Valve ACURA INTEGRA 1994 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1994, Model line: INTEGRA, Model: ACURA INTEGRA 1994Pages: 1413, PDF Size: 37.94 MB

Page 644 of 1413

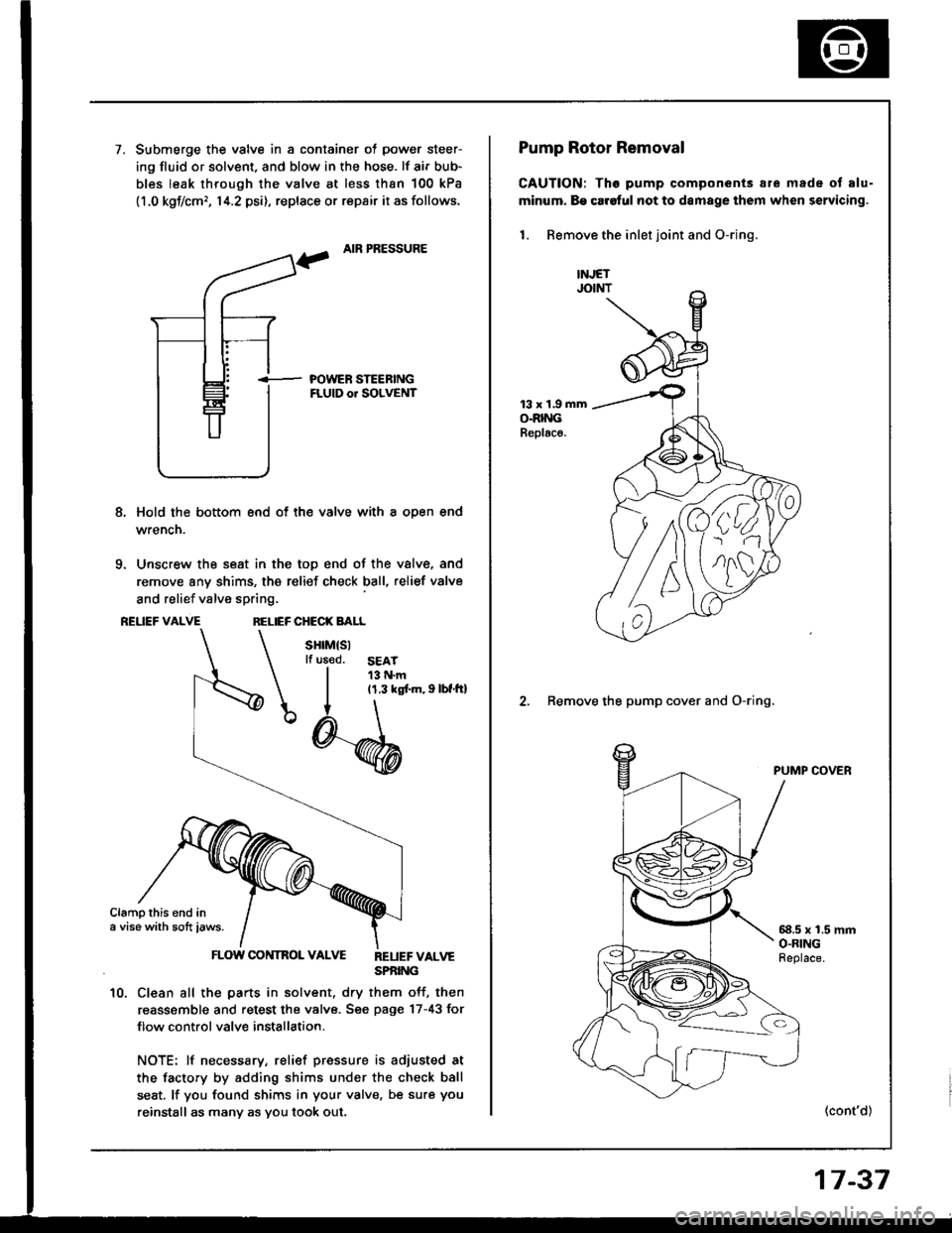

7.Submerge the valve in a container of power steer-

ing fluid or solvent, and blow in the hose. lf air bub-

bles leak through the valve at less than 100 kPa

11.0 kgf/cm,, 14.2 psi), replace or repair it as follows.

AIR PRESSURE

i- POWER STEEBINGFLUID or SOLVENT

8, Hold the bottom end of th€ valve with a oDen end

wrencn.

9. Unscrew the seat in the top end of the valve, and

remove any shims, the relief check ball, relief valve

and relief valve spring,

REUEF VALVERELIEF CHECK BALL

sHrM(sllf us€d.SEAT13 N.m11.3 ks[.m, I lbf.tt]

Clampthis end ina vise with sott iaws.

FLOW CONTROL VALVE REUEFvALvESPBING

10. Clean all the parts in solvent, dry them off, then

reassemble and retest the valve. Sge page 17-43 for

f low control valve installation.

NOTE: lf necessary, relief pressure is adiusted at

the facto.y by adding shims under the check ball

seat. lf you found shims in your valve, be sure you

reinstall as many as you took out,

')4.

nlll

Pump Rotor Removal

CAUTION: Tho pump components are made ot alu-

minum. B€ car6ful not to damage them when servicing.

1. Remove the inlet joint and O-rjng.

13 x 1.9 mmO.RINGReplac€.

2. Remove the pump cover and O-ring.

PUMP COVER

58.5 x 1.5 mmO.RINGFeplace.

