torque ACURA INTEGRA 1994 Service Manual PDF

[x] Cancel search | Manufacturer: ACURA, Model Year: 1994, Model line: INTEGRA, Model: ACURA INTEGRA 1994Pages: 1413, PDF Size: 37.94 MB

Page 553 of 1413

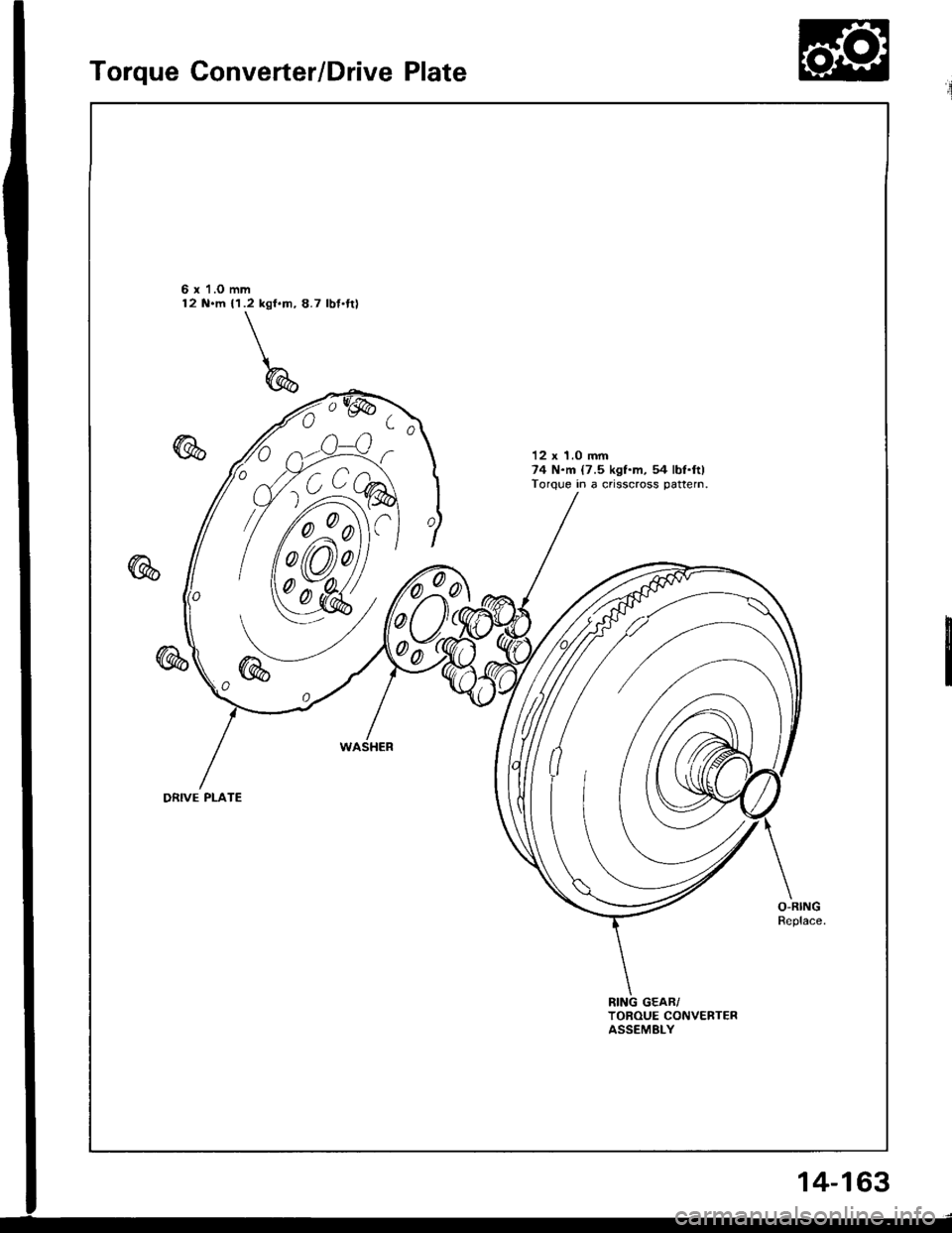

Torque Converter/Drive Plate

6 x'l.O mm12 N.m {1.2 kgf.m, 8.7 lbf'tt)

12 x 1.0 mm74 N.m {7.5 kgf.m, 54 lbl.ftlTorque in a crisscross pattern.

