light YAMAHA WR 450F 2005 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: WR 450F, Model: YAMAHA WR 450F 2005Pages: 758, PDF Size: 17.3 MB

Page 276 of 758

3 - 48

INSP

ADJ

ELECTRICAL/SPARK PLUG INSPECTION

EC370000

ELECTRICAL

EC371001

SPARK PLUG INSPECTION

1. Remove:

Spark plug

2. Inspect:

Electrode 1

Wear/damage → Replace.

Insulator color 2

Normal condition is a medium to light tan

color.

Distinctly different color → Check the

engine condition.

NOTE:

When the engine runs for many hours at low

speeds, the spark plug insulator will become

sooty, even if the engine and carburetor are in

good operating condition.

3. Measure:

Plug gap a

Use a wire gauge or thickness gauge.

Out of specification → Regap.

Spark plug gap:

0.7 ~ 0.8 mm (0.028 ~ 0.031 in)

4. Clean the plug with a spark plug cleaner if

necessary.

5. Tighten:

Spark plug

NOTE:

Before installing a spark plug, clean the gas-

ket surface and plug surface.

Finger-tighten a the spark plug before torqu-

ing to specification b.

T R..13 Nm (1.3 m · kg, 9.4 ft · lb)

Page 278 of 758

3 - 49

INSP

ADJ

IGNITION TIMING CHECK

IGNITION TIMING CHECK

1. Remove:

Timing plug 1

1

2. Attach:

Timing light

Inductive tachometer

To the ignition coil lead (orange lead 1).

Timing light:

YM-33277-A/90890-03141

1

3. Adjust:

Engine idling speed

Refer to “IDLE SPEED ADJUSTMENT”.

4. Check:

Ignition timing

Visually check the stationary pointer a is

within the firing range b on the rotor.

Incorrect firing range → Check rotor and

pickup assembly.

5. Install:

Timing plug

Page 280 of 758

3 - 50

INSP

ADJ

BATTERY INSPECTION AND CHARGING

WARNING

Batteries generate explosive hydrogen gas

and contain electrolyte which is made of

poisonous and highly caustic sulfuric acid.

Therefore, always follow these preventive

measures:

Wear protective eye gear when handling

or working near batteries.

Charge batteries in a well-ventilated area.

Keep batteries away from fire, sparks or

open flames (e.g., welding equipment,

lighted cigarettes).

DO NOT SMOKE when charging or han-

dling batteries.

KEEP BATTERIES AND ELECTROLYTE

OUT OF REACH OF CHILDREN.

Avoid bodily contact with electrolyte as it

can cause severe burns or permanent eye

injury.

FIRST AID IN CASE OF BODILY CONTACT:

EXTERNAL

Skin — Wash with water.

Eyes — Flush with water for 15 minutes

and get immediate medical attention.

INTERNAL

Drink large quantities of water or milk fol-

lowed with milk of magnesia, beaten egg

or vegetable oil. Get immediate medical

attention.

CAUTION:

Charging time, charging amperage and

charging voltage for an MF battery are dif-

ferent from those of conventional batteries.

The MF battery should be charged as

explained in the charging method illustra-

tions. If the battery is overcharged, the

electrolyte level will drop considerably.

Therefore, take special care when charging

the battery.

BATTERY INSPECTION AND CHARGING

Page 298 of 758

3 - 57

INSP

ADJ

REPLACING THE HEADLIGHT BULBS

3. Replace:

Blown fuse

WARNING

Never use a fuse with an amperage rating

other than that specified. Improvising or

using a fuse with the wrong amperage rat-

ing may cause extensive damage to the

electrical system, cause the starting and

ignition systems to malfunction and could

possibly cause a fire.

4. Install:

Fuse cover

Seat Replacement steps:

Set the main switch to “OFF”.

Install a new fuse of the correct amperage.

Set on the switches to verify if the electri-

cal circuit is operational.

If the fuse immediately blows again, check

the electrical circuit.

ItemsAmperage

ratingQ’ty

Main fuse 10 A 1

REPLACING THE HEADLIGHT BULBS

1. Remove:

Headlight

Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section in the CHAPTER 4.

2. Remove:

Headlight bulb holder cover 1

3. Detach:

Headlight bulb holder 1

4. Remove:

Headlight bulb 2

WARNING

Since the headlight bulb gets extremely

hot, keep flammable products and your

hands away from the bulb unit it has cooled

down.

