Lash ACURA INTEGRA 1994 Service User Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1994, Model line: INTEGRA, Model: ACURA INTEGRA 1994Pages: 1413, PDF Size: 37.94 MB

Page 556 of 1413

Transmission

Installation {cont'd)

14.

15.

Install new set rings on the end of the intermediate

shaft and the driveshaft.

Install the intermediate shaft.

SET RINGBeplace.

16.

10 x 139 N.m14.O kgf.m, 29 lbf.ftl

Install exhaust pipe A. and connect the heated oxv-gen sensor {HO2S) connector.

SELF-LOCKING NUT10 x 1.25 mm54 N.m (5.5 kgl.m,40 rbt.trlReplace.

GASKETReplace.

SELF.LOCKING NUTSI x 1.25 mm22 N.m 12.2 kgl'n,16 lbt.trlRepl6ce.

SHAFT

14-166

DAMPER PINCH BOLT10 x 1.25 mm43 N.m 14.4 kgf.m,32 tbr.ftl

1 7. Install the right and left drivershafts (see section l6l.

NOTE: Turn the right and left steering knuckle fullyoutward, and slide the right driveshaft into the

differential until you feel its spring clip engages theside geaf. Slide the left driveshaft into the intermedi-

ate shaft until you teel the spring clip of the inter-mediate shaft engage the driveshaft.

18. Install right damper fork, then install the right andlett balljoints to each lower arm with the castle nuts

and new cotter Dins.

\

COTTERReplace.CASTLE NUT12 x 1.25 mm49-59 N.m{5.O-6.0 ksf.m, 36-43

SELF.LOCKING NUT12 x 1 .25 mm64 N.m (6.5 kgl.h, 47 lbt.ftlReplace.

