Torque mount ACURA INTEGRA 1994 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1994, Model line: INTEGRA, Model: ACURA INTEGRA 1994Pages: 1413, PDF Size: 37.94 MB

Page 46 of 1413

Engine Removal/lnstallation

Special Tools ........ .".....5-2

Engine Removal/lnstallation ..."........ 5-3

Mount/Bracket Torque ..' 5-16

Page 61 of 1413

il

I

I

I

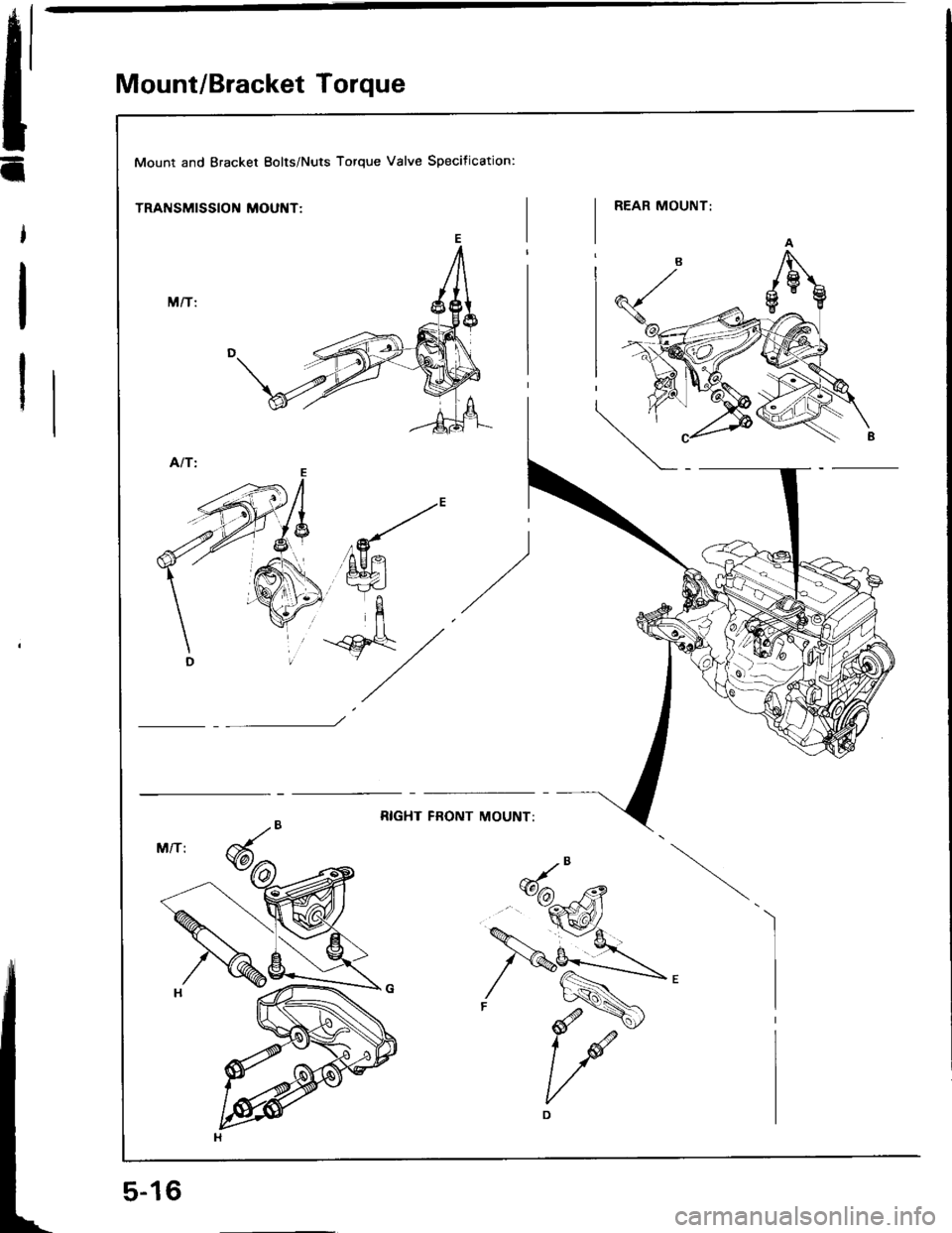

Mount/Bracket Torque

Mount and Bracket Eolts/Nuts Torque Valve Specification:

TRANSMISSION MOUNT:

