engine ACURA INTEGRA 1994 Service Workshop Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1994, Model line: INTEGRA, Model: ACURA INTEGRA 1994Pages: 1413, PDF Size: 37.94 MB

Page 115 of 1413

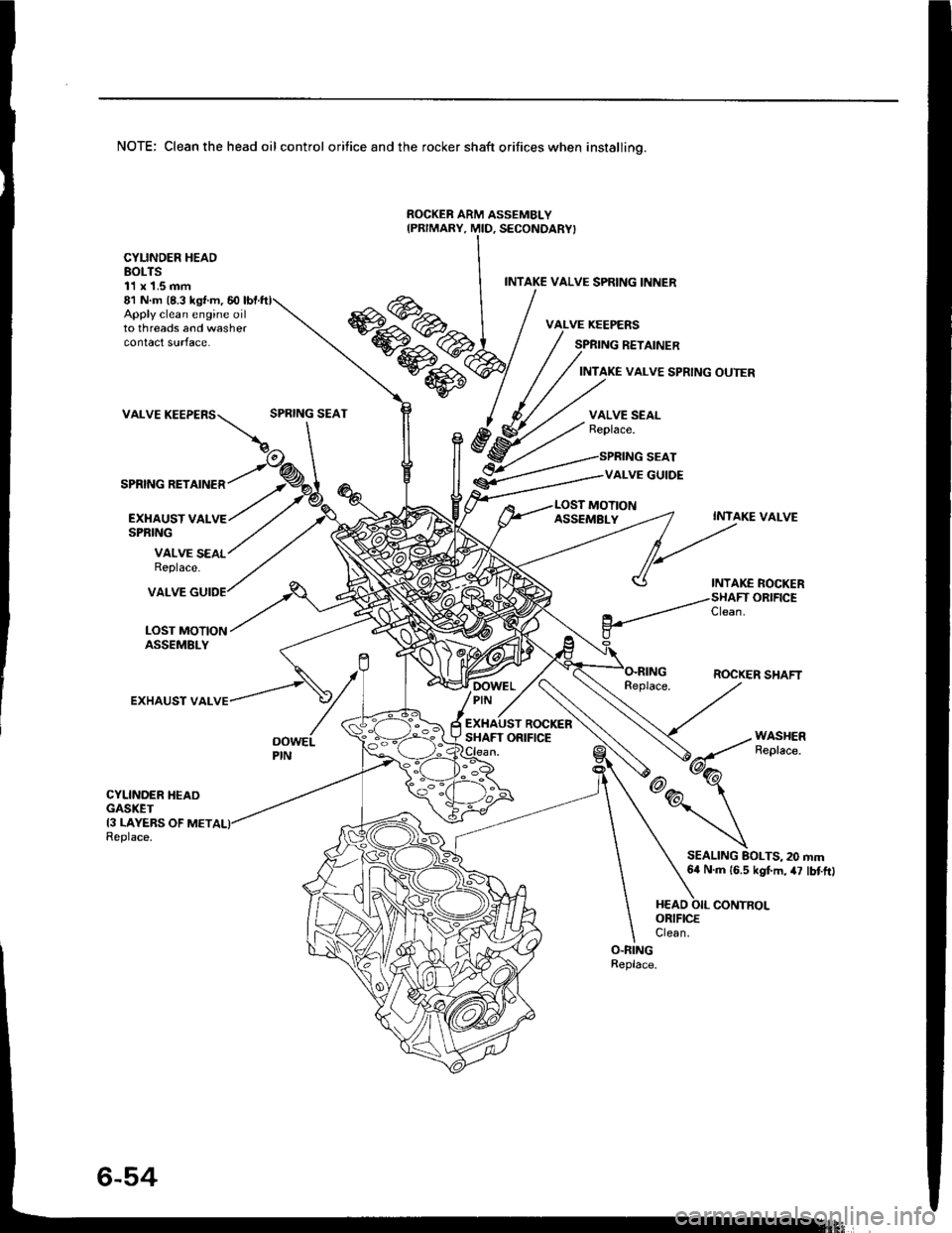

NOTE: Clean the head oil control orifice and the rocker shaft orifices when installino.

ROCKEB ARM ASSEMBLY

Apply clean engine oilto threads and washercontact surface.

81 N m (8.3 ks{ m, 60

VALVE

SPRING RETAINER

CYLINDER HEADBOLTS11 x 1.5 mm

EXI{AUST VALSPRING

INTAKE VALVE SPRING INNER

SPRING RETAINER

INTAKE VALVE SPRING OUTER

SPRING SEATVALVE SEALReplace.

SPRING SEAT

VALVE GUIDE

MOTION

VALVE SEALReplace.

ASSEMBLYINTAKE VALVE

INTAKE ROCKERORIFICE

LOST MOTIONASSEMBLY

VALVE

EXHAUST VAL

Clean.

ROCKER SHAFTDOWELPIN -,

ROCKERSHAFT ORIFICEOOWELPIN

CYLINDER HEAOGASKET13 LAYEBS OF METReplace.

