engine YAMAHA YZ125LC 2002 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: YZ125LC, Model: YAMAHA YZ125LC 2002Pages: 564, PDF Size: 13.86 MB

Page 268 of 564

4-28

ENGCYLINDER HEAD, CYLINDER AND PISTON

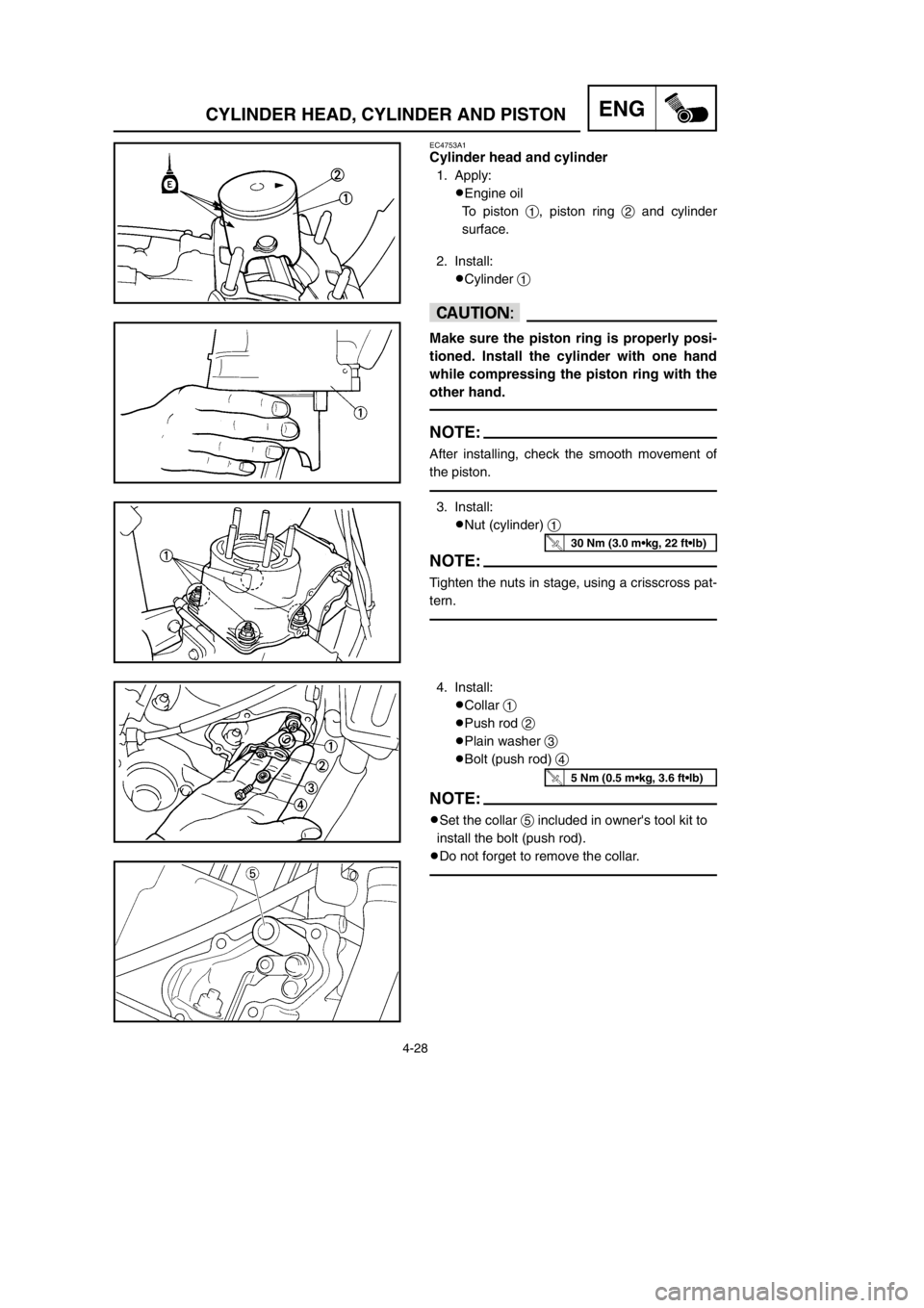

3. Install:

9Nut (cylinder) 1

NOTE:

Tighten the nuts in stage, using a crisscross pat-

tern.

4. Install:

9Collar 1

9Push rod 2

9Plain washer 3

9Bolt (push rod) 4

NOTE:

9Set the collar 5included in owner's tool kit to

install the bolt (push rod).

9Do not forget to remove the collar.

EC4753A1

Cylinder head and cylinder

1. Apply:

9Engine oil

To piston 1, piston ring 2and cylinder

surface.

2. Install:

9Cylinder 1

cC

Make sure the piston ring is properly posi-

tioned. Install the cylinder with one hand

while compressing the piston ring with the

other hand.

NOTE:

After installing, check the smooth movement of

the piston.

30 Nm (3.0 m•kg, 22 ft•lb)

5 Nm (0.5 m•kg, 3.6 ft•lb)

5NY-9-30-4B 5/23/01 8:48 PM Page 22

Page 270 of 564

4-29

ENGCYLINDER HEAD, CYLINDER AND PISTON

7. Install:

9Cylinder head 1

9Copper washer 2

9Nut (cylinder head) 3

NOTE:

Tighten the nuts (cylinder head) in stage, using a

crisscross pattern.

8. Install:

9Engine bracket 1

9Bolt (engine bracket) 2

9CDI unit bracket 3

9Engine mounting bolt (upper) 4

9. Install:

9Spark plug 1

9Spark plug cap 2

9Radiator hose 2 3

28 Nm (2.8 m•kg, 20 ft•lb)

34 Nm (3.4 m•kg, 24 ft•lb)

34 Nm (3.4 m•kg, 24 ft•lb)

20 Nm (2.0 m•kg, 14 ft•lb)

5. Install:

9Gasket (power valve housing)

9Power valve housing 1

9Bolt (power valve housing) 2

6. Install:

9O-ring 1

NOTE:

Apply the lithium soap base grease on the O-

rings.