Page 63 of 1413

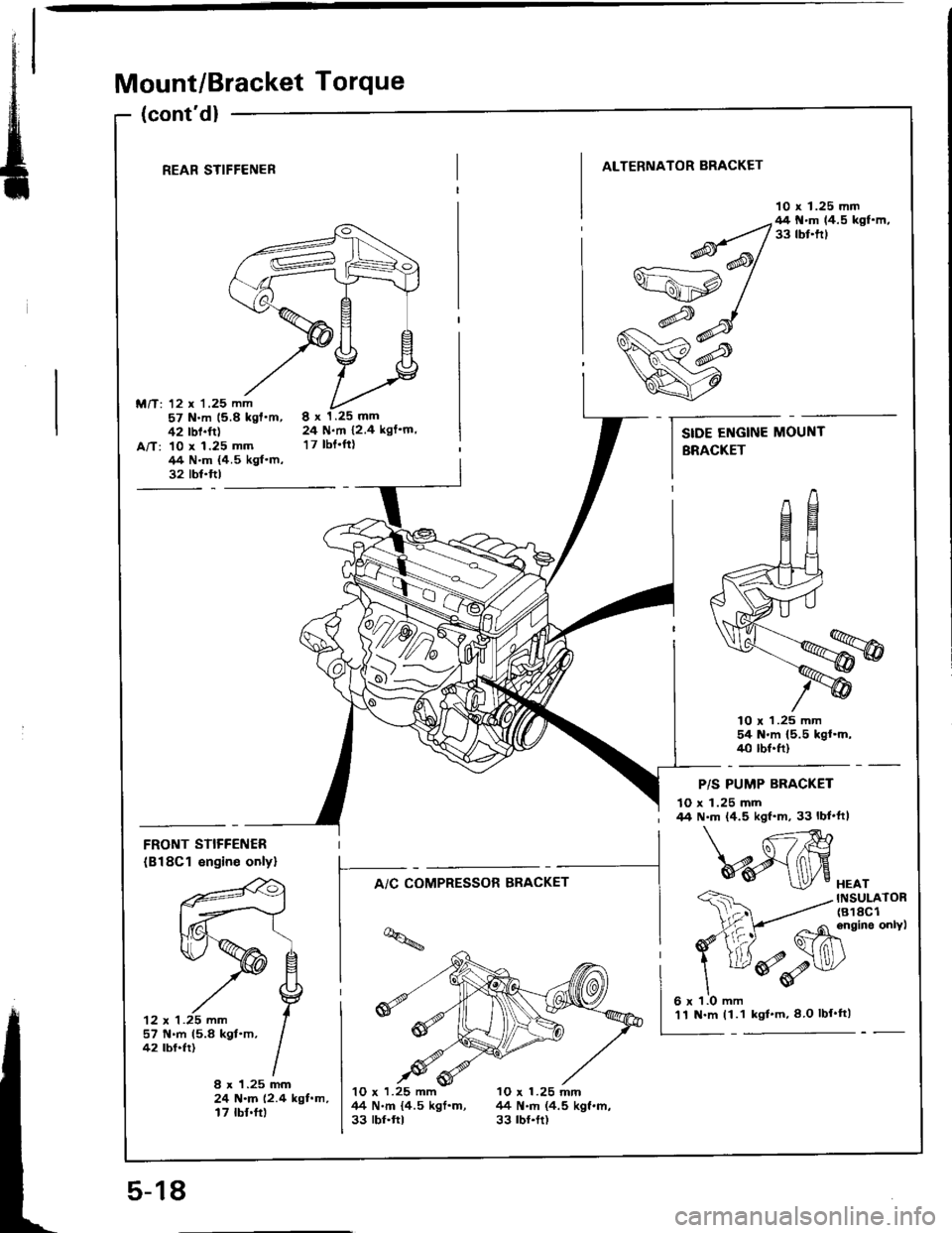

Mount/Bracket Torque

(cont'd)

REAR STIFFENER

M/T: 12 x '1.25 mm57 N.m 15.8 kgf'm,42 rbf.ft)A/T: 10 x 1.25 mm/14 N.m {4.5 kgf.m,32 tbt.ftl

ALTERNATOR BRACKET

10 x 1.25 mm

8x1.25mm24 N.m 12.4 kgf'm,

17 tbt.ftt

lO r 1.25 mm54 N'm (5.5 kgl.m,40 tbf.ft)

FRONT STIFFENER

(B18Cl engin€ onlyl

'12 x 1 .25 mm

f--^,c*;"*".*-

t-*i;

lq

I -4M

- Ghinein"onvt

ddv

HEATINSULATOR(818C1

P/S PUMP BRACKET

10 x 1.25 mm44 N.m (4.5 kgf'm, 33 lbf'ft|

57 N.m 15.8 kgt.m,42 tbf.fr)

8 x 1.25 mm24 N.m (2.4 kgf.m,17 tbf.ft)

10 x 1.25 mm 10 x 1.25 mnl44 N.m {4.5 kgf.m, 44 N.m (4.5 kgf.m,33 rbr.ftt 33 rbr.tt)

SIDE ENGINE MOUNT

BRACKET

5-18

'11 N.m (1.1 kgl'm,8 O lbf'tt)