rbt'ft1

19. Install the splash shield.

6 x 10 mm BOLT

cltPs, 5

Page 568 of 1413

Differential (81881 enginel

Speciaf Tools ........ ........15-2

Differential

lllustrated Index ......... . 15-3

Backlash Inspection .... 15-4

Final Driven Gear Replacement ...... 15-4

Bearing Replacement .................... 1 5-5

Oil Seal Removal ........ 15-5

Side Clearance Adiustment ........... 15-6

Oil Seal lnstallation ..... 15-8

Page 571 of 1413

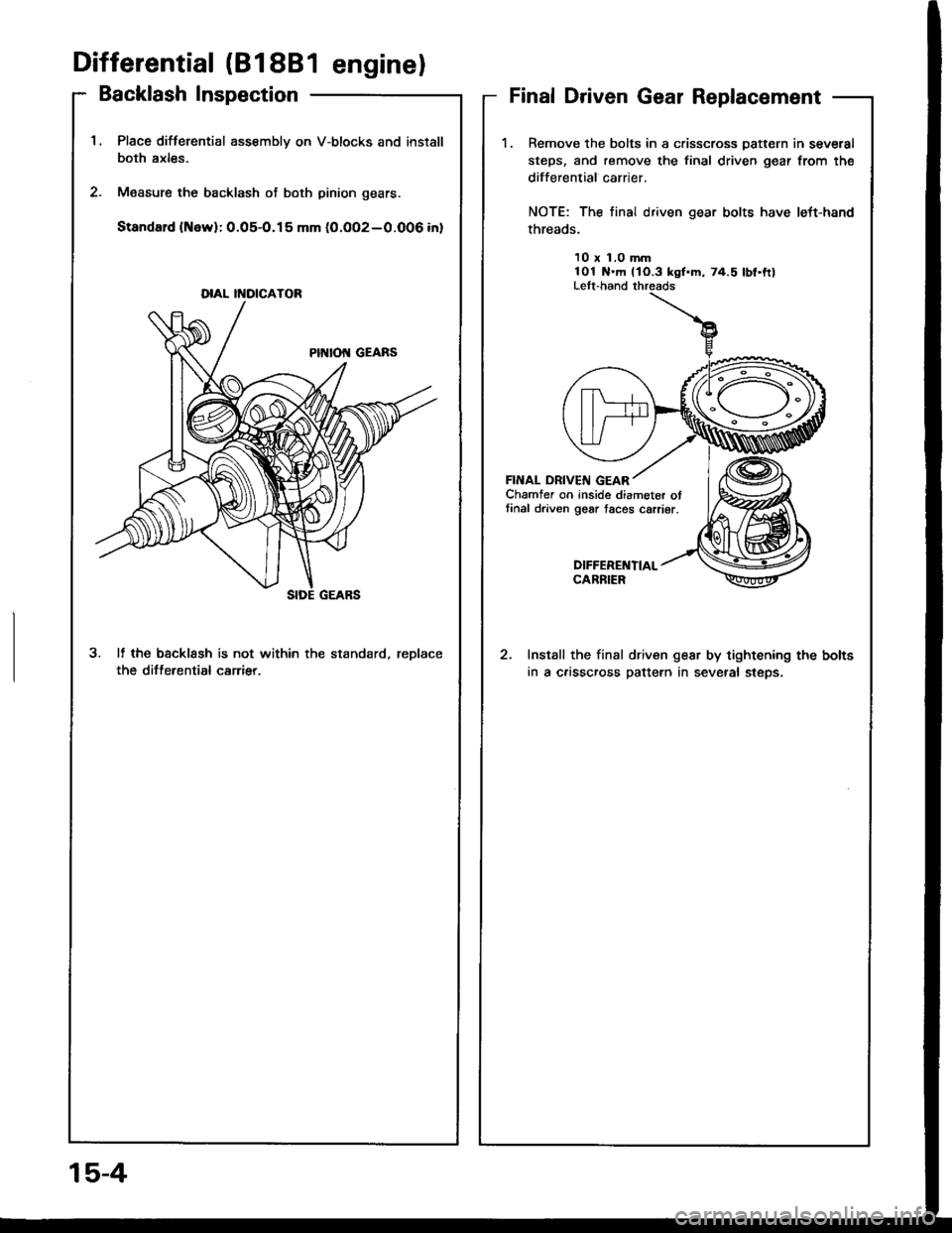

'1.Place difterential assembly on V-blocks and install

both axles.

M€asure the backlash of both pinion gears.

Standard (New):0.05-O.15 mm (0.OO2-0.006 inl

3. It the bscklssh is not within the standard, reDlace

the differential carrier.

DIAL II{OICATOR

Differential (818B1 enginel

Backlash InspectionFinal Driven Gear Replacement

1.Remove the bolts in a crisscross Datt€rn in several

steps, and remove the final driven gear from the

differential carrier.

NOTE: The final driven gear bolts have left-hand

threads.

10 x 1.0 mm101 N.m llO.3 kgl.m, 74.5 lbf.ftlLelt-hand threads

FINAL DRIVEIII GEARChamfer on inside diameter otlinal driven gear taces carrier.

DIFFEREI{TIALCARBIER

Install the final driven gear by tightening the bolts

in a c.isscross pattern in several steps.

15-4

Page 576 of 1413

Differential (818C1 enginel

Special Tools ........

Differential

lllustrated Index .........

Backlash Inspection

Final Driven Gear Replacement ......

Tapered Roller Bearing Replacement.

Oil Seal Removal

Bearing Outer Race Replacement ...