0

0d

DRIVE PLATE

TOROUE CONVERTERASSEMELY

14-163

Page 554 of 1413

Transmission

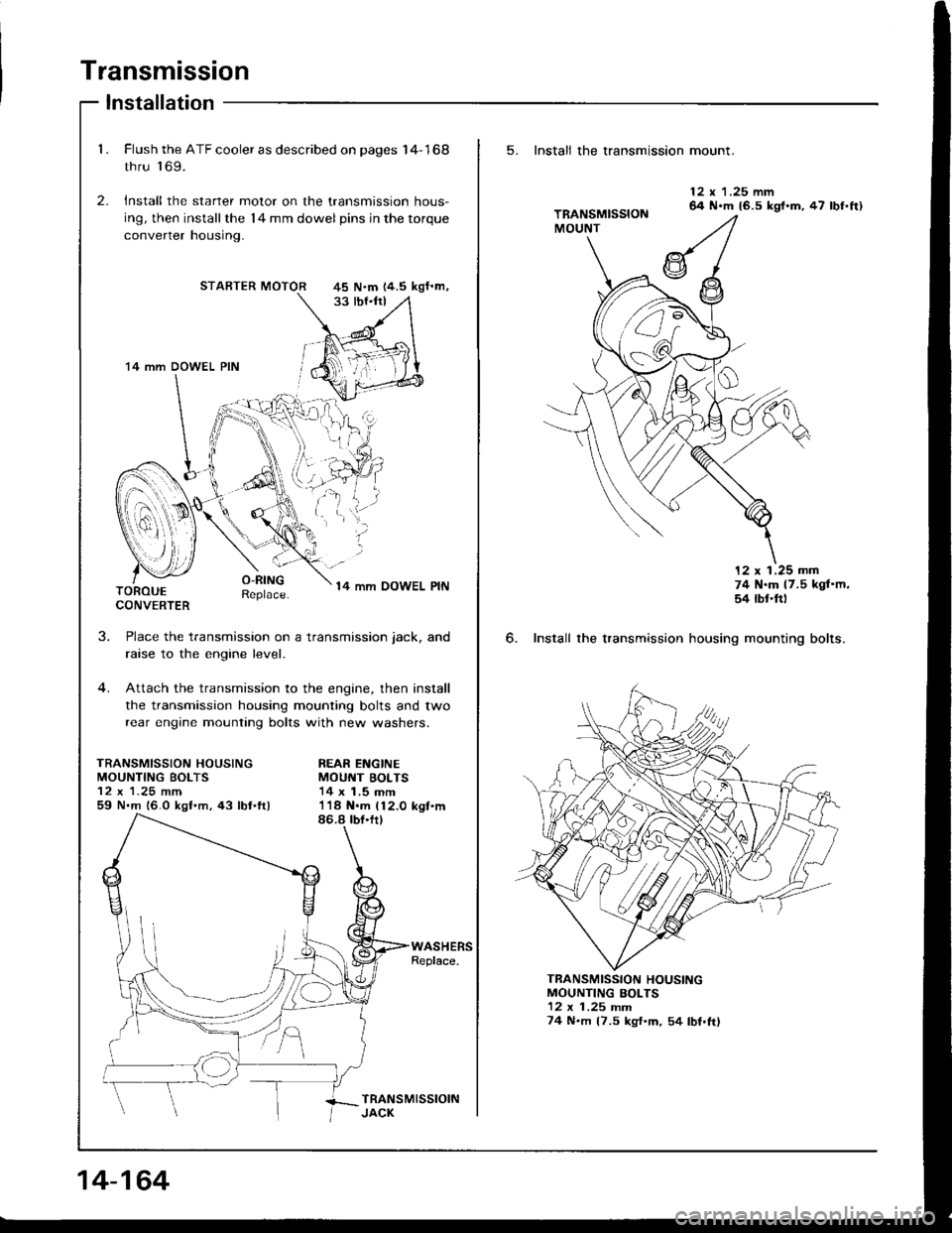

Installation

1. Flush the ATF cooler as described on pages I4-168

thru 'l 69.

2. Install the starter motor on the transmission hous-

ing, then installthe l4 mm dowel pins in the torque

converrer nousrng.

STARTER MOTOR

O-RINGReplace.14 mm OOWEL PINTOROUECONVERTER

J.

TRANSMISSION HOUSINGMOUNTING BOLTS

59 N.m 16.0 kgf.m,43 lbl.ftl

Place the transmission on a transmission jack, and

raise to the engine level.

Attach the transmission to the engine, then install

the transmission housing mounting bolts and two

rear engine mounting bolts with new washers.

REAR ENGINEMOUNT BOLTS14 x 1.5 mm

45 N.m 14.5 kgf'm,

'14 mm DOWEL PIN

I

i.'l,i;

14-164

5. Install the transmission mount.

6. Install the transmission

12 x 1.25 mm64 N.m 16.5 kgl.m, 47 lbf.ft)

12 x 1.25 mm74 N.m 17.5 kgf'm,54 rbt'ft)

housing mounting bolts.

MOUNTING BOLTS12 x 1 .25 rnm74 N.m (7.5 kgf'm, 54 lbf.ftl

TRANSMISSION HOUSING

Page 555 of 1413

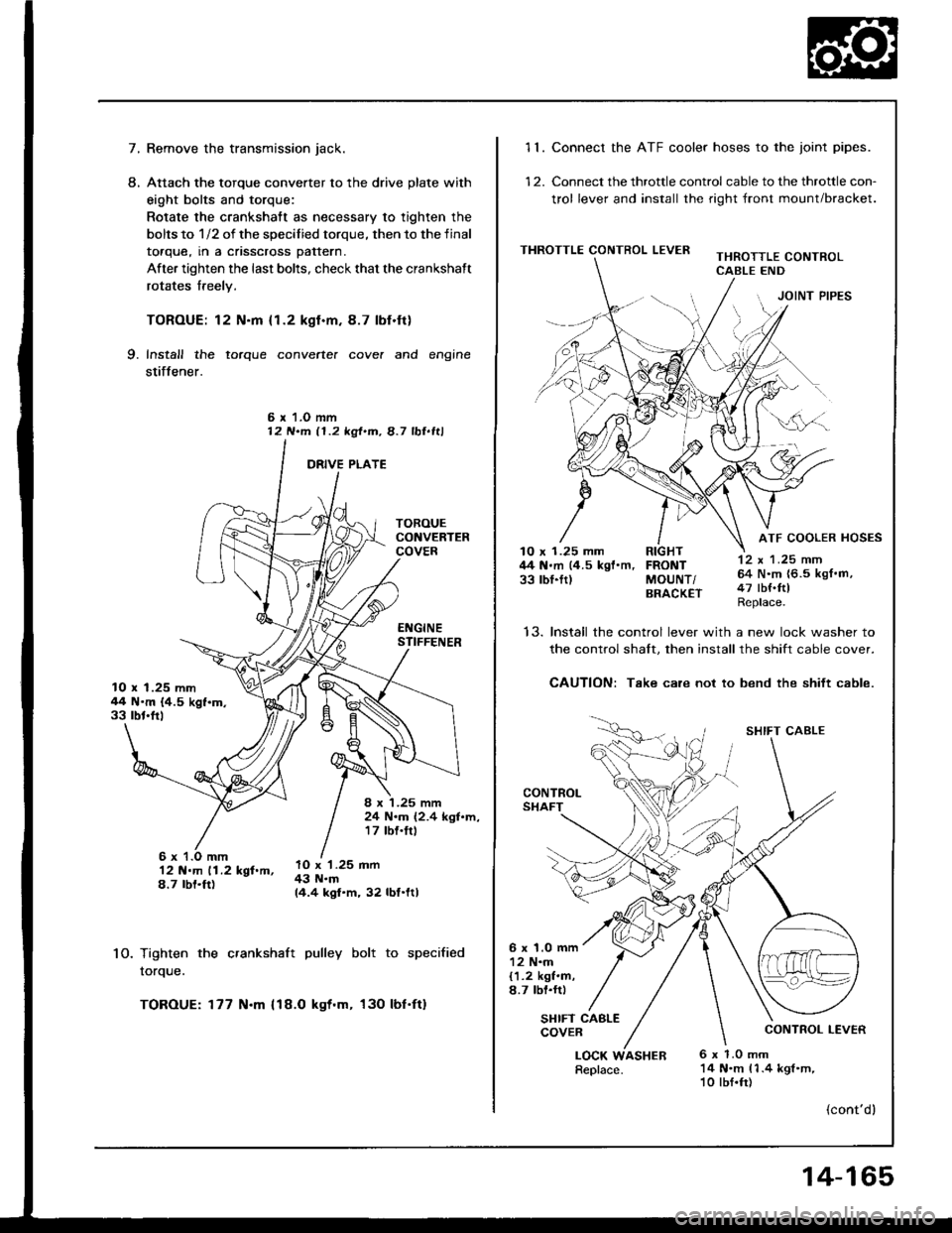

7.Remove the transmission jack.

