torque Abarth 124 Spider 2020 Owner handbook (in English)

[x] Cancel search | Manufacturer: ABARTH, Model Year: 2020, Model line: 124 Spider, Model: Abarth 124 Spider 2020Pages: 224, PDF Size: 3.9 MB

Page 75 of 224

ACTIVE SAFETY

SYSTEMS

The vehicle has the following active

safety systems:

ABS (Anti-lock Braking System);

TCS (Traction Contol System);

DSC (Dynamic Stability Control);

Active bonnet (active pedestrian

protection).

For the operation of the systems, see

the following pages.

ABS SYSTEM (Antilock

Brake System)

66) 67) 68) 69)

The ABS control unit continuously

monitors the speed of each wheel. If

one wheel is about to lock up, the ABS

responds by automatically releasing

and reapplying that wheel's brake.

The driver will feel a slight vibration in

the brake pedal and may hear a

chattering noise from the brake system.

This is normal ABS system operation.

Continue to depress the brake pedal

without pumping the brakes.

The warning light turns on when the

system has a malfunction. Refer to

“Warning lights and messages”

paragraph in “Knowing the instrument

panel” chapter.

NOTE Braking distances may be longer

on loose surfaces (snow or gravel, forexample) which usually have a hard

foundation. A vehicle with a normal

braking system may require less

distance to stop under these conditions

because the tires will build up a wedge

of surface layer when the wheels skid.

NOTE The sound of the ABS operating

may be heard when starting the engine

or immediately after starting the vehicle,

however, it does not indicate a

malfunction.

TCS SYSTEM (Traction

Control System)

70) 71) 72)

The Traction Control System (TCS)

enhances traction and safety by

controlling engine torque and braking.

When the TCS detects driving wheel

slippage, it lowers engine torque and

operates the brakes to prevent loss of

traction.

This means that on a slick surface, the

engine adjusts automatically to provide

optimum power to the drive wheels,

limiting wheel spin and loss of traction.

The warning light turns on when the

system has a malfunction. Refer to

“Warning lights and messages”

paragraph in “Knowing the instrument

panel” chapter.

NOTE To turn off the TSC, press the

DSC OFF switch.

TCS / DSC indicator light

Theindicator light stays on for a few

seconds when the ignition is switched

ON.

If the TCS or DSC is operating, the

indicator light flashes.

If the

light stays on, the TCS, DSC or

the brake assist system may have a

malfunction and they may not operate

correctly. Contact an Abarth Dealership.

IMPORTANT In addition to the warning

light flashing, a slight labouring sound

will come from the engine. This

indicates that the TCS/DSC is

operating properly.

IMPORTANT On slippery surfaces, such

as fresh snow, it will be impossible to

achieve high rpm when the TCS is on.

DSC SYSTEM (Dynamic

Stability Control)

73) 74) 75)

The Dynamic Stability Control (DSC)

automatically controls braking and

engine torque in conjunction with

systems such as ABS and TCS to help

control side slip when driving on

slippery surfaces, or during sudden or

evasive manoeuvring, enhancing vehicle

safety. Refer to “ABS system (Antilock

Brake System)” and “TCS system

(Traction Control System)”.

73

Page 81 of 224

When changing tires yourself:ifyou

or someone else changes tires, you or

someone else can also undertake the

steps for the TPMS to complete the ID

signal code registration:

after tires have been changed, switch

the ignition ON, then back to ACC or

OFF;

wait for about 15 minutes;

after about 15 minutes, drive the

vehicle at a speed of at least 25 km/h

for 10 minutes and the tire pressure

sensor ID signal code will be registered

automatically.

IMPORTANT If the vehicle is driven

within about 15 minutes of changing

tires, the

warning light will flash

because the sensor ID signal code

would not have been registered. If this

happens, park the vehicle for about

15 minutes, after which the sensor ID

signal code will register upon driving the

vehicle for 10 minutes.

Replacing tires and wheels

IMPORTANT When replacing/repairing

the tires or wheels or both, have the

work done by an Abarth Dealership, or

the tire pressure sensors may be

damaged.