(cont'd)

17-37

Page 647 of 1413

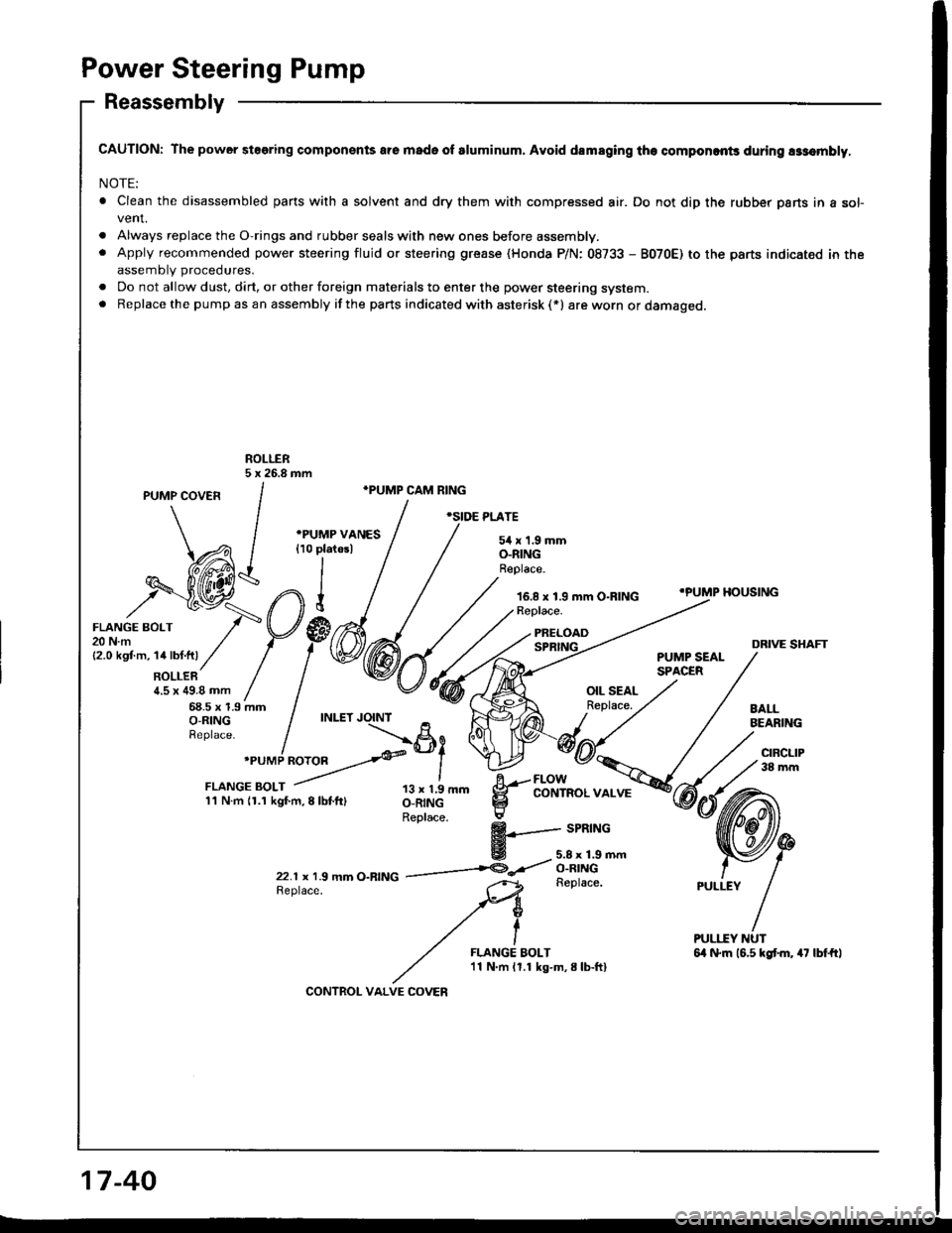

Power Steering Pump

Reassembly

CAUTION: The power steering componsnts are mado of sluminum. Avoid dsmaging th€ componcnts during assombly,

NOTE:

. Clean the disassembled pans with a solvent and dry them with compressed air. Do not dip the rubber parts in a sofvent.

. Always replace the O-rings and rubber seals with new ones before assembly.. Apply recommended power steering fluid or steering grease (Honda P/N: 08733 - B070E) to the parts indicated in theassemblv procedures.

. Do not allow dust, dirt, or other foreign materials to enter the power steering system.. Replacethe pump asan assembly ifthe parts indicated with asterisk (*) are worn or damaged.

ROLLER5 x 26.8 mm

PUMP covEn /

."'MP cAM RING

, / .",or r*r,

^ / -e^urrae vrues / / sirx1.smm

\Al {ro pratesl I / o_nrNc

dA-h1//EZil*l///'^ee'ace

o-ntNGReplace.

16.8 x 1.9 mm O-RING

\A I {ro Platesl

,h$;@:",n1

i'"otr

/-V#mtt.m,1a|t�t.fti// / / \E

RoLLER / |a.5 x ag.a mm / |68.5 x 1.9 mm Io-RING / INLET

Reptace.

I

.PUMP HOUSING

xf:.i'/pp@6{fr;ryDRIVE SHAFTPUMP SEALSPACERROLLER /1.5 x 49.8 mm /68.5 x 1.9 mmO-R|NG / INLET JO-INT

Replace.

I'PUMP ROTOR>ei

iiij:f:,ll-T;-,",,,, ll;il'- g--lblY""."*";

Replace. :

$+--- srntnc

E -5.8x1.9mm

22.r x r.9 mm o-RfNG ------t@-<'t o^::t:\-GReplace.Replace.

