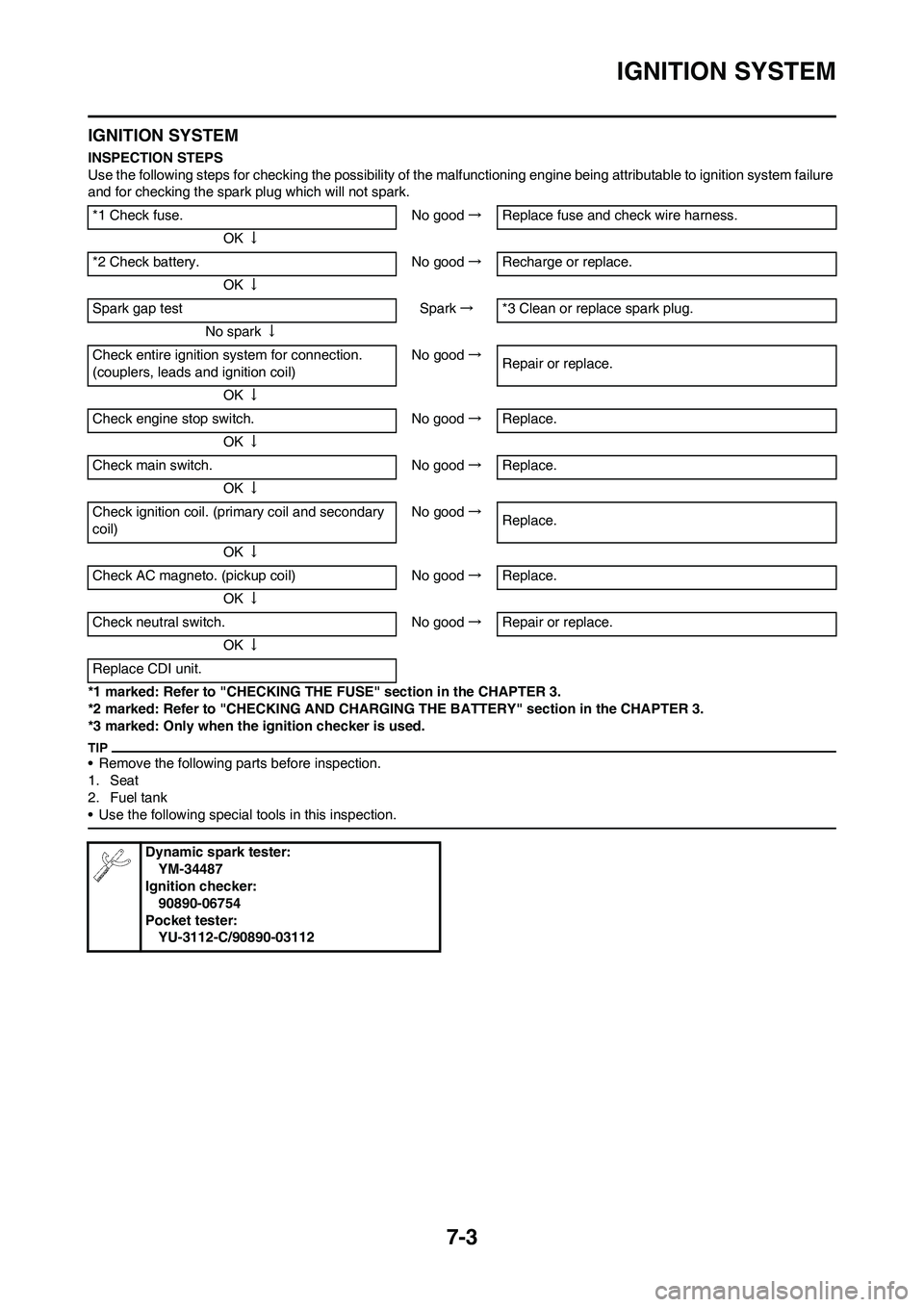

IGNITION SYSTEM

IGNITION SYSTEM

INSPECTION STEPS

Use the following steps for checking the possibility of the malfunctioning engine being attributable to ignition system failure

and for checking the spark plug which will not spark.

*1 marked: Refer to "CHECKING THE FUSE" section in the CHAPTER 3.

*2 marked: Refer to "CHECKING AND CHARGING THE BATTERY" section in the CHAPTER 3.

*3 marked: Only when the ignition checker is used.

• Remove the following parts before inspection.

1. Seat

2. Fuel tank

• Use the following special tools in this inspection.