Page 105 of 1413

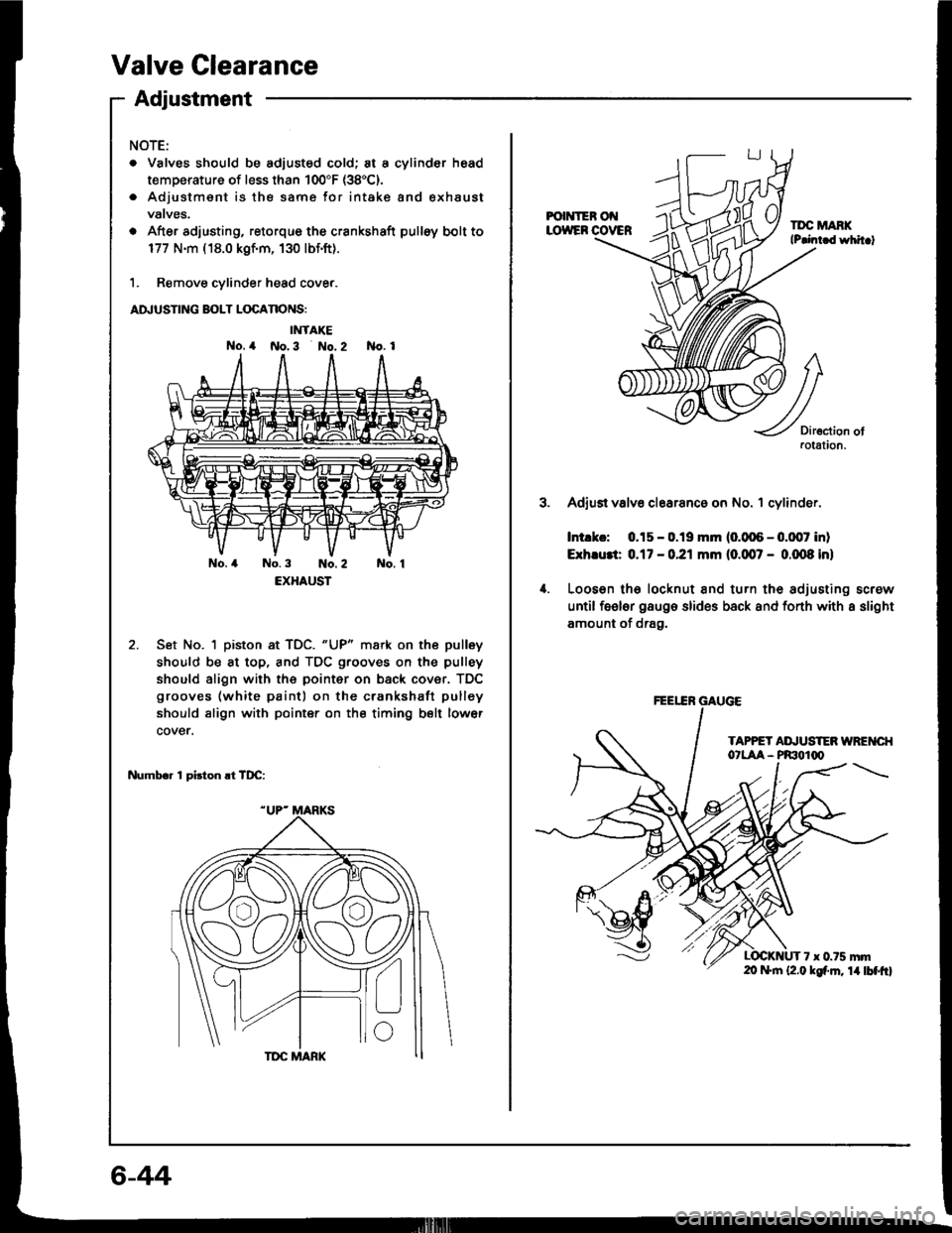

Valve Clearance

Adiustment

NOTE:

. Valves should be adjusted cold; at a cylinder head

temperature of less than 100"F (38'C).

. Adjustmsnt is the same for intake and exhaust

vatves.

o After adjusting, retorque the crankshaft pulloy bolt to

177 N.m ( 18.0 kgf.m, 130 lbf.ft).

1. Remove cylinder head cove..

ADJUSTING BOLT LOCANONS:

IMTAKE

No. 4 No.3 No. 2 No. 1

No.4 No.3 No.2 No. 1

EXHAUST

Set No. 1 piston at TDC. "UP" mark on the pulley

should be at top, and TDC grooves on the pulley

should align with the pointer on back cover. TDC

grooves (white paint) on the crankshatt pulley

should align with pointer on the timing belt lower

cover.

Numbr. 1 pirton .t TDC:

6-44

FOI{IER Ot{LOWEF COVERTDC MANKlP.int d whit.t

3.

4.

Diroction ofaotation.

Adjust valv6 clearanc6 on No. 1 cylinder.

Intlkc: 0.15 - 0.19 mm (0.006 - 0.0,07 inl

Exh.u3t 0.17 - 0.21 mm (0.007 - 0.m8 inl

Looson lh6 locknut and turn the adjusting screw

until feeler gaugo slides back and fonh with a slight

amount of drag.

TAPPET AI\,USTEN WREI{CI{O'LAA - PRIOIq'