Tapered Roller Bearing Preload

Adjustment

Oil Seal Installation

1 5-10

15-1 1

15-12

15-12

15-13

15-13

15-14

15-15

15-17

Page 579 of 1413

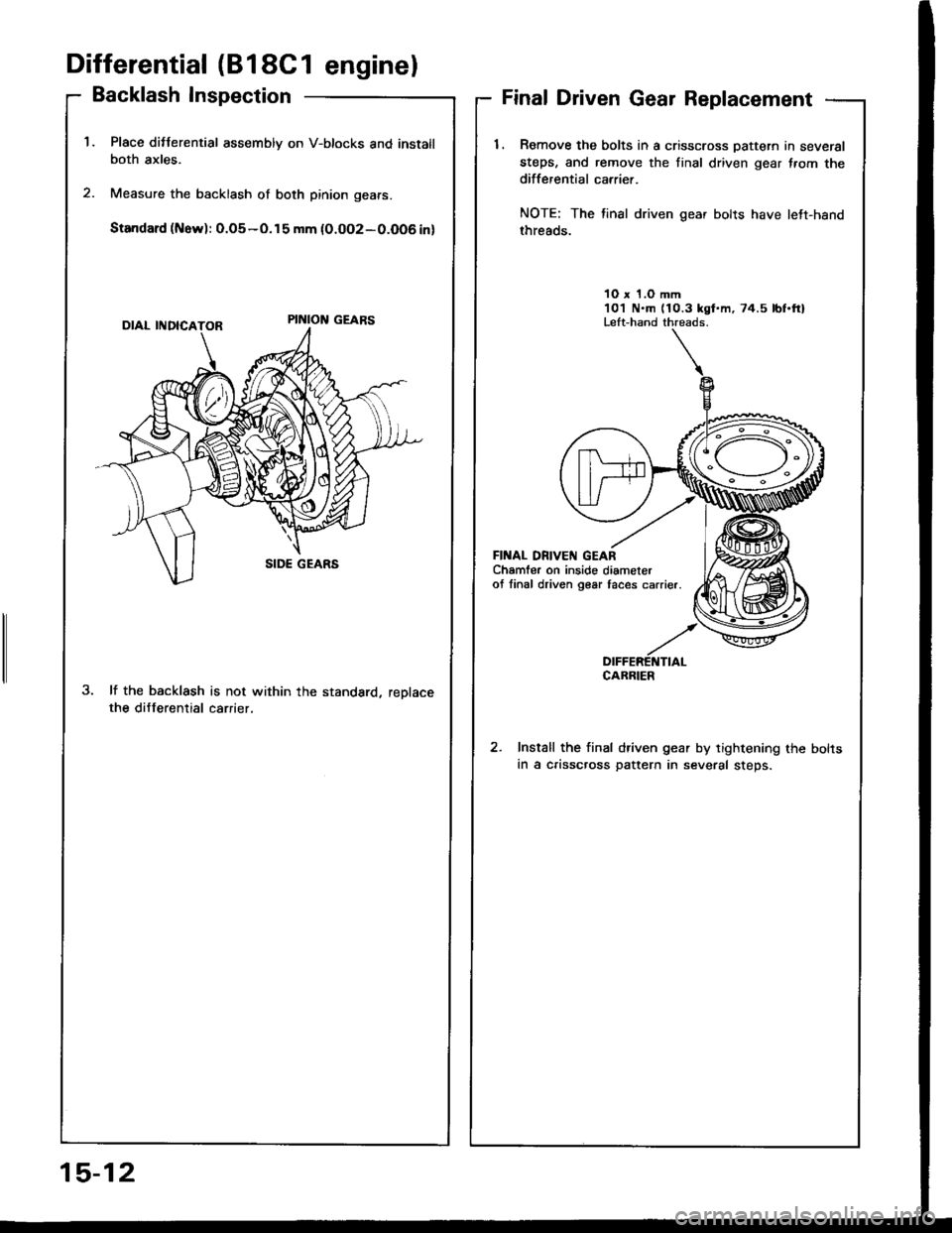

Differential (818C1 enginel

Backlash Inspection

Place ditterential assembly on V-btocks and instatlboth axles.

Measure the backlash of both pinion gears.

Standard (Now): 0.o5-o.15 mm {0.oo2-0.O06 in)

lf the backlash is not within the standard, reDlacethe differential carrier,

Final Driven Gear Replacement

1. Romove the bolts in a crisscross Dattern in several

steps, and remove the tinal driven gear f.om thedifferential carrier.

NOTE: The tinal driven gear bolts have lett-hand

threads.

10 x 1.O mm101 N.m (10.3 kgt.m, 74.5 lbf.ftlLeft-hand threads.

FII{AL DN|VEN GEARChamfer on inside diameterof linal driven g€ar taces carrier.

DIFFERETTTIALCABRIER

Install the final driven gear by tightening the bolts

in a crisscross pattern in several steps.

