engine YAMAHA YZ250LC 2001 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: YZ250LC, Model: YAMAHA YZ250LC 2001Pages: 578, PDF Size: 14.12 MB

Page 518 of 578

6-12

TPS (THROTTLE POSITION SENSOR) SYSTEMELEC

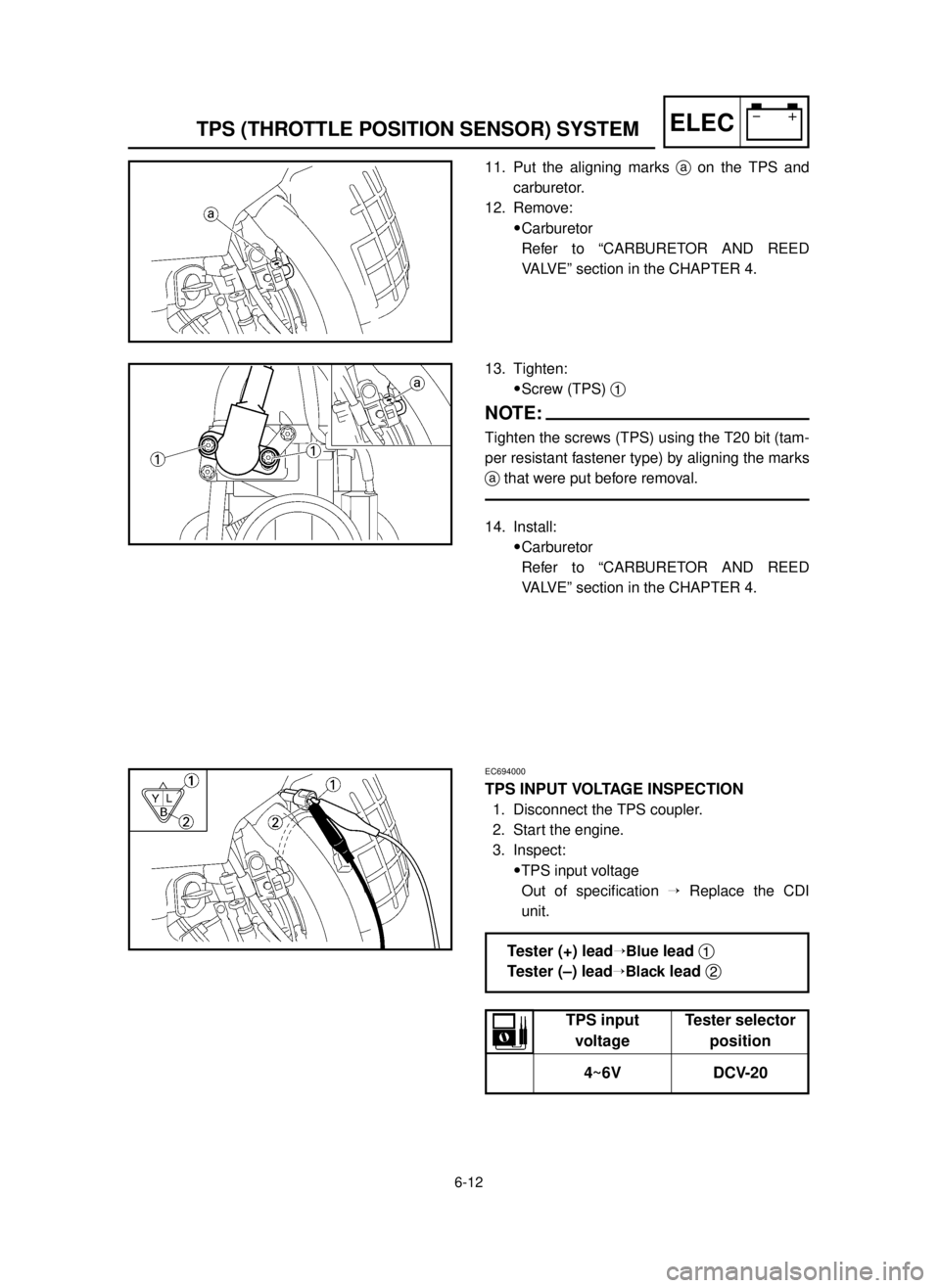

11. Put the aligning marks aon the TPS and

carburetor.

12. Remove:

9Carburetor

Refer to “CARBURETOR AND REED

VALVE” section in the CHAPTER 4.

13. Tighten:

9Screw (TPS) 1

NOTE:

Tighten the screws (TPS) using the T20 bit (tam-

per resistant fastener type) by aligning the marks

athat were put before removal.

14. Install:

9Carburetor

Refer to “CARBURETOR AND REED

VALVE” section in the CHAPTER 4.