FLANGE BOLT'11 N.m 11.1 kg-m,8lb-ftI

17-40

CONTROL VALVE COVEN

Page 650 of 1413

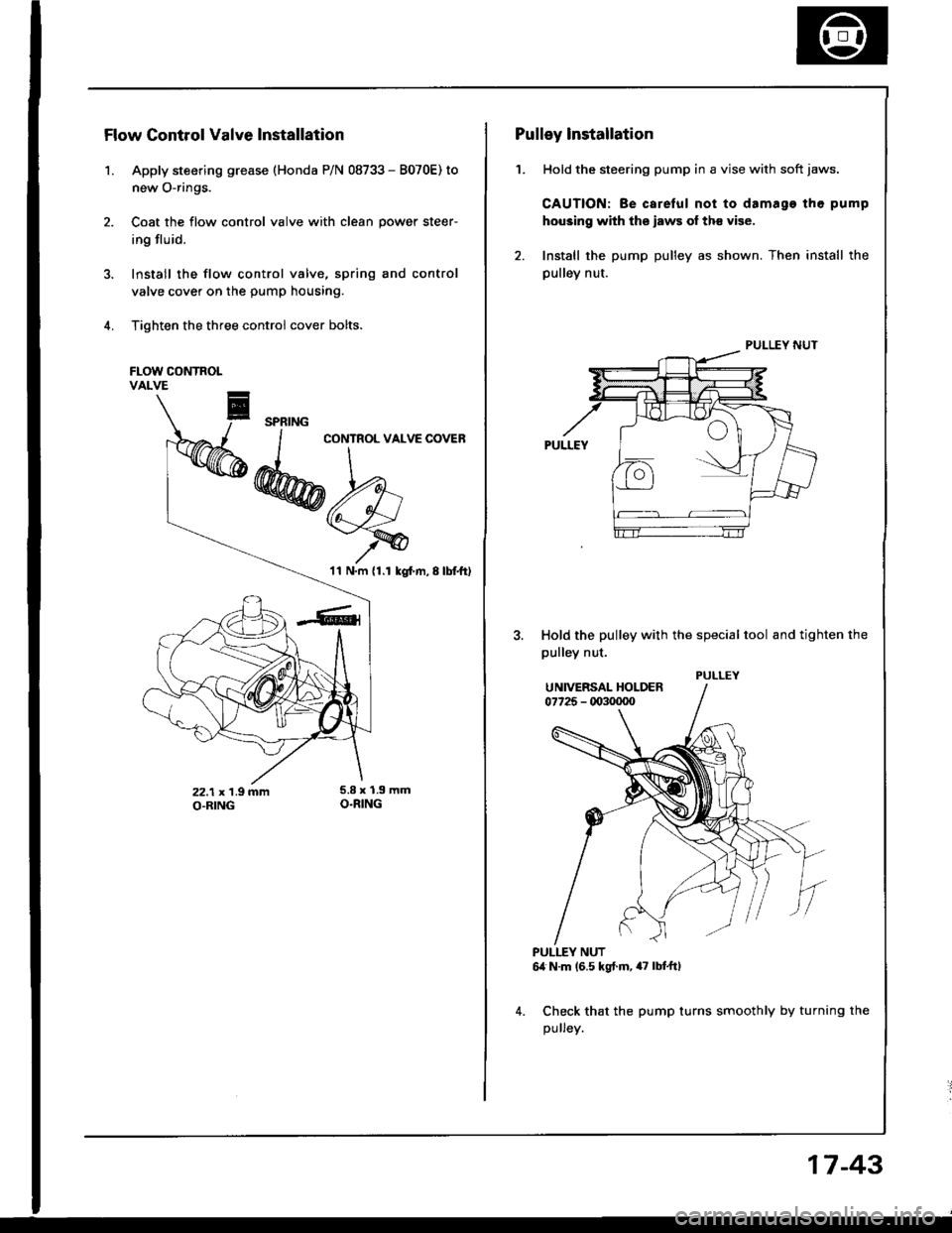

Flow Gontrol Valve Installation

1. Apply steering grease (Honda P/N 08733 - B070E) to

new O-rings.

2. Coat the flow control valve with clean power steer-

ing fluid.

3. Install the flow control valve, spring and control

valve cover on the pump housing.

4. Tighten the three control cover bolts.

FLOW CONTROLVALVE

SPRING

E;W

11 N.m {1.1 kgl.m,8lbtftl

2

Pulley Installation

1. Hold the steering pump in a vise with soft jaws.

CAUTION: Be careful not to damago the pump

hou3ing with the laws ol th€ vise.

2. Install the pump pulley as shown. Then install the

pulley nut.

Hold the pulley with the special tool and tighten the

pulley nut.

PULLEY NUT6ir N.m (6.5 kgt.m,47 lbt tt)

Check that the pump turns smoothly by turning the

pulrey.

PULLEY NUT

PULLEY

17-43

Page 652 of 1413

Steering Gearbox

Removal

NOTE: Using solvent and a brush, wash any oil and dirt

off the valve body unit, its lines, and the end if the gear-

box. Blow dry with compressed air.

1. Drain the power steering fluid as described on page

17 -21.

2. Rsise the front of car, and support on safety stands

in the propsr locations (see section 1).

3. Remove the front wheels.

il. Removs the st€ering joint cove.,

SIEERING JOIi{T COVEB

Remove the steering joint lower bolt, and move thejoint toward the column.

NOTE: Lock the steering shaft with the ignition key

to retain the steering shaft position.

Remove the cotter pin trom the castle nut and

removo the nut.

Installthe 10 mm hex nut on the balljoint.

Be sure that ths 10 mm hex nut is flush with the ball

ioint pin end, or the threaded section of the ball

ioint pin might be damaged by the ball iointremover.

NOTE: Remove the ball joint using the Ball Joint

Remover, 28 mm {07MAC - 5100200}. Refer to page

l8-11 fot how to use the ball joint rcmover,

Separat€ the tie-rod ball joint and knuckle using the

soscialtool.

CAUTION: Avold d.maging th. blllloint boot.

BALL JOlt{T REMOVER. 28 mm07MAC - SLqt2|X)

Disconnect the shift linkage {MfI model: see section

13, A/[ model see section 14).

Disconnect the heated oxygen sensor (H02S) con-

ngctor, and separate the three way catalytic conver-

ter by removing the s€lf-locking nuts.

NOTE: Always replace the gaskets with new ones.

OXycEt{S€NSOnOONNECTOR SELF.LOCKINGNUT

{cont'd)IHREE WAYCA?ALYTIC CONVERTEN

8.

10.

HEATED

Replacs.