*1 Check fuse. No good→Replace fuse and check wire harness.

OK↓

*2 Check battery. No good→Recharge or replace.

OK↓

Spark gap test Spark→*3 Clean or replace spark plug.

No spark↓

Check entire ignition system for connection.

(couplers, leads and ignition coil)No good→

Repair or replace.

OK↓

Check engine stop switch. No good→Replace.

OK↓

Check main switch. No good→Replace.

OK↓

Check ignition coil. (primary coil and secondary

coil)No good→

Replace.

OK↓

Check AC magneto. (pickup coil) No good→Replace.

OK↓

Check neutral switch. No good→Repair or replace.

OK↓

Replace CDI unit.

Dynamic spark tester:

YM-34487

Ignition checker:

90890-06754

Pocket tester:

YU-3112-C/90890-03112

Page 213 of 232

7-4

IGNITION SYSTEM

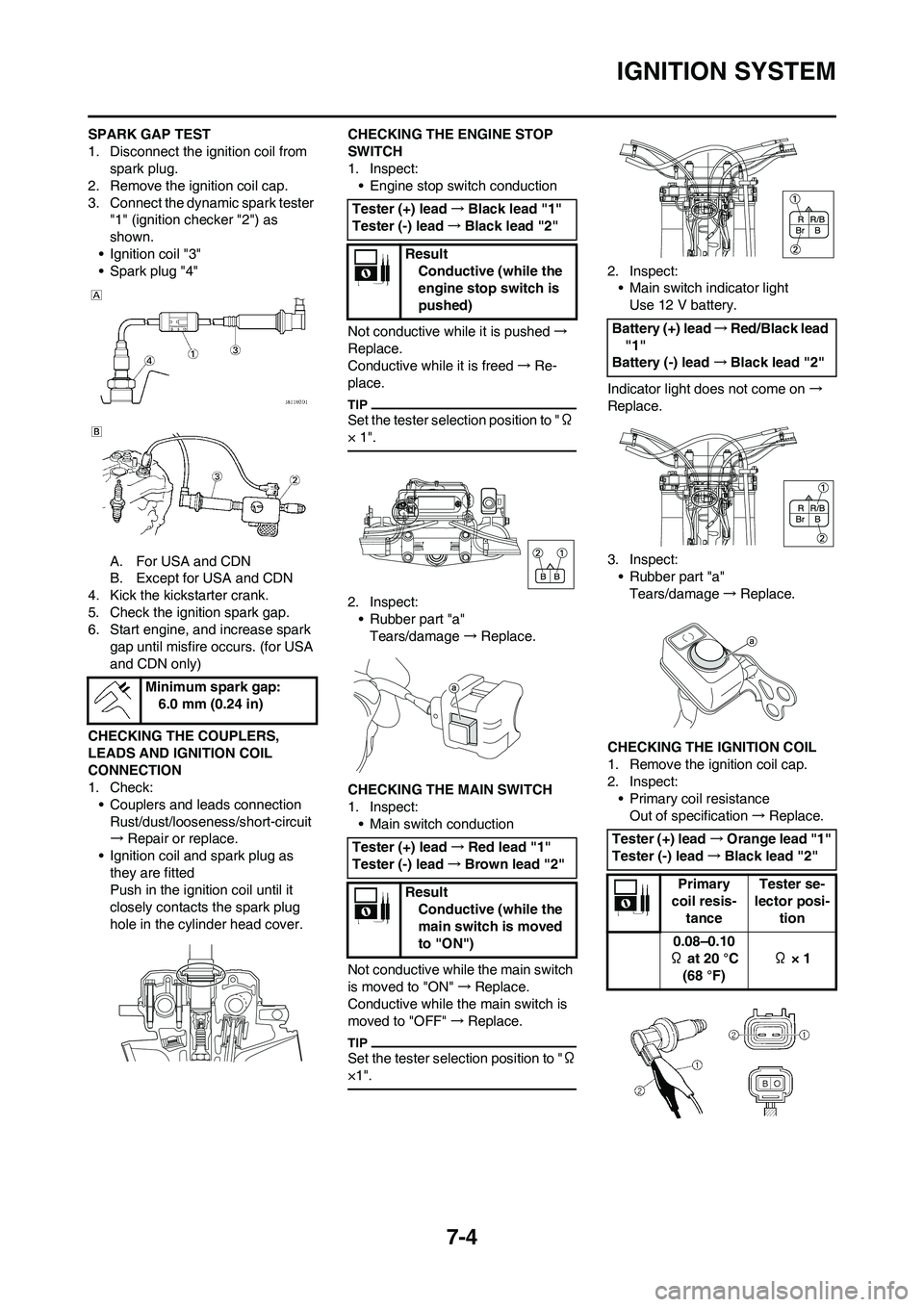

SPARK GAP TEST

1. Disconnect the ignition coil from

spark plug.