Attach the torque converter to the drive plate with

eight bolts and torque:

Rotate the crankshatt as necessary to tighten the

bolts to 1/2 of the specilied torque, then to the final

toaque, rn a cnsscross pattern.

After tighten the last bolts, check that the crankshaft

rotates freely.

TOROUE: 12 N.m {1.2 kgl.m.8.7 lbf.ft}

Install the torque converte. cove. and engine

stiffener.

L

9.

6 r 1.O mm12 N.m 11.2 kgt.m, 8.7 lbl.ltl

10.

12 N.m 11.2 kgf.m,8.7 rbt.ft)

Tighten the crankshaft pulley bolt to specified

rorque.

TOROUE: 177 N.m {18.O kgt.m, 130 lbf'ft}

10 x 1.25 mm44 N'm {4.5 kgf.m.33 rbt'frl

8 x '1.25 mm24 N.m (2.4 kgl.m,17 tbf.trl

lO x '1.25 mm43 N.m14.4 kgf.m, 32 lbf.ltl

11. Connect the ATF cooler hoses to the joint pipes.

12. Connect the throttle control cable to the throttle con-

trol lever and install the right front mount/bracket.

THROTTLE CONTROL LEVERTHROTTLE CONTROLCABLE END

JOINT PIPES

12 x 1 .25 mm64 N.m {6.5 kgf.m,47 tbf.ftlReplace.

ATF COOLER HOSES10 x 1.25 mm RIGHT44 N.m (4.5 kgf'm, FRONT33 rbl.ftl MoUNT/BRACK€T

t5.Install the control lever with a new lock washer to

the control shalt. then install the shift cable cover.

CAUTION: Take care not to bend the shift cable.

CONTROLSHAFT

SHIFT CABLE

CONTROL LEVER

6 x 1.0 mm12 N.m{1.2 kgf.m,8.7 lbl.rr)

SHIFT CABLECOVER

LOCK6 x 1.0 mm14 N.m 11.4 kgl.m,10 lbf.fr)

(cont'dl

Replace.ASHER

14-165

Page 582 of 1413

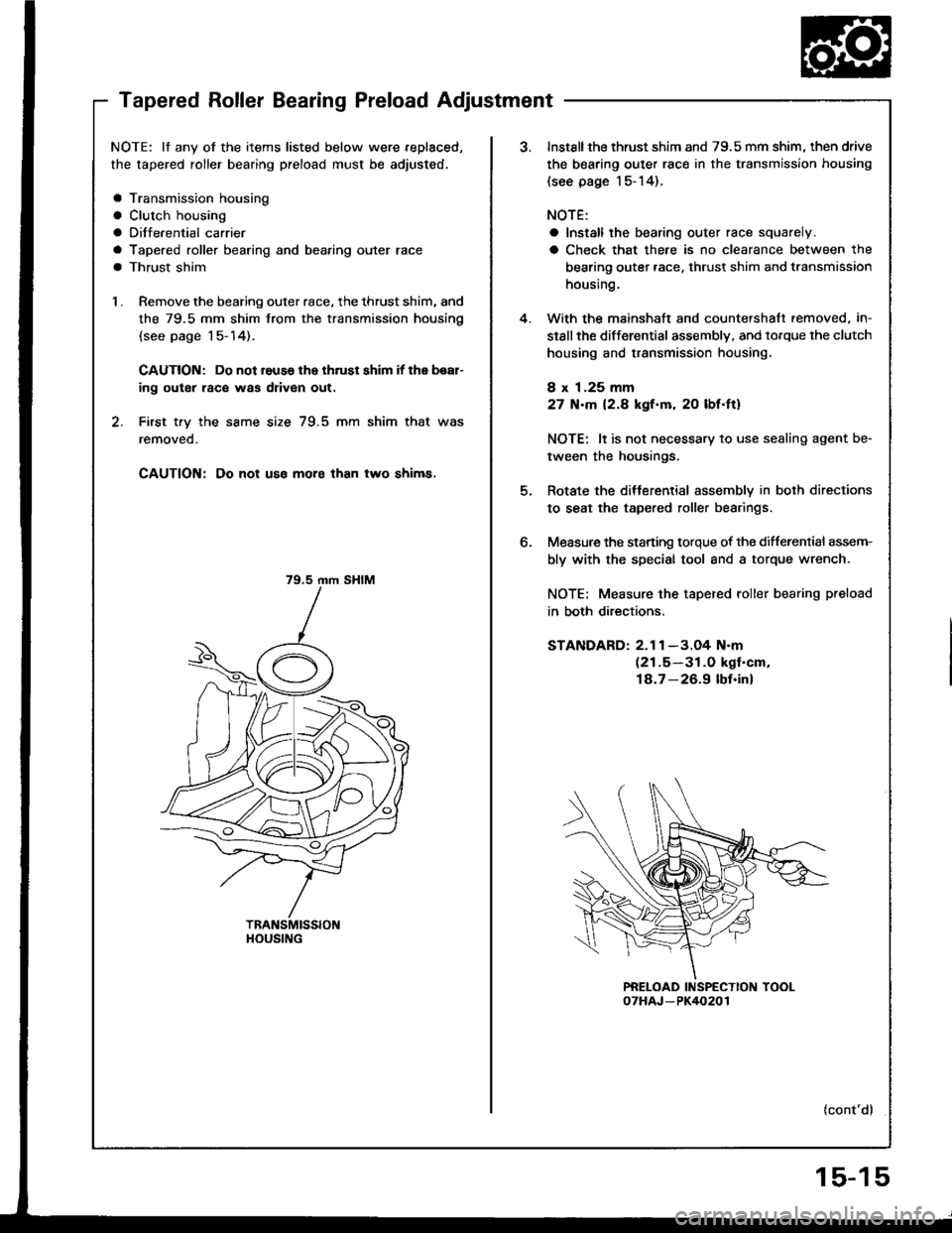

Tapered Roller Bearing Preload Adjustment

NOTE: lf any of the items listed below were replaced,

the tapered roller bearing preload must be adjusted,

a Transmission housing

a Clutch housing

a Diffe.ential carrier

a Tapered roller bearing and bea,ing outer race

a Thrust shim

1 . Remove the bearing outer race, the thrust shim, and

the 79.5 mm shim from the transmission housing

(see page 1 5- 14).

