gearbox Abarth Grande Punto 2007 Owner handbook (in English)

[x] Cancel search | Manufacturer: ABARTH, Model Year: 2007, Model line: Grande Punto, Model: Abarth Grande Punto 2007Pages: 207, PDF Size: 3.01 MB

Page 81 of 207

ESP SYSTEM ACTIVATION

The ESP system is automatically activat-

ed when the car is started and cannot be

de-activated.

FAILURE INDICATIONS

In the event of failure, the ESP system is

automatically disconnected, the warning

light

á, comes on with fixed light on the

instrument panel, together with the mes-

sage on the multifunction display (where

provided) (see section “Warning lights and

messages”) and with the button led ASR

OFF. In this case contact a Abarth Deal-

ership as soon as possible.

Performance of the ESP sys-

tem, in terms of active safe-

ty should not induce the driver to take

pointless and unnecessary risks. The

style of driving must in any case al-

ways be adapted to the conditions of

the road surface, visibility and traffic.

Road safety is always the driver’s re-

sponsibility.

WARNING

79

SAFETY

DEVICES

CORRECT USE

OF THE CAR

WARNING

LIGHTS AND

MESSAGES

IIN AN

EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

HILL HOLDER SYSTEM

This system is an integral part of the ESP

system and it is provided to facilitate start-

ing on slopes.

It will activate automatically with the fol-

lowing conditions:

❒uphill: vehicle stationary on a road with

a gradient of more than 5%, engine run-

ning, brake pressed and gearbox in neu-

tral or gear other than reverse engaged;

❒downhill: vehicle stationary on a road

with a gradient of more than 5%, engine

running, brake pressed and reverse gear

engaged.

Page 111 of 207

109

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

ENGINE STARTING ........................................................... 110

PARKING THE CAR ............................................................ 112

USING THE MANUAL GEARBOX ................................. 113

CONTAINING RUNNING COSTS................................. 114

TOWING TRAILERS............................................................ 116

SNOW CHAINS ................................................................... 119

CAR INACTIVITY ............................................................... 120

C C

O O

R R

R R

E E

C C

T T

U U

S S

E E

O O

F F

T T

H H

E E

C C

A A

R R

Page 115 of 207

113

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

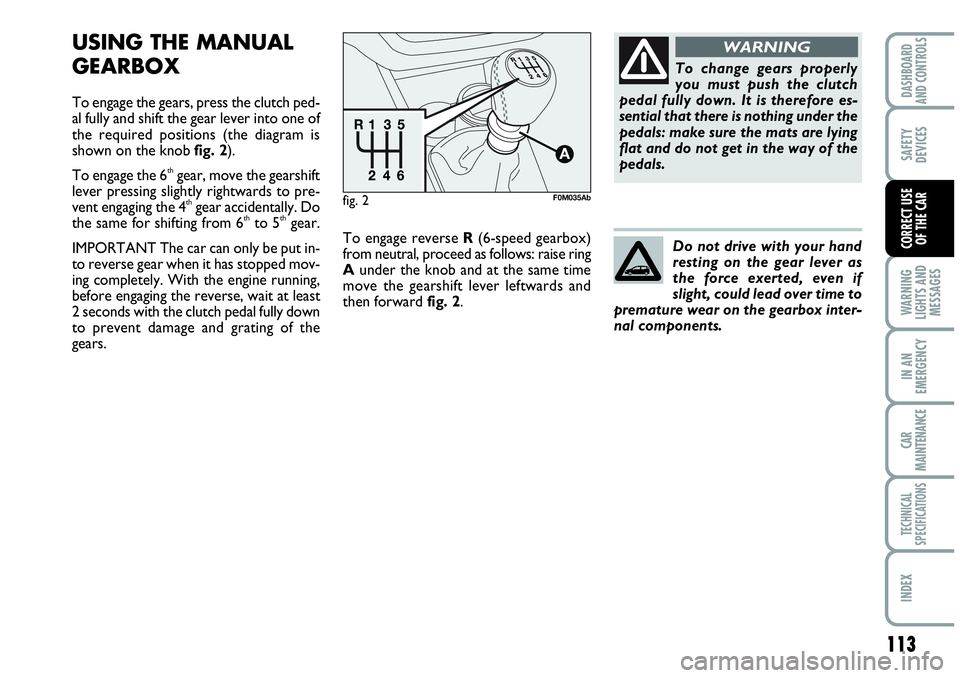

USING THE MANUAL

GEARBOX

To engage the gears, press the clutch ped-

al fully and shift the gear lever into one of

the required positions (the diagram is

shown on the knob fig. 2).

