hub ACURA INTEGRA 1998 Service User Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1998, Model line: INTEGRA, Model: ACURA INTEGRA 1998Pages: 1680, PDF Size: 53.14 MB

Page 397 of 1680

Gountershaft Assembly

Reassembly

CAUTION:

. Press 4th and sth gears on the countershaft without

lubrication.

. When installing 4th and 5th gears, supPort the shaft

on steel blocks, and install the gears using a press.

. Install 4th and sth geal with a maximum pressure of

25.5 kN {2,600 kgf, 18,806 lbfl.

NOTEr Refer to page '13-28 for reassembly sequence

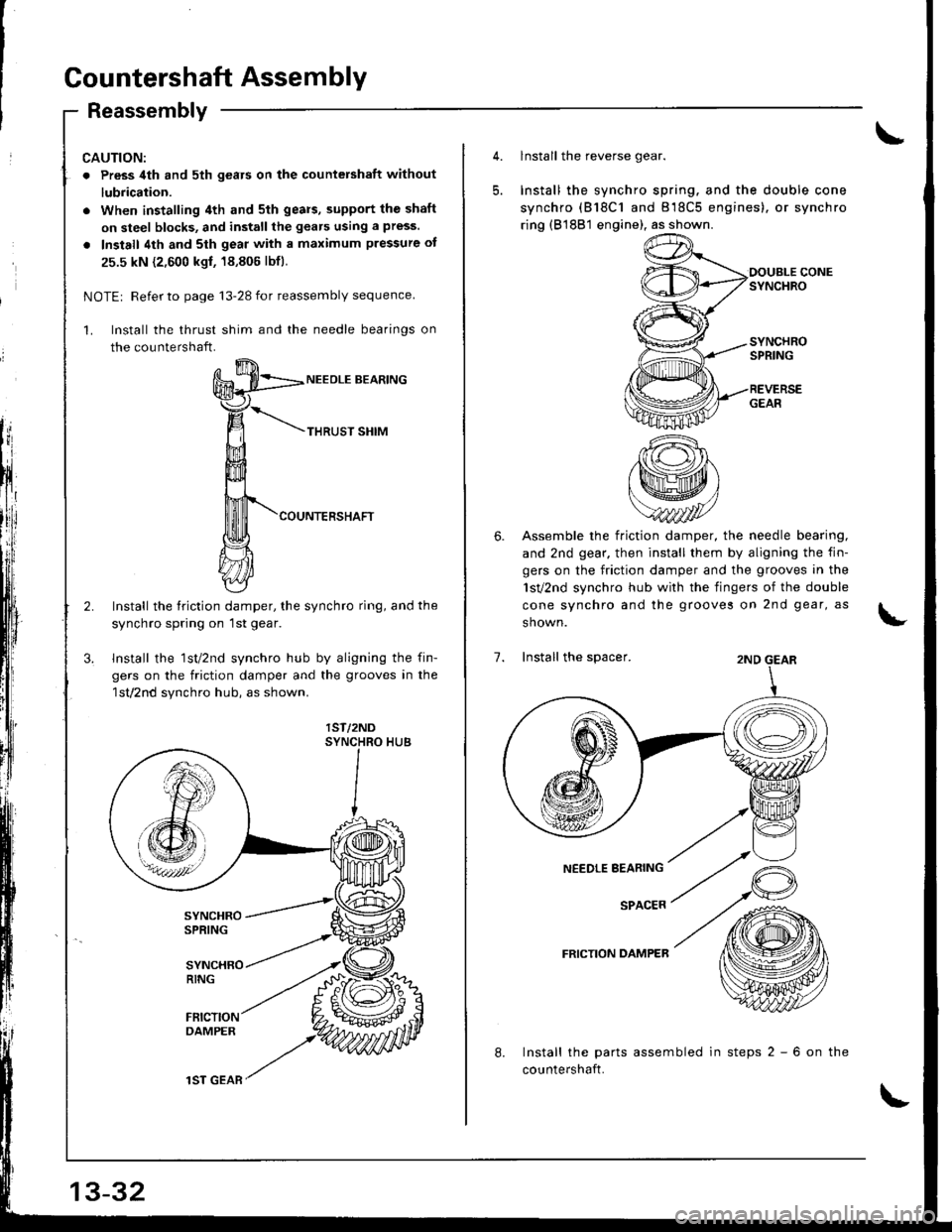

Install the thrust shim and the needle bearings on

the countershaft.

NEEOLE BEARING

THRUST SHIM

COUNTERSHAFT

Install the friction damper, the synchro ring, and the

synchro spring on lst gear.

Install the lst/2nd synchro hub by aligning the fin-

gers on the friction damper and the grooves in the

lst/2nd synchro hub, as shown.

lST/2ND

13-32

1ST GEAR

5.

lnstall the reverse gear.

Install the synchro spring. and the double cone

synchro (818C1 and 818C5 engines). or synchro

ring (81881 engine), as shown.