5 Nm (0.5 m•kg, 3.6 ft•lb)

1 Nm (0.1 m•kg, 0.7 ft•lb)

5NY-9-30-4B 5/23/01 8:48 PM Page 24

Page 272 of 564

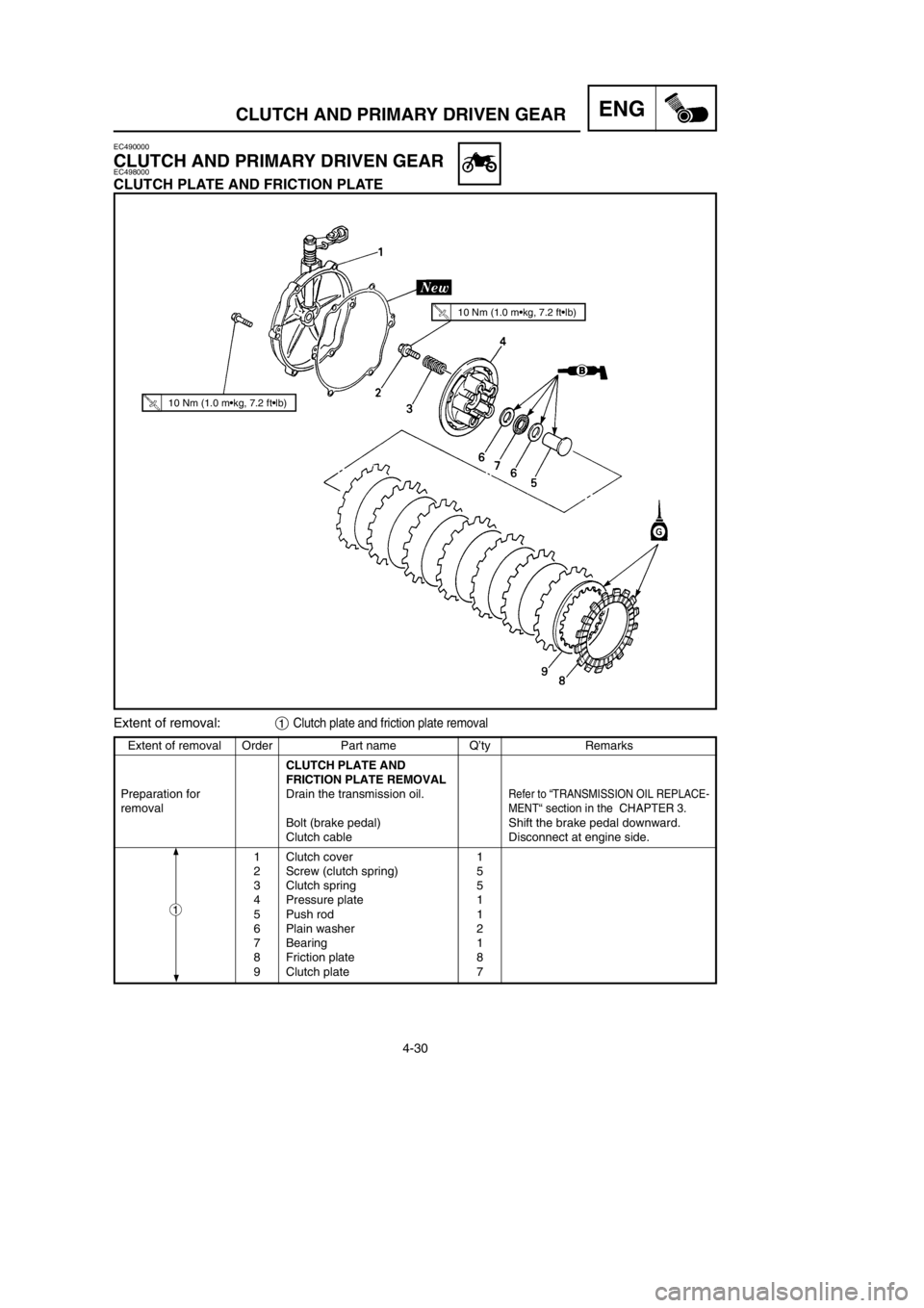

4-30

ENGCLUTCH AND PRIMARY DRIVEN GEAR

Extent of removal Order Part name Q’ty Remarks

CLUTCH PLATE AND

FRICTION PLATE REMOVAL

Preparation for Drain the transmission oil.

Refer to “TRANSMISSION OIL REPLACE-

removalMENT“ section in the CHAPTER 3.

Bolt (brake pedal) Shift the brake pedal downward.

Clutch cable Disconnect at engine side.