To engage the 6

thgear, move the gearshift

lever pressing slightly rightwards to pre-

vent engaging the 4

thgear accidentally. Do

the same for shifting from 6thto 5thgear.

IMPORTANT The car can only be put in-

to reverse gear when it has stopped mov-

ing completely. With the engine running,

before engaging the reverse, wait at least

2 seconds with the clutch pedal fully down

to prevent damage and grating of the

gears.

To change gears properly

you must push the clutch

pedal fully down. It is therefore es-

sential that there is nothing under the

pedals: make sure the mats are lying

flat and do not get in the way of the

pedals.

WARNING

Do not drive with your hand

resting on the gear lever as

the force exerted, even if

slight, could lead over time to

premature wear on the gearbox inter-

nal components.To engage reverse R (6-speed gearbox)

from neutral, proceed as follows: raise ring

Aunder the knob and at the same time

move the gearshift lever leftwards and

then forward fig. 2.

fig. 2F0M035Ab

Page 136 of 207

134

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

ENGINE

STARTING

EMERGENCY START-UP

If the

Ysign keeps being displayed, im-

mediately call the Abarth Dealership.

JUMP STARTING fig. 1

If the battery is flat, it is possible to start

the engine using an auxiliary battery with

the same capacity or a little higher than

the flat one. Proceed as follows:

❒connect positive terminals (+near the

terminal) of the two batteries with a

jump lead;

❒with a second lead, connect the nega-

tive terminal (–) of the auxiliary battery

to an earthing point

Eon the engine or

the gearbox of the car to be started;

❒ start the engine;

❒when the engine has been started, re-

move the leads reversing the order

above.

If after a few attempts the engine does not

start, do not insist but contact the near-

est Abarth Dealership.

IMPORTANT Do not directly connect the

negative terminals of the two batteries:

sparks could ignite the flammable gas from

the battery. If the other battery is fitted in

another car, prevent accidental contacts

between the metal parts of the two cars.BUMP STARTING

Never bump start the engine (by pushing,

towing, or coasting downhill) as this could

cause fuel to flow into the catalytic ex-

haust system and damage it beyond repair.

IMPORTANT Remember that the brake

booster and the power steering system

are not operating until the engine is start-

ed, a greater effort will therefore be re-

quired to press the brake pedal or turn

the steering wheel.

The starting procedure must

be carried out by qualified

personnel because incorrect opera-

tions may cause electrical discharge of

considerable intensity. The liquid con-

tained in the battery is poisonous and

corrosive. Avoid contact with the skin

and eyes. Keep naked flames and light-

ed cigarettes away from the battery

and do not cause sparks.

WARNING

fig. 1F0M104Ab

Page 167 of 207

USE OF THE CAR

UNDER HEAVY

CONDITIONS

Should prevailing use of the car be under

one of the following specially heavy con-

ditions:

❒trailer or caravan towing;

❒dusty roads;

❒short distances (less than 7-8 km) and

repeated with external temperatures

below zero;

❒frequently idling engines or long dis-

tance low speed driving (e.g.: door-to-

door deliveries) or in case of a long

term inactivity;

❒urban routes;

carry out checks more frequently than re-

quired on Service Schedule:

❒check front disk brake pad conditions

and wear;

❒check cleanness of bonnet and boot

locks and lever cleanness and lubrica-

tion;

❒sight inspect the conditions of: engine,

gearbox, transmission, pipes and hoses

(exhaust - fuel - brakes), rubber parts

(boots, sleeves, bushes, etc.);

❒check battery charge and fluid level

(electrolyte);

❒visual check on various drive belt con-

ditions;

❒check and replace pollen filter, if re-

quired;

❒check and replace air cleaner, if re-

quired.

PERIODICAL CHECKS

Every 1,000 km or before long journeys,

check and top up if required:

❒engine coolant fluid level;

❒brake fluid level;

❒windscreen washer fluid level;

❒tyre pressure and conditions;

❒check light system operation (head-

lights, direction indicators, hazard

lights, etc.);

❒check windscreen wiper/washer op-

eration and windscreen/rear window

blade position/wear.