CAUTION: Do not reuss lhe thrust shim it the bear-

ing outer raco was driven out.

2. First t.y the same size 79.5 mm shim that was

removeo.

CAUTION; Do not uso moro than two shims.

79.5 rnm SHIM

HOUSING

4.

o.

Instsllthe thrust shim and 79.5 mm shim, then drive

the bearing outer race in the transmission housing

{see page l5-14).

NOTE:

a Install the bearing outer race squarely.

a Check that there is no clearance between the

bearing outer race. thrust shim and transmission

housing.

With the mainshaft and countershaft.emoved, in-

stsllthe differential assembly, and lorque the clutch

housing and transmission housing,

8 x 1.25 mm

27 N.m 12.8 kgf.m, 20 lbf.ft)

NOTE: lt is not necessary to use sealing agent be-

tween the housings.

Rotate the ditterential assembly in both directions

to seat the tapered roller bearings.

Measure the starting torque of the differenlial assem-

bly with the special tool and a torque wrench.

NOTE: Measure the tapered roller bearing preload

in both directions.

STANDARD: 2.1 1 -3.O4 N.m(21.5-31.0 kgf'cm,

18.7-26.9 lbf.inl

{cont'd}

15-15

Page 589 of 1413

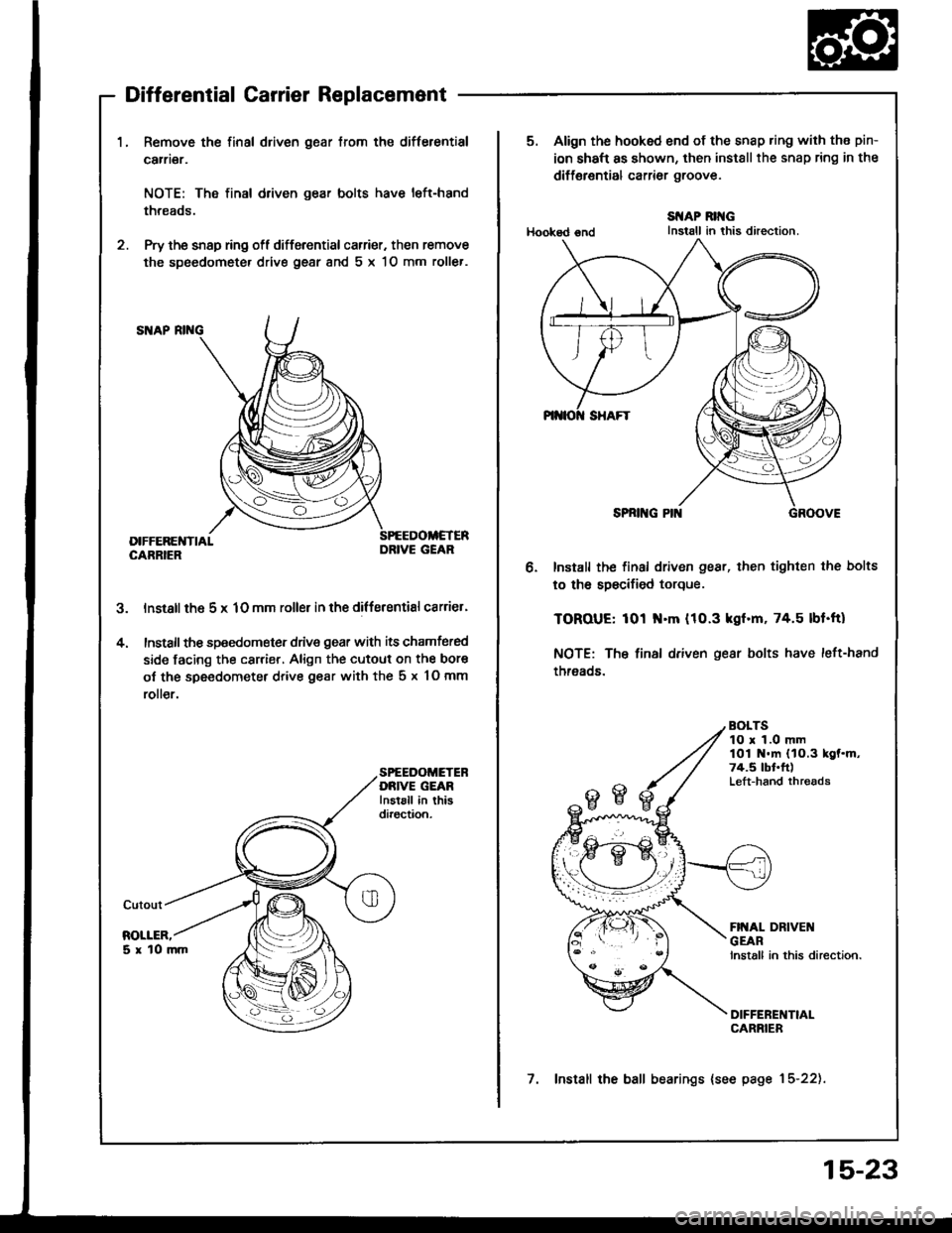

Differential Carrier Replacement

1.Remove the final driven gear from the differential

carrier.

NOTE: Tho final driven gear bolts have left-hand

threads.

Pry the snsp ring ofl differential carrier. then remove

the speedometer drive gear 8nd 5 x 1O mm roller.

lnstall th6 5 x 1O mm roller in the differentisl csrrier'

Install the speedom€ter drive gear with its chamfered

side facing the carrier, Align the cutout on the bore

of the speedometer drive gesr with the 5 x 10 mm

roll€r.