7 x 0.75 mrn20 f+|n (2.0 kgf'm. 14lbtftl

FEEEN GAUGE

Page 174 of 1413

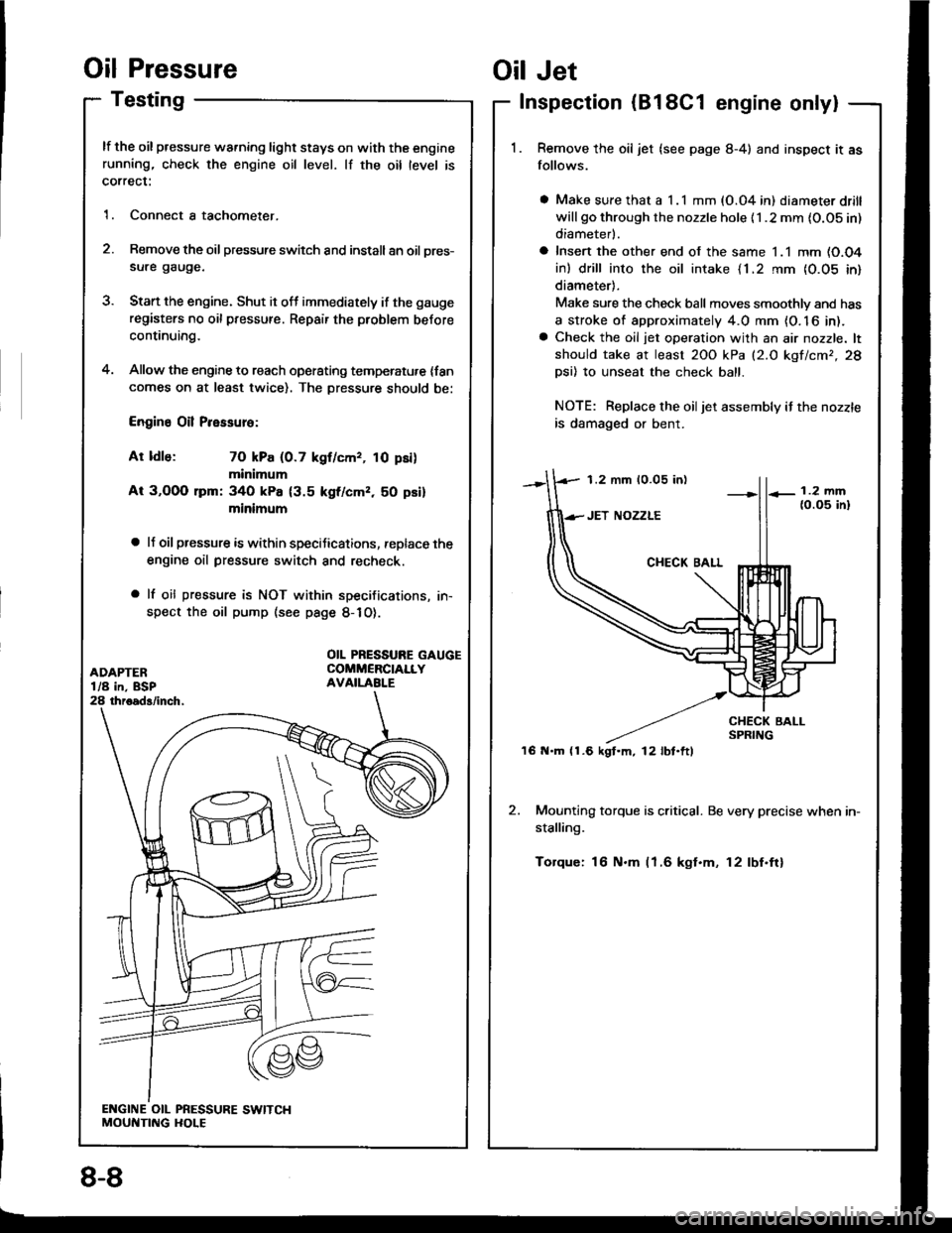

Oil Pressure

Testing

lf the oil pressure warning light stays on with the enginerunning, check the engine oil level. lf the oil level is

correct:

1. Connect a tachometer.

2. Remove the oil pressure switch and install an oil pres-

sure gauge.

3. Stan the engine. Shut it off immediately if the gauge

registers no oil pressure. Repair the problem before

continuing.

4. Allow the engine to reach operating temperatu,e {fancomes on at least twice). The Dressure should be:

Engine Oil Pressure:

At ldle: 70 kPa (0.7 kgf/cmr, 10 psi)

minimum

At 3,OOO lpm: 340 kPa {3.5 kgf/cmz, 50 psi}

minimum

a lJ oil pressure is within speciJications, replace the

engine oil pressure switch and recheck.

a lf oil pressure is NOT within specifications, in-

spect the oil pump (see page 8-1O).

1.2 mm 10.05 in)

'16 N.m (1.6 kgt.m, l2lbt.ftl

Oil Jet

Inspection (B18C1 engine only|

Remove the oil jet (see page 8-4) and inspect it as

follows.

a Make sure that a I .l mm (O.04 in) diameter drill

will go through the nozzle hole {1 .2 mm {O.OS in)

diameterl.

a Insert the other end of the same 1.1 mm (O.O4

in) drill into the oil intake {1.2 rnm {0.05 in}

diameter).

Make sure the check ball moves smoothlv and has

a stroke of approximately 4.0 mm {O. 16 in).a Check the oil jet operation with an air nozzle. lt

should take at least 2OO kPa (2.O kgf/cmr,28

Dsi) 10 unseat the check ball.

NOTE: Replace the oiljet assembly if the nozzle

is damaged or bent.

2. Mounting torque is critical. Be very precise when in-

stalling.