EC694000

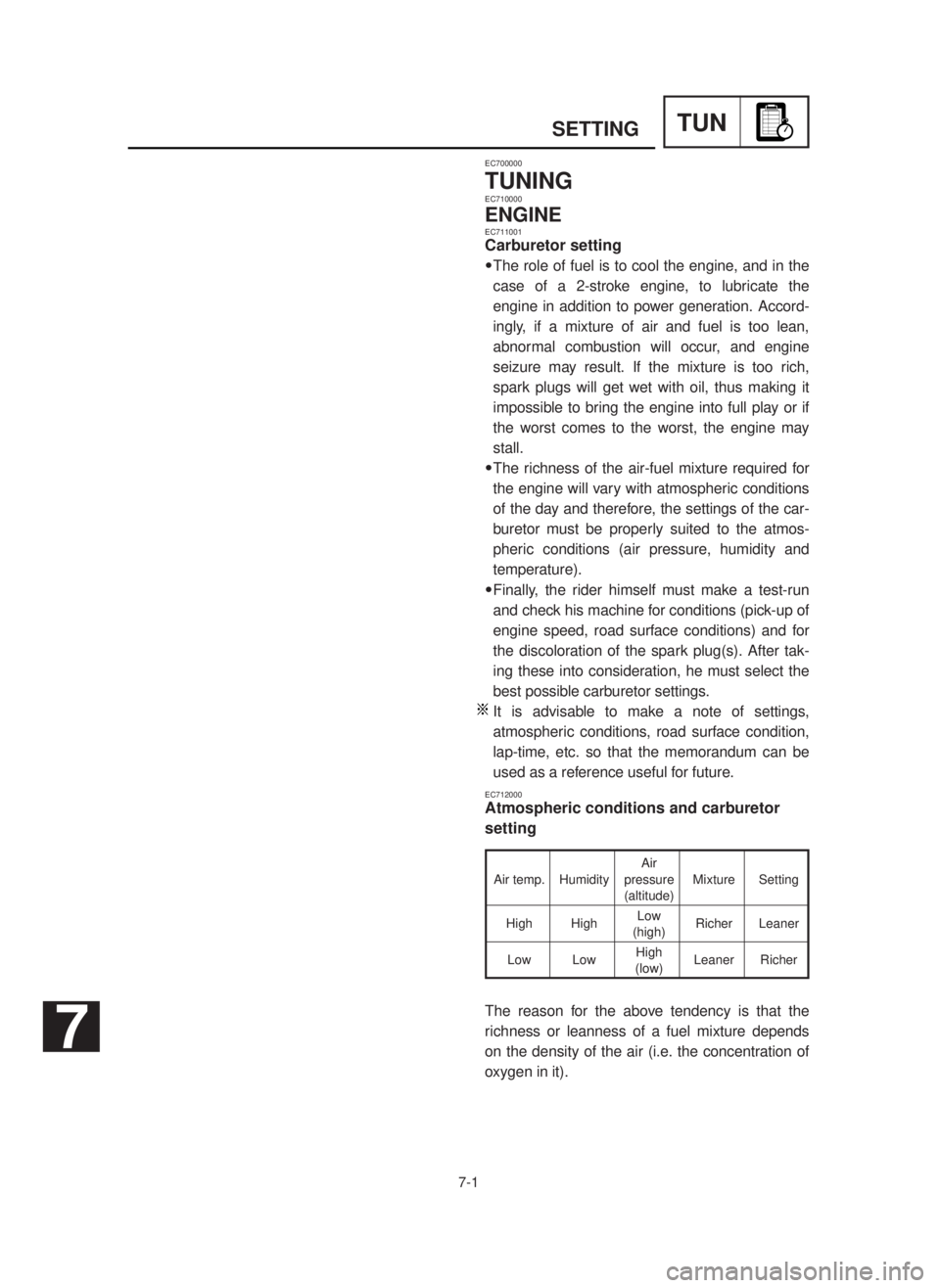

TPS INPUT VOLTAGE INSPECTION

1. Disconnect the TPS coupler.

2. Start the engine.

3. Inspect:

9TPS input voltage

Out of specification ÕReplace the CDI

unit.

Tester (+) leadÕBluelead 1

Tester (–) lead

ÕBlacklead 2

TPS input Tester selector

voltage position

4~6V DCV-20

5MW-9-30-6 7/6/00 1:40 PM Page 30

Page 520 of 578

7-1

SETTINGTUN

EC700000

TUNINGEC710000

ENGINEEC711001

Carburetor setting

9The role of fuel is to cool the engine, and in the

case of a 2-stroke engine, to lubricate the

engine in addition to power generation. Accord-

ingly, if a mixture of air and fuel is too lean,

abnormal combustion will occur, and engine

seizure may result. If the mixture is too rich,

spark plugs will get wet with oil, thus making it

impossible to bring the engine into full play or if

the worst comes to the worst, the engine may

stall.

9The richness of the air-fuel mixture required for

the engine will vary with atmospheric conditions

of the day and therefore, the settings of the car-

buretor must be properly suited to the atmos-

pheric conditions (air pressure, humidity and

temperature).

9Finally, the rider himself must make a test-run

and check his machine for conditions (pick-up of

engine speed, road surface conditions) and for

the discoloration of the spark plug(s). After tak-

ing these into consideration, he must select the

best possible carburetor settings.

It is advisable to make a note of settings,

atmospheric conditions, road surface condition,

lap-time, etc. so that the memorandum can be

used as a reference useful for future.

EC712000

Atmospheric conditions and carburetor

setting

The reason for the above tendency is that the

richness or leanness of a fuel mixture depends

on the density of the air (i.e. the concentration of

oxygen in it).

Air

Air temp. Humidity pressure Mixture Setting

(altitude)

High HighLow

Richer Leaner

(high)

Low LowHigh

Leaner Richer

(low)

7

5MW-9-30-7 7/6/00 2:15 PM Page 2

Page 522 of 578

7-2

SETTINGTUN

That is:

9Higher temperature expands the air with its

resultant reduced density.

9Higher humidity reduces the amount of oxygen

in the air by so much of the water vapor in the

same air.

9Lower atmospheric pressure (at a high altitude)

reduces the density of the air.