Every 3,000 km check and top up if re-

quired: engine oil level.

You are recommended to use FL Selenia

products, designed and produced specifi-

cally for Abarth cars (see table “Capaci-

ties” in section “Technical specifications”).

165

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

CAR

MAINTENANCE

Page 187 of 207

185

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

Modifications or repairs to the fuel feed system that are not carried out properly or do not take the system’s

technical specifications into account can cause malfunctions leading to the risk of fire.

WARNING

FUEL FEED/IGNITION

1.4 T-JET

Fuel feed Multipoint electronic injection

TRANSMISSION

1.4 T-JET

Gearbox Six forward gears and reverse with synchromesh for forward gear engagement

Clutch Self-adjusting pedal without idle stroke

Drive Front

Page 194 of 207

192

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

1.4 T-JET

45

5 ÷ 7

6

2.4

2.6

2

0.5

2.2

CAPACITIES

Fuel tank: litresincluding a reserve of: litres

Engine cooling system: litres

Engine sump: litresEngine sump and filter: litres

Gearbox/differential casing litres

Hydraulic brake circuit: kg

Windscreen, rear window

andheadlight washer litres

(❑) For particularly hard climate conditions, we recommend use of a 60% Paraflu UP and 40% demineralized water mixture.

Specified fuels and

original lubricants

Unleaded petrol with no less than 95 R.O.N.

(EN 228 Specification)

Mixture of 50% water and

PARAFLU UP

(❑)

SELENIA ABARTH 10W50

TUTELA CAR MATRYX

TUTELA TOP 4

Mixture of water and

TUTELA PROFESSIONAL SC 35

Page 196 of 207

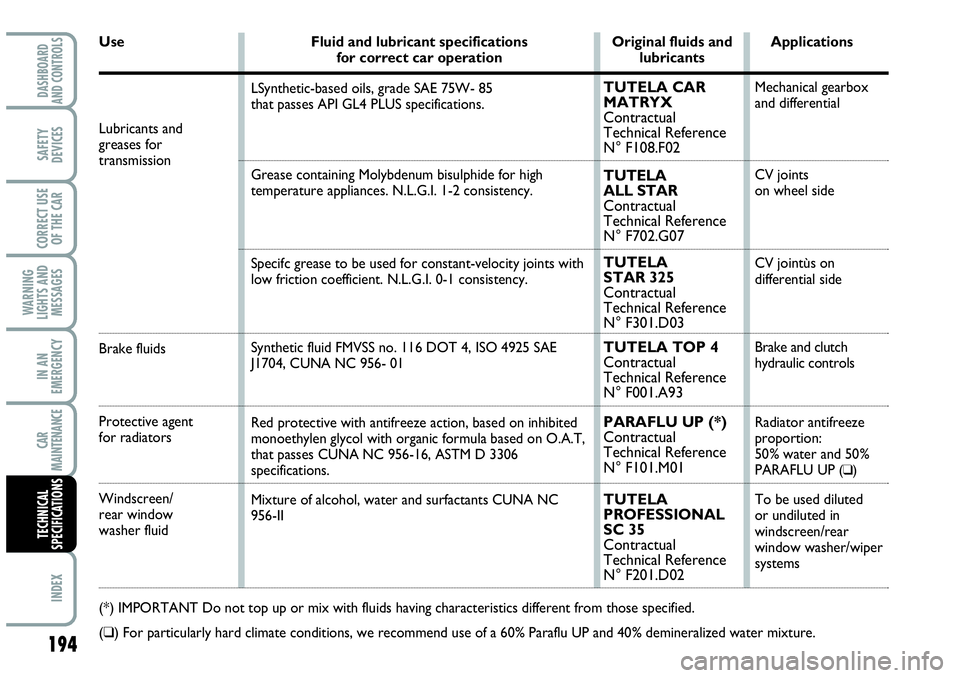

Lubricants and

greases for

transmission

194

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

Use Fluid and lubricant specifications Original fluids and Applicationsfor correct car operation lubricants

Brake fluids

Protective agent

for radiators

Windscreen/

rear window

washer fluid

(*) IMPORTANT Do not top up or mix with fluids having characteristics different from those specified.

(❑) For particularly hard climate conditions, we recommend use of a 60% Paraflu UP and 40% demineralized water mixture. LSynthetic-based oils, grade SAE 75W- 85

that passes API GL4 PLUS specifications.