Torque: 16 N.m (1.6 kgt.m, 12lbf.ftl

OIL PRESSURE GAUGECOMMERCIALLYAVAILABI.E

8-8

Page 340 of 1413

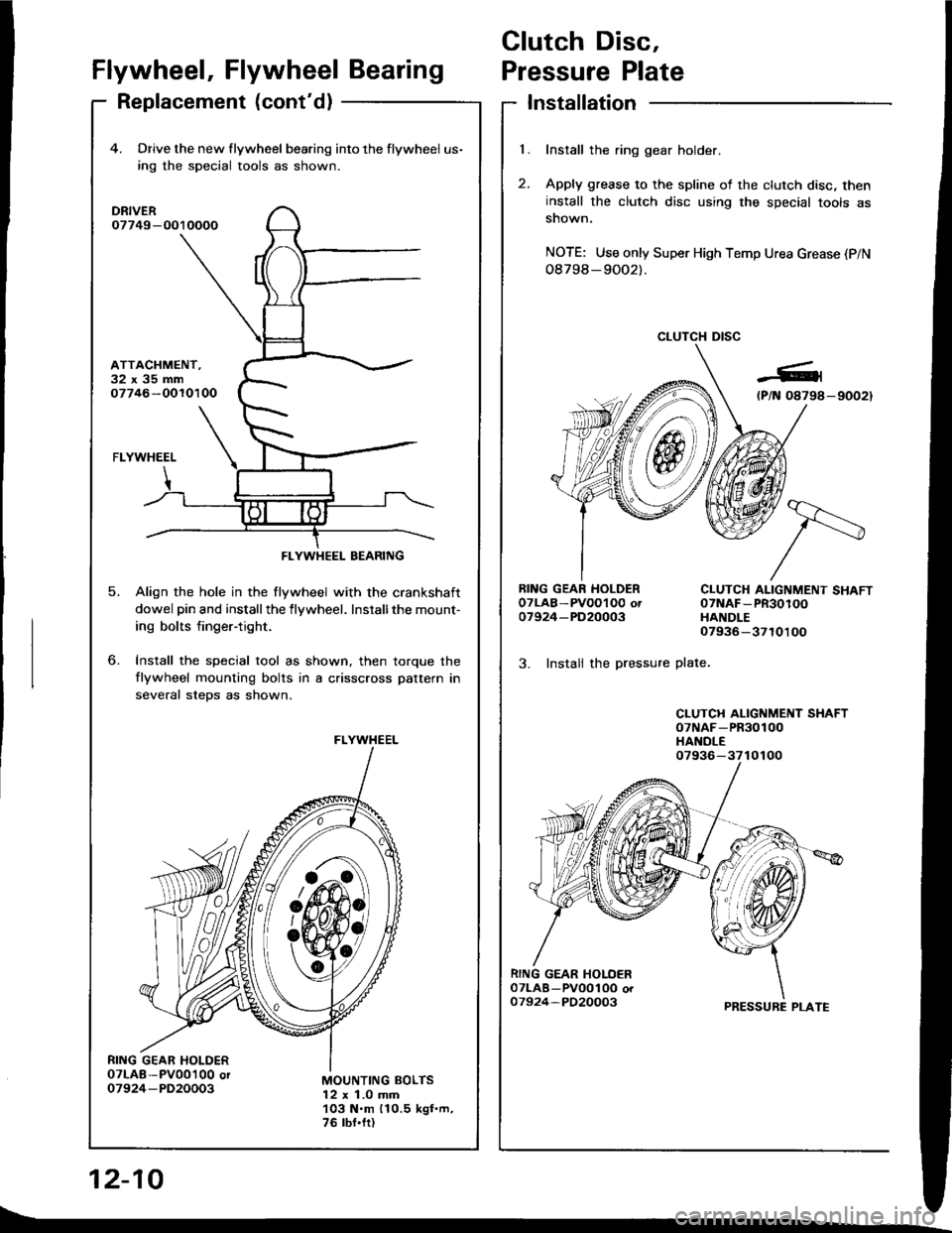

Clutch Disc,

l.

t

Flywheel, Flywheel BearingPressure Plate

Replacement (cont'd)Installation

Install the ring gear holder.

Apply grease to the spline of the clutch disc, theninstall the clutch disc using the special tools assnown.

NOTE: Use only Super High Temp Urea Grease (P/N

08798-9OO2).

CLUTCH DISC

RING GEAR HOLDEROTLAB-PVOOI O0 ot07924-PD20003

3. Instali the pressure

CLUTCH ALIGNMENT SHAFT07NAF-PR30100HANDLE07936-3710100

plate.

CLUTCH ALIGNMENT SHAFToTNAF-PR30100HANDLE

PRESSURE PLATE

12-10

4. Drive the new flywheel bearing into the flywheel us-

ing rhe special tools as shown.

DRIVER07749-O010000

ATTACHMENT.32x35mm07746-OOlO100

o.

5.

FLYWHEEL

Align the hole in the flywheel with the crankshaft

dowel pin and installthe flywheel. Installthe mount-

ing bolts finger-tight.

Install the special tool as shown, then torque the

flywheel mounting bolts in a crisscross pattern in

several steDs as shown.

MOUNTING BOLTS12 x 1.0 mm103 N.m 110.5 kgf.m,76 tbf.fr)