1 Clutch cover 1

2 Screw (clutch spring) 5

3 Clutch spring 5

4 Pressure plate 1

5 Push rod 1

6 Plain washer 2

7 Bearing 1

8 Friction plate 8

9 Clutch plate 7

Extent of removal:1Clutch plate and friction plate removal

EC490000

CLUTCH AND PRIMARY DRIVEN GEAREC498000

CLUTCH PLATE AND FRICTION PLATE

1

10 Nm (1.0 m•kg, 7.2 ft•lb)

10 Nm (1.0 m•kg, 7.2 ft•lb)

5NY-9-30-4B 5/23/01 8:48 PM Page 26

Page 288 of 564

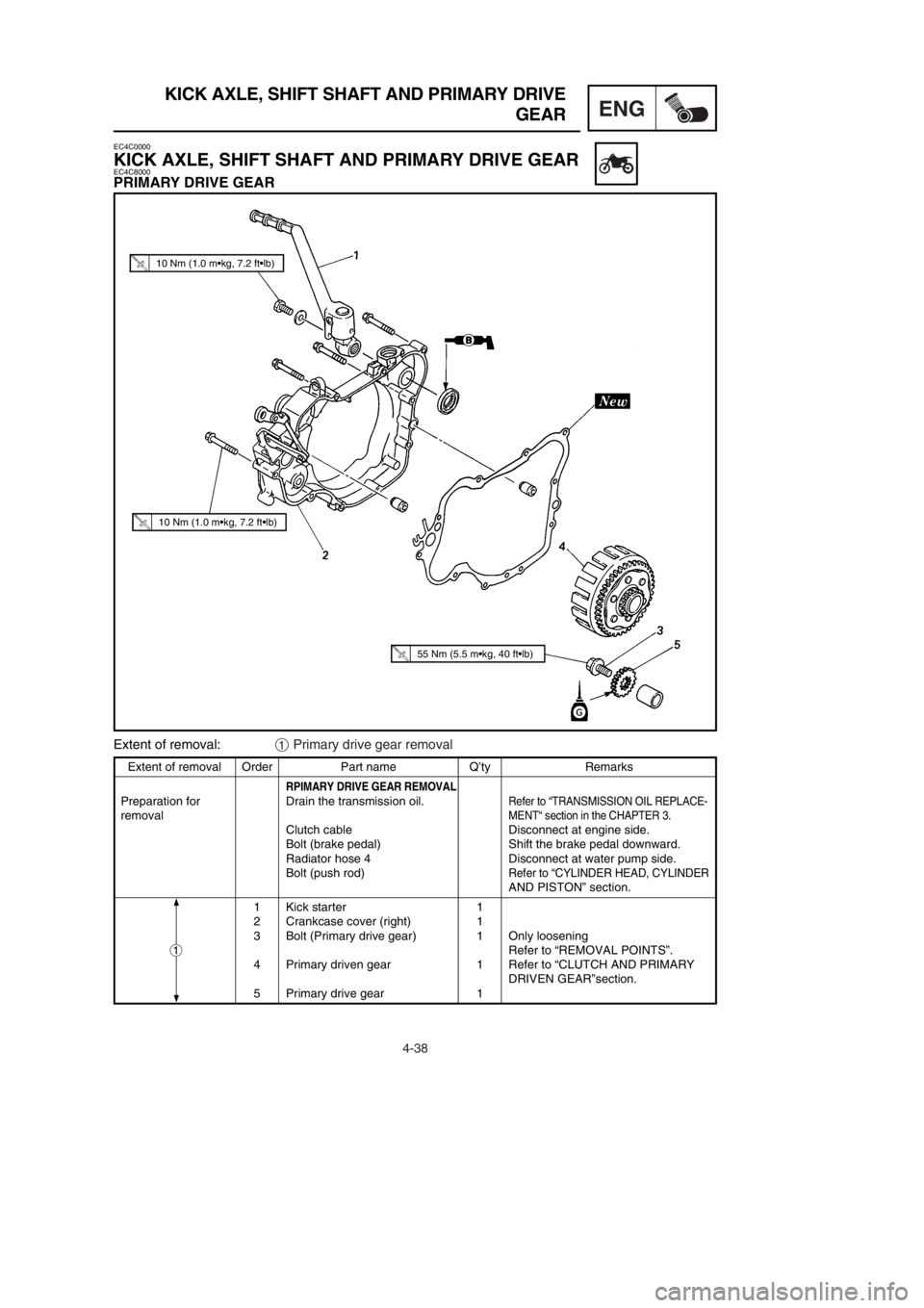

4-38

ENG

KICK AXLE, SHIFT SHAFT AND PRIMARY DRIVE

GEAR

Extent of removal Order Part name Q’ty Remarks

RPIMARY DRIVE GEAR REMOVAL

Preparation for Drain the transmission oil.Refer to “TRANSMISSION OIL REPLACE-

removalMENT“ section in the CHAPTER 3.

Clutch cable Disconnect at engine side.

Bolt (brake pedal) Shift the brake pedal downward.

Radiator hose 4 Disconnect at water pump side.

Bolt (push rod)

Refer to “CYLINDER HEAD, CYLINDER

AND PISTON” section.

1 Kick starter 1

2 Crankcase cover (right) 1

3 Bolt (Primary drive gear) 1 Only loosening

Refer to “REMOVAL POINTS”.

4 Primary driven gear 1 Refer to “CLUTCH AND PRIMARY

DRIVEN GEAR”section.