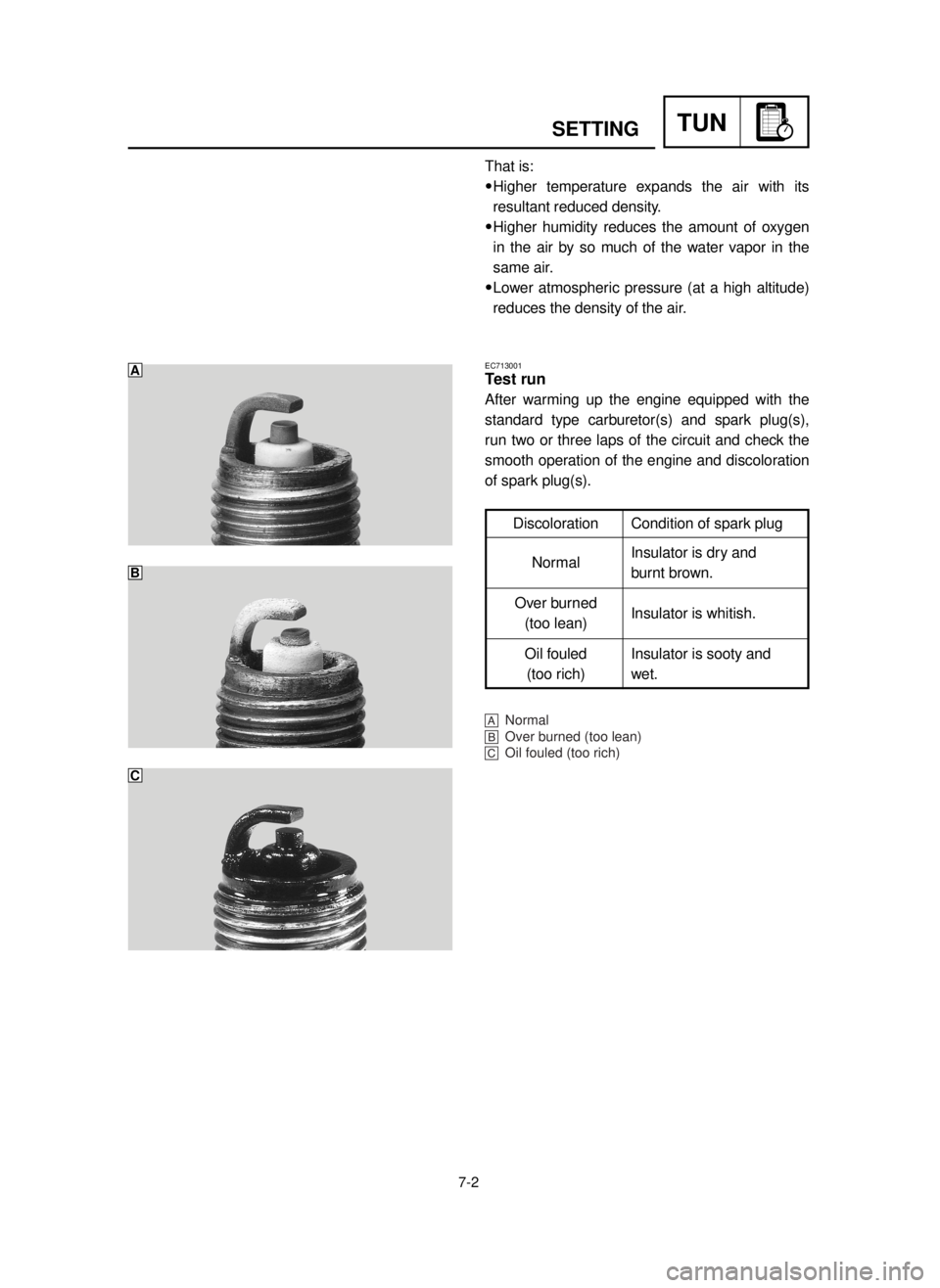

EC713001

Test run

After warming up the engine equipped with the

standard type carburetor(s) and spark plug(s),

run two or three laps of the circuit and check the

smooth operation of the engine and discoloration

of spark plug(s).

ŒNormal

ºOver burned (too lean)

Oil fouled (too rich)

Discoloration Condition of spark plug

NormalInsulator is dry and

burnt brown.

Over burned

Insulator is whitish.

(too lean)

Oil fouled Insulator is sooty and

(too rich) wet.