15-12

Page 588 of 1413

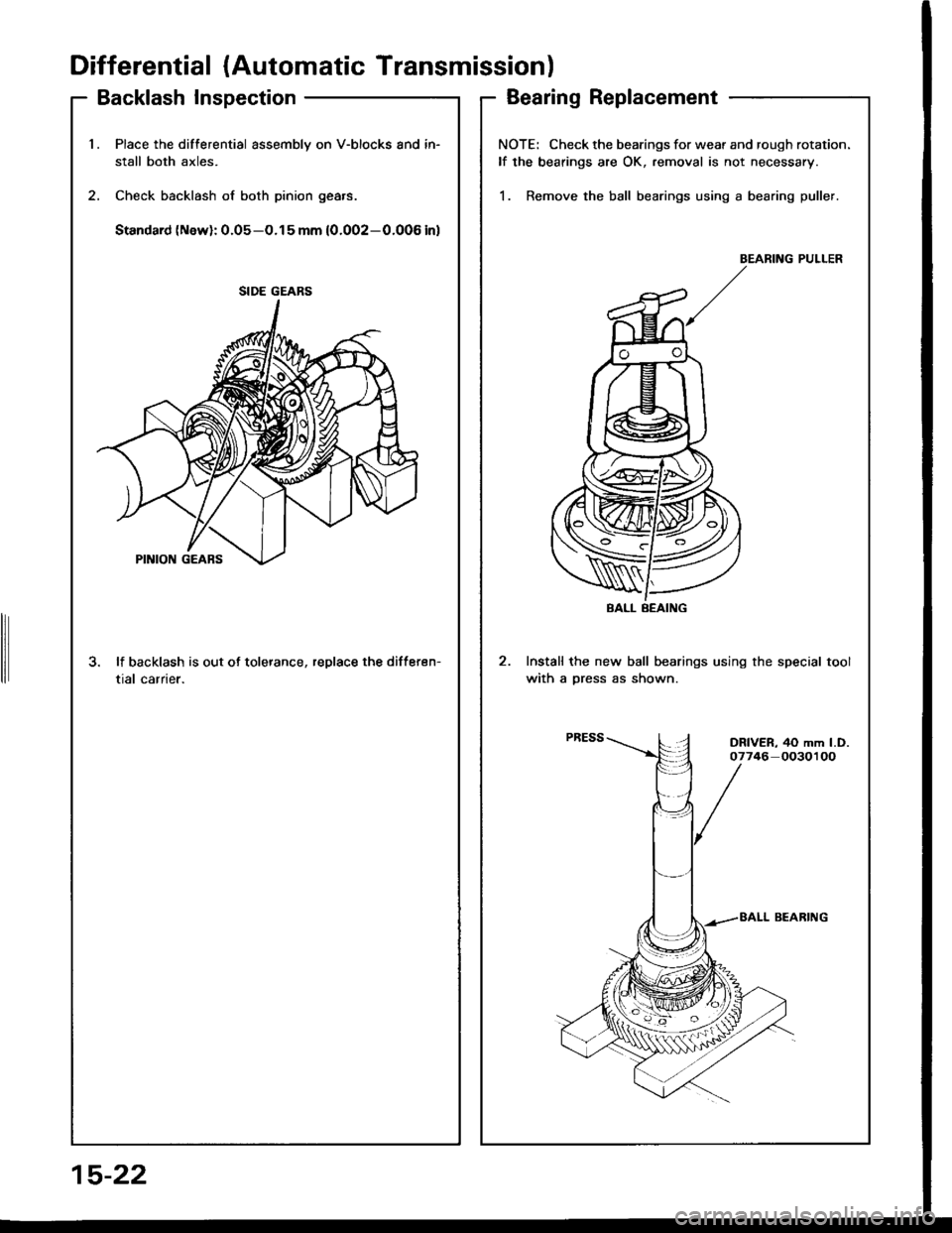

Differential (AutomaticTransmission)

Backlash InspectionBearing Replacement

1.Place the differential assembly on V-blocks and in-

stall both axles.

Check backlash of both pinion gears.

Standard (New): 0.05-O.15 mm (0.002-0.006 inl

3. lf backlash is out of tolerance, replace the differen-

tial carrier.

SIDE GEARS

NOTE: Check the bearings for wear and rough rotation.

lf the bearings are OK, removal is not necessary.

1. Remove the ball bearings using a bearing puller.

BEARING PULLER

Install the new ball bearings using the special tool

with a Dress as shown.