Page 300 of 758

3 - 58

INSP

ADJ

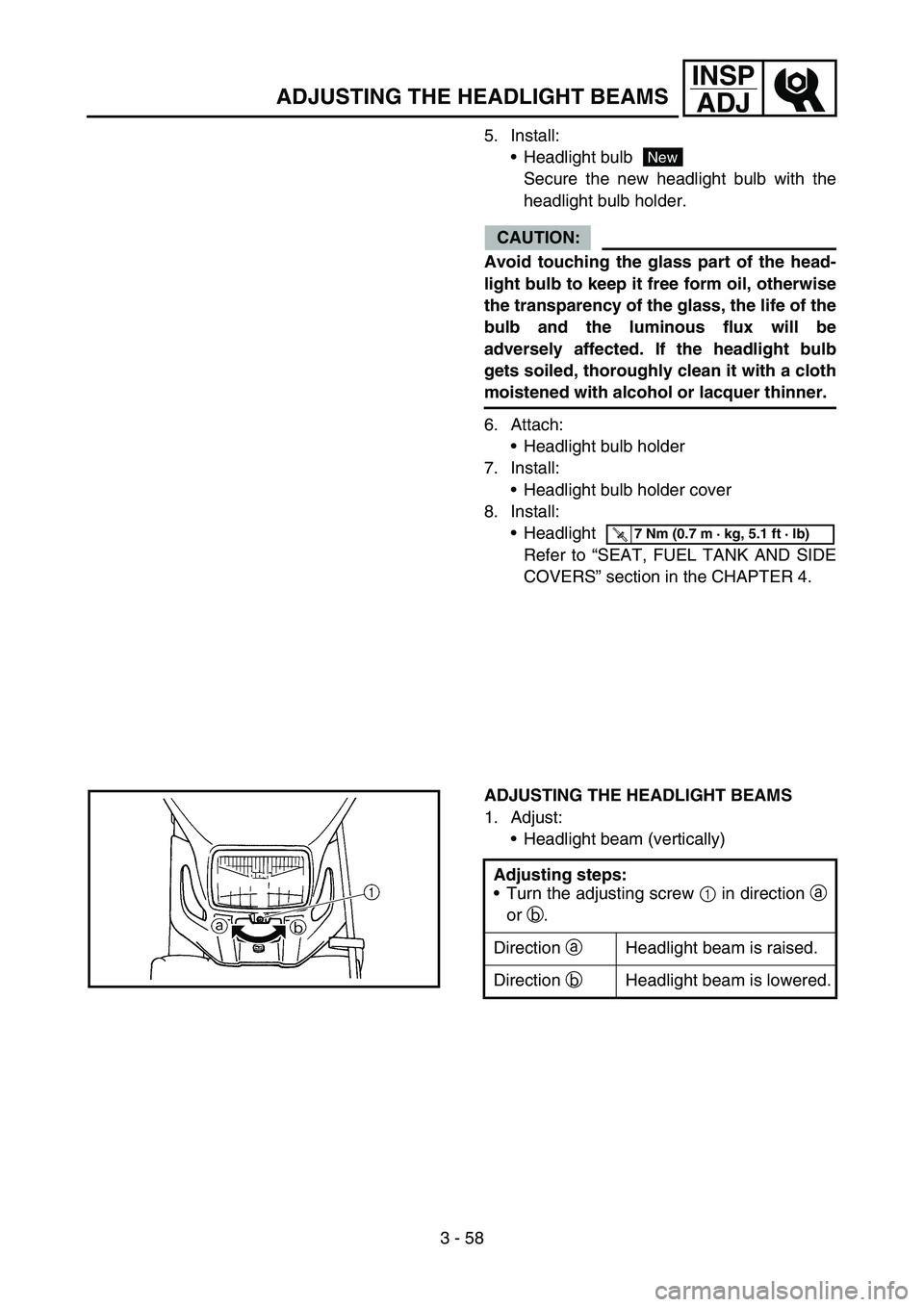

ADJUSTING THE HEADLIGHT BEAMS

5. Install:

Headlight bulb

Secure the new headlight bulb with the

headlight bulb holder.

CAUTION:

Avoid touching the glass part of the head-

light bulb to keep it free form oil, otherwise

the transparency of the glass, the life of the

bulb and the luminous flux will be

adversely affected. If the headlight bulb

gets soiled, thoroughly clean it with a cloth

moistened with alcohol or lacquer thinner.

6. Attach:

Headlight bulb holder

7. Install:

Headlight bulb holder cover

8. Install:

Headlight

Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section in the CHAPTER 4.

New

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

ADJUSTING THE HEADLIGHT BEAMS

1. Adjust:

Headlight beam (vertically)

Adjusting steps:

Turn the adjusting screw 1 in direction a

or b.