SEALING BOLTS, 20 mm64 N.m 16.5 kgf.m, 47 lbtftl

Page 116 of 1413

Cylinder Head

Removal

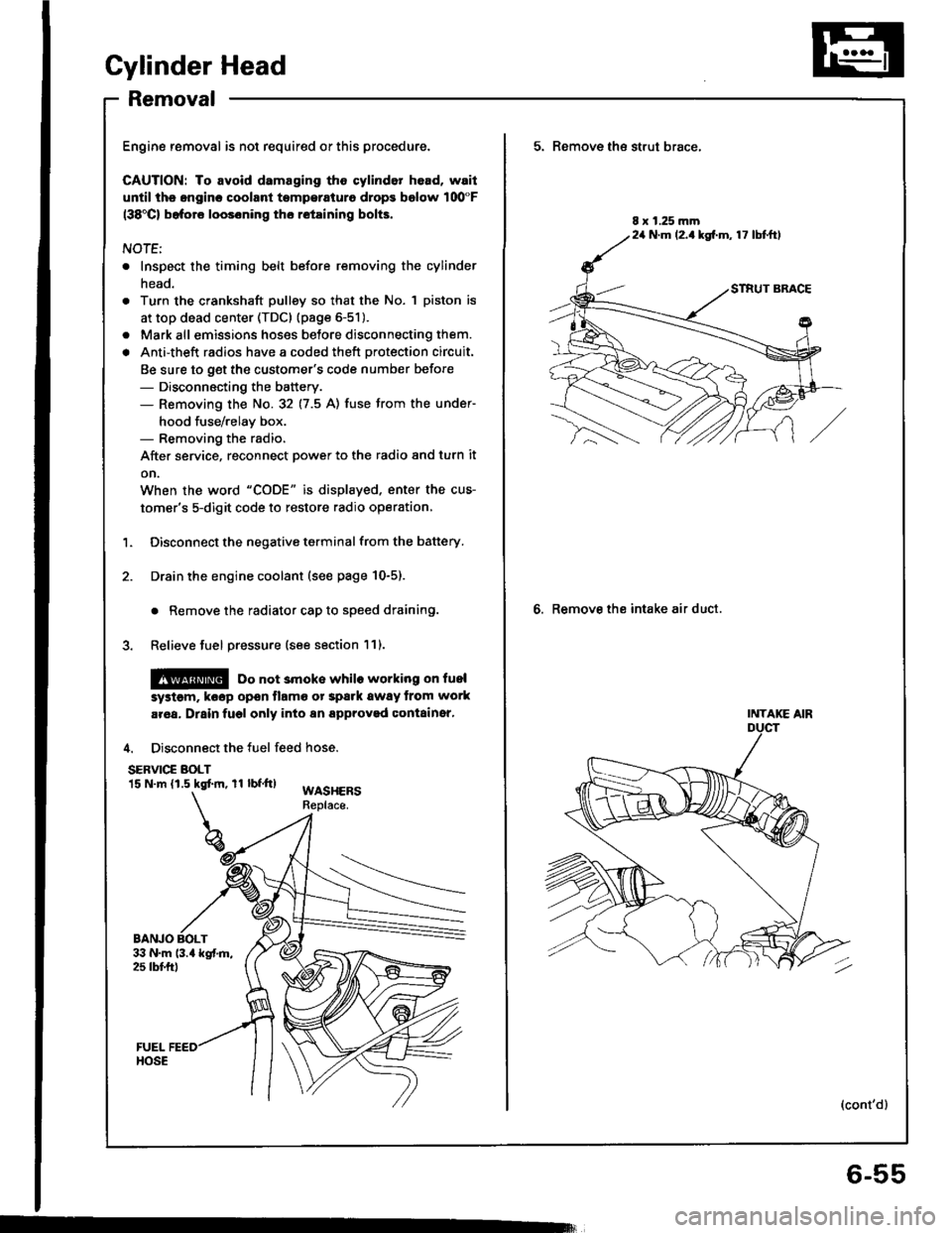

Engine removal is not required or this procedure.

CAUTION: To avoid damaging tho cylinder head, wail

u[tilths.nginc coolant tsmperaturo drops bolow 100"F(38'Cl bafore loos6ning tho retaining bolts.

NOTE;

. Inspect the timing belt before removing the cylinder

head.

Turn the crankshaft pulley so that the No. 1 piston is

at top dead center (TDc) {page 6-51).

Mark all emissions hoses betore disconnecting them.

Anti-theft radios have a coded theft protection circuit.

Be sure to get the customer's code number before- Disconnecting the battery.- Removing the No.32 (7.5 A) fuse trom the under-

hood fuse/relay box.- Removing the radio.

After service, reconnect power to the radio 8nd turn it

on.

When the word "CODE" is displaved. enter the cus-

tomer's 5-digit code to restore radio operation,

Disconnect the negative terminal from the battery.

Drain the engine coolant (see page 10-5).

. Remove the radiator cap to speed draining.

Relieve fuel pressure (see section 111.

l@ Do not 3moke whilo working on fuel

a

a

'1.

systgm. ko6p opon tlamo ot Spark away trom work

aroa. Drain fugl only into an approved containsr,

4. Disconnect the fuel feed hose.

SERVIC€ BOLT15 N.m (1.5 kgtm, rl bf.tt)WASHERSReplace.

BANJO BOLT

5. Remove th€ strut brace,

6. Remove the intake air duct.

8 x 1.25 mm24 N.m (2.1kg[.m, 17 lbtftl

INTAKE AIR

(cont'd)