5 Primary drive gear 1

EC4C0000

KICK AXLE, SHIFT SHAFT AND PRIMARY DRIVE GEAREC4C8000PRIMARY DRIVE GEAR

1

Extent of removal:1Primary drive gear removal

10 Nm (1.0 m•kg, 7.2 ft•lb)

10 Nm (1.0 m•kg, 7.2 ft•lb)

55 Nm (5.5 m•kg, 40 ft•lb)

5NY-9-30-4C 5/23/01 8:56 PM Page 2

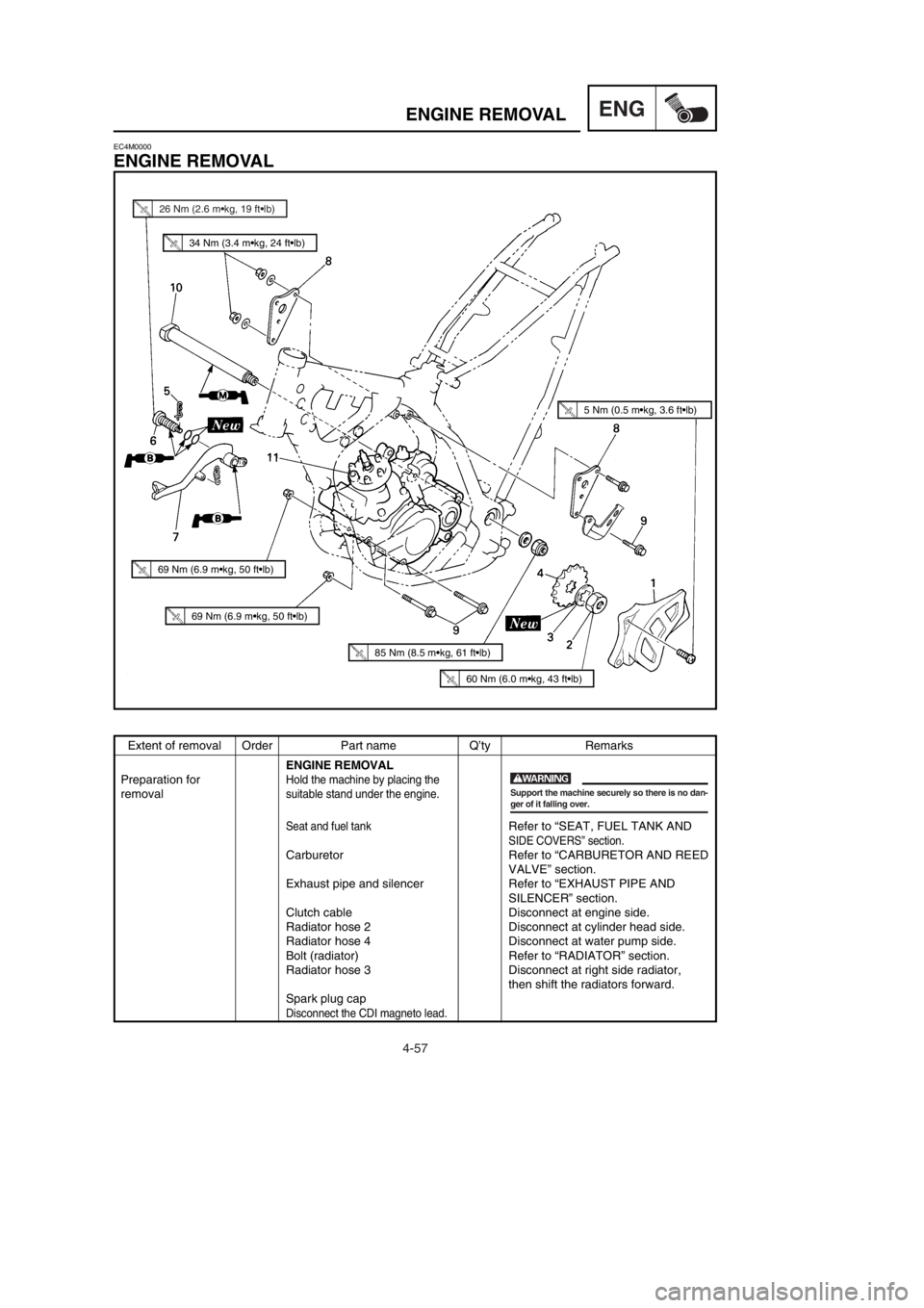

Page 326 of 564

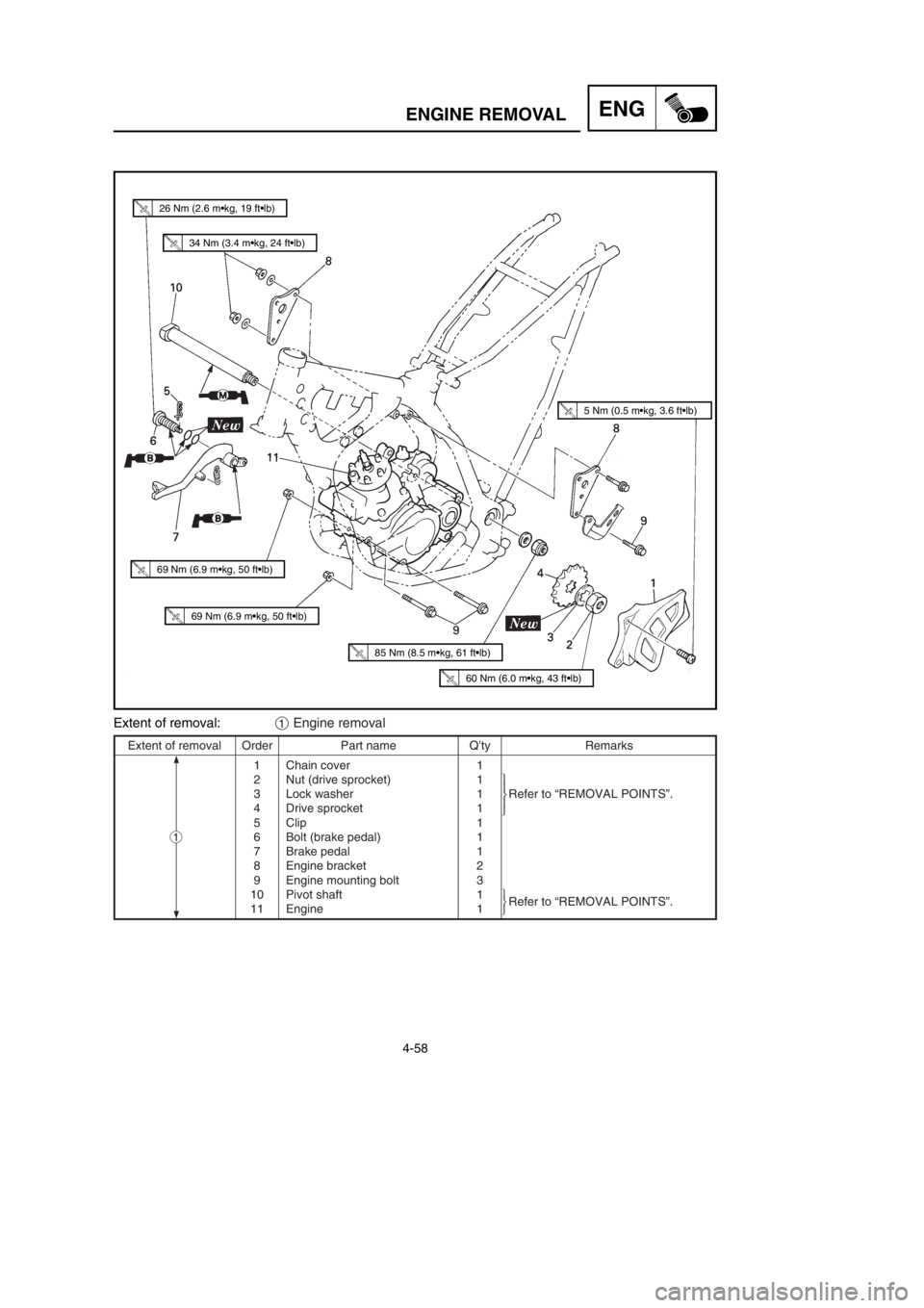

4-57

ENGENGINE REMOVAL

Extent of removal Order Part name Q’ty Remarks

ENGINE REMOVAL

Preparation for

Hold the machine by placing the

removalsuitable stand under the engine.

Seat and fuel tankRefer to “SEAT, FUEL TANK AND

SIDE COVERS” section.

Carburetor Refer to “CARBURETOR AND REED

VALVE” section.

Exhaust pipe and silencer Refer to “EXHAUST PIPE AND

SILENCER” section.

Clutch cable Disconnect at engine side.

Radiator hose 2 Disconnect at cylinder head side.

Radiator hose 4 Disconnect at water pump side.