OOUELE CONESYNCHRO

SYNCHROSPRING

REVERSEGEAR

6. Assemble the friction damper, the needle bearing.

and 2nd gear. then install them by aligning the fin-

gers on the friction damper and the grooves in the

1sv2nd synchro hub with the fingers of the double

cone synchro and the grooves on 2nd gear, as

shown.

7. Install the spacer.2ND GEAR

SPACER

FRICTION DAMPER

8.Install the parts assembled in steps 2 - 6 on the

countershaft.

Page 399 of 1680

Synchro Sleeve, Synchro Hub

Inspection

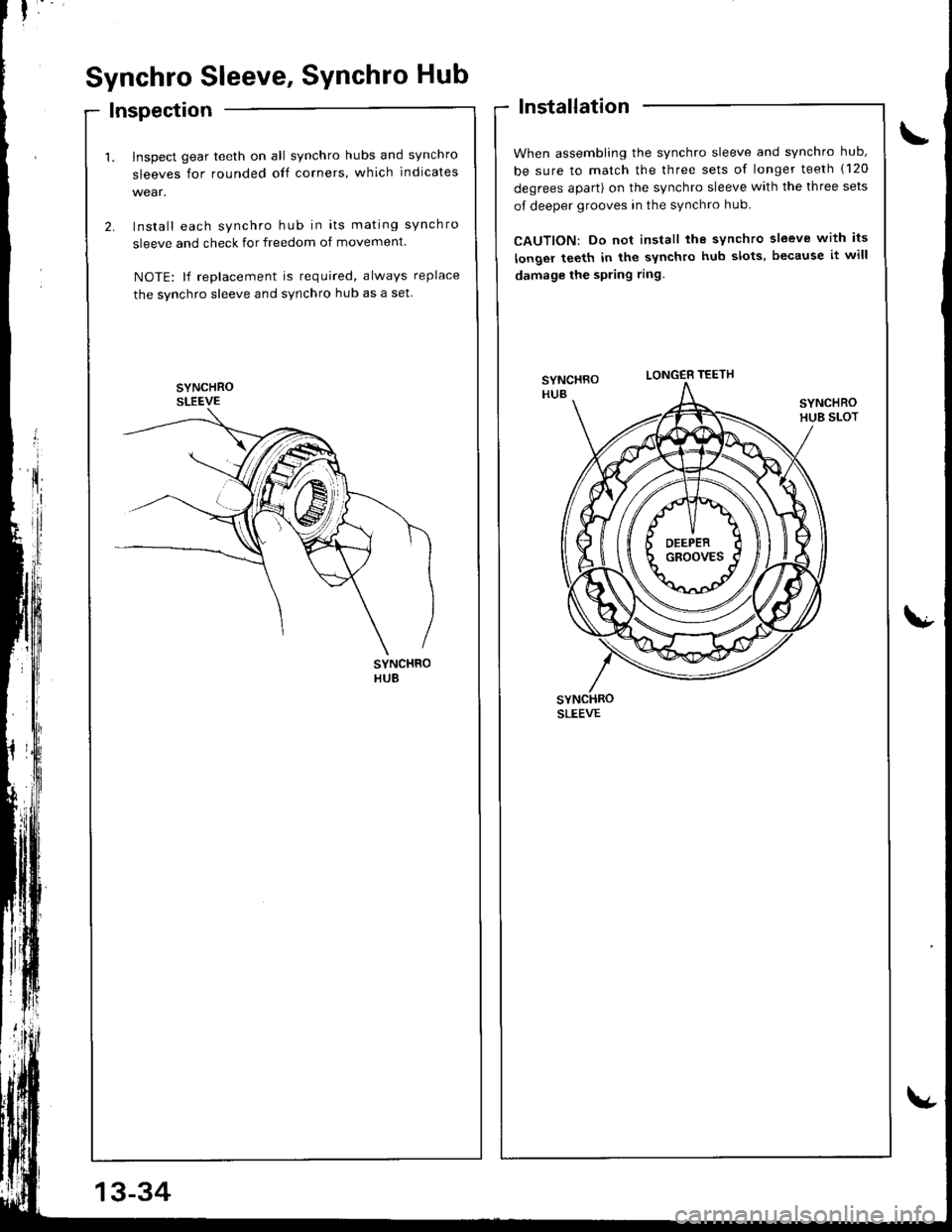

1. lnspect gear teeth on all synchro hubs and synchro

sleeves for rounded off corners, which indicates

2. Install each synchro hub in its mating synchro

sleeve and check for freedom of movement.

NOTE: lf replacement is required, always replace

the synchro sleeve and synchro hub as a set.

lnstallation

When assembling the synchro sleeve and synchro hub,

be sure to match the three sets of longer teeth (120

degrees apart) on the synchro sleeve with the three sets

of deeper grooves in the synchro hub.