2. Remove the ignition coil cap.

3. Connect the dynamic spark tester

"1" (ignition checker "2") as

shown.

• Ignition coil "3"

• Spark plug "4"

A. For USA and CDN

B. Except for USA and CDN

4. Kick the kickstarter crank.

5. Check the ignition spark gap.

6. Start engine, and increase spark

gap until misfire occurs. (for USA

and CDN only)

CHECKING THE COUPLERS,

LEADS AND IGNITION COIL

CONNECTION

1. Check:

• Couplers and leads connection

Rust/dust/looseness/short-circuit

→Repair or replace.

• Ignition coil and spark plug as

they are fitted

Push in the ignition coil until it

closely contacts the spark plug

hole in the cylinder head cover.CHECKING THE ENGINE STOP

SWITCH

1. Inspect:

• Engine stop switch conduction

Not conductive while it is pushed→

Replace.

Conductive while it is freed→Re-

place.

Set the tester selection position to "Ω

× 1".

2. Inspect:

• Rubber part "a"

Tears/damage→ Replace.

CHECKING THE MAIN SWITCH

1. Inspect:

• Main switch conduction

Not conductive while the main switch

is moved to "ON"→Replace.

Conductive while the main switch is

moved to "OFF"→Replace.

Set the tester selection position to "Ω

×1".

2. Inspect:

• Main switch indicator light

Use 12 V battery.

Indicator light does not come on→

Replace.

3. Inspect:

• Rubber part "a"

Tears/damage→Replace.

CHECKING THE IGNITION COIL

1. Remove the ignition coil cap.

2. Inspect:

• Primary coil resistance

Out of specification→Replace. Minimum spark gap:

6.0 mm (0.24 in)

Tester (+) lead→Black lead "1"

Tester (-) lead→Black lead "2"

Result

Conductive (while the

engine stop switch is

pushed)

Tester (+) lead→Red lead "1"

Tester (-) lead→Brown lead "2"

Result

Conductive (while the

main switch is moved

to "ON")

Battery (+) lead→Red/Black lead

"1"

Battery (-) lead→Black lead "2"

Tester (+) lead→Orange lead "1"

Tester (-) lead→Black lead "2"