BALL BEAING

DRIVER, 40 mm l.D.07746 0030100

15-22

Page 1172 of 1413

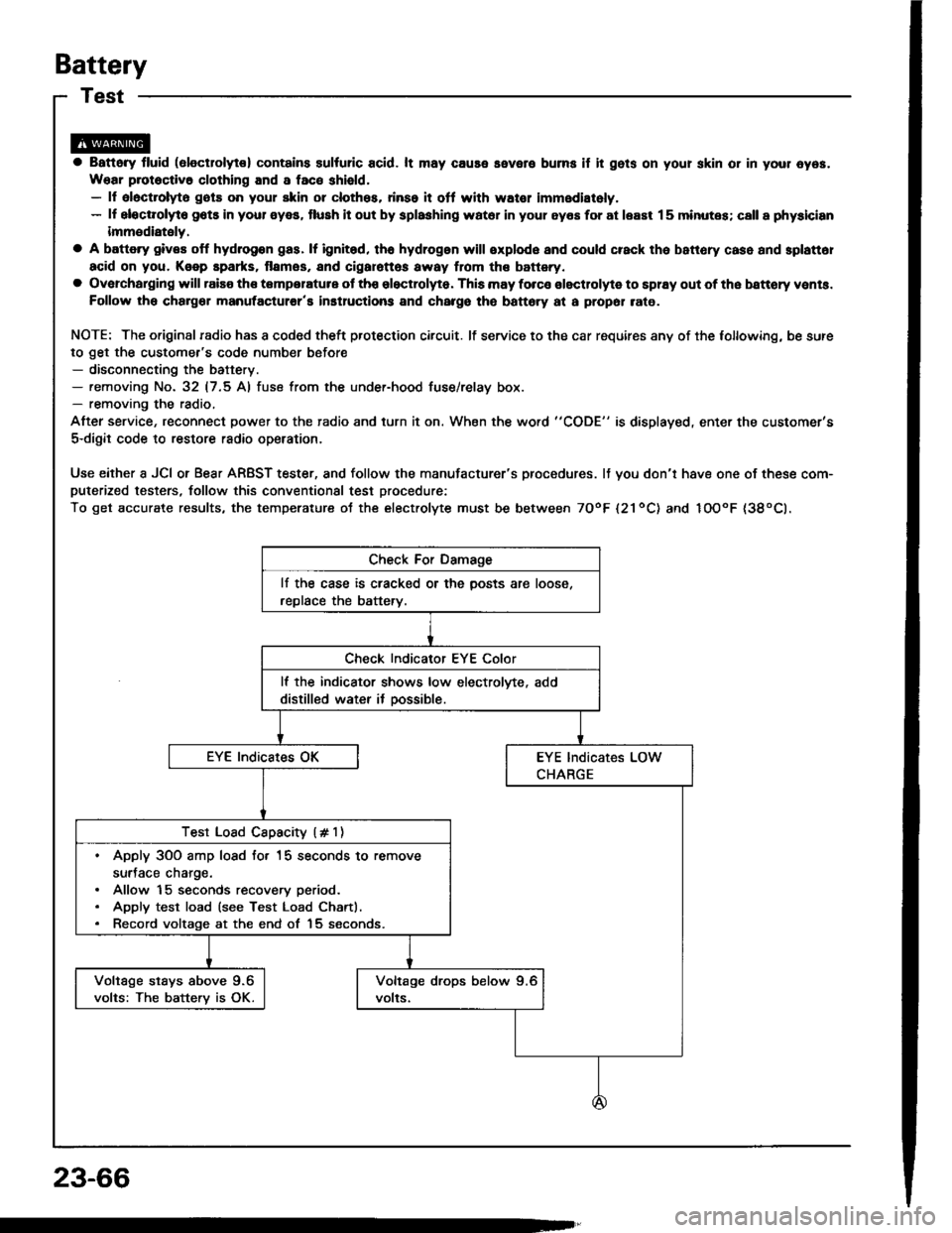

Battery

a Battory tluid (6lectrolyt€l contains sulturic acid. lt may cauaa aevere burns iI it gots on your skin or in youl oyos.

Woar protoctivo clothing and I fac€ shield,- ll aloctrolyt6 gots on youl skin or clothos, rimo it off with wator immediately,- lf eloclrolyto g6ts in your oyos, tlush it out by splashing wat6r in youl eyes for at least 15 minutes; call a physiclan

immediately,

a A battery gives off hydrogon gas, lf ignit6d. tha hydrogsn will orploda and could crack tho baflory cas6 and splattor

acid on you. Koep spa*s. flames, and cigarottos away from the baftery.

a Overcharging will raiso ths tempelature ot th€ electrolyte. This may force electrolyte to splay out of the battery venta.

Follow lhe chargor manutacturer's instluctions and chargo tho battory at a prop61 rate.

NOTE: The original radio has a coded theft protection circuit. lt service to the car requires any of the lollowing, be sure

to get the customer's code number before- disconnecting the battery.- removing No. 32 (7.5 Al fuse from the under-hood fuse/relay box- removing the radio,

After service, reconnect power to the radio and turn it on. When the word "CODE" is displayed, enter the customer's

s-digir code to restore radio operation,

Use either a JCI or Bear ARBST tester, and follow the manufacturer's procedures. It you don'r have one of these com-puterized testers, follow this conventional test procedure:

To get accurate results, the temperature ot the electrolyte must be between TOoF l21ool and IOOoF {38oCl.

lf the case is cracked or the posts are loose,

replace the battery.

lf the indicator shows low electrolvte, add

distilled water it oossible.

Test Load Cspacity (# 1)

. Apply 3OO amp losd fo. 15 seconds to remove

surJace charge.. Allow 15 seconds recovery period.. Apply test load (see Test Load Chartl.. Record voltage at the end of 15 seconds.

Voltage stays above 9.6

volts: The batterv is OK.