FLYWHEEL BEARING

FLYWHEEL

07936-3710100

t\_

Page 341 of 1413

spection

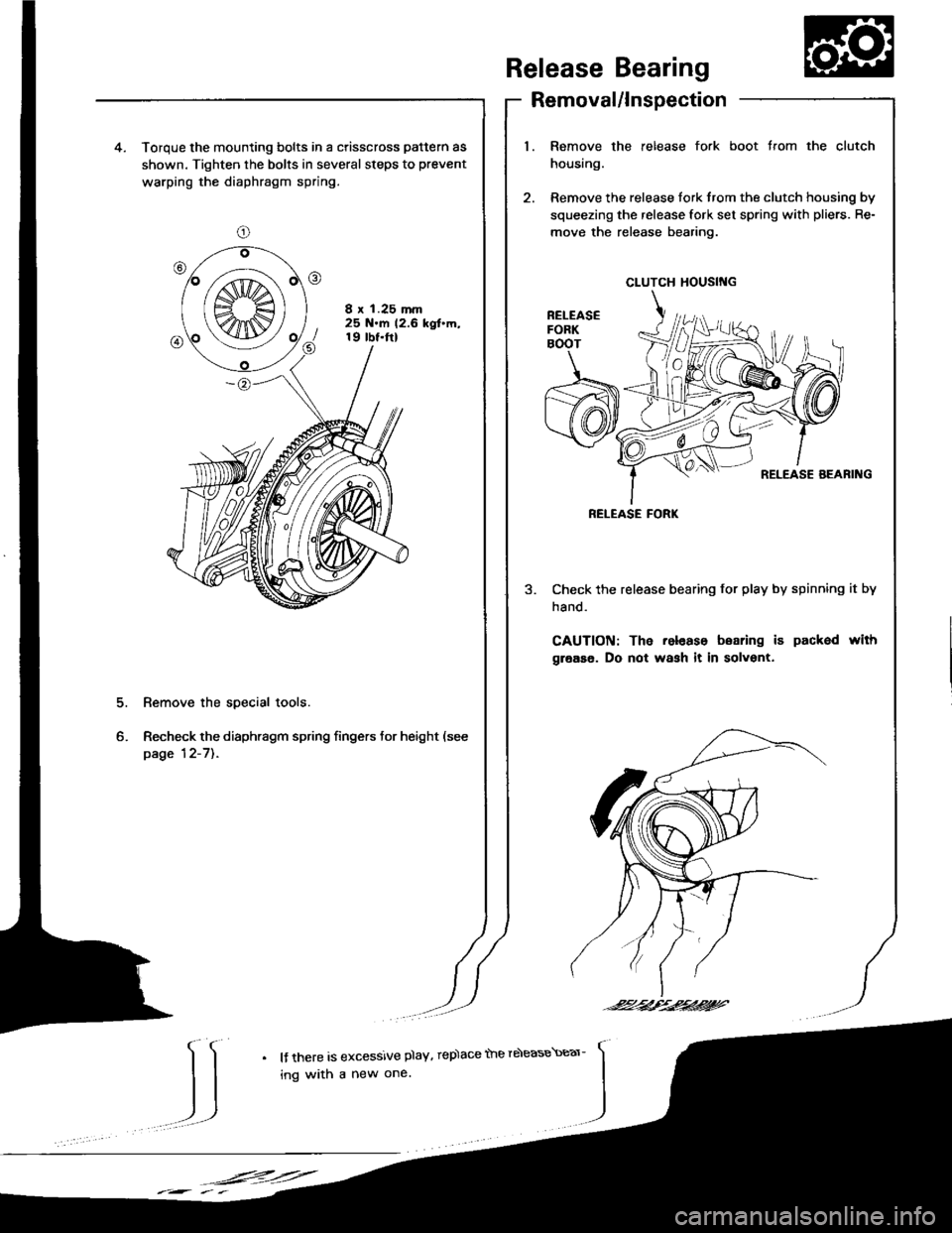

release fork boot trom the clutch4. Torque the mounting bolts in a crisscross pattern as

shown. Tighten the bolts in several steps to prevent

warping the diaphragm spring.

8 x 1.25 mm25 N.m 12.6 kgt'm,19 tbt.ftl

2. Remove the release tork trom the clutch housing by

squeezing the release fork set spring with pliers. Re-

move the release bearing.

Check the release bearing for play by spinning it by

hand.

CAUTION: The release boaring i6 packed with

grease. Do not wash it in solvent.

Remove the special tools.

Recheck the diaphragm spring fingers tor height (see

page 12-7]..

Release Bearing

Removal/ln

1. Remove the

housing.

CLUTCH HOUSING

RELEASE FORK

-24/--2,t'.2424?'

IJ

l{ there is excessive plaY, rep)ace the rdease\Ear-

ing with a new one.