5.

4.

SPEEDOMETEBDRIVE GEARInstsll in thisdiroction.

DRIVE GEAR

5. Align the hooked end of the snap ring with the pin-

ion shaft as shown, then installthe snap ring in the

diff€rential carrior groove.

Hooksd €nd

SI{AP RII{GInstall in this direction.

o.Install the final driven gear, then tighten the bolts

to th6 spscified torque.

TOROUE: 101 N.m (10.3 kgf.m, 74.5 lbf.ft)

NOTE: The final driven gear bolts have left-hand

threads.

BOLTS10 r 1.0 mmlOi N.m (1O.3 kgf.m,74.5 tbt'ft)Left-hand thrgads

7. Install the ball bearings {see page 15-22).

15-23

Page 590 of 1413

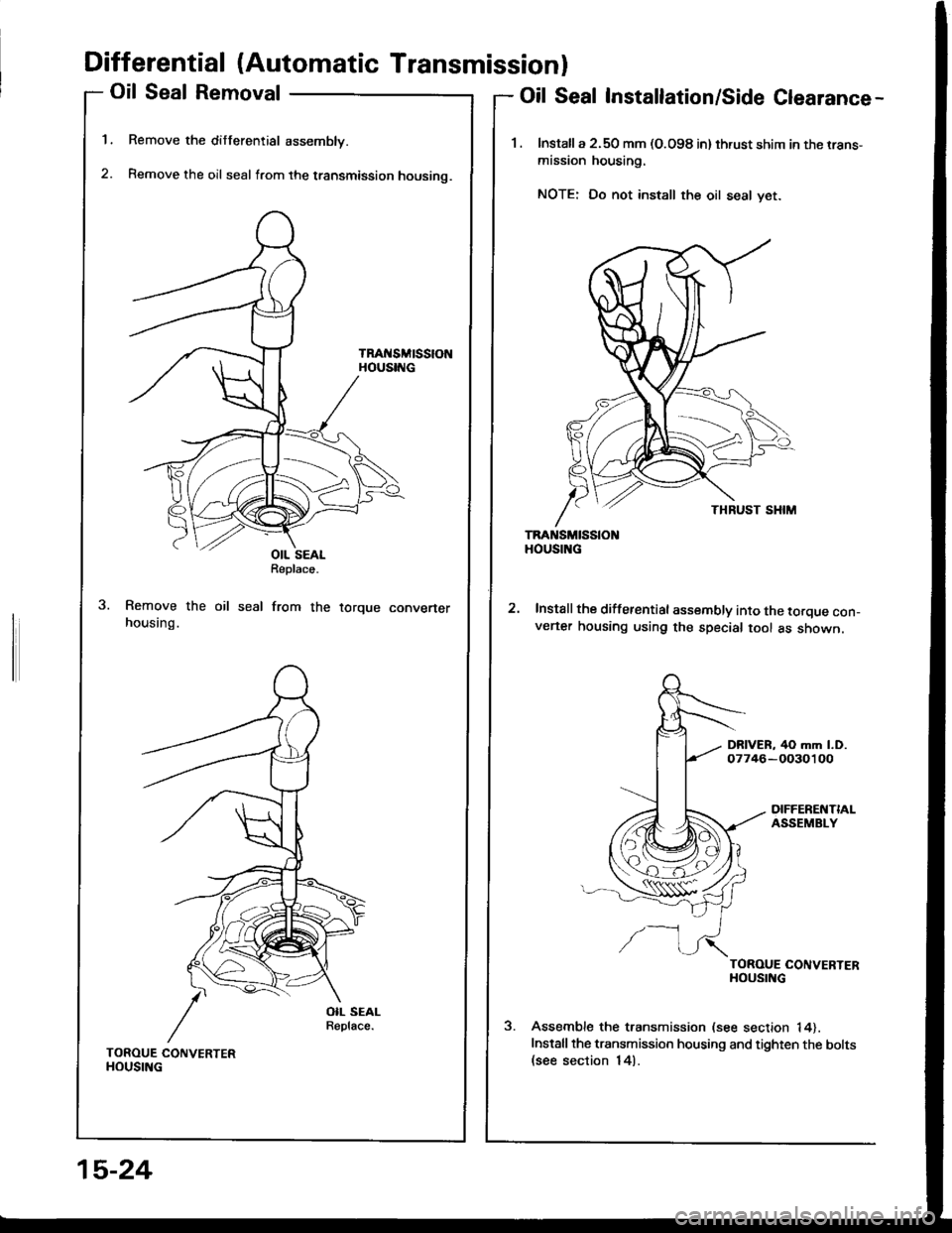

Differential (Automatic Transmissionl

Oil Seal Removal

Remove the differential assembly.

Remove the oil seal from the transmission housino.

TRAt{SMtSStONHOUSING

1.

2.

Oil Seal Installation/Side Clearance-

1. lnstalla 2.50 mm (O.O98 in) thrust shim in the rrans-

mission housing.

NOTE: Do not install the oil seal yet.

TRANSMISSIOHOUSING

Install the differential assembly into the torque con_v€ner housing using the special tool as shown.

DRIVER, 40 mm l.D.07746-OO30100

DIFFERENTIALASSEMBLY

/-l

TOROUE CONVERTERHOUSING

Assemble the transmission (see section 14).

Installthe transmission housing and tighten the bolts(see section 14).

OIL SEALReplace.