6-55

Page 118 of 1413

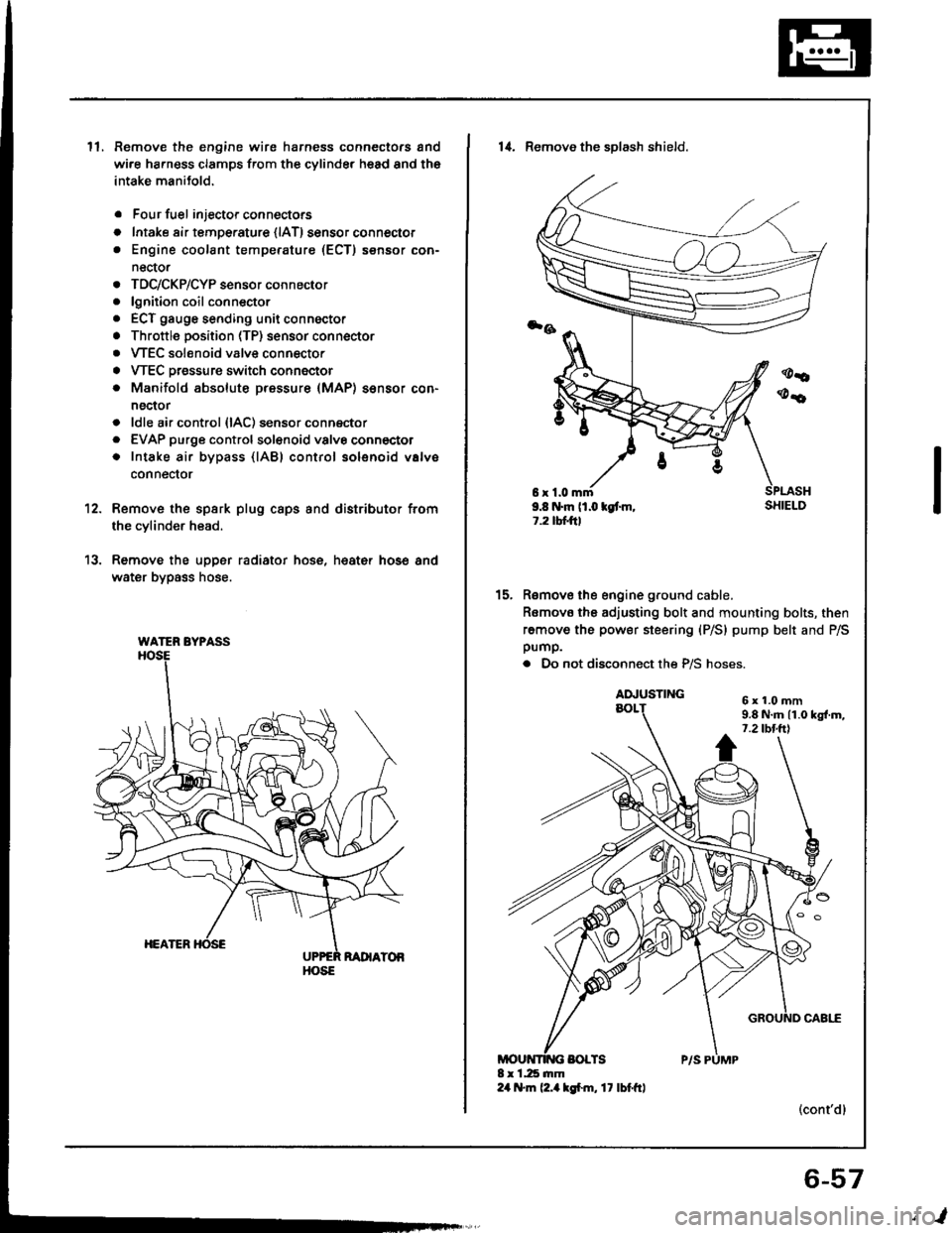

ll.Remove the engine wire harness connectors and

wi.e ha.ness clamps from the cylinder head and the

intake manitold.

Four fuel injector connectors

Intake air tempe.ature {lAT) sensor connector

Engine coolant temperature (ECT) sensor con-

nector

TDC/CKP/CYP sensor connector

lgnition coil conn€ctor

ECT gauge sending unit connector

Throttle position (TP) sensor connector

VTEC solenoid valve connector

VTEC Dressure switch connector

Manifold absolute pressure (MAP) sensor con-

nector

ldle air control {lAC) sensor connector

EVAP purge controlsol€noid valvo connector

Intake air bypass {lABl control solenoid valve

conneclor

a

o

a

o

a

a

a

a

a

a

a

a

a

12.

13.

Remove the spsrk plug caps and distributor from

the cylinder head.

Remove the upper radiator hose, heat€r hose and

water bypass hose.

WATER BYPASS

HOSE

6r1.0mm9.8 N.m (1.0 kgt m,1.2 tbtftl

14. Remove the sDlash shield.

Remove the engine ground cable.

Romovo the adjusting bolt and mounting bolts, then

remove the power steering (P/S) pump belt and P/Spump.

. Do not disconnect the P/S hoses.

(cont'dl

15.