A

B

C

5MW-9-30-7 7/6/00 2:16 PM Page 4

Page 524 of 578

7-3

SETTINGTUN

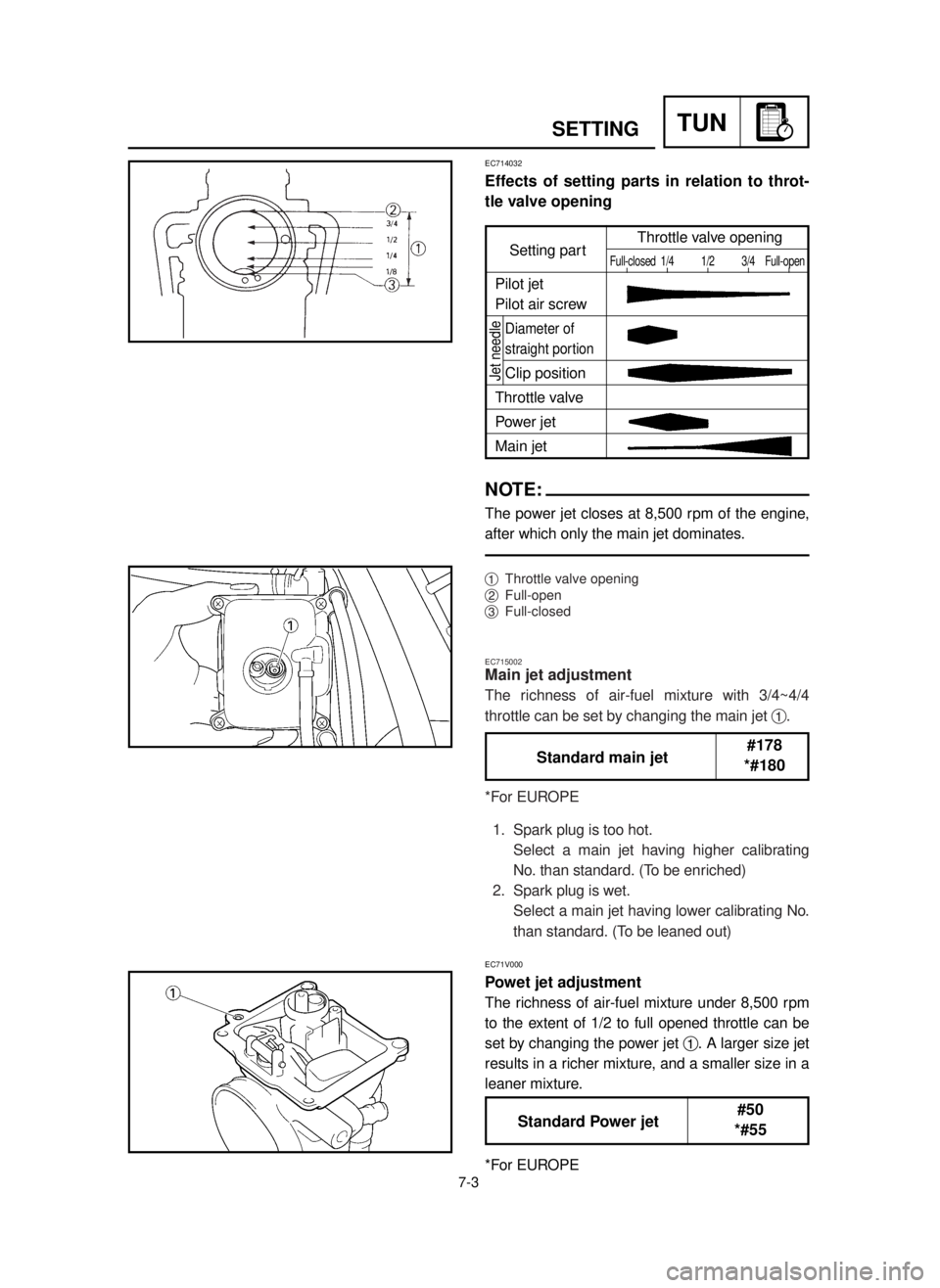

EC714032

Effects of setting parts in relation to throt-

tle valve opening

NOTE:

The power jet closes at 8,500 rpm of the engine,

after which only the main jet dominates.

1Throttle valve opening

2Full-open

3Full-closed

EC715002

Main jet adjustment

The richness of air-fuel mixture with 3/4~4/4

throttle can be set by changing the main jet 1.

*For EUROPE

1. Spark plug is too hot.

Select a main jet having higher calibrating

No. than standard. (To be enriched)

2. Spark plug is wet.

Select a main jet having lower calibrating No.

than standard. (To be leaned out)

Standard main jet#178

*#180

EC71V000

Powet jet adjustment

The richness of air-fuel mixture under 8,500 rpm

to the extent of 1/2 to full opened throttle can be

set by changing the power jet 1. A larger size jet

results in a richer mixture, and a smaller size in a

leaner mixture.