23-66

Page 1250 of 1413

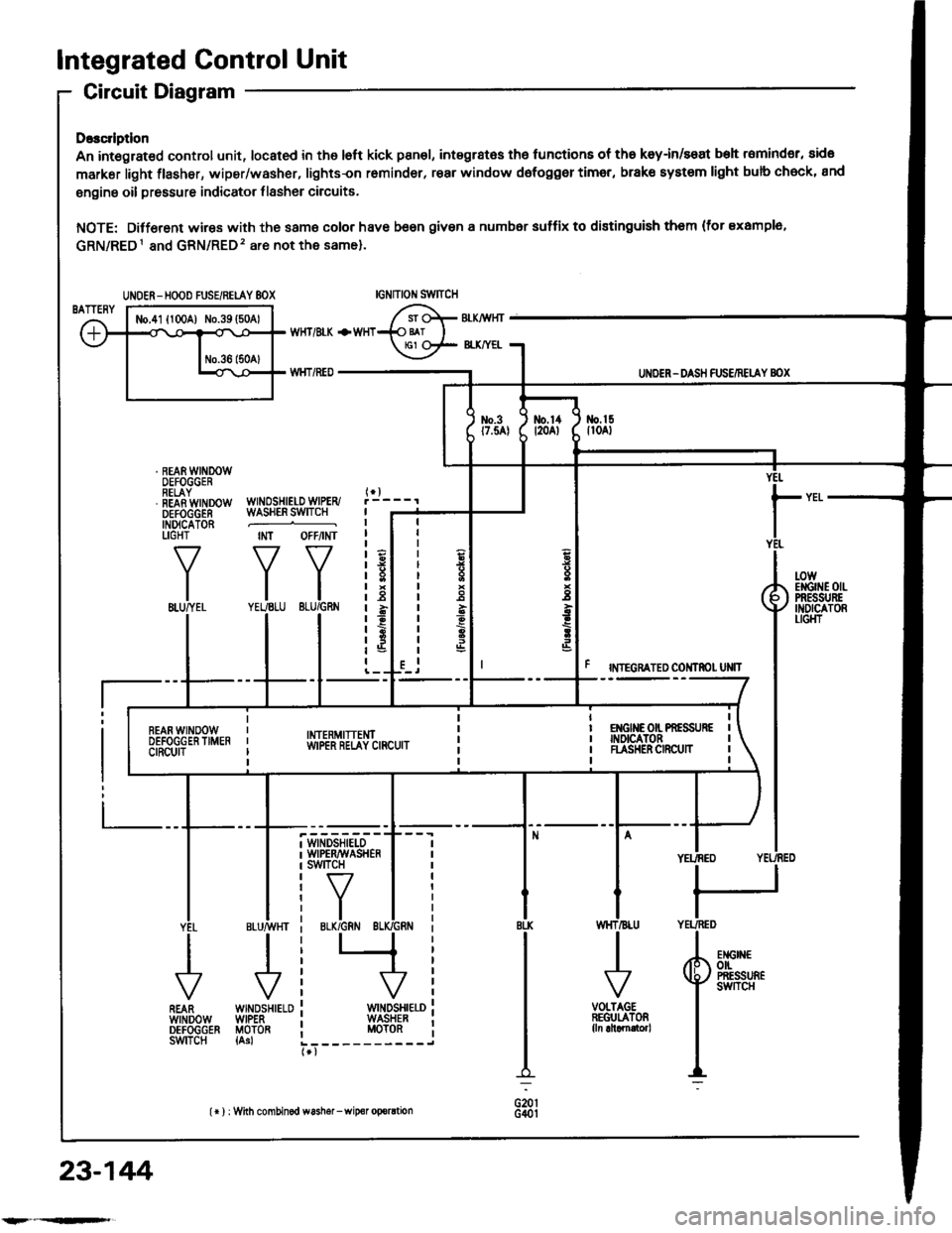

Integrated Control Unit

Circuit Diagram

D.3c ptlon

An integrat€d control unit, located in the left kick panel, integratss the functions of tho keyin/seat beh r6mind€r, sido

markar light {lasher, wiper/washer, lights-on r6minder, rear window dsfogger timer, brak€ system light bulb check, and

enging oil pressure indicator flasher circuitE,

NOTE: Difforent wires with the same color have be6n given a numbor suffix to distinguish them (for Example,

GRN/RED1 and GRN/RED'� are not the same).