6x1.0mm9.8 N.m 11.0 kgl.m,7.2 tbt.ttl

6-57

,l

Page 119 of 1413

Cylinder Head

Removal (cont'dl

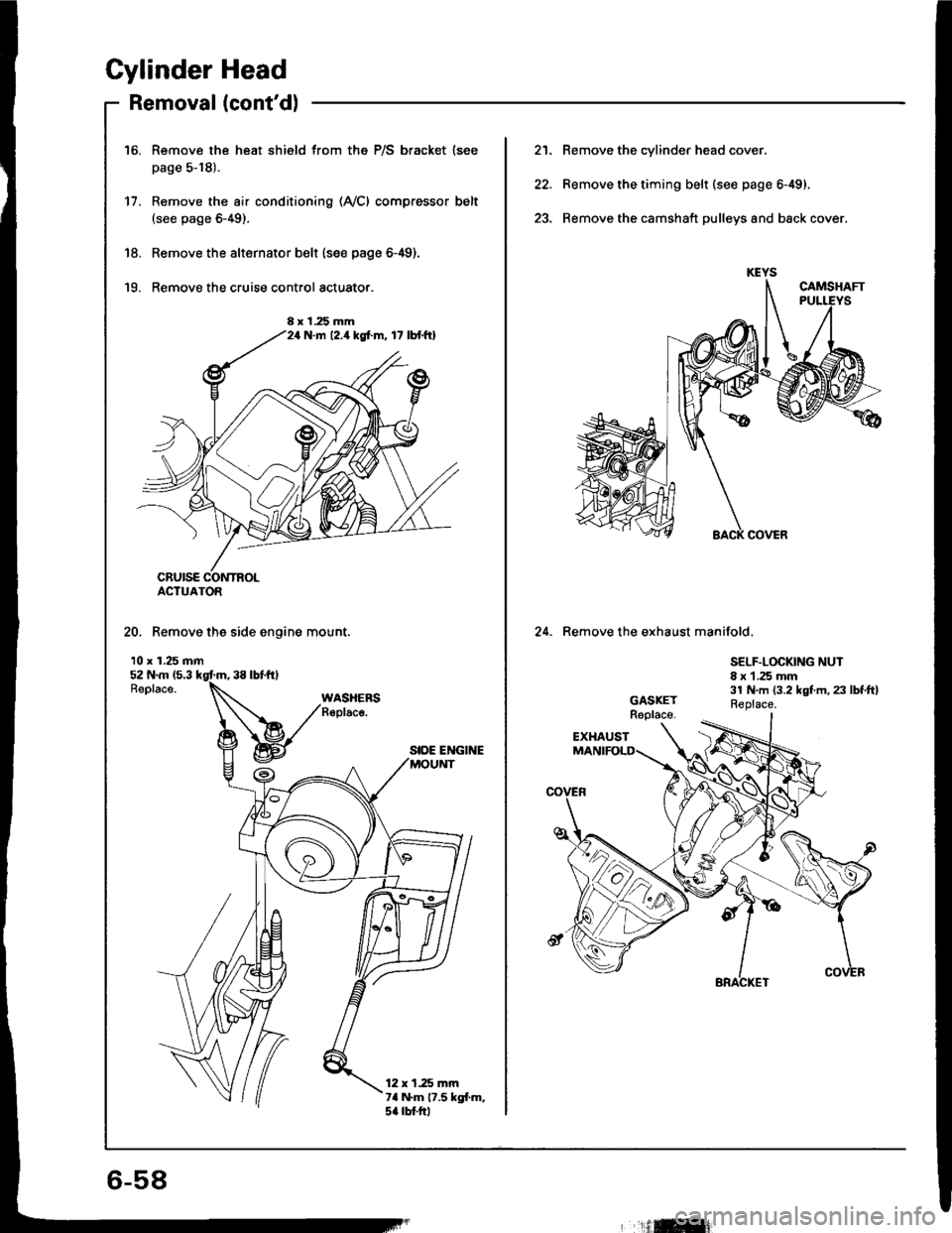

Remove the heat shield from the P/S bracket (see

page 5-18).

Remove the air conditioning (Ay'Cl compressor belt(see page 6-49).

Remove the alternator belt {s€e page 6-49).

Remove the cruise control actuato..

16.

17.

'18.

'19.

ACTUATOR

20. Remove the side engine mount.

10 x 1.25 mm

SIDE ENGINE

12 x 1.25 mrn7a N.m 17.5 kgl.m,5a rbtftl

8 x 1.25 mmN.m 12.4 kgf.m, 17 lbtftl

21. Remove the cylinder head cover.

22. Remove the timing belt (see page 6-49).

23. Remove the camshaft pulleys and back cover.

24. Remove the exhaust manifold.

SELF.LOCKING NUT8 x 1 .25 mm31 N.m {3.2 kgt m, 23 lbf.ftlReplace.

6-58

'ilffi{

Page 136 of 1413

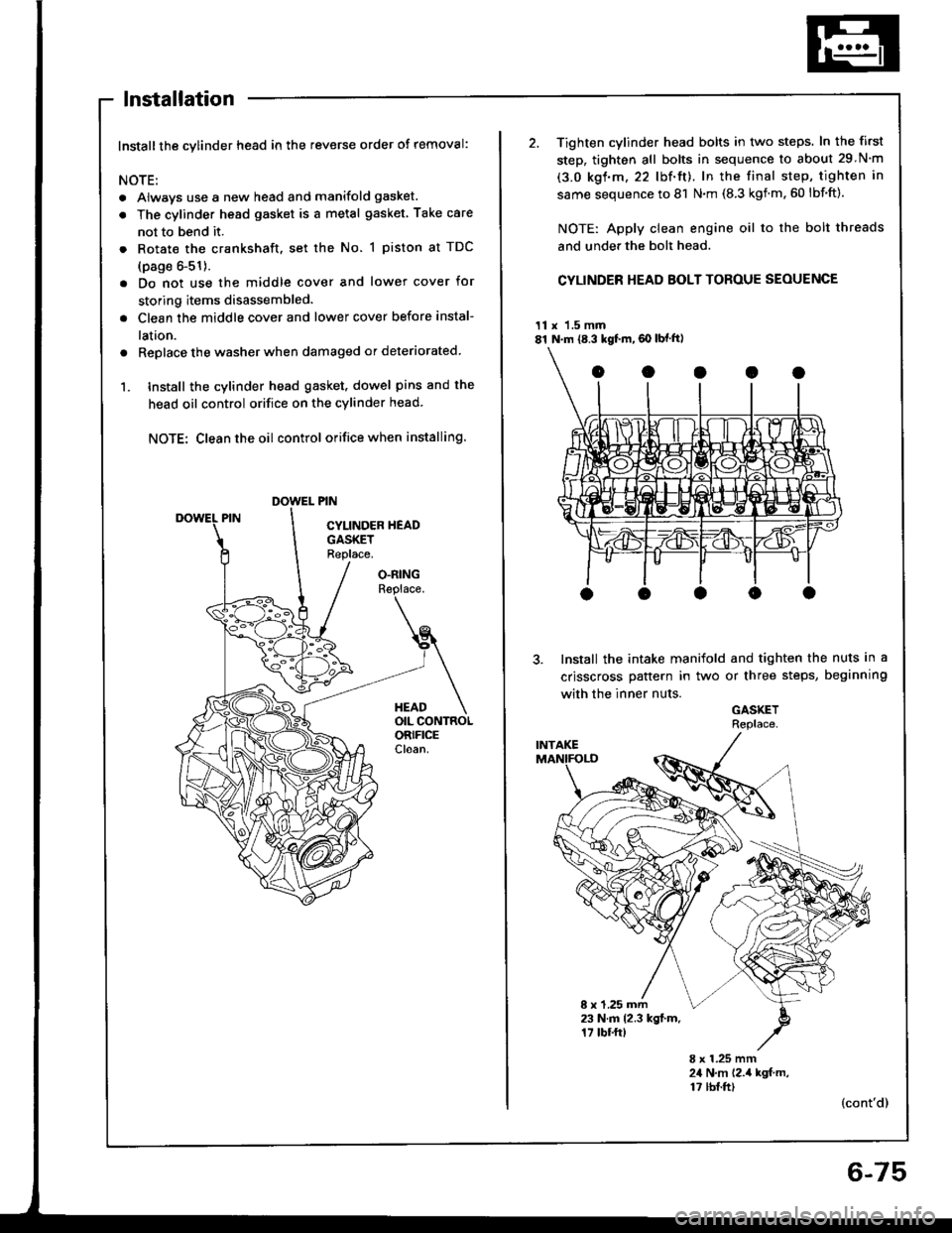

lnstallation

Installthe cylinder head in the reverse order of removal:

NOTE:

. Always use a new head and manifold gasket.