*For EUROPE

Standard Power jet#50

*#55

Setting partThrottle valve openingFull-closed 1/4 1/2 3/4 Full-open

Pilot jet

Pilot air screw

Diameter of

straight portion

Clip position

Throttle valve

Power jet

Main jet

Jet needle

5MW-9-30-7 7/6/00 2:17 PM Page 6

Page 526 of 578

7-4

SETTINGTUN

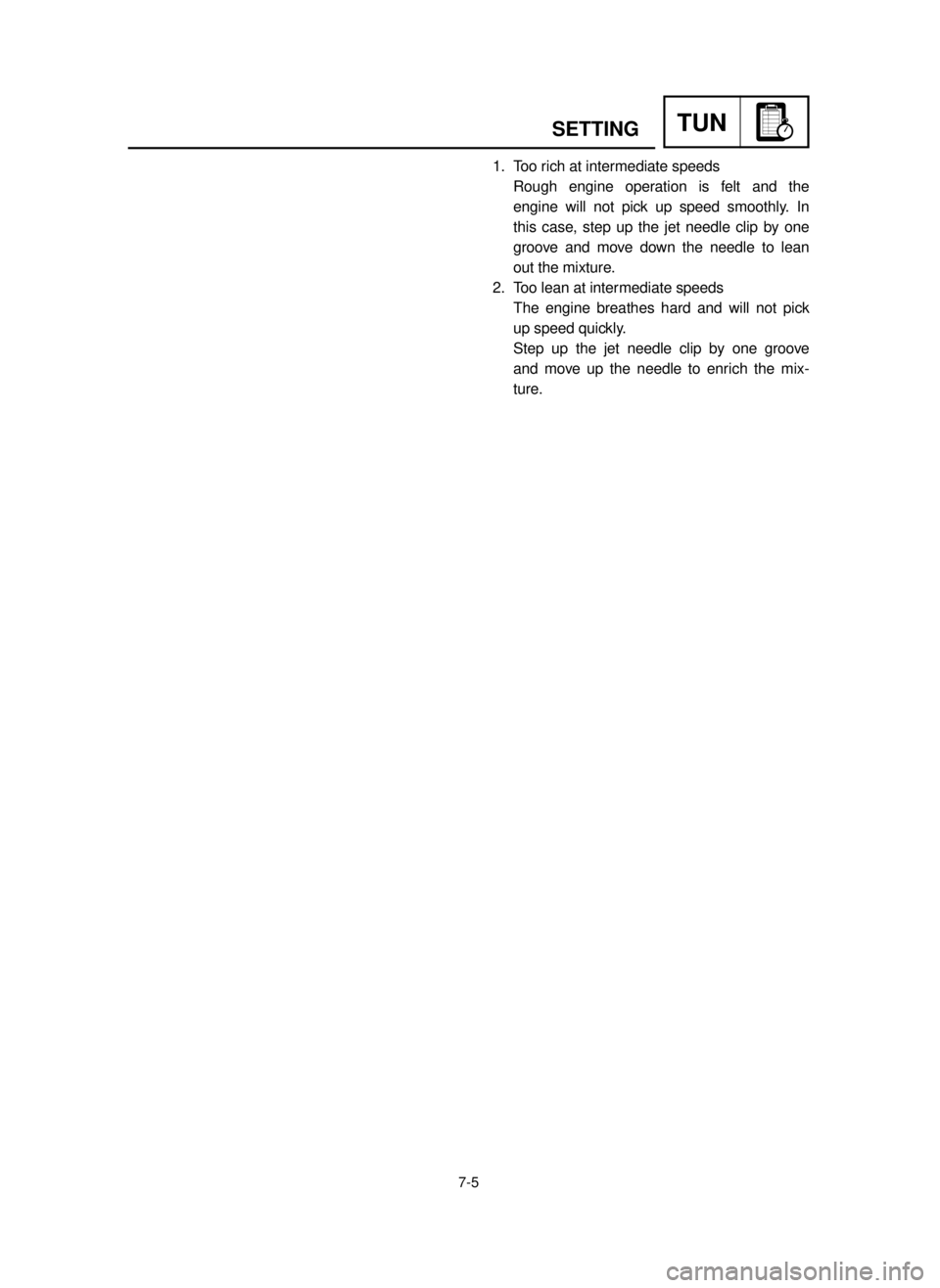

EC71R000

Pilot jet adjustment

The air-fuel mixture can basically be adjusted by

the pilot air screw from full closed to 1/8 throttle.

If the pilot air screw is not enough for this adjust-

ment, the pilot jet 1is changed.

A larger size jet results in a richer mixture at low

speeds, and a smaller size in a leaner mixture.