Grease containing Molybdenum bisulphide for high

temperature appliances. N.L.G.I. 1-2 consistency.

Specifc grease to be used for constant-velocity joints with

low friction coefficient. N.L.G.I. 0-1 consistency.

Synthetic fluid FMVSS no. 116 DOT 4, ISO 4925 SAE

J1704, CUNA NC 956- 01

Red protective with antifreeze action, based on inhibited

monoethylen glycol with organic formula based on O.A.T,

that passes CUNA NC 956-16, ASTM D 3306

specifications.

Mixture of alcohol, water and surfactants CUNA NC

956-II

TUTELA CAR

MATRYX

Contractual

Technical Reference

N° F108.F02

TUTELA

ALL STAR

Contractual

Technical Reference

N° F702.G07

TUTELA

STAR 325

Contractual

Technical Reference

N° F301.D03

TUTELA TOP 4

Contractual

Technical Reference

N° F001.A93

PARAFLU UP (*)

Contractual

Technical Reference

N° F101.M01

TUTELA

PROFESSIONAL

SC 35

Contractual

Technical Reference

N° F201.D02Mechanical gearbox

and differential

CV joints

on wheel side

CV jointùs on

differential side

Brake and clutch

hydraulic controls

Radiator antifreeze

proportion:

50% water and 50%

PARAFLU UP

(❑)

To be used diluted

or undiluted in

windscreen/rear

window washer/wiper

systems

Page 200 of 207

198

WARNING

LIGHTS AND

MESSAGES

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

Fiat CODE system............................. 7

Fix & Go automatic ............................ 135

Fluid levels ............................................ 166

Fluids and lubricants ........................... 193

Front ceiling lights

– bulb replacement ........................... 146

– control ............................................ 54

Front fog lights

– bulb replacement .......................... 143

– control button .............................. 55

Fuel

– consumption................................... 195

– cut-off system................................. 57

– level gauge ....................................... 15

Fuel cut-off system.............................. 88

Fuel filler cap ....................................... 89

Fuel level gauge ................................... 15

Fuses (replacement) ........................... 148

Gearbox

– using manual gearbox .................. 113

Glove box/oddment compartment .. 59

Handbrake .......................................... 112Hazard lights ........................................ 55

Head restraints..................................... 30

Headlights.............................................. 74

Heated rear window .......................38-46

Identification data .............................. 182

Ignition switch ..................................... 13

In an emergency .................................. 134

Instrument panel ................................. 13

Instruments .......................................... 14

Interior fittings .................................... 179

Interiors ................................................ 179

Isofix (child restraint system) .......... 102

Jacking the car .................................... 158

Key with remote control ................ 8

Key without remote control ........... 10

Keys ........................................................ 8

Load limiters ...................................... 94

Manual climate control system ...... 34

Number plate light ............................ 145 Dipped beam headlights

– bulb replacement ........................... 142

– control ............................................ 47

Direction indicators

– control ............................................ 48

– front bulb replacement ............... 142

– rear bulb replacement ................. 143

– side bulb replacement ................. 143

Doors ..................................................... 64

Electrical socket ................................ 60

Engine

– identification code ........................ 184

– marking ........................................... 182

– technical data ................................ 184

Engine coolant temperature gauge .. 15

Engine oil

– consumption .................................. 167

– level check....................................... 167

– specifications ................................. 193

EOBD system ...................................... 83

ESP system............................................ 78

External lights ...................................... 47

Page 202 of 207

200

WARNING

LIGHTS AND

MESSAGES

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

Tyres

– changing .......................................... 135

– maintenance .................................. 173

– standard tyres ................................ 189

– understanding tyre marking ....... 187

Using the manual gearbox .............. 113

Weights .............................................. 191

Wheel..................................................... 181

Wheel geometry ................................. 187

Wheel rims

– understanding rim marking ........ 187

Window (washing/cleaning) ............. 49

Window winders ................................. 66

Windscreen/rear window/

headlight washer fluid level ............ 168

Windscreen/rear window

wiper blades ...................................... 174

Windscreen washer

– control ............................................ 49

Windscreen wiper

– blades .............................................. 174

– control ............................................ 49

– nozzles ............................................ 175Wiring for navigation system

(My Port) ............................................ 88