. The cylinder head gasket is a metal gasket Take care

not to bend it.

. Rotate the crankshaft, set the No. 1 piston at TDC

(page 6-51).

. Do not use the middle cover and lower cover for

storing items disassembled.

. Clean the middle cover and lower cover before instal-

lation.

a Replace the washer when damaged or deteriorated

1. tnstall the cylinder head gasket. dowel pins and the

head oil control orifice on the cylinder head

NOTE: Clean the oil control orifice when installing.

O.RINGReplace.

HEADOIL CONTROLORIFICECloan.

2. Tighten cylinder head bolts in two steps. In the first

step, tighten all bolts in sequence to about 29 N'm

(3.0 kgf.m.22 lbf'ft). In the final step, tighten in

same sequence to 81 N.m (8.3 kgnm.60 lbf'ft).

NOTE: Apply clean engine oil to the bolt threads

and under the bolt head.

CYLINDER HEAD BOLT TOROUE SEOUENCE

11 x 1.5 mm81 N.m {8.3 kgf.m,60 lbf ft)

Install the intake manifold and tighten the nuts in a

crisscross pattern in two or three steps, beginning

with the inner nuts.

GASKETRePlace

8 x 1.25 mm23 N.m 12.3 kgl.m.17 tbf.ftt

8 x 1.25 mm24 N,m 12.,4 kgf m,17 tbf.ft)(cont'd)

6-75

Page 139 of 1413

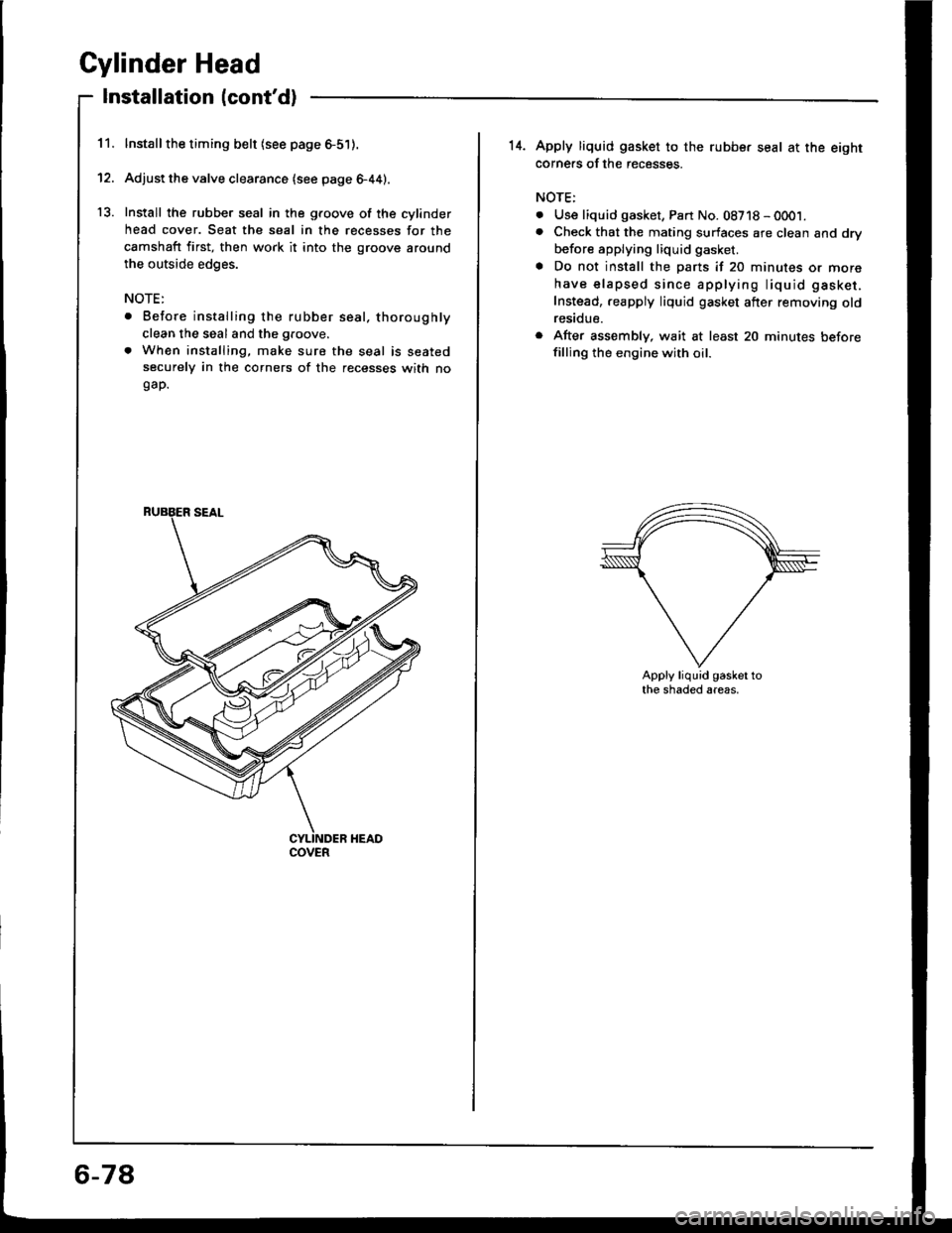

11.

12.

13.

Cylinder Head

Installation lcont'd)

lnstallthe timing belt lsee page 6-51).

Adjust the valve clearance (see page 6-44).

Install the rubber seal in the groove of the cylinder

head cover. Seat the seal in the recesses for the

camshaft first, then work it into the groove around

the outside edges.

NOTE:

. Before installing the rubber seal. thoroughly

clean the seal and the groove.

. When installing, make sure the seal is seatedsecurely in the corners of the recesses with nogap.