IMPORTANT The wheels equipped on

your vehicle are specially designed for

installation of the tire pressure sensors.Do not use non-genuine wheels,

otherwise it may not be possible to

install the tire pressure sensors.

Be sure to have the tire pressure

sensors installed whenever tires or

wheels are replaced.

When having a tire or wheel or both

replaced, the following types of tire

pressure sensor installations are

possible:

the tire pressure sensor is removed

from the old wheel and installed to the

new one;

the same tire pressure sensor is used

with the same wheel. Only the tire is

replaced;

a new tire pressure sensor is installed

to a new wheel.

IMPORTANT The tire pressure sensor

ID signal code must be registered when

a new tire pressure sensor is

purchased. For purchase of a tire

pressure sensor and registration of the

tire pressure sensor ID signal code,

consult an Abarth Dealership.

IMPORTANT When reinstalling a

previously removed tire pressure sensor

to a wheel, replace the grommet (seal

between valve body/sensor and wheel)

for the tire pressure sensor.

MECHANICAL LIMITED

SLIP DIFFERENTIAL

Your vehicle is equipped with a

mechanical limited slip differential. In

particular this vehicle adopts a

super-LSD which guarantees improved

vehicle traction and handling.

A super-LSD with a low torque bias

ratio (*) has been adopted to improve

performance when starting from a

standstill, driving straight-ahead and

response.

(*)Torque bias ratio: when a wheel

slips due to a low-traction surface, the

LSD provides proportionally more

torque to the opposite wheel. The

torque bias ratio is the ratio of torque

supplied to the right and left wheels in

such cases, and represents the

performance capability of the LSD.

The super-LSD is a torque-sensing type

that provides improved driving stability

due to the following characteristics:

low torque bias ratio provides

improved controllability (torque bias

ratio: 2.0);

creation of initial torque provides

improved starting from a standstill and

acceleration/deceleration response, and

driving straight-ahead (initial torque:

49 Nm);

simplified construction provides

weight reduction.

79

Page 82 of 224

Super-LSD operation

Straight ahead driving

When driving straight, the right and left

side gears rotate at the same speed,

and the pinion and side gears rotate

together with the differential gear case.

Input force from the ring gear is

transmitted to the pinion gears via the

gear case and to the drive shaft via the

side gears. Due to this, a speed

difference between right and left in the

differential does not occur.

Differential operation

If the rotation speed between the right

and left wheels becomes different

(during normal driving), the pinion gears

rotate together while revolving around

the center axle of the drive shaft,

thereby absorbing the difference in

rotation speed. This mechanism serves

as a differential.

Limited-slip operation

If the differential encounters a condition

requiring limited-slip control such as

wheel spin, thrust force acts on the side

gears due to the reaction force from the

meshing of the pinion and side gears.

This thrust force presses the side gears

against the taper ring, generating

friction between the side gear cone and

the taper ring and reducing the torque

of the slipping wheel.The reduced torque is transmitted

without change to the wheel with higher

traction, and the limited slip differential

function is provided. The torque

transmitted to the wheel with higher

traction is proportionate to the input

torque of the ring gear.

HLA (Hill Launch Assist)

FUNCTION

80)

Hill Launch Assist (HLA) is a function

which assists the driver in accelerating

from a stop while on a slope. When the

driver releases the brake pedal and

depresses the accelerator pedal while

on a slope, the function prevents the

vehicle from rolling. The braking force is

maintained automatically after the brake

pedal is released on a steep grade.

For vehicles with a manual

transmission, Hill Launch Assist

operates on a downward slope when

the shift lever is in the reverse (R)

position, and on an upward slope when

the shift lever is in a position other than

the reverse (R) position.

For vehicles with an automatic

transmission, Hill Launch Assist

operates on a downward slope when

the selector lever is in the reverse (R)

position, and on an upward slope when

the selector lever is in a forward gear.

IMPORTANT Hill Launch Assist does

not operate on a gentle slope. In

addition, the gradient of the slope on

which the system will operate changes

depending on the vehicle's load.