,F=:=

Page 388 of 1413

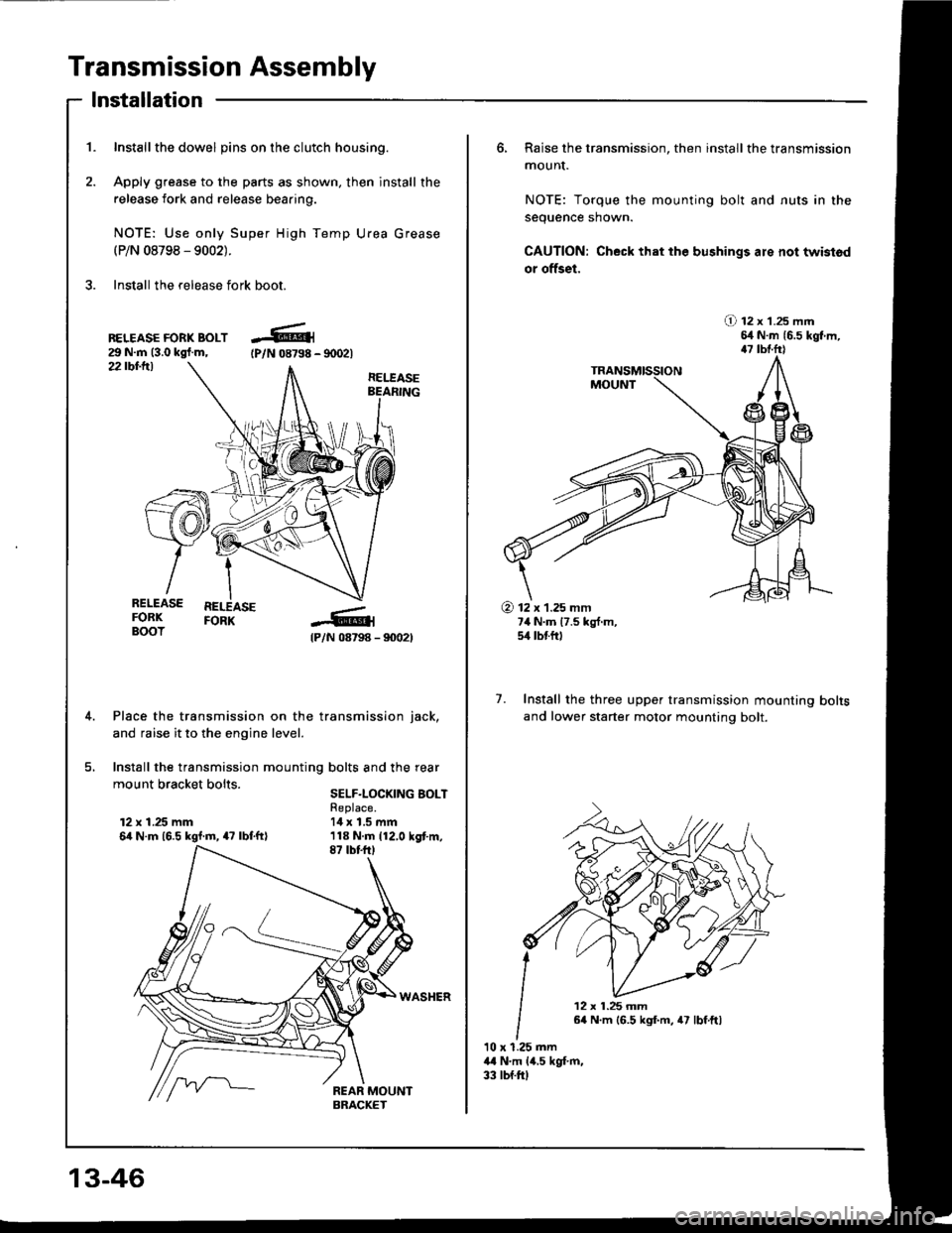

Transmission Assembly

1. Inst€llthe dowel pins on the clutch housing.

2. Apply grease to the parts as shown, then install the

release fork and release beaaing.

NOTE: Use only Super High Temp Urea Grease(P/N 08798 - 9002).

3. Install the release fork boot.

lnstallation

22 tbt-ttl

BELEASE FORK BOLT29 N.m (3.0 kgl.m,tPlN 08798 - 90021

RELEASEBEARING

@

I

{P/N 08798 - 90021

Place the transmission on the transmission iack,

and raise it to the engine level.

Install the transmission mounting bolts and the rear

mount bracket bolts sELF-LocKrNG BoLT

RELEASE REEASEFORK FORKBOOT

12 x 1.25 mm6it N.m 16.5 kgl.m, 47 lbf.ftl

Replace.14 x 1.5 mm

13-46

6, Raise the transmission, then install the transmission

mounI.

NOTE: Torque the mounting bolt and nuts in the

sequence shown.

CAUTION: Check that the bushings are not twistod

or offset,

O 12 x 1.25 mm54 N.m {6.5 kgt m,47 tbtfrl

7. Install the three upper transmission mounting

and lower starter motor mounting bolt.

bolts

10 x 1.25 mm44 N.m lil,s kgt m,33 tbf.ftl

@ 12 x 1.25 mm7,1 N.m 17.5 kg{.m,5/r lbtftl

12 x 1.25 mm64 N.m 16.5 kgf.m, 47 lbf.ftl

Page 395 of 1413

The Automatic Transmission is a combination of a 3-e,ement torque convefter and triple-shaft electfonically controlled

automatic transmission which provides 4 speeds forward and 1 speed reverse. The entire unit is positioned in line with

the engine.

Torque Converter, Gears and Clutches

The torque converter consists of a pump, turbine and stator assembly in a single unit, The torque converter is connected

to the engine crankshaft so they turn together as a unit as the engine turns. Around the outside of the torque converter

is a ring gear which meshes with the starter pinion when the engine is being staned. The entire torque converter assem-

bly serves as a flywheel while transmitting power to the transmission mainshaft.

The transmission has three parallel shafts, the mainshaft. countershaft and sub-shaft. The mainshatt is in line with the

engine crankshaft.

The mainshaft includes the clutches for 1 st, and 2ndl4th, and gears for 3rd. 2nd, 4th, reverse and l st (3rd gear is in-

tegral with the mainshaft, while reverse gear is integral with the 4th gear).

The countershaft includes the 3rd clutch and gears Ior 3rd, 2nd,4th, reverse, lst and parking. Reverse and 4th gears

can be locked to the countershaft at its center, providing 4th gear or reverse, depending on which way the selector is moved.

The sub-shaft includes the lst-hold clutch and gears for 1st and 4th

The gears on the mainshait are in constant mesh with those on the countershaft and sub-shaft. When certain combina-

tions of gears in the transmission are engaged by the clutches, power is transmitted from the mainshaft to the counter-

shaft via the sub-shatt to provide @, E, tr. tr and @ position.

Electronic Control

The electronic control system consists of the Transmission Control Module {TCM), sensors, and 4 solenoid valves. Shift-

ing and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located below the dashboard, behind the left side kick panel on the driver's side.

Hydraulic Control

The valve bodies include the main valve body, secondary valve body, regulator valve body. servo body, and lock-up valve

body throuqh the respective separator plates.

They are bolted on the torque converter housing.

The main valve body contains the manual valve, 1-2 shift valve, 2-3 shift valve, Clutch Pressure Cont.ol (CPC) valve,

4th exhaust valve, relief valve, and oil pump gears.

The secondary valve body contains the 4-3 kick-down valve,3-2 kick-down valve,2-3 orifice cont.ol valve, 3-4 shitt

valve, orifice control valve. modulator valve, and servo control valve

The regulator valve body contains the pressure regulator valve. lock-up control valve, torque converter check valve, and

cooler check valve.

The servo bodv contains the servo valve which is integrated with the reverse shift fork, throttle valve B, and accumulators.

The lock-ug valve bodv contains the lock-up shift valve and lock-up timing B valve. and is bolted on the secondary valve

body.

Fluid from the regulator passes through the manual valve to the various control valves.

Shitt Control Mochanism

Input to the TCM i.om various sensors located throughout the car determines which shift control solenoid valve should

be activated.

Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes

a line to one of the clutches. engaging that clutch and its corresponding gear.