Bolt (radiator) Refer to “RADIATOR” section.

Radiator hose 3 Disconnect at right side radiator,

then shift the radiators forward.

Spark plug cap

Disconnect the CDI magneto lead.

EC4M0000

ENGINE REMOVAL

w

Support the machine securely so there is no dan-

ger of it falling over.

26 Nm (2.6 m•kg, 19 ft•lb)

34 Nm (3.4 m•kg, 24 ft•lb)

69 Nm (6.9 m•kg, 50 ft•lb)

69 Nm (6.9 m•kg, 50 ft•lb)

85 Nm (8.5 m•kg, 61 ft•lb)

60 Nm (6.0 m•kg, 43 ft•lb)

5 Nm (0.5 m•kg, 3.6 ft•lb)

5NY-9-30-4D 5/24/01 8:33 PM Page 2

Page 328 of 564

4-58

ENGENGINE REMOVAL

Extent of removal:1Engine removal

Extent of removal Order Part name Q’ty Remarks

1 Chain cover 1

2 Nut (drive sprocket) 1

3 Lock washer 1 Refer to “REMOVAL POINTS”.

4 Drive sprocket 1

5 Clip 1

6 Bolt (brake pedal) 1

7 Brake pedal 1

8 Engine bracket 2

9 Engine mounting bolt 3

10 Pivot shaft 1

Refer to “REMOVAL POINTS”.