Primary

coil resis-

tanceTester se-

lector posi-

tion

0.08–0.10

Ω at 20 °C

(68 °F) Ω × 1

Page 214 of 232

7-5

ELECTRIC STARTING SYSTEM

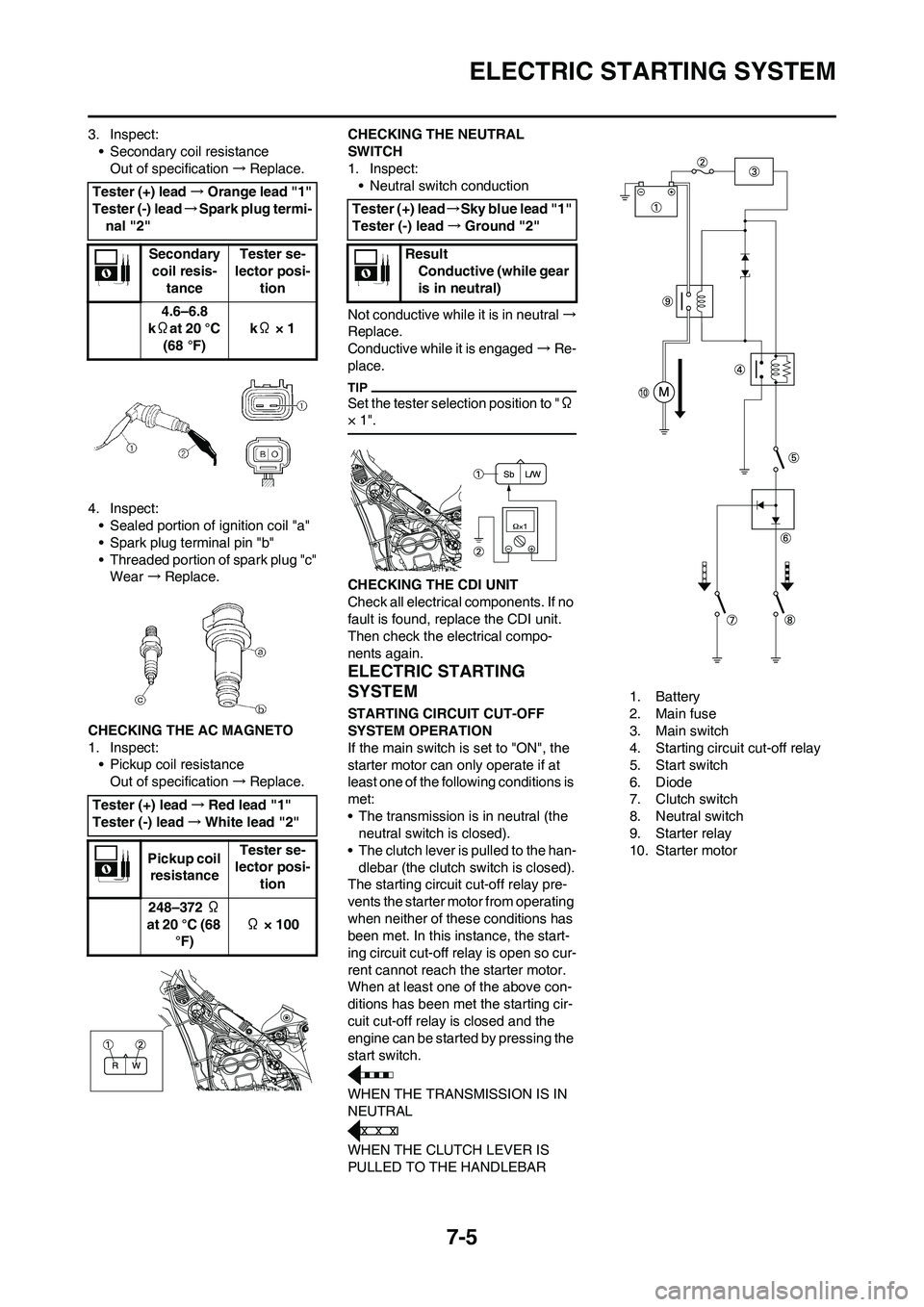

3. Inspect:

• Secondary coil resistance

Out of specification→Replace.

4. Inspect:

• Sealed portion of ignition coil "a"

• Spark plug terminal pin "b"

• Threaded portion of spark plug "c"

Wear →Replace.

CHECKING THE AC MAGNETO

1. Inspect:

• Pickup coil resistance

Out of specification→Replace.CHECKING THE NEUTRAL

SWITCH

1. Inspect:

• Neutral switch conduction

Not conductive while it is in neutral→

Replace.

Conductive while it is engaged→Re-

place.

Set the tester selection position to "Ω

× 1".

CHECKING THE CDI UNIT

Check all electrical components. If no

fault is found, replace the CDI unit.

Then check the electrical compo-

nents again.

ELECTRIC STARTING

SYSTEM

STARTING CIRCUIT CUT-OFF

SYSTEM OPERATION

If the main switch is set to "ON", the

starter motor can only operate if at

least one of the following conditions is

met:

• The transmission is in neutral (the

neutral switch is closed).

• The clutch lever is pulled to the han-

dlebar (the clutch switch is closed).

The starting circuit cut-off relay pre-

vents the starter motor from operating

when neither of these conditions has

been met. In this instance, the start-

ing circuit cut-off relay is open so cur-

rent cannot reach the starter motor.

When at least one of the above con-

ditions has been met the starting cir-

cuit cut-off relay is closed and the

engine can be started by pressing the

start switch.

WHEN THE TRANSMISSION IS IN

NEUTRAL

WHEN THE CLUTCH LEVER IS

PULLED TO THE HANDLEBAR1. Battery

2. Main fuse

3. Main switch

4. Starting circuit cut-off relay

5. Start switch

6. Diode

7. Clutch switch

8. Neutral switch

9. Starter relay

10. Starter motor Tester (+) lead→Orange lead "1"

Tester (-) lead→Spark plug termi-

nal "2"

Secondary

coil resis-

tanceTester se-

lector posi-

tion

4.6–6.8

kΩat 20 °C

(68 °F) kΩ × 1

Tester (+) lead→Red lead "1"

Tester (-) lead→White lead "2"

Pickup coil

resistanceTester se-

lector posi-

tion

248–372 Ω

at 20 °C (68

°F) Ω × 100

Tester (+) lead→Sky blue lead "1"

Tester (-) lead→Ground "2"

Result

Conductive (while gear

is in neutral)