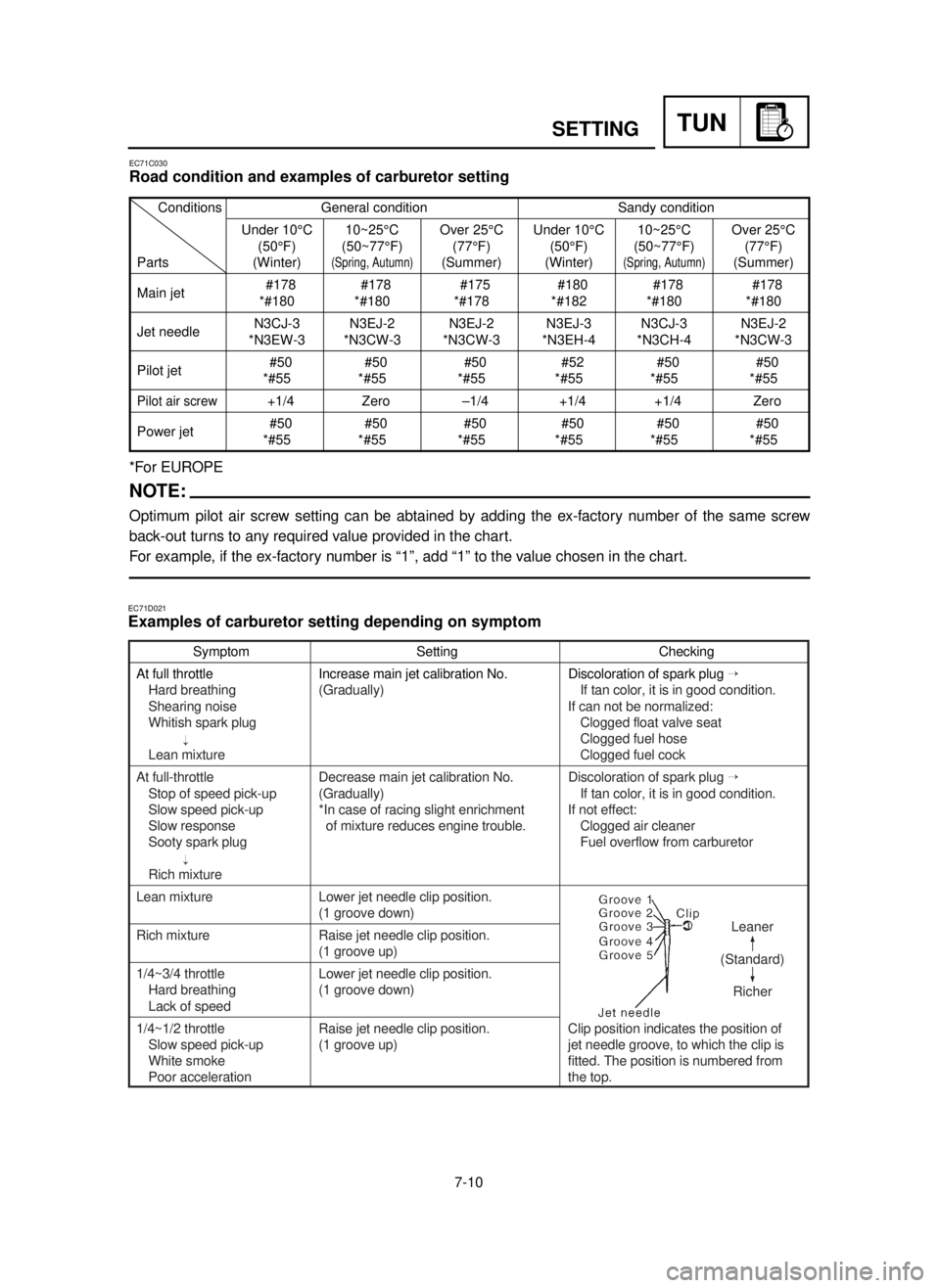

EC718001

Jet needle groove position adjustment

Should the engine be hard to run smoothly at

intermediate speeds, the jet needle 1must be

adjusted. If the mixture is too rich or too lean at

intermediate speed operation, irregular engine

operation and poor acceleration will result.

Whether or not the richness of the mixture is

proper is hard to be determined by means of the

spark plug and therefore, it should be judged

from your feeling of actual engine operation.

*For EUROPE

Standard pilot jet#50

*#55

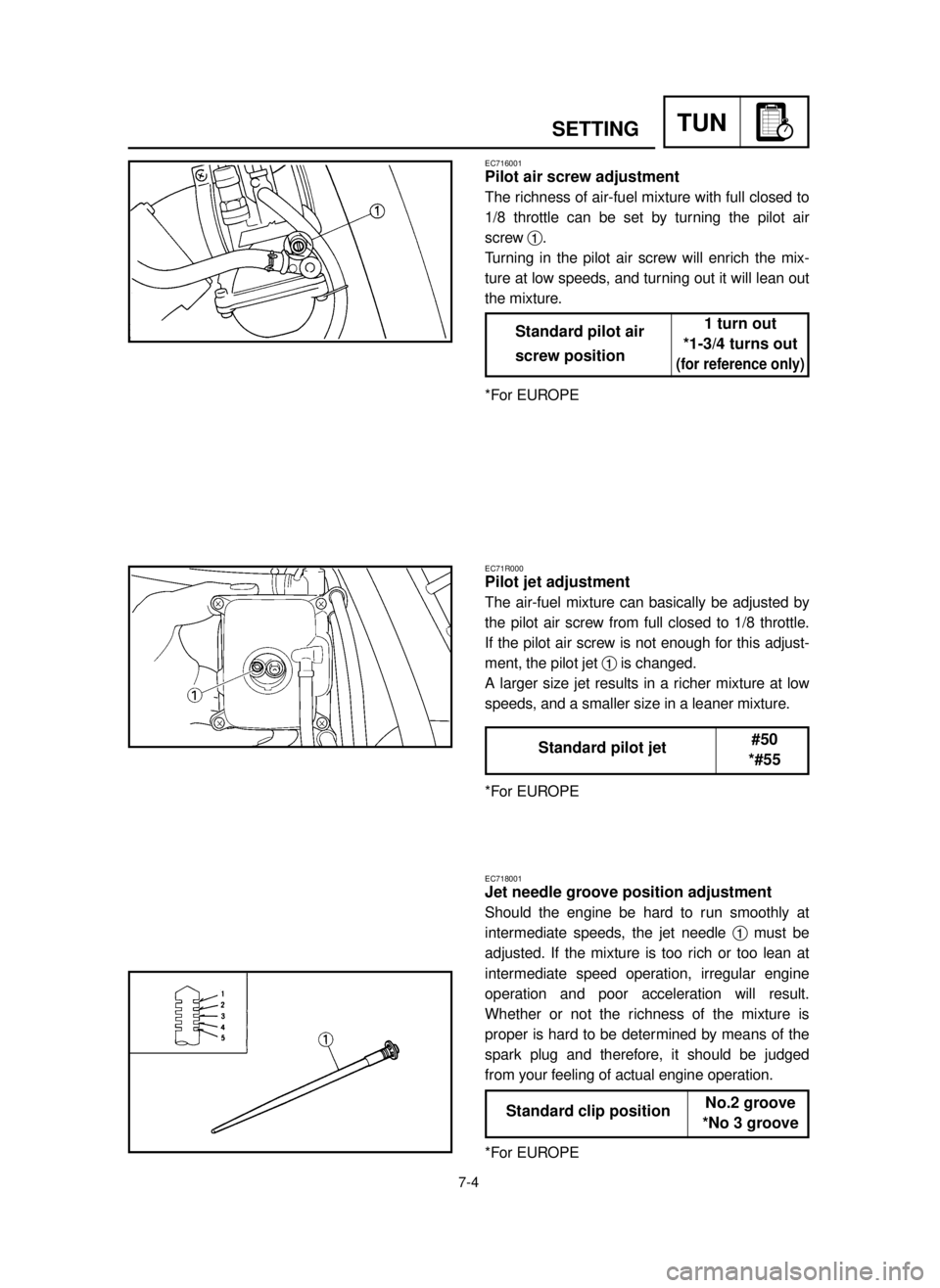

EC716001

Pilot air screw adjustment

The richness of air-fuel mixture with full closed to

1/8 throttle can be set by turning the pilot air

screw 1.

Turning in the pilot air screw will enrich the mix-

ture at low speeds, and turning out it will lean out

the mixture.