11 Engine 1

1

26 Nm (2.6 m•kg, 19 ft•lb)

34 Nm (3.4 m•kg, 24 ft•lb)

69 Nm (6.9 m•kg, 50 ft•lb)

69 Nm (6.9 m•kg, 50 ft•lb)

85 Nm (8.5 m•kg, 61 ft•lb)

60 Nm (6.0 m•kg, 43 ft•lb)

5 Nm (0.5 m•kg, 3.6 ft•lb)

5NY-9-30-4D 5/24/01 8:33 PM Page 4

Page 330 of 564

4-59

ENGENGINE REMOVAL

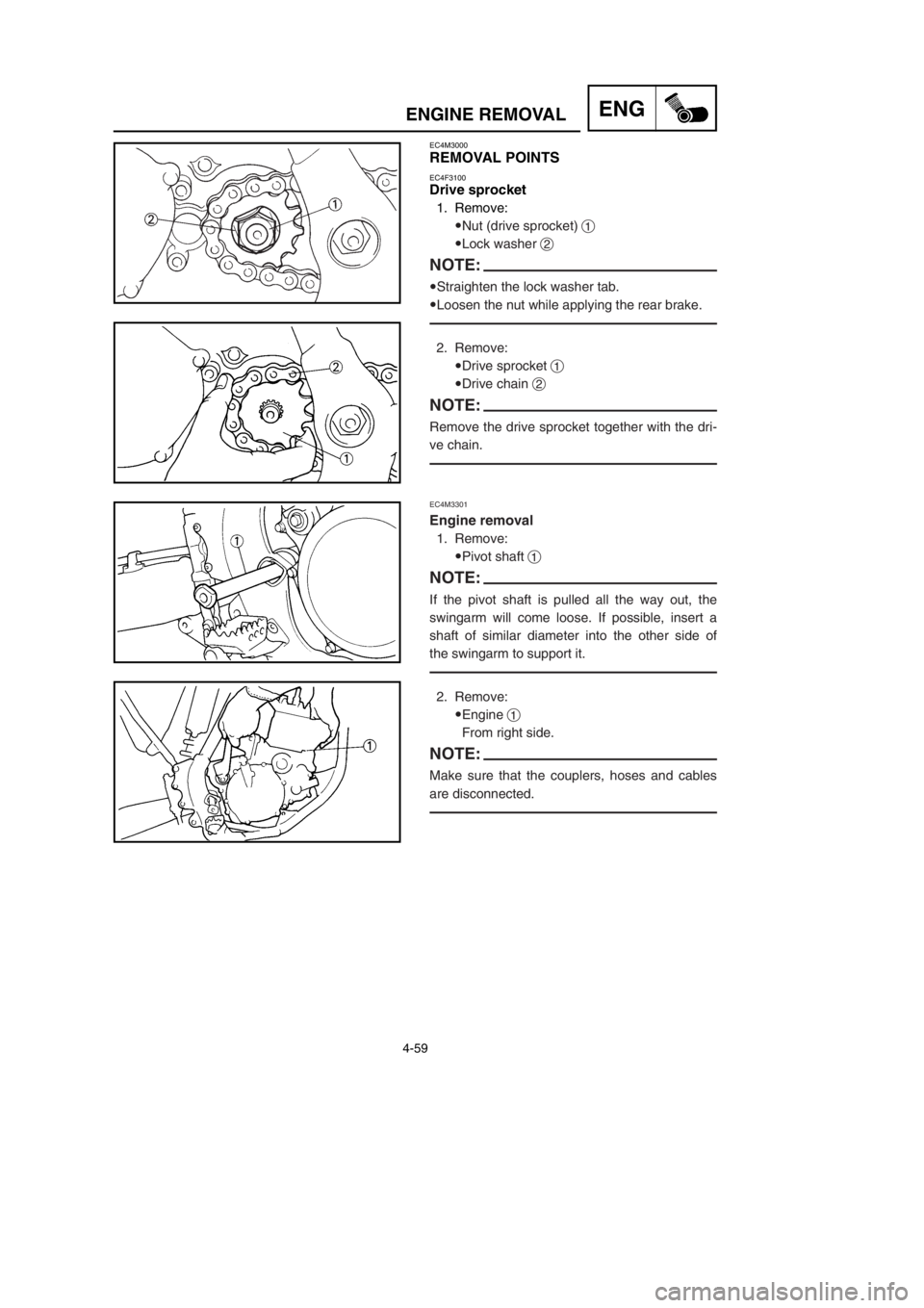

EC4M3000

REMOVAL POINTS

EC4F3100

Drive sprocket

1. Remove:

9Nut (drive sprocket) 1

9Lock washer 2

NOTE:

9Straighten the lock washer tab.

9Loosen the nut while applying the rear brake.

2. Remove:

9Drive sprocket 1

9Drive chain 2

NOTE:

Remove the drive sprocket together with the dri-

ve chain.

EC4M3301

Engine removal

1. Remove:

9Pivot shaft 1

NOTE:

If the pivot shaft is pulled all the way out, the

swingarm will come loose. If possible, insert a

shaft of similar diameter into the other side of

the swingarm to support it.

2. Remove:

9Engine 1

From right side.

NOTE:

Make sure that the couplers, hoses and cables

are disconnected.

5NY-9-30-4D 5/24/01 8:33 PM Page 6

Page 332 of 564

4-60

ENGENGINE REMOVAL

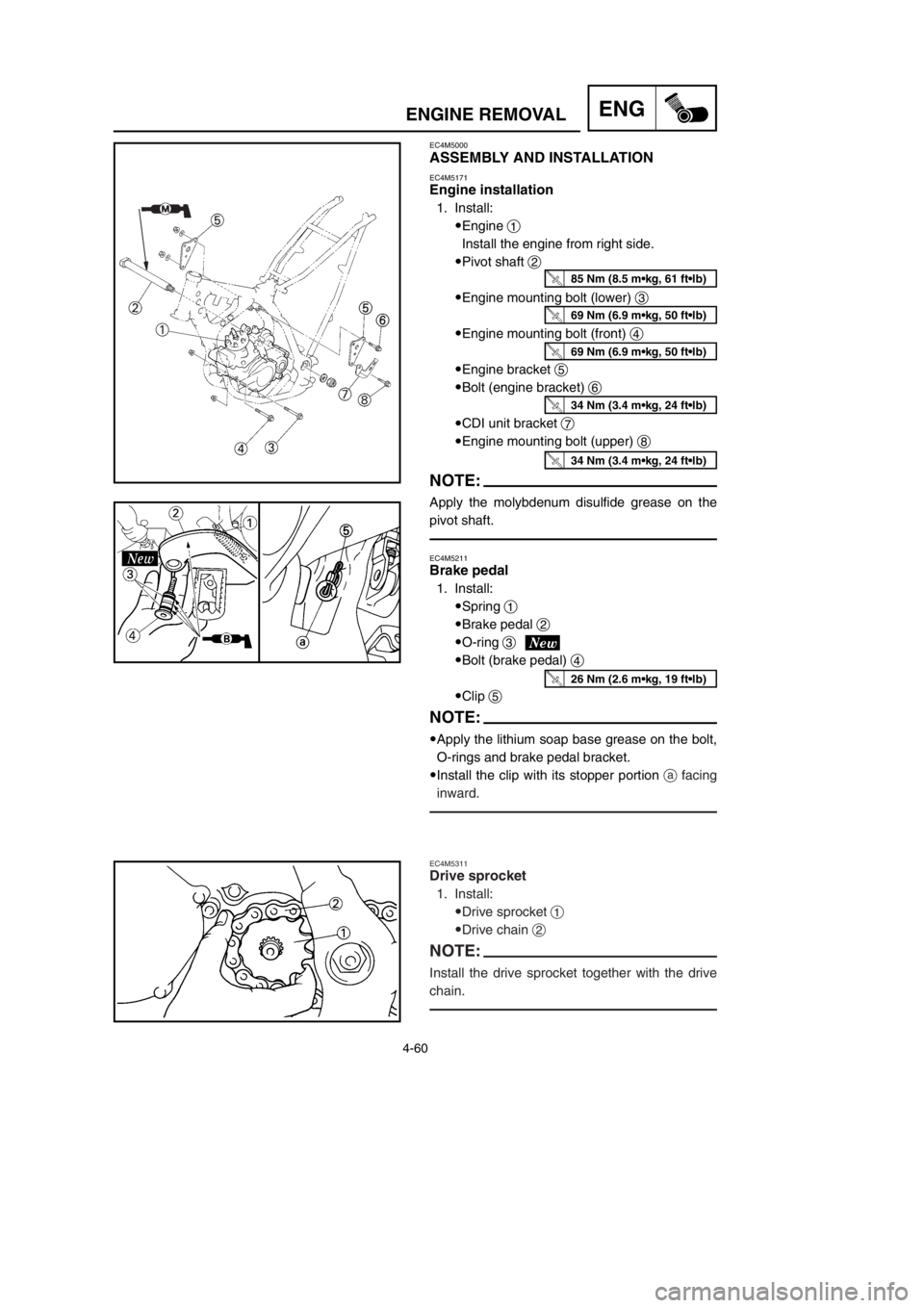

EC4M5000

ASSEMBLY AND INSTALLATION

EC4M5171

Engine installation

1. Install:

9Engine 1

Install the engine from right side.