Lock-up Mechanism

In @ position. in 2nd, 3rd and 4th, and E position in 3rd, pressurized tluid can be drained from the back of the tor-

que converter through an oil passage, causing the lock-up piston to be held against the torque converter cover. As this

takes Dlace, the mainshaft rotates at the same speed as the engine crankshatt. Together with hydraulic control, the TCM

optimizes the timing ol the lock-up mechanism.

The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and B, and throttle valve B

When lock-up control solenoid valves A and B activate, modulator pressure changes. Lock-up control solenoid valves

A and B are mounted on the torque converter housing, and are controlled by the TCM.

(cont'd)

14-3

Page 417 of 1413

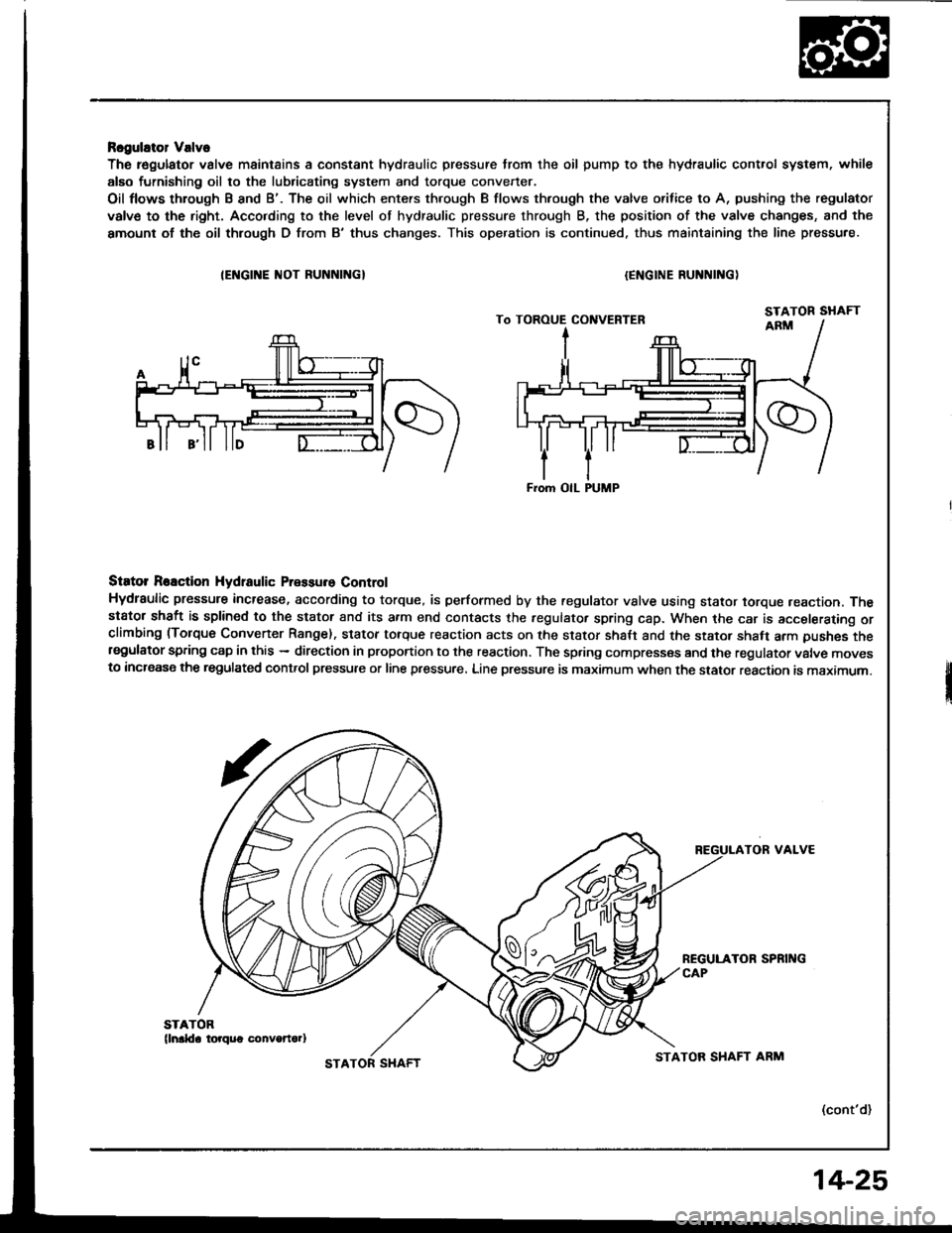

Rcgulator Valve

The r€gulator valve maintains a constant hydraulic pressure from the oil pump to the hydraulic control system, whil€

alEo furnishing oil to the lubricating system and torque convener.

Oil flows through B and B'. The oil which enters through B flows thfough the valve orifice to A, pushing the regulator

valve to the right. Acco.ding to the level of hydraulic pressure through B, the position of the valve changes, and the

amount of the oil thlough D from B'thus changes. This operation is continued. thus maintaining the line pressure.

IEI{GINE ]IIOT RUNNINGI{ENGINE RUNNING)

Siator Reaction Hydtaulic Pressure Control

Hydraulic pressure increase, according to torque, is performed by the regulator vslve using stator torque reaction. Thestator shaft is splined to the stator and its a.m end contacts the fegulator spring cap. When the car is accelerating orclimbing (Torque Convener Range). stator torque reaction acts on the stator shalt and the stator shaft arm pushes thersgulator spring cap in this - direction in proportion to the reaction. The spring compresses and the regulator valve movesto increase the regulated control pressure or line pressure. Line pressure is maximum when the stator reaction is maximum.

TOR VALVE

(cont'd)

From OIL PUMP

STATOR SHAFTSTATOR SHAFT ARM

14-25