COVER

6-78

14. Apply liquid gasket to the rubbe. seal at the eightcorne.s of the recesses.

NOTE:

. Use liquid gasket, Part No. 08718 - 0001.. Check that the mating surfaces are clean and dry

before applying liquid gasket.

a Do not install the parts if 20 minutes or more

have elapsed since applying liquid gasket.

Instead,.eapply liquid gasket after removing oldresidue.

r After assembly, wait at least 20 minutes beforefilling the engine with oil.

Apply liquid gasket tothe shaded areas.

Page 141 of 1413

Engine Block

Speciaf Tools .............7'2

lllustrated Index ................................... 7-3

Flywheel and Drive Plate

Repfacement .........7-7

Main Bearings

Clearance ,.............. 7-8

Selection ................ 7-8

Connecting Rod Bearings

Clearance ............... 7-9

Selection ................ 7-9

Crankshaft

Removal .................7-10

End Play .................7-12

lnspection ........,,,.,,7-12

fnstallation .............7'22

Cylinder Block

Inspeetion ..............7-13

Bore Honing .....,.,,.7'14

Pistons

Inspaction ..............7-15

Installation .............7-16

Piston Rings

Replacement .........7-16

End Gap .................7-17

Ring-To-Groove C|earance,,,,.,,,...... 7 -17

Alignment ..............7-18

Piston Pins

Removal ........,........7-18

Installation (818B1 engine) ............. 7-19

fnstaffation (818C1 enginel ............. 7-20

fnspection ..............7-2O

Connecting Rods

End Play .................7-21

Sefeetion ..........,,,,,,7-22

Oil Seal

fnstaffation .............7-25

Installation

(engine removal not requiredl.. .......7-26

Page 143 of 1413

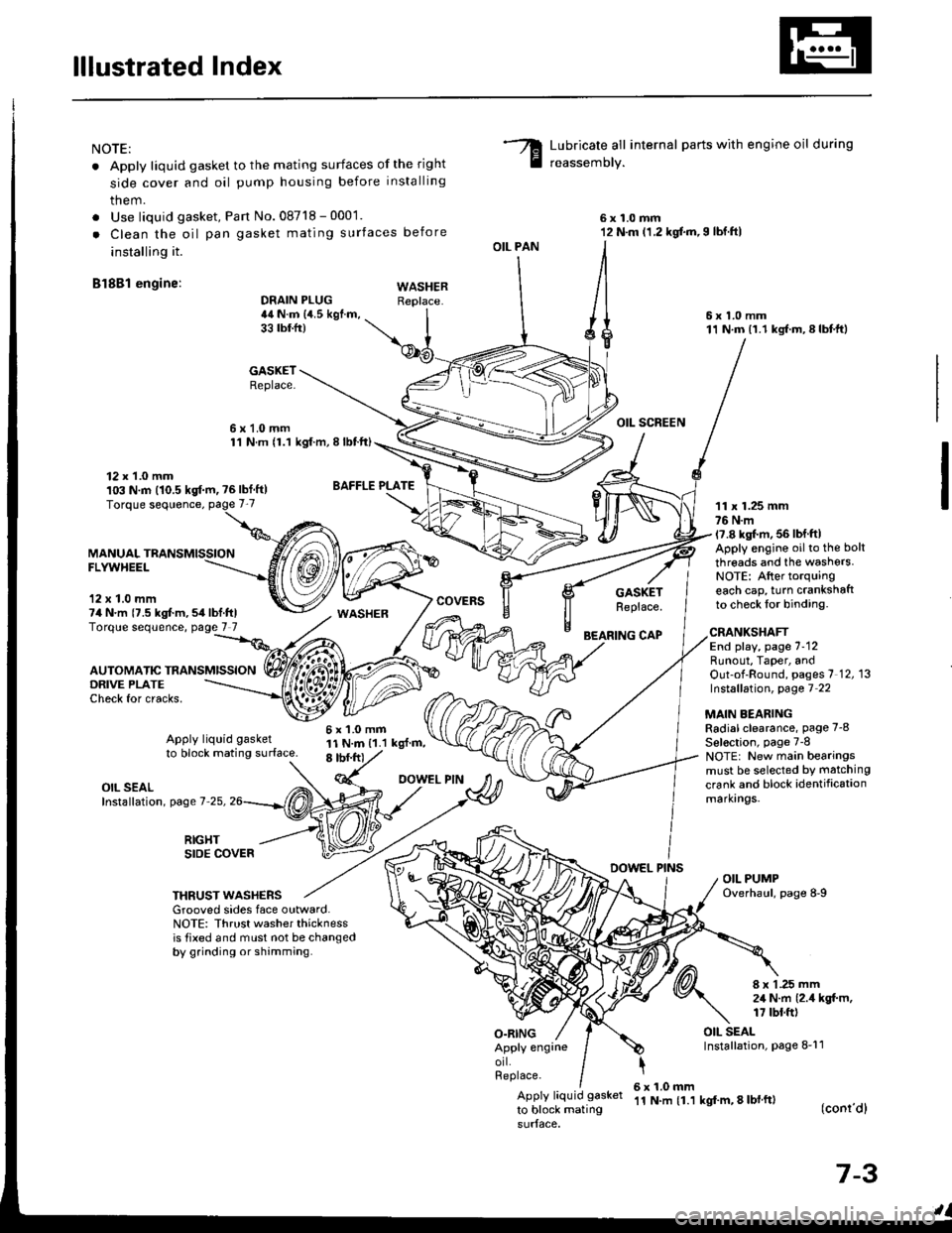

lllustrated Index

NOTE:

. Apply liquid gasket to the mating surfaces of the right

side cover and oil pump housing before installing

them.

. Use liquid gasket, Pan No.08718 - 0001.

. Clean the oil pan gasket mating surfaces before

installing it.

Bl8Bl engine: wAsHEF

Lubricate all internal parts with engine oil during

reassemory.

6x1.0mm12 N.m (1.2 kgf.m,I lbf.ftl

6x1.0mm11 N.m (1.1 kgf.m,8lbtft)

OIL SCREEN

11 x 1.25 mm76 N.m17.8 kgl.m, 56 lbf ftlApply engine oilto the bolt

threads and the washers.NOTE: After torquingeach cap, turn crankshaftto check lor binding.