seal from therorque convener

TOROUE CONVERTERHOUSING

15-24

Page 591 of 1413

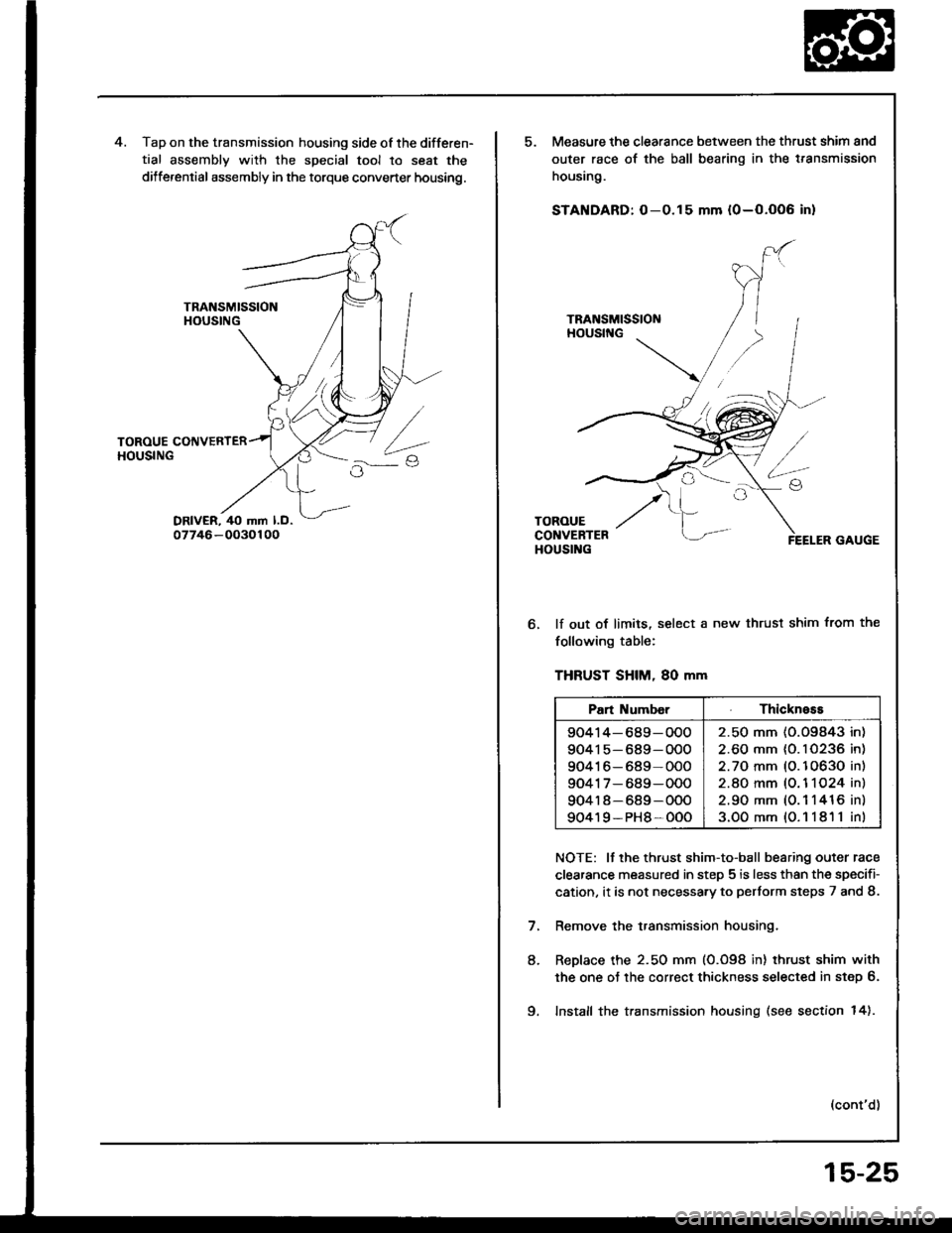

Tap on the transmission housing side of the differen-

tial assembly with the special tool to seat the

dilferential assembly in the torque converter housing.

Measure the clearance between the thrust shim and

outer race of the ball bearing in the t.ansmission

housing.

STANDARD: O-0.15 mm {0-O.OO6 in}

lf out of limits, select a new thrust shim from the

following table:

THFUST SHIM, 80 mm

NOTE: It the thrust shim-to-ball bearing outer race

clearance measured in step 5 is less than the specifi-

cation, it is not necessa.y to pertorm steps 7 and 8.

Remove the transmission housing.

ReDlace the 2.50 mm (0.098 in) thrust shim with

the one oJ the correct thickness selected in step 6.

Install the transmission housing (see section 14).

(cont'd)

8.

Pan Numb€rThickness

90414-689-OOO

90415-689-OOO

90416-689-000

9041 7- 689-000

904r 8-689-OOO

90419-PH8-OOO

2.50 mm (O.O9843 in)

2.60 mm {0. I 0236 in)

2.70 mm (O.10630 in)

2.8O mm (O. 1 1O24 in)

2.90 mm (0.1 1416 in)

3.OOmm{O.11811in)

9.