17-45

Page 653 of 1413

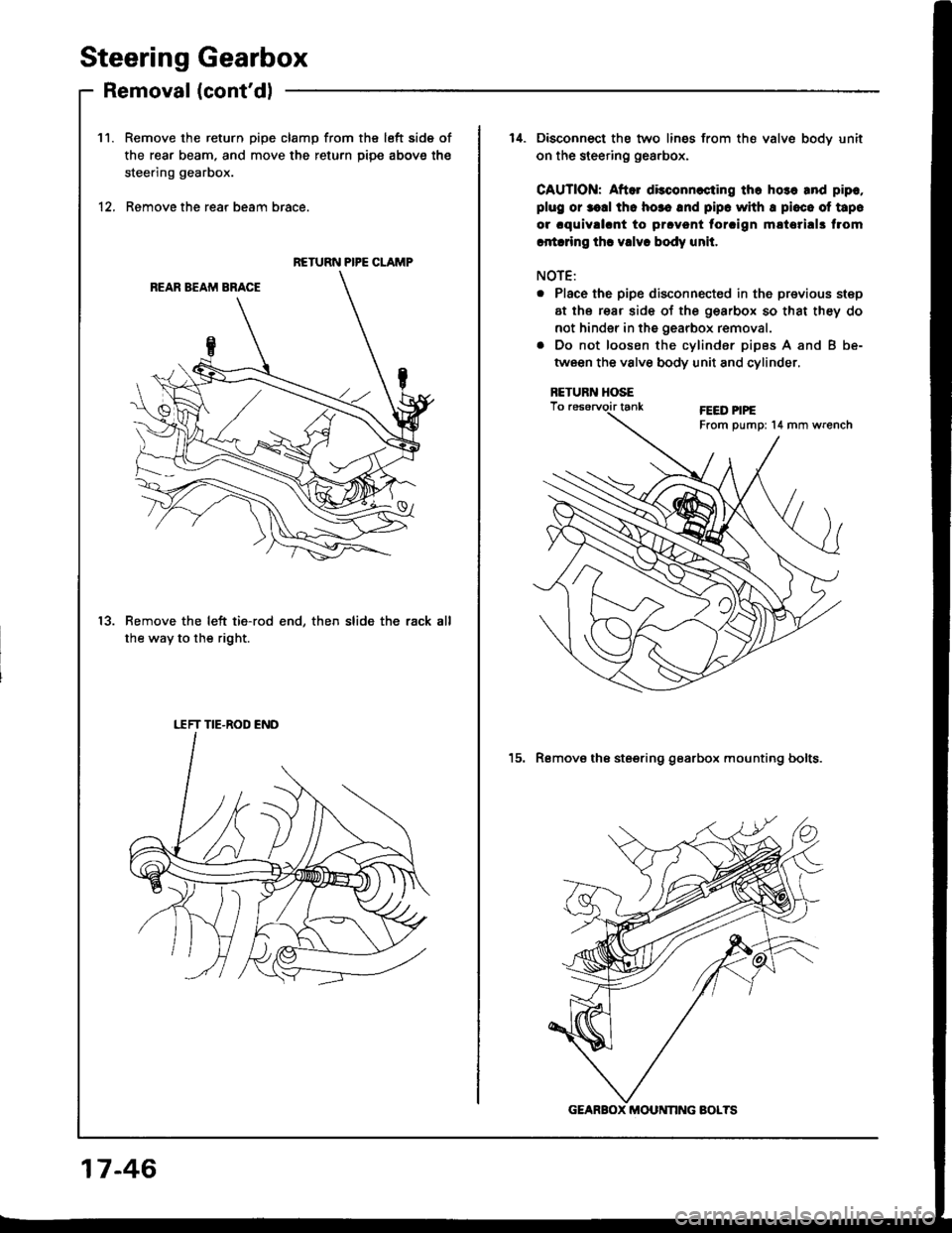

Steering Gearbox

Removal (cont'dl

Remove the return pipe clamp from the left side of

the rear beam. and move the return piDe above the

steering gearbox.

Remove the rear beam brace.

Remove the left tie-rod end, then slide the rack

the way to the right.

11.

12.

RETURN PIPE CLAMP

13.

I.TFT TIE-ROD END

14. Disconnect the two lines from th€ valve bodv unit

on the steering gea.box.

CAUTION: Aftor dkconnccting tho ho3o and pip.,

plug or r.d thc ho3. rnd pipc whh I pioco of tapo

or .quivll.nt to prcvont torcign m!tori!|3 f.om

ritrdng thc vdv. body unit.

NOTE:

. Place the pipe disconnected in the previous step

at the rear side of the gearbox so that they do

not hinder in the gearbox removal.