DRAIN PLUG44 N.m {4.5 kgf.m,33 tbtfr)

GASKETReplace.

6x1.0mm1'l N.m {1.1 kgt.m, I lbtft)

OIL PAN

O.RING

GASKETReplace.

BEARING CAP

12 x 1.0 mm103 N.m (10.5 kgf.m, ?6lbf ft)

MANUALFLYWHEEL

'12 x 1.0 mm74 N.m {7.5 kgt m,54lbf.ftlTorque sequence, page 7 7

DRIVE PLATECheck for cracks,

AUTOMATIC TRANSMISSION

WASHER

6x1.0mm11 N.m {1.1 kgl.m,8 tbf.frt

CRANKSHAFTEnd play, page 7-12Runout, Taper, andOut-of-Round, pages 7 12, 13Instsllation, page 7 22

MAIN BEARINGRadial clearance, page 7-8

Sel€ction, page 7-8NOTE: New main bearingsmust be selected by matching

crank and block identificationmarkrngs.

Apply liquid gasket

to block mating surface.

OIL SEALInstallation, page 7-25,

RIGHTSIDE COVERDOWEL PINSOIL PUMPOverhaul, page 8-9THRUST WASHERSGrooved sides face outward.NOTE: Thrust washer thicknessis tixed and must not be changedby grinding or shamming.

8 x 1 .25 mm2,1 N.m {2.4 kgt m,17 tbt.ft)

OIL SEALInstallation, page 8-11Apply engrneorl.Replace.

Apply liquid gasket

to block mating

6x1.0mm'11 N.m {1.1 kgf'm, 8 lbl ft)(conr'dl

7-3

Page 144 of 1413

lllustrated Index

(cont'd)

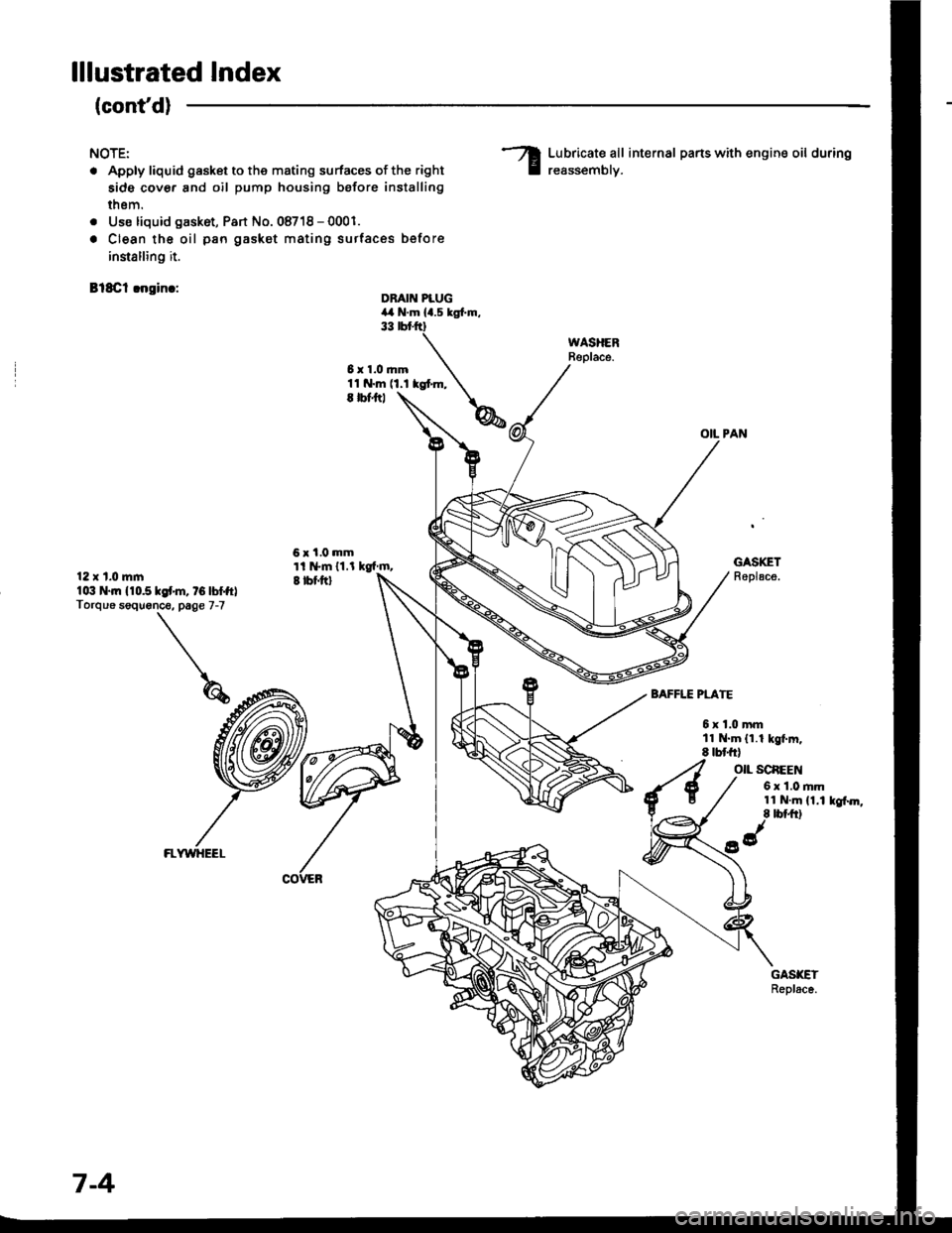

NOTE:

. Apply liquid gasket to the mating surfaces of the right

side cover and oil pump housing before installing

thsm.

. Use liquid gask6t, Part No. 08718 - 0001.

. Clean the oil pan gasket mating surtac€s before

innalling it.

Bl8Cl !ngin.:

Lubricate all internal parts with engine oil during

reassemblv.