WNOSHIELD WIPER/WASHER SWITCH

IMT OFFiINT

I

II

IIIIIIIIIIII

YEUEE

rl

t

P

UNOER - DASH FUS€/RETAY BOX

r NTEGRATED COI{TROI UNIT

t-0wErGrilE 0|lPRESSI'REINDICATORLIGI{T

WINDSHIELOWIPERAVASHERswtTcH

tr-/

IBLK/GRN BI

WINDSHIELOWIPERMOTOR{Asl

VOLTAGEREGULATOR{ln ahamator,

UNOER- HOOD FUSE/RELAY 8OX

I

r3

r8relit;rBt5I

23-144

lr ) : With combinod washef-wip€r oporation

Page 1254 of 1413

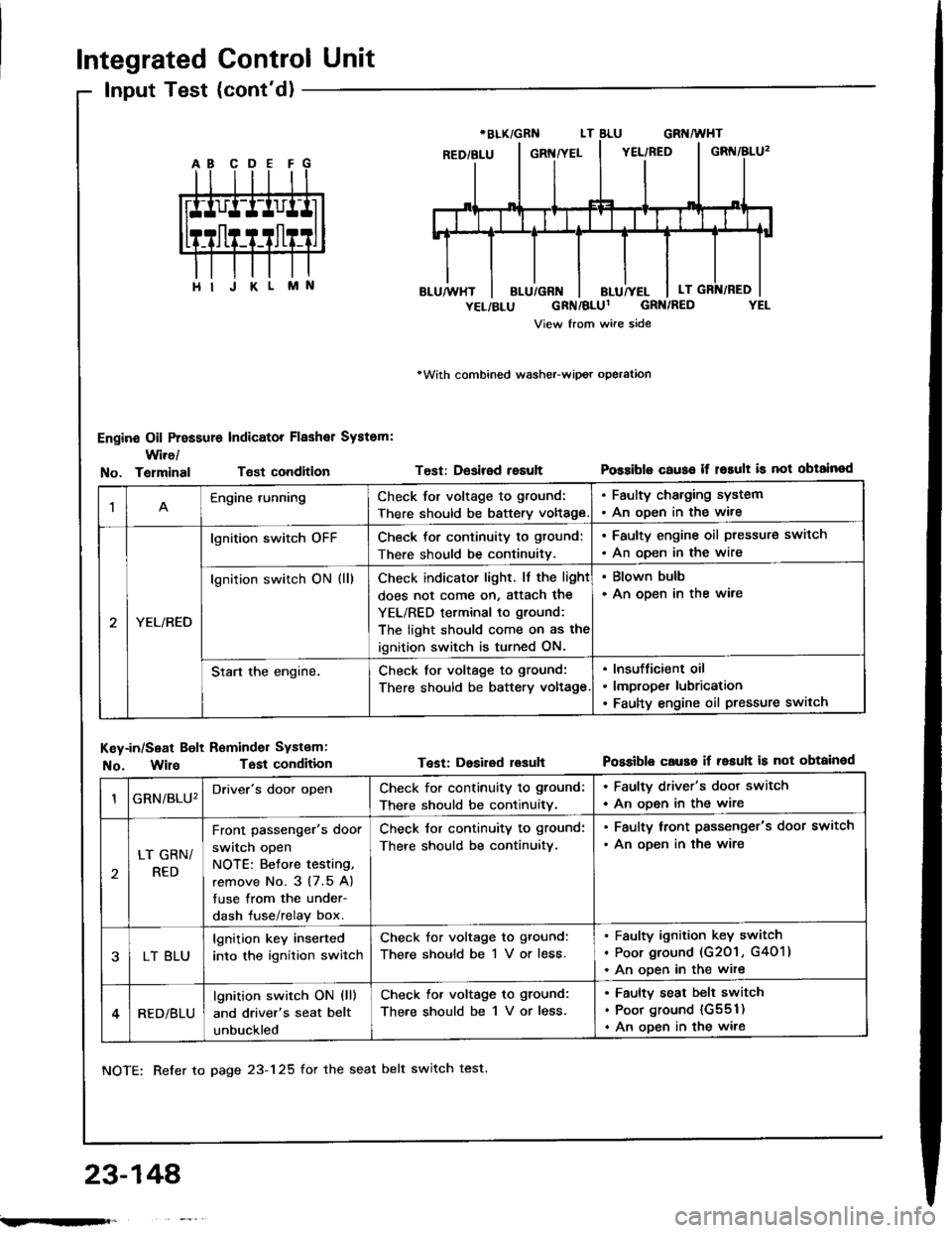

Integrated Control Unit

Input Test (cont'd)

Engine Oil Pressure Indicator Flashal System:

Wire/

rWith combined washeFwipot operation

Test: Desired resultPossiblo c€use if r6rult is not obtainodNo. TelminalTsst condition

M

1Engine runningCheck for voltage to ground:

There should be battery voltage

. Faulty charging system. An oDen in the wire

YEL/RED

lgnition switch oFFCheck for continuity to gtound:

There should be continuitv.

. Faulty engine oil ptessure switch

. An oDen in the wire

lgnition switch ON (ll)Check indicator light. lf the light

does not come on, Sttach the

YEL/RED terminal to ground:

The light should come on as the

ignition switch is turned ON.

. Blown bulb. An open in the ware

Start the engine.Check for voltage to ground:

There should be battery voltage

Insufficient oil

lmproper lubrication

Faulty engine oil pressure switch

Key-in/Seat Bolt Reminder Systam:

No. WilaTest condition

NOTE: Refer to page 23-125 for the seat belt switch test.

Test: Dosired lesuhPossible causo if resuh is not obtainod

23-148'

GRN/BLU'Driver's door openCheck for continuity to ground;

There should be continuitv.

. Faulty driver's door switch

. An ooen in the wire

LT GRN/

RED

Front passenger's door

switch open

NOTE: Betore testing,

remove No. 3 (7.5 A)

tuse from the under-

dash fuse/relay box.

Check tor continuity to ground:

There should be continuitv.

. Faulty lront passenger's door switch

. An ooen in the wire

LT BLU

lgnition key inserted

into the ignition switch

Check for voltage to ground:

There should be 1 V or less.

Faulty ignition key switch

Poor ground (G201 , G401)

An ooen in the wite

RED/BLU

lgnition switch ON (ll)

and driver's seat belt

unbuckled

Check lor voltage to ground:

There should be 1 V or less.

Faulty seat belt switch

Poor ground {G551)