Direction a Headlight beam is raised.

Direction bHeadlight beam is lowered.

Page 302 of 758

4 - 1

ENG

EC400000

ENGINE

EC4R0000

SEAT, FUEL TANK AND SIDE COVERS

Extent of removal:

1 Seat removal

2 Fuel tank removal

3 Side covers removal

4 Headlight removal

Extent of removal Order Part name Q’ty Remarks

SEAT, FUEL TANK AND SIDE

COVERS REMOVAL

Preparation for removal Turn the fuel cock to “OFF”.

Disconnect the fuel hose.

1Seat 1

2 Air scoop (left and right) 2

3 Fitting band 1 Remove on fuel tank side.

4 Bolt (fuel tank) 2

5 Fuel tank 1

6 Side cover (left) 1

Refer to “REMOVAL POINTS”.

7 Side cover (right) 1

8 Headlight coupler 1

9 Headlight 1

31

2

3

4

SEAT, FUEL TANK AND SIDE COVERS

Page 336 of 758

4 - 18

ENGCARBURETOR

16. Install:

Throttle valve assembly 1

Screw (throttle shaft) 2

NOTE:

Install the valve lever rollers 3 into the slits a

of the throttle valve.

17. Install:

O-ring 1

Valve lever housing cover 2

Bolt (valve lever housing cover) 3

18. Install:

Carburetor breather hose 1

Refer to “CABLE ROUTING DIAGRAM”

section in the CHAPTER 2.

Accelerator pump timing adjustment

Adjustment steps:

NOTE:

In order for the throttle valve height a to

achieve the specified value, tuck under the

throttle valve plate 1 the rod 2 etc. with the

same outer diameter as the specified value.

Throttle valve height:

3.1 mm (0.122 in)

Fully turn in the accelerator pump adjust-

ing screw 3.

Check that the link lever 4 has free play

b by pushing lightly on it.

Gradually turn out the adjusting screw

while moving the link lever until it has no

more free play.