9Pivot shaft 2

9Engine mounting bolt (lower) 3

9Engine mounting bolt (front) 4

9Engine bracket 5

9Bolt (engine bracket) 6

9CDI unit bracket 7

9Engine mounting bolt (upper) 8

NOTE:

Apply the molybdenum disulfide grease on the

pivot shaft.

EC4M5211

Brake pedal

1. Install:

9Spring 1

9Brake pedal 2

9O-ring 3

9Bolt (brake pedal) 4

9Clip 5

NOTE:

9Apply the lithium soap base grease on the bolt,

O-rings and brake pedal bracket.

9Install the clip with its stopper portion afacing

inward.

EC4M5311

Drive sprocket

1. Install:

9Drive sprocket 1

9Drive chain 2

NOTE:

Install the drive sprocket together with the drive

chain.

85 Nm (8.5 m•kg, 61 ft•lb)

69 Nm (6.9 m•kg, 50 ft•lb)

69 Nm (6.9 m•kg, 50 ft•lb)

34 Nm (3.4 m•kg, 24 ft•lb)

34 Nm (3.4 m•kg, 24 ft•lb)

26 Nm (2.6 m•kg, 19 ft•lb)

5NY-9-30-4D 5/24/01 8:33 PM Page 8

Page 334 of 564

4-61

ENGENGINE REMOVAL

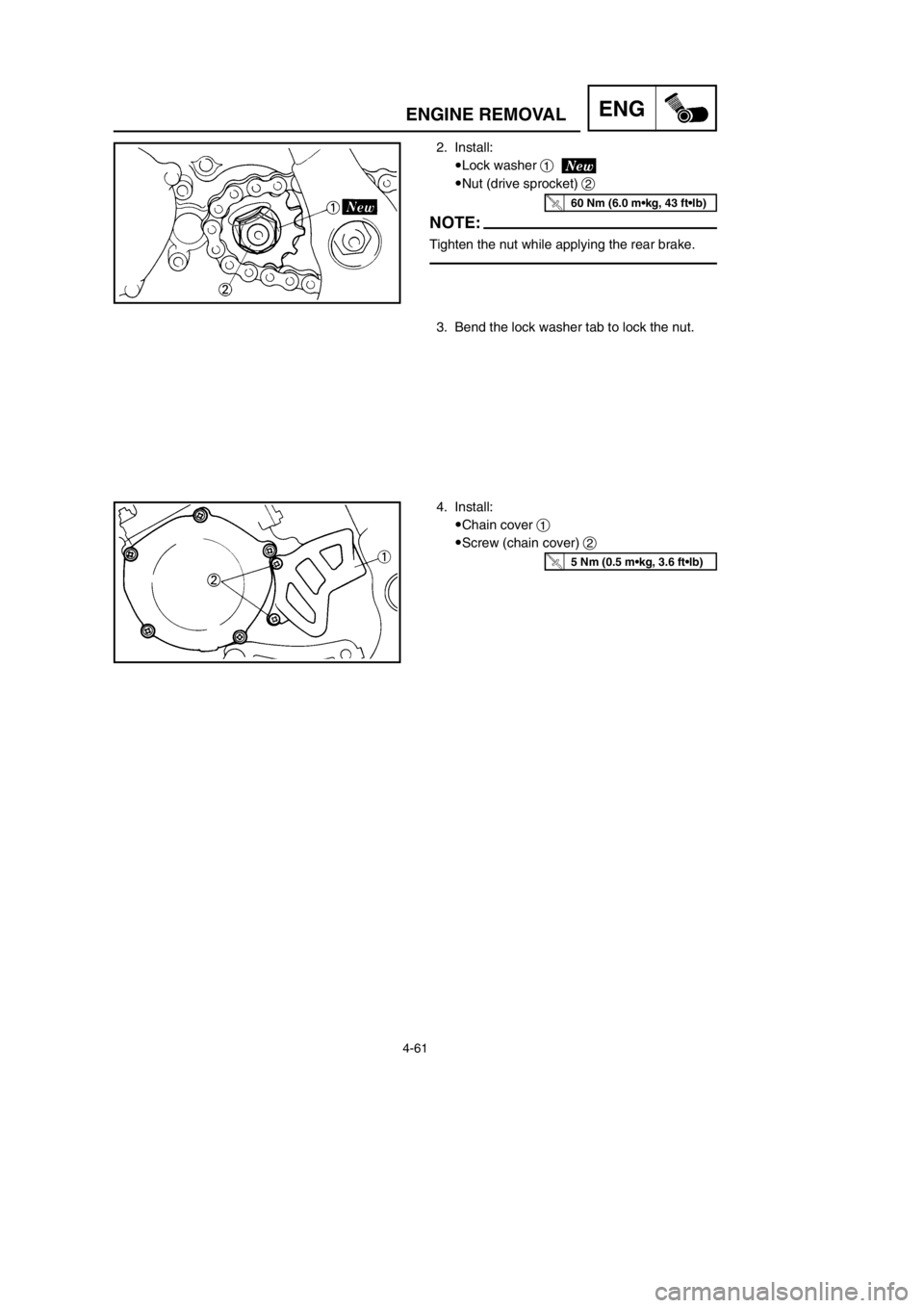

2. Install:

9Lock washer 1

9Nut (drive sprocket) 2

NOTE:

Tighten the nut while applying the rear brake.