. Do not loosen the cylinder pipes A and B be-

tween the valve body unit and cylinder,

RETUR]T HOSE

15. Remove the steering gearbox mounting bolts.

GEARBOX MOU NNG BOLTS

17-46

Page 656 of 1413

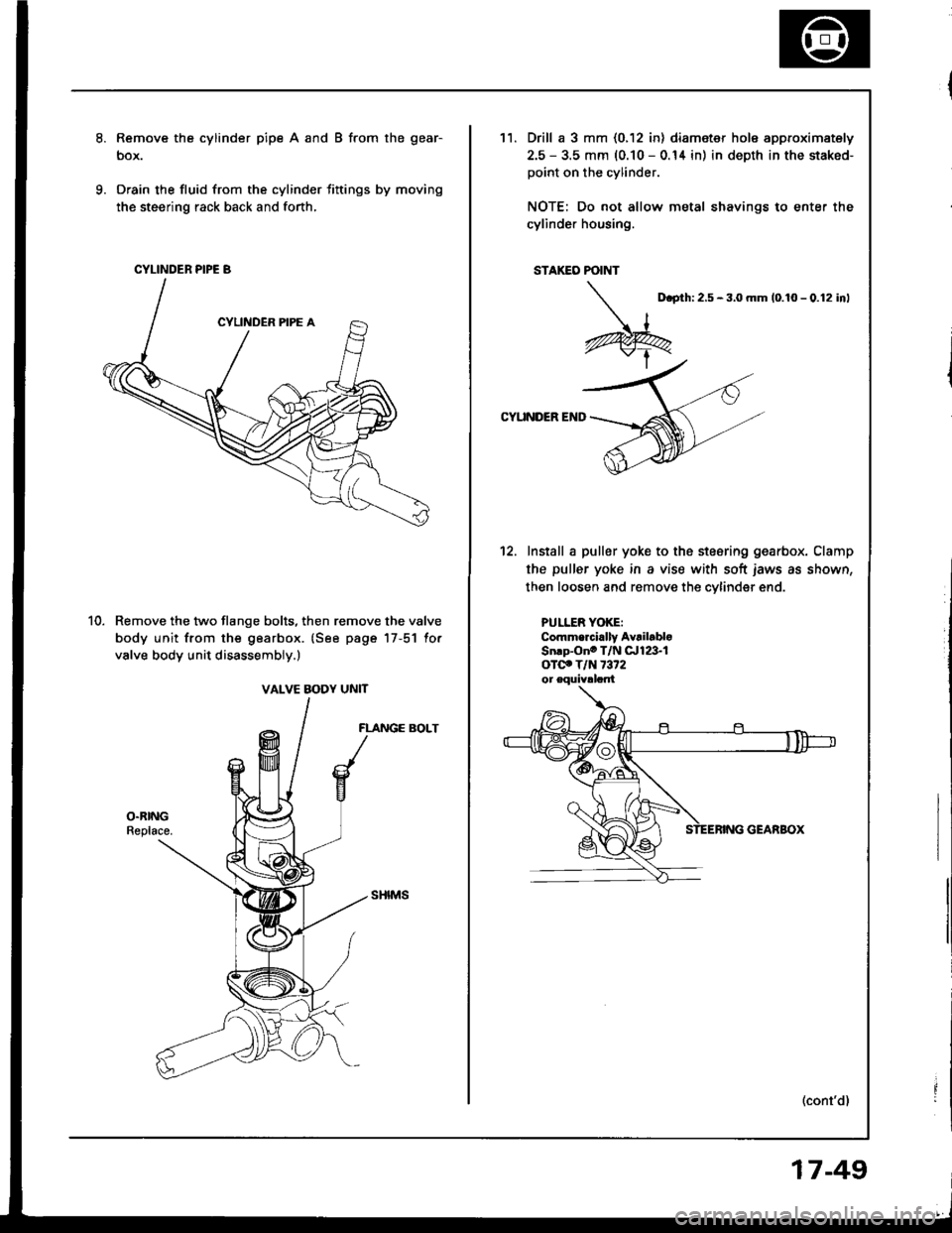

Remove the cylinder pipe A and B from the gear-

box.

Drain the fluid from the cylinder fittings by moving

the steering rack back and forth,

Remove the two flange bolts, then remove the valve

body unit from the gearbox. {See page 17-51 for

valve body unit disassembly.)

FLANGE BOLT

CYLINDER PIPE B

VALVE BODY UNIT

11.Drill a 3 mm {0.12 in) diameter hole approximately

2.5 - 3.5 mm (0.10 - 0.14 in) in depth in the staked-

point on the cylinder.

NOTE: Do not allow metal shavings to enter the

cylinder housing.

STAKEO POINT

D.prh:2.5 - 3,0 mm 10.10 - 0.12 inl

CYUNDER END

12. Install a puller yoke to the stesring gearbox. Clamp

the puller yoke in a vise with soft iaws as shown,

then loosen and remove the cvlinder end.

PULLER YOKE:Commercirlly AvrilabloSn.p-Ono T/N qrie'-1

oTclo T/N 7372

(cont'd)