15-25

Page 592 of 1413

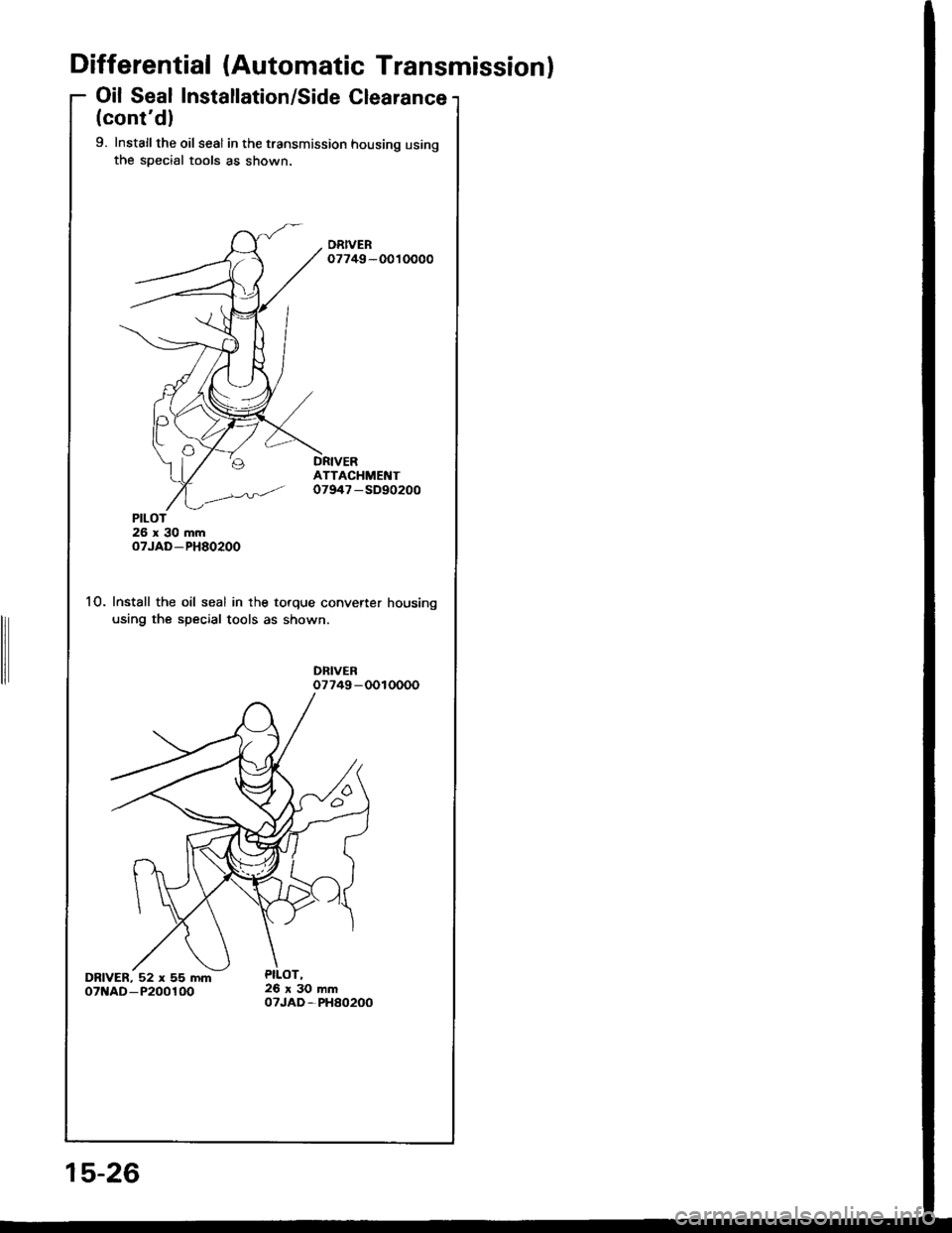

Differential (Automatic Transmissionl

Oil Seal Installation/Side Clearance

(cont'dl

9. Installthe oil seal in the transmission housing usingthe special tools as shown.

DRIVER07749-0010000

ATTACHMENT07947 -SD90200

26x30mmoTJAD-PH80200

10. Install the oil seal in the torque converter housing

using the special tools as shown.

DFIVER07749-0010000

DRIVER, 52 x 55 mmoTNAD-P200100

PILOT

15-26

Page 618 of 1413

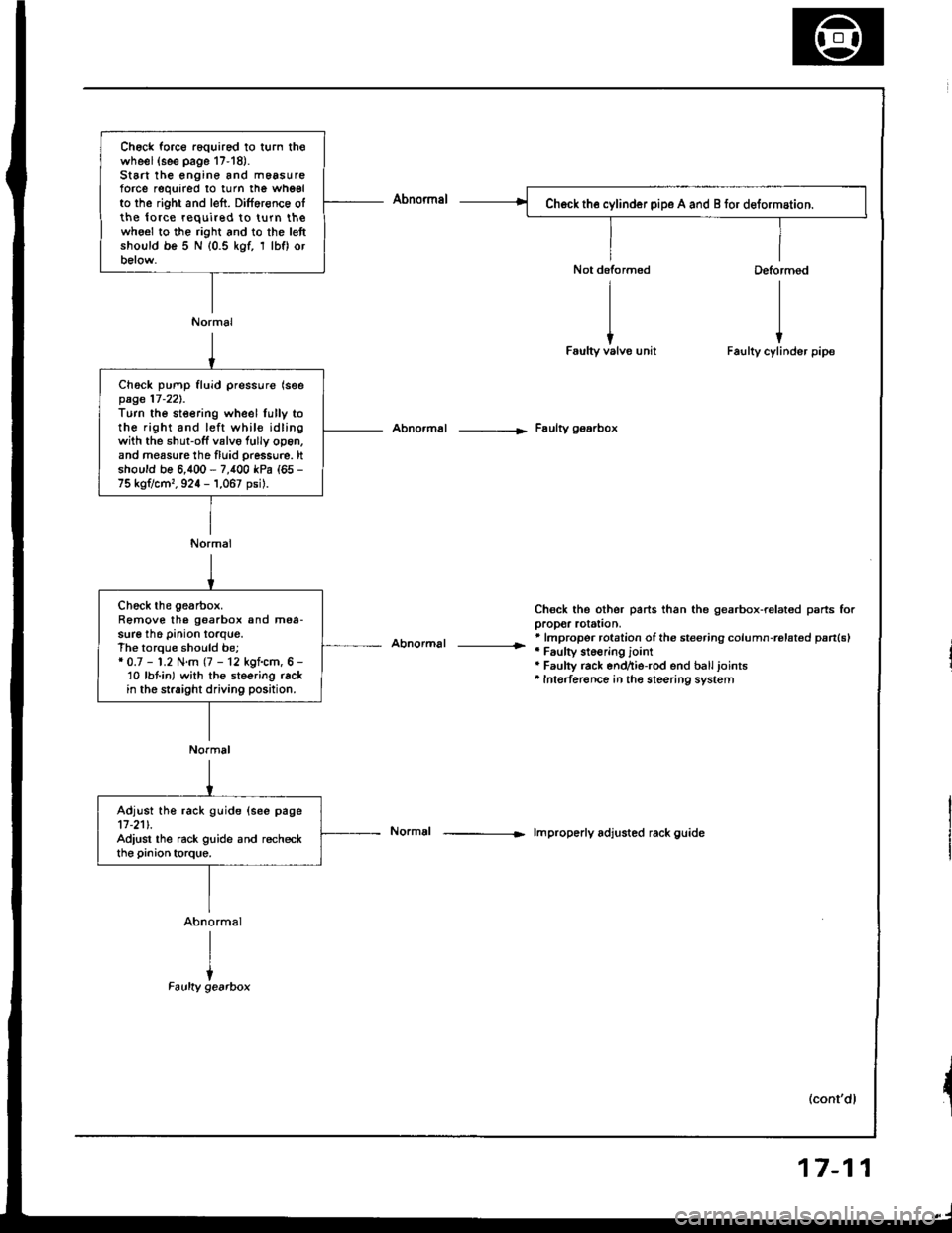

Ch6ck force r6quired to turn thowheel(see page 17-18).St6 the engine and m6asureforce required to turn the whgelto the right and left. Dilference olthe lo.ce required to turn thewho€l to the right and to the lettshould be 5 N (0.5 kgf, 1 lbf) orbelow.