3. Bend the lock washer tab to lock the nut.

4. Install:

9Chain cover 1

9Screw (chain cover) 2

5 Nm (0.5 m•kg, 3.6 ft•lb)

60 Nm (6.0 m•kg, 43 ft•lb)

5NY-9-30-4D 5/24/01 8:33 PM Page 10

Page 336 of 564

4-62

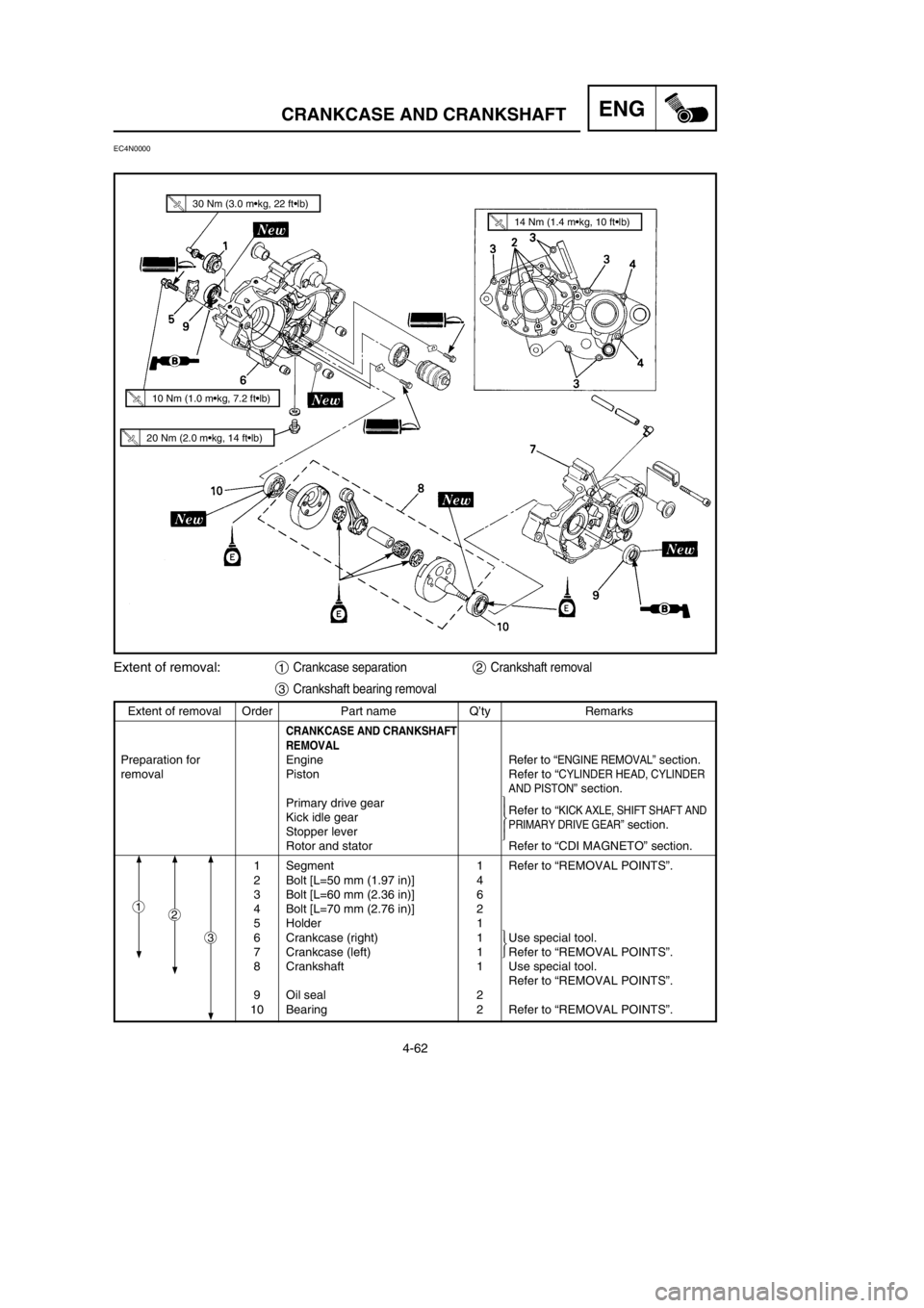

ENGCRANKCASE AND CRANKSHAFT

Extent of removal Order Part name Q’ty Remarks

CRANKCASE AND CRANKSHAFT

REMOVAL

Preparation for Engine Refer to “ENGINE REMOVAL”section.

removal Piston Refer to “

CYLINDER HEAD, CYLINDER

AND PISTON

” section.

Primary drive gear

Kick idle gearRefer to “

KICK AXLE, SHIFT SHAFT AND

Stopper leverPRIMARY DRIVE GEAR”section.

Rotor and stator Refer to “CDI MAGNETO” section.

1 Segment 1 Refer to “REMOVAL POINTS”.

2 Bolt [L=50 mm (1.97 in)] 4

3 Bolt [L=60 mm (2.36 in)] 6

4 Bolt [L=70 mm (2.76 in)] 2

5 Holder 1

6 Crankcase (right) 1 Use special tool.

7 Crankcase (left) 1 Refer to “REMOVAL POINTS”.

8 Crankshaft 1 Use special tool.

Refer to “REMOVAL POINTS”.

9 Oil seal 2

10 Bearing 2 Refer to “REMOVAL POINTS”.

EC4N0000

12

3

Extent of removal:1Crankcase separation2Crankshaft removal

3Crankshaft bearing removal

30 Nm (3.0 m•kg, 22 ft•lb)

10 Nm (1.0 m•kg, 7.2 ft•lb)

20 Nm (2.0 m•kg, 14 ft•lb)

14 Nm (1.4 m•kg, 10 ft•lb)

5NY-9-30-4D 5/24/01 8:33 PM Page 12