17-49

Page 658 of 1413

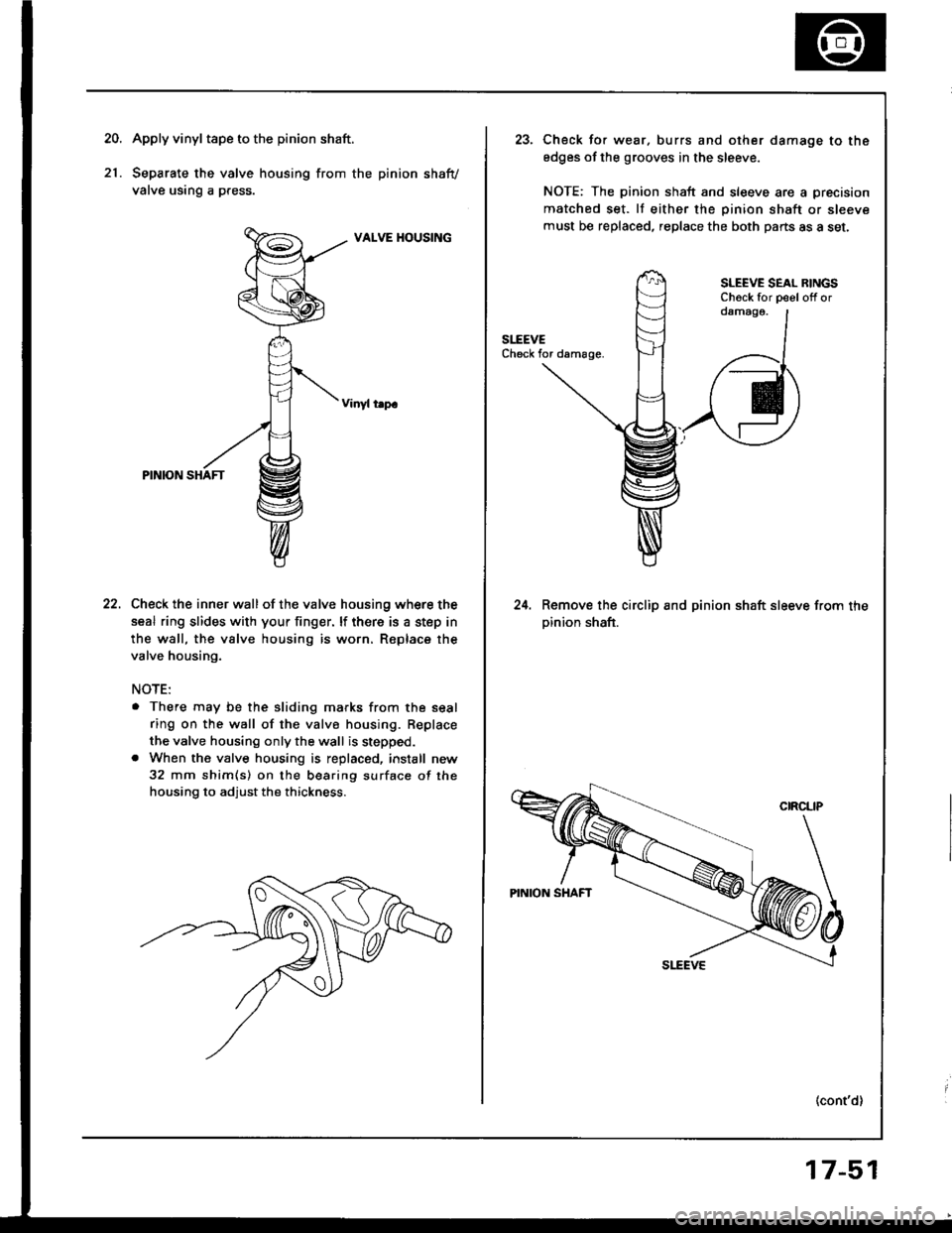

20.Apply vinyl tape to the pinion shaft.

Separate the valve housing from the pinion shafv

valve using a press.

VALVE HOUSING

Vinyl t.p.

Check the inner wall of the valve housing where the

seal ring slides with your finger. lf there is a step in

the wall, the valve housing is worn. Replace the

valve housing.

NOTE:

There may be the sliding marks from the seal

ring on the wall of the valve housing. Replace

the valve housing only the wall is stepped.

When the valve housing is replaced, install new

32 mm shim(s) on the bearing surface of the

housing to adjust the thickness.

21.

22.

23. Check fo. wear. burrs and other damage to the

edges of the grooves in the sleeve.

NOTE: The pinion shaft and sleeve are a precision

matched set. It either the pinion shaft or sleeve

must be replaced, replace the both parts as a set.

SLEEVE SEAL RINGSCh6ck for oeel off oroamag0,

24. Remove the circlip and pinion shaft sleeve from the

oinion shaft.

(cont'd)

17-51

Page 659 of 1413

Steering Gearbox

Disassembly (cont'dl

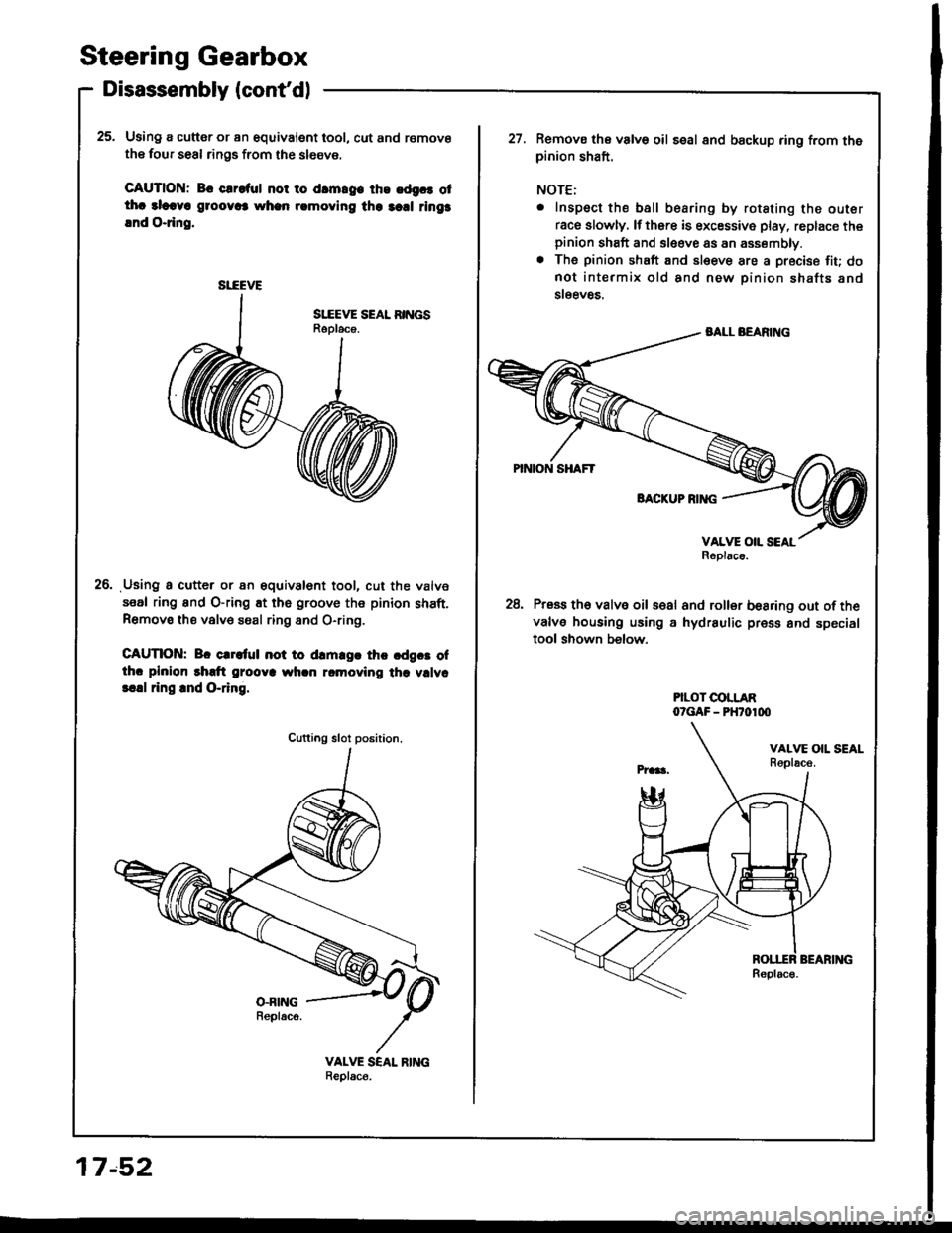

25. Using a cutter or an equivalent tool, cut and remove

the four seal rings from the sl6eve.