OIL PAN

DBAIN PLUG4,a N.m la.s tgl.m.33 rbr.ftt

6x1.0mm11 N.m (1.1 kgt m,E |bfitl

6x1.0mmti l*m 11.l kgf m,I tbf.ftl

GASKETReplace.12 x t.0 mlnlo:t N.|n 110.510f'm, tG lbffrlTorque soquonce. page 7-7

BAFFLE PLATE

6xl.0mmll N.m (1.1 kgt m.8 tbt frl

O|L SCAEEN

6 x 1.0 rim11 N.m (1.1 kgf.m,8 tbt ft)

FLWYHEEL

7-4

Page 145 of 1413

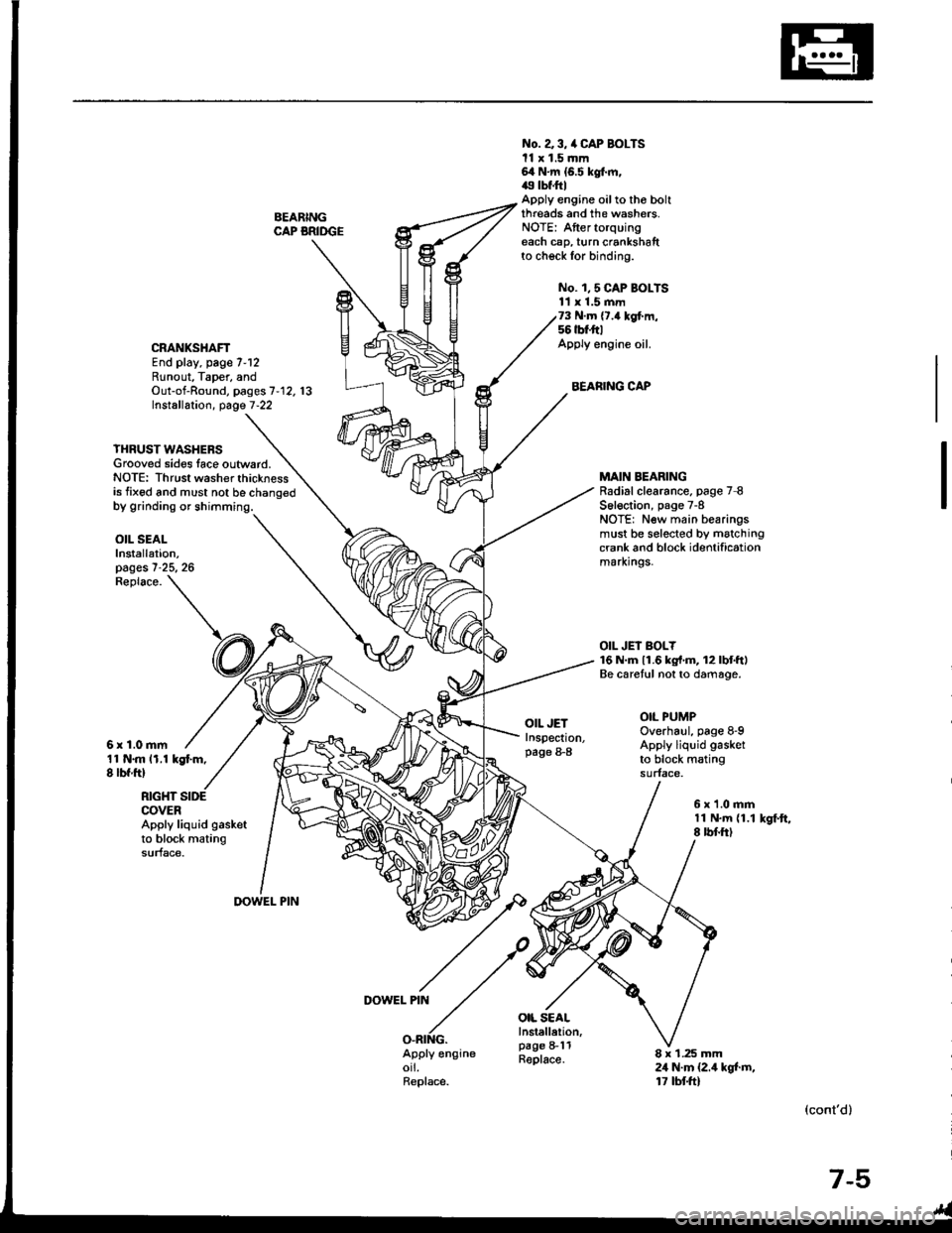

BEARINGCAP BRIDGE

No. a 3, /a CAP BOLTSll x 1.5 mm64 N.m {6.5 kgt m,49 tbf.ftlApply engine oilto tho boltthreads and the washers.NOTE: Aftertorquingeach cap, turn crankshaftto check for binding.

No. 1,5 CAP BOI-TS11 x 1.5 mm73 N.m {7.4 kgf.m,56 tbt'ft|Apply engine oil.

BEARING CAP

CRANKSHAFTEnd play, page 7-12Runout, Taper, andOut-of-Round, pages 7'12. 13Installation, page 7-22

YHRUST WASHERSGrooved sides lace outward.NOTE: Thrust washer thicknessis fixed and must not be chano€d

MAIN BEARINGRadial clearance. page 7 8S6l€ction, page 7-8NOTE: New main bearingsmust be selected by matchingcrank and block identificationmarxrngs.

OIL JEI BOLY16 N.m 11.6 kg{'m, 12lbtftlBe caretul not to damage.

OIL PUMPOverhaul, page 8-9Apply liquid gasket

to block matingsurface.

OIL SEALInstallation,pages 7-25, 26

11 N.m 11.1 kgt m,8 lbf ftl

Replace.

6r1.0mm

OIL JETInspection,page 8-8

OIL SEALInstellelion,page 8-11Replace.

RIGHT SIDECOVERApply liquid gasketto block matingsurface.

6x1.0mm11 N.m {1.18 rbf.ftlkSf.ft,

DOWEL PIN

DOWEL PIN

O.RING.Apply engineorl.Replace.

8 x 1.25 mm24 N.m {2.4 kgt m,17 tbtft)

(cont'd)

7-5