An open in the wire

;.rqFft,

Page 1255 of 1413

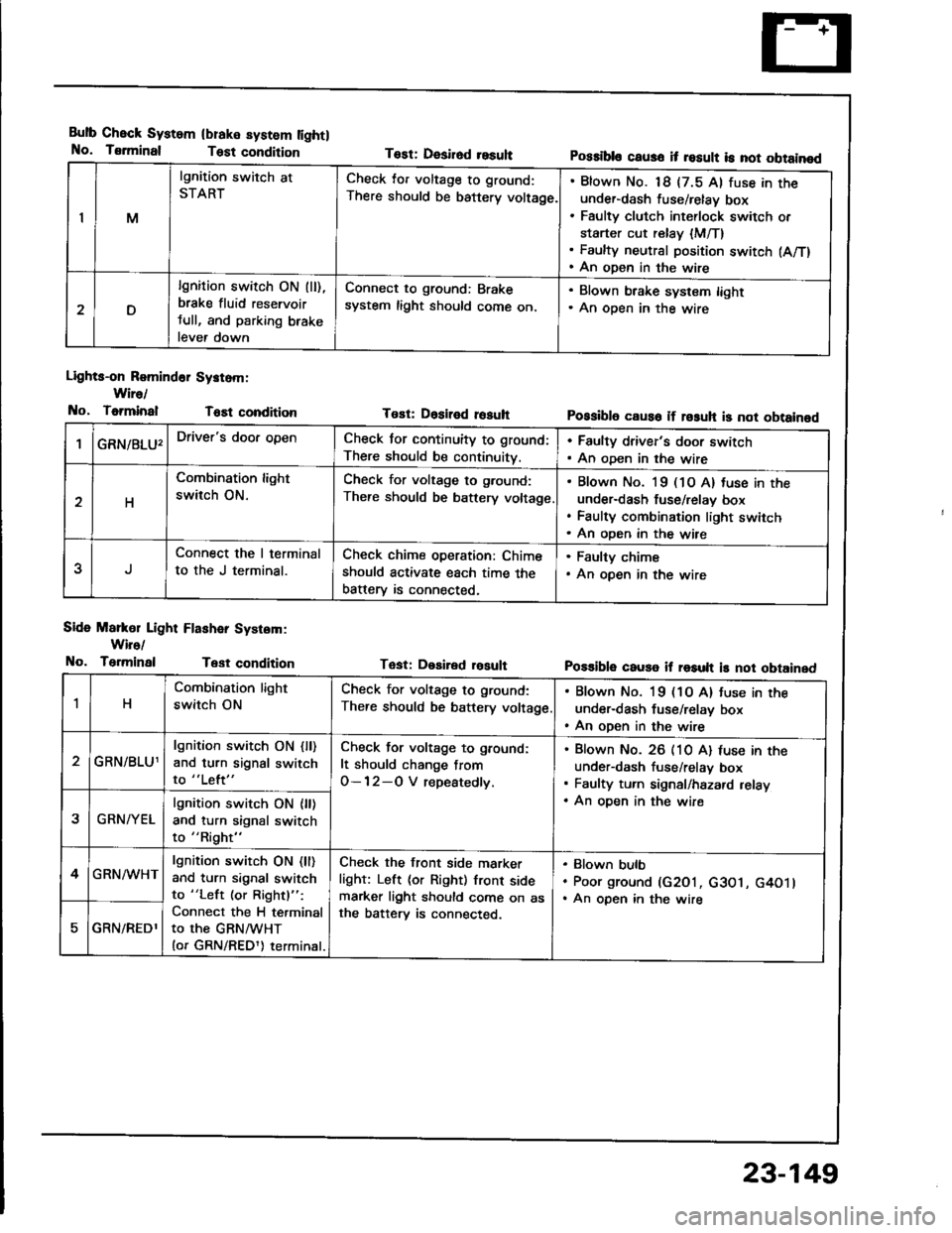

Bulb Check System

No. Tsrminal

(blake system lightl

Test condition

Lights-on Romind6r Systom:

Wire/

No, ToiminalT6Et condition

Side Markol Light Flashar System:

Wiro/

No. TerminalTest condition

Tost: Desirod resuhPossibls caus6 it result is not obtainod

Tost: Dositod rosuhPossibl6 caus6 if rosuh is not obtainod

Tast: Desired rosultPo$ible cause if result is not obtained

IM

lgnition switch at

STARTCheck lor voltage to ground:

There should be battery voltage.

Blown No. 18 {7.5 Al fuse in theunder-dash fuse/relay box

Faulty clutch int€rlock switch or

starter cut relay {M/T}Faulty neutral position switch (A/T)

An open in the wire

D

lgnition switch ON (ll),

brake fluid reservoir

tull, and parking brake

lever down

Connect to ground: Brake

system light should come on.

. Blown brake system light. An oDen in the wire

GRN/8LU'Driver's door openCheck for continuity to ground:

There should be continuity.

. Faulty driver's door switch. An oDen in the wire

H

Combination light

switch ON.

Check for voltage to g.ound:

There should be battery voltage

Blown No. l9 (1O A) tuse in the

under-dash fuse/relav box

Faulty combination light switch

An oDen in the wire

5

Connect the I terminal

to the J terminal.

Check chime operation: Chime

should activate each time the

batterv is connected,

. Faulty chime. An open in the wire

1H

Combination light

switch ON

Check for voltage to ground:

There should be battery voltage

. Blown No. 19 (1O A) tuse in the

under-dash fuse/relay box. An open in the wire

GRN/BLU1

lgnition switch ON {ll)and turn signal switch

to "Left"

Check for voltage to ground:

It should change from

O-12-O V repeatedly.

Blown No. 26 (10 A) luse in theunder-dash fuse/relav box

Faulty turn signal/hazard relay

An oDen in the wire2GRN/YEL

lgnition switch ON {ll)and turn signal switch

to "Right"

4GRN/WHTlgnition switch ON (ll)

and turn signal switch

to "Left (or Rightl":

Connect the H terminal

to the GRNMHT(or GRN/REDl) terminal.

Check the front side marker

light: Left (or Right) front sidemarker light should come on asthe batterv is connected.

Blown bulb

Poor ground (G2O1, c3O1, G4O1lAn open in the wire

GRN/REDl

23-149