CAUTION: Bc clroful not to drmrg. ths .dgc. otthc alcava g1oov6 whan rcmoving the 3cd rings

lnd O.ring.

Using a cutter or an gquivalent tool, cut the valve

seal ring and O-ring Et the groove the pinion shaft.Remove the valv€ saal ring 8nd O-ring,

CAUTION: Br crrltul not to drm.gr thc cdgct ofthc plnion rhdt grooya whcn rcmoving the vllvc

!.!l ring rnd O-ring.

26.

SI-EEVE

Cutting slot position.

17.52

Remova the valve oil seal 8nd backup ring from thepinion shaft.

NOTE:

. Inspect the ball bearing by rotating the outer

race slowly. lf thsre is excessive play, replace thepinion shaft and sleeve as an assembly.. The pinion shaft and sleeve are a precise fiu donot intermix old and new pinion shafts and

steev8s,

28, Press th6 valve oil s€al and roller besring out ofthe

valve housing using a hydraulic press and specialtool shown below.

PILOT COLLARO?GAF - PHTO1OO

Page 660 of 1413

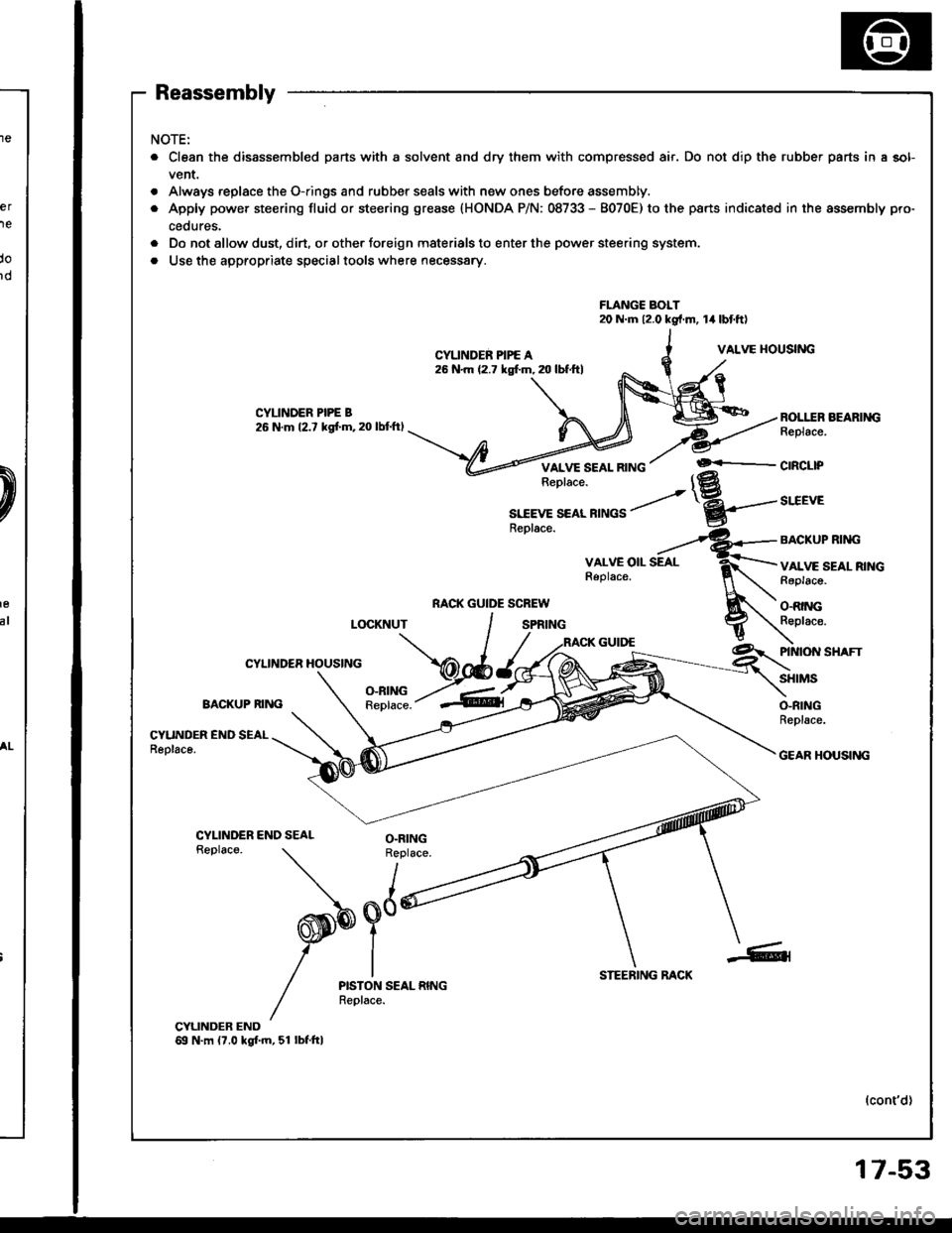

Reassembly

NOTE:

. Clean the disassembled parts with a solvent and dry them with compressed air. Do not dip the rubber parts in a sol-

vent.

. Always replace the O-rings and rubber seals with new ones before assembly.

. Apply power steering fluid or steering grease {HONDA P/N: 08733 - 8070E) to the parts indicated in the assembly pro-

cedures.

. Do not allow dust, dirt. or other foreign materials to enter the power steering system.

. Use the appropriate specialtools where necessary.

FLANGC BOLT20 N.m 12.0 kg{.m, lil lbt'ftl

CYLINDER PIPE A26 N'm (2.7 kgf.m, 20 lbf.ftl

VALVE I{OUSING

BOLI..ER BEARINGReplace.

VALVE SEAL RINGReplace.+-cncl|P

RACK GUIDE SCREW

S1IEVE SEAI RINGSReolace.

SITEVE

BACKUP RIM}

VALVE SEAL RINGRaplacs.