*For EUROPE

*For EUROPE

Standard pilot air1 turn out

*1-3/4 turns out

screw position

(for reference only)

Standard clip positionNo.2 groove

*No 3 groove

5MW-9-30-7 7/6/00 2:17 PM Page 8

Page 528 of 578

7-5

SETTINGTUN

1. Too rich at intermediate speeds

Rough engine operation is felt and the

engine will not pick up speed smoothly. In

this case, step up the jet needle clip by one

groove and move down the needle to lean

out the mixture.

2. Too lean at intermediate speeds

The engine breathes hard and will not pick

up speed quickly.

Step up the jet needle clip by one groove

and move up the needle to enrich the mix-

ture.

5MW-9-30-7 7/6/00 2:17 PM Page 10

Page 538 of 578

7-10

SETTINGTUN

EC71D021

Examples of carburetor setting depending on symptom

Symptom Setting Checking

At full throttle Increase main jet calibration No. Discoloration of spark plug Õ

Hard breathing (Gradually) If tan color, it is in good condition.

Shearing noise If can not be normalized:

Whitish spark plug Clogged float valve seat

Clogged fuel hose

Lean mixture Clogged fuel cock

At full-throttle Decrease main jet calibration No. Discoloration of spark plug Õ

Stop of speed pick-up (Gradually) If tan color, it is in good condition.

Slow speed pick-up *In case of racing slight enrichment If not effect:

Slow response of mixture reduces engine trouble. Clogged air cleaner

Sooty spark plug Fuel overflow from carburetor

Rich mixture

Lean mixture Lower jet needle clip position.

(1 groove down)

Rich mixture Raise jet needle clip position.

(1 groove up)

1/4~3/4 throttle Lower jet needle clip position.

Hard breathing (1 groove down)

Lack of speed

1/4~1/2 throttle Raise jet needle clip position. Clip position indicates the position of

Slow speed pick-up (1 groove up) jet needle groove, to which the clip is

White smoke fitted. The position is numbered from

Poor acceleration the top.

Leaner

(Standard)

Richer

Õ

Õ

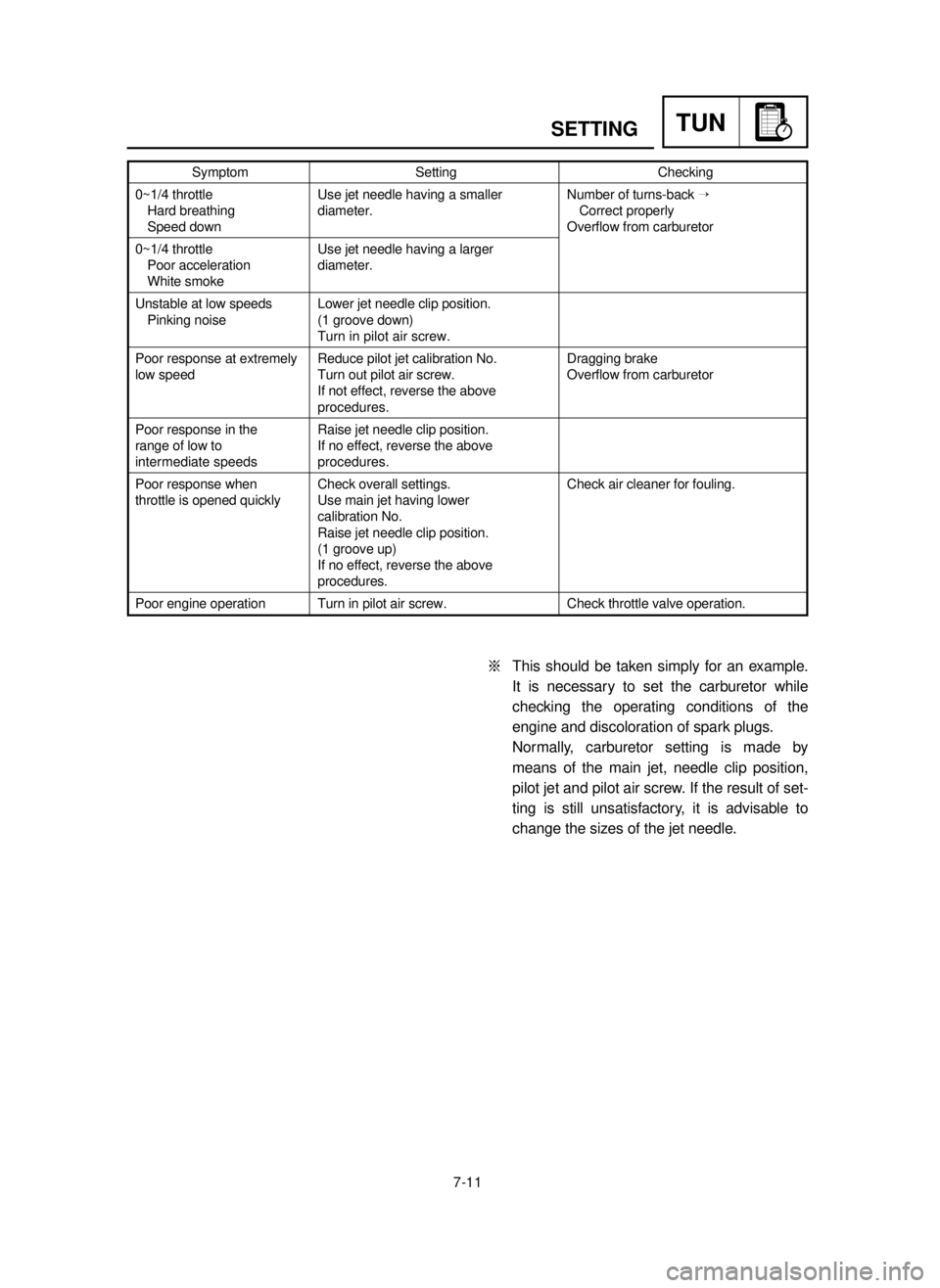

EC71C030

Road condition and examples of carburetor setting

Conditions General condition Sandy condition

Under 10°C 10~25°C Over 25°C Under 10°C 10~25°C Over 25°C

(50°F) (50~77°F) (77°F) (50°F) (50~77°F) (77°F)