Page 356 of 758

4 - 28

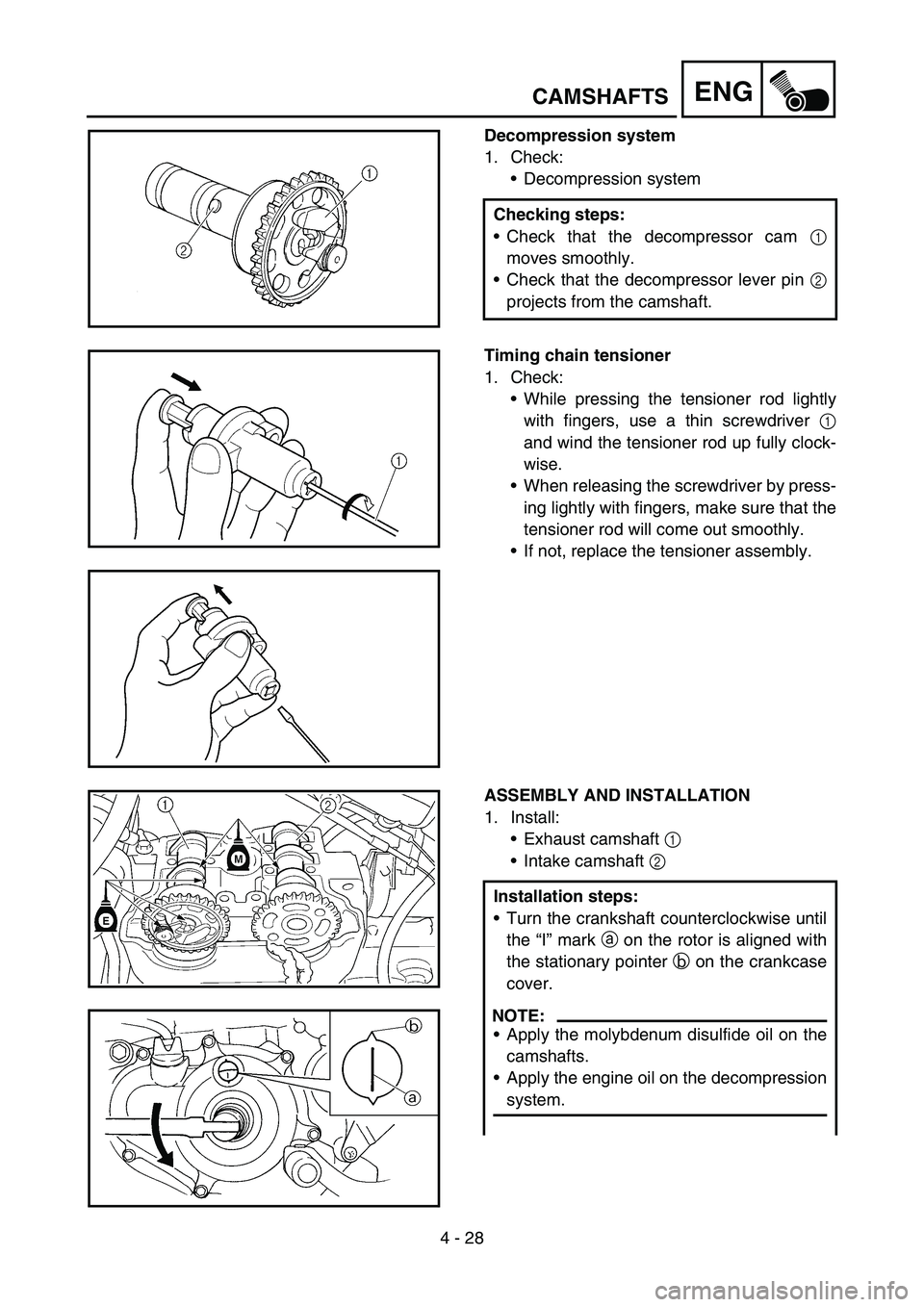

ENGCAMSHAFTS

Decompression system

1. Check:

Decompression system

Checking steps:

Check that the decompressor cam 1

moves smoothly.

Check that the decompressor lever pin 2

projects from the camshaft.

Timing chain tensioner

1. Check:

While pressing the tensioner rod lightly

with fingers, use a thin screwdriver 1

and wind the tensioner rod up fully clock-

wise.

When releasing the screwdriver by press-

ing lightly with fingers, make sure that the

tensioner rod will come out smoothly.

If not, replace the tensioner assembly.

ASSEMBLY AND INSTALLATION

1. Install:

Exhaust camshaft 1

Intake camshaft 2

Installation steps:

Turn the crankshaft counterclockwise until

the “I” mark a on the rotor is aligned with

the stationary pointer b on the crankcase

cover.

NOTE:

Apply the molybdenum disulfide oil on the

camshafts.

Apply the engine oil on the decompression

system.

Page 358 of 758

4 - 29

ENGCAMSHAFTS

Fit the timing chain 3 onto both camshaft

sprockets and install the camshafts on the

cylinder head.

NOTE:

The camshafts should be installed onto the

cylinder head so that the exhaust cam

sprocket punch mark c and the intake cam

sprocket punch mark d align with the sur-

face of the cylinder head.

CAUTION:

Do not turn the crankshaft during the

camshaft installation. Damage or

improper valve timing will result.

Install the clips and camshaft caps 4.

T R..

Bolt (camshaft cap):

10 Nm (1.0 m kg, 7.2 ft lb)

NOTE:

Apply the engine oil on the thread and

contact surface of the bolts (camshaft cap)

5.

Tighten the bolts (camshaft cap) in a criss-

cross pattern.

CAUTION:

The bolts (camshaft cap) must be tight-

ened evenly, or damage to the cylinder

head, camshaft caps, and camshaft will

result.

5

4

E

2. Install:

Timing chain tensioner

Installation steps:

While pressing the tensioner rod lightly

with fingers, use a thin screwdriver and

wind the tensioner rod up fully clockwise.

Page 382 of 758

4 - 41

ENGVALVES AND VALVE SPRINGS

9. Lap:

Valve face

Valve seat

NOTE:

After refacing the valve seat or replacing the

valve and valve guide, the valve seat and

valve face should be lapped.

Lapping steps:

Apply a coarse lapping compound to the

valve face.

CAUTION:

Do not let the compound enter the gap

between the valve stem and the guide.

Apply molybdenum disulfide oil to the

valve stem.

Install the valve into the cylinder head.

Turn the valve until the valve face and

valve seat are evenly polished, then clean

off all of the compound.

NOTE:

For best lapping results, lightly tap the valve

seat while rotating the valve back and forth

between your hands.

Apply a fine lapping compound to the

valve face and repeat the above steps.

NOTE:

After every lapping operation be sure to

clean off all of the compound from the valve

face and valve seat.

Apply Mechanic’s blueing dye (Dykem) to

the valve face.

Install the valve into the cylinder head.

Press the valve through the valve guide

and onto the valve seat to make a clear

pattern.

Measure the valve seat width again. If the

valve seat width is out of specification,

reface and relap the valve seat.