IMPORTANT Hill Launch Assist does

not operate if the parking brake is

applied, the vehicle has not stopped

completely, or the clutch pedal is

released.

IMPORTANT While Hill Launch Assist is

operating, the brake pedal may feel stiff

and vibrate, however, this does not

indicate a malfunction.

IMPORTANT Hill Launch Assist does

not operate while the TCS/DSC

indicator light is illuminated. Refer to

“Warning lights and messages”

paragraph in “Knowing the instrument

panel” chapter.

IMPORTANT Hill Launch Assist (HLA)

does not turn off even if the DSC OFF

switch is pressed to turn off the

TCS/DSC.

IMPORTANT For vehicles with an

automatic transmission although the Hill

Launch Assist does not operate during

idling stop, the vehicle roll prevention

function operates to prevent vehicle roll.

80

SAFETY

Page 186 of 224

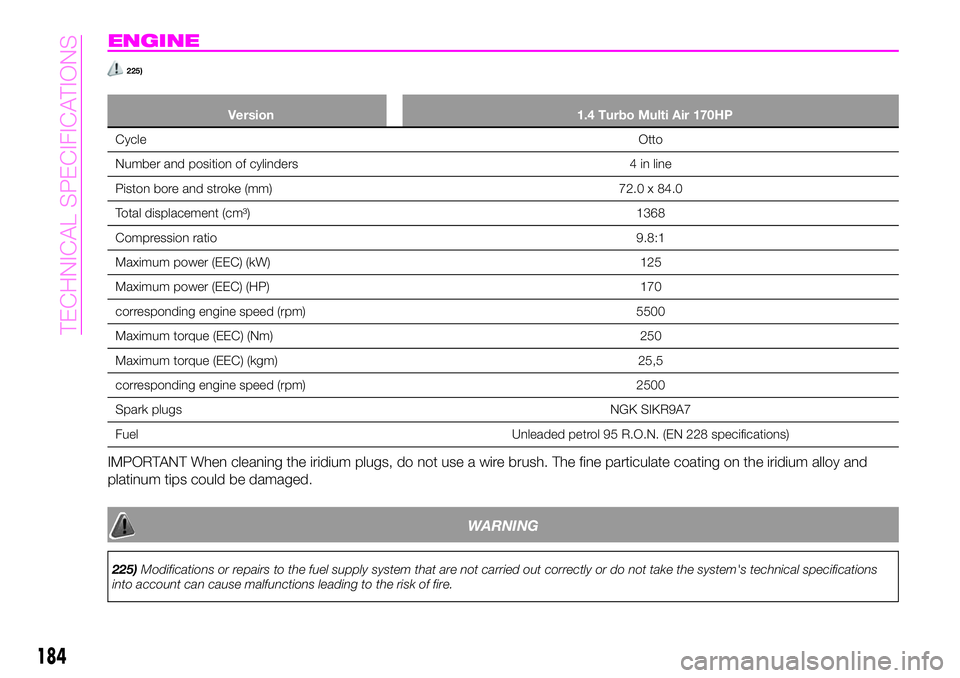

ENGINE

225)

Version 1.4 Turbo Multi Air 170HP

CycleOtto

Number and position of cylinders 4 in line

Piston bore and stroke (mm) 72.0 x 84.0

Total displacement (cm³) 1368

Compression ratio9.8:1

Maximum power (EEC) (kW) 125

Maximum power (EEC) (HP) 170

corresponding engine speed (rpm) 5500

Maximum torque (EEC) (Nm) 250

Maximum torque (EEC) (kgm) 25,5

corresponding engine speed (rpm) 2500

Spark plugsNGK SIKR9A7

Fuel Unleaded petrol 95 R.O.N. (EN 228 specifications)

IMPORTANT When cleaning the iridium plugs, do not use a wire brush. The fine particulate coating on the iridium alloy and

platinum tips could be damaged.

WARNING

225)Modifications or repairs to the fuel supply system that are not carried out correctly or do not take the system's technical specifications

into account can cause malfunctions leading to the risk of fire.

184

TECHNICAL SPECIFICATIONS