Parts (Winter)(Spring, Autumn)(Summer) (Winter)(Spring, Autumn)(Summer)

Main jet#178 #178 #175 #180 #178 #178

*#180 *#180 *#178 *#182 *#180 *#180

Jet needleN3CJ-3 N3EJ-2 N3EJ-2 N3EJ-3 N3CJ-3 N3EJ-2

*N3EW-3 *N3CW-3 *N3CW-3 *N3EH-4 *N3CH-4 *N3CW-3

Pilot jet#50 #50 #50 #52 #50 #50

*#55 *#55 *#55 *#55 *#55 *#55

Pilot air screw+1/4 Zero –1/4 +1/4 +1/4 Zero

Power jet#50 #50 #50 #50 #50 #50

*#55 *#55 *#55 *#55 *#55 *#55

*For EUROPE

NOTE:

Optimum pilot air screw setting can be abtained by adding the ex-factory number of the same screw

back-out turns to any required value provided in the chart.

For example, if the ex-factory number is “1”, add “1” to the value chosen in the chart.

5MW-9-30-7 7/6/00 2:18 PM Page 20

Page 539 of 578

7-11

SETTINGTUN

Symptom Setting Checking

0~1/4 throttle Use jet needle having a smaller Number of turns-back Õ

Hard breathing diameter. Correct properly

Speed down Overflow from carburetor

0~1/4 throttle Use jet needle having a larger

Poor acceleration diameter.

White smoke

Unstable at low speeds Lower jet needle clip position.

Pinking noise (1 groove down)

Turn in pilot air screw.

Poor response at extremely Reduce pilot jet calibration No. Dragging brake

low speed Turn out pilot air screw. Overflow from carburetor

If not effect, reverse the above

procedures.

Poor response in the Raise jet needle clip position.

range of low to If no effect, reverse the above

intermediate speeds procedures.

Poor response when Check overall settings. Check air cleaner for fouling.

throttle is opened quickly Use main jet having lower

calibration No.

Raise jet needle clip position.

(1 groove up)

If no effect, reverse the above

procedures.

Poor engine operation Turn in pilot air screw. Check throttle valve operation.

This should be taken simply for an example.

It is necessary to set the carburetor while

checking the operating conditions of the

engine and discoloration of spark plugs.

Normally, carburetor setting is made by

means of the main jet, needle clip position,

pilot jet and pilot air screw. If the result of set-

ting is still unsatisfactory, it is advisable to

change the sizes of the jet needle.

5MW-9-30-7 7/6/00 2:18 PM Page 21

Page 546 of 578

7-12

SETTINGTUN

EC71M001

Change of the heat range of spark plugs

Judging from the discoloration of spark plugs, if

they are found improper, it can be corrected by

the following two methods; changing carburetor

settings and changing the heat range of spark

plug.

9In principle, it is advisable to first use spark

plugs of standard heat range, and judging from

the discoloration of spark plugs, adjust carbure-

tor settings.

9If the calibration No. of the main jet must be

changed by ±30, it is advisable to change the

heat range of spark plugs and newly select the

proper main jet.

NOTE:

9When checking the discoloration of spark

plugs, be sure to stop the engine immediately

after a run and check.

9Avoid racing.

9When changing the heat range of spark plugs,

never attempt to change it more than ±1 rank.

9When using spark plugs other than standard,

make sure of the difference in heat range and

find the equivalent to the standard.

9Note that even if the discoloration seems prop-

er, it may slightly vary with the spark plug

maker and oil in use.

Standard spark plug BR8EG/NGK

5MW-9-30-7 7/6/00 2:19 PM Page 28

Page 548 of 578

7-13

SETTINGTUN

EC720000

CHASSISEC71P002

Selection of the secondary reduction ratio

(Sprocket)

Secondary Number of driven sprocket teethreduction =

ratioNumber of drive sprocket teeth

9It is generally said that the secondary gear ratio

should be reduced for a longer straight portion

of a speed course and should be increased for

a course with many corners. Actually, however,

as the speed depends on the ground condition

of the day of the race, be sure to run through

the circuit to set the machine suitable for the

entire course.

9In actuality, it is very difficult to achieve settings

suitable for the entire course and some settings

may be sacrificed. Thus, the settings should be

matched to the portion of the course that has

the greatest effect on the race result. In such a

case, run through the entire course while mak-

ing notes of lap times to find the best balance;

then, determine the secondary reduction ratio.

9If a course has a long straight portion where a

machine can run at maximum speed, the

machine is generally set such that it can devel-

op its maximum revolutions toward the end of

the straight line, with care taken to avoid the

engine over-revving.

NOTE:

Riding technique varies from rider to rider and

the performance of a machine also vary from

machine to machine. Therefore, do not imitate

other rider’s settings from the beginning but

choose your own setting according to the level of

your riding technique.

Standard secondary

50/14 (3.571)

reduction ratio

5MW-9-30-7 7/6/00 2:29 PM Page 30