O.RINGReplac€.LOCKNUT

CYLINDER HOUSING

O-RINGBACKUP RING Replace.

\

PINION SHAFT

SHIMS

O-RINGReplace.

CYUNDER END SEALReolace.GEAR HOUSING

CYLINDER END SEALReplaco.O.RINGReplace.

I

x nd#$Y

IPISTON SEAL RINGReplace.

STEERING RACK

(cont'd)

17-53

Page 661 of 1413

Steering Gearbox

Reassembly lcont'd)

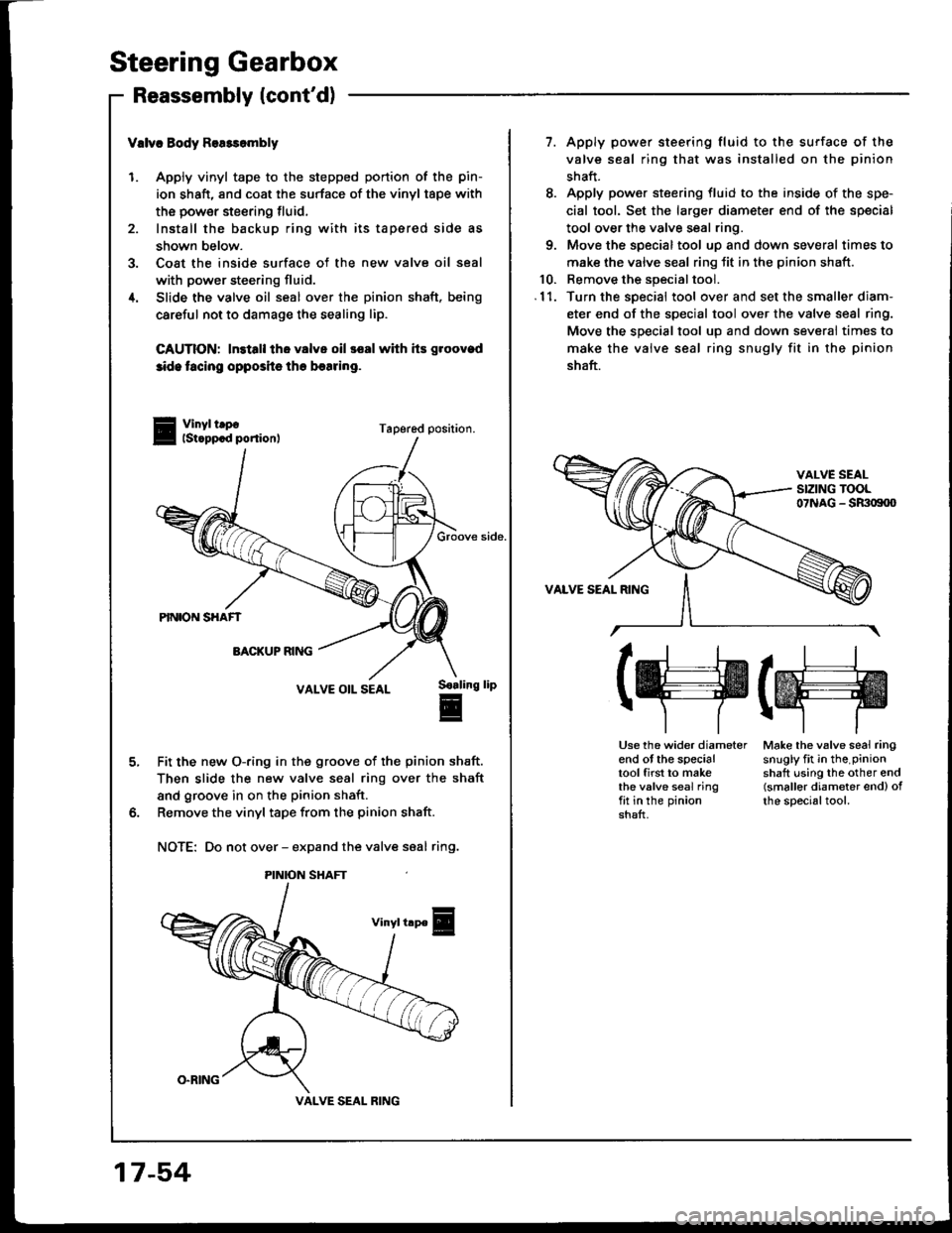

Vllvc Body Rea3sombly

1. Apply vinyl tape to the stepped portion of the pin-

ion shaft, and coat the surface of the vinyl tape with

the power steering tluid,

2. Install the backup ring with its tapered side as

shown below.

3. Coat the inside surface of the new valve oil seal

with power steering fluid.

4. Slide the valve oil seal over the pinion shaft. being

careful not to damage the sealing lip.

CAUTION: ln3tall the valve oil ssal with hs groovad

3ide tacing opposits the besring.

Vinyl trpolst.ppcd ponion,Tapered position.

Groove side.

VALVE OIL SEAL

Fit the new O-ring in the groove of the pinion shaft.

Then slide the new valve seal ring over the shaft

and groove in on the pinion shaft.

Remove the vinyl tape from the pinion shaft.

NOTE: Do not over - expand the valve saal ring.

S€aling

E

lip

PINION SHAFT

VALVE SEAL RING

17-54

7. Apply power steering fluid to the surface of the

valve seal ring that was installed on the pinion

shaft.

8. Apply power steering fluid to the inside of the spe-

cial tool. Set the larger diameter end of the special

tool over the valve seal ring.

9. Move the special tool up and down several times to

make the valve seal ring Jit in the pinion shaft.

10. Remove the special tool.

.11. Turn the special tool over and setthe smallerdiam-

eter end of the special tool over the valve seal ring.

Move the sDecial tool uD and down severai times to

make the valve seal ring snugly fit in the pinion

shaft.

VALVE SEAL RING

(H(ffi

Use the wider diameterend ot the specialtool first to makethe valve seal ringfit in the pinionshaft.

Make the valve seal ringsnugly fit in the.pinionshaft using the other end(smaller diameter end) ofthe specialtool.