Normal

Ch6ck pump fluid pressure (seepage 17-221.Turn the steering wheel lully tothe right and left whil€ idlingwith the shut-off valvo fully op6n,and measure tho fluid pressu.e. ltshould be 6,400 - 7,400 kPa (65 -

75 kg?cm,, 924 - 1,067 psil.

Normal

Abnormal -----|. Faulty gearbox

Abnormal |r

Chsck the other parts than the gearbox-ralated psrts forpropor rotstion,* lmpropor rotation ofthe steering column-rolat€d pan(sl'Faulty st6€ring jointa Faulty rack end^ie-rod end balljoints'Intederence in the steering system

lmproperly adjusted rack guide

(cont'dl

Chock the gearbox.Remove the goarbox and mea-sure the pinion torque.The torque should be;* 0.7 - 1.2 N.m (7 - 12 kgf.cm, 6 -'10 lbt in) with the steering rackin the straight driving position.

Normal

Adjust the rack guide (see page11-211.Adiust the rack guide and recheckthe pinion torque.

17-11

Page 639 of 1413

Steering Column

Installation (cont'dl

Finaltorque:22 N.m{2.2 kgf.m, 16lbt.ftl

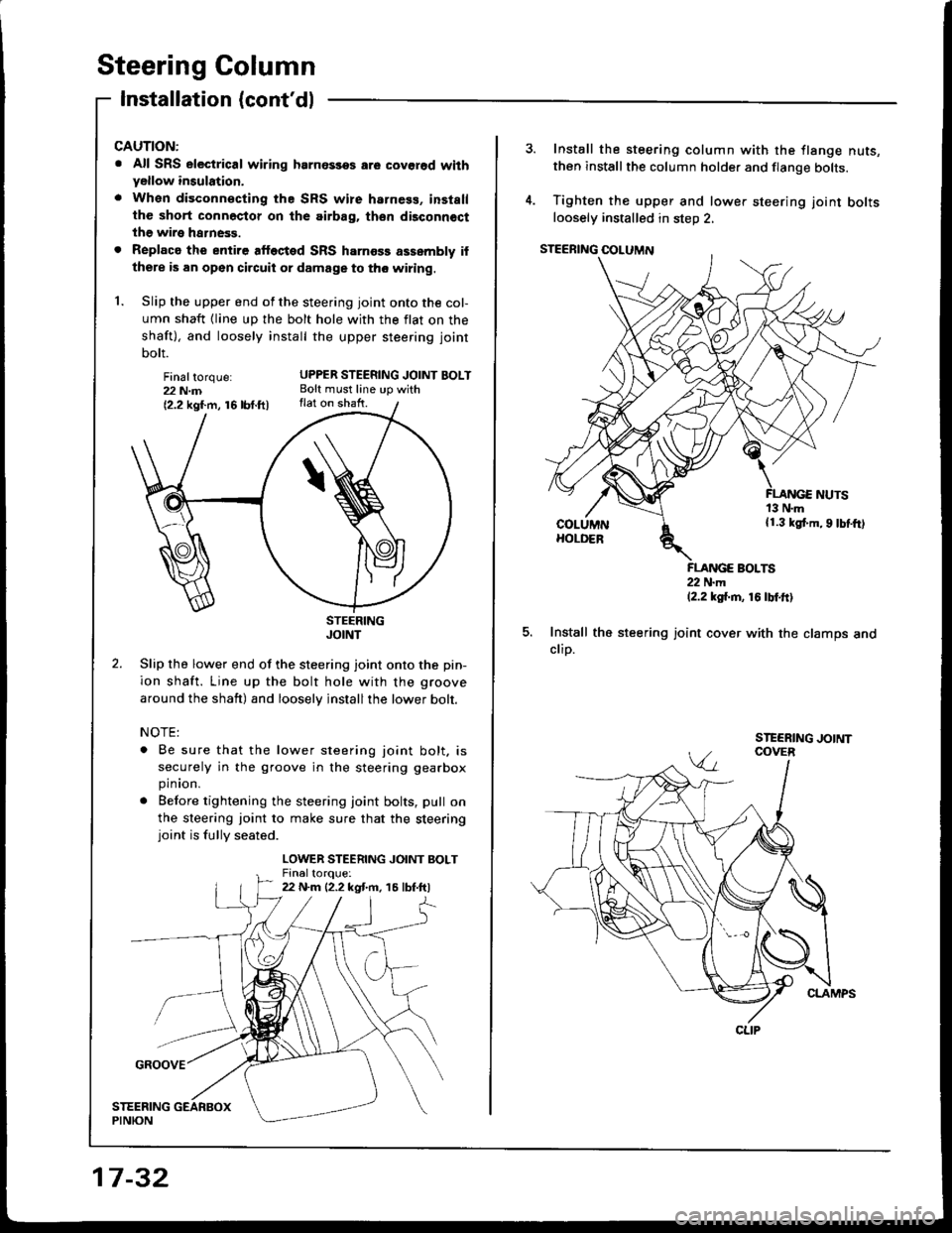

CAUTION:

. All SRS electrical wiring hrrnossos are covgrod wilhyellow insulation,

. When disconn€cting the SRS wire harness, installthe short connector on the airbag. th€n dbconnoct

the wire harness.

. Replaca the entire alfected SRS harness assembly if

there is an open circuit or damage to tho wiring.

1. Slip the upper end of the steering joint onto the col-

umn shaft {line up the bolt hole with the flat on the

shaft), and loosely install the upper steering joint

bolt.

UPPER STEERING JOINT BOLTBolt must line up withflat on shaft.

STEERINGJOINT

Slip the lower end of the steering joint onto the pin-

ion shaft. Line up the bolt hole with the groove

around the shaft) and loosely jnstallthe lower bolt.

NOTE:

. Be sure that the lower steering joint bolt. is

securely in the groove in the steering gearbox

pinion.

. Before tightening the steering joint bolts, pull on

the sleering joint to make sure that the steeringjoint is fully seated.

LOWER STEERING JOINT BOLTFin6ltoroue:22 N.m {2.2 kgt m. 15 lbf.ftl

17 -32

Install the steering column with the flange nuts,then installthe column holder and flange bolts.

Tighten the upper and lower steering joint boltsloosely installed in steD 2,

FLANGE BOLTS22 N.m12.2 ksi.m, 16 tbtftl

Install the steering joint cover with the clamps andclip.

CLIP