CAUTION: Do not install the synchro sleeve with its

longer teeth in the synchro hub slots, because it will

damage the spring ring

SYNCHROHUB SLOT

fll!)

LONGER TEETH

SLEEVE

SYNCHROHUB

13-34

Page 400 of 1680

Synchro Ring, Gear

Inspection

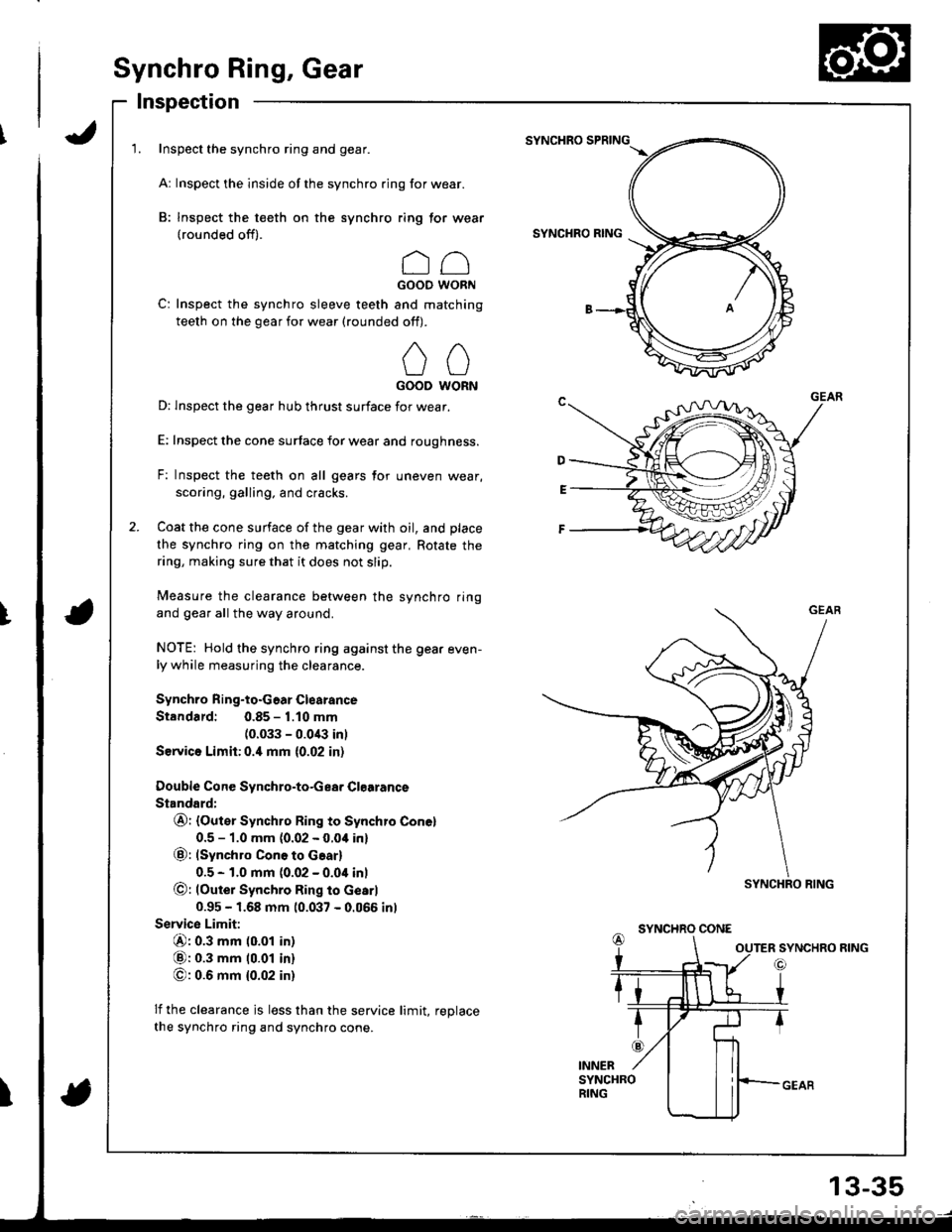

1. Inspect the synchro ring and gear.

Ar Inspect the inside of the synchro ring for wear.

B: Inspect the teeth on the synchro ring tor wear(rounded off).

ccGOOD WORN

C: Inspect the synchro sleeve teeth and matching

teeth on the gear for wear (rounded off).

00GOOD WORN

D: lnspect the gear hub thrust surface for wear.

E: Inspect the cone surtace for wear and roughness.

F: Inspect the teeth on all gears for uneven wear,

scoring, galling. and cracks.

Coat the cone surface of the gear with oil, and place

the synchro ring on the matching gear, Rotate the

ring, making sure that it does not slip.

Measure the clearance between the synchro ring

and gear all the way around.

NOTE: Hold the synchro ring against the gear even-ly while measuring the clearance.

Synchro Ring-to.Goar Clearance

Standard: 0.85 - 1.10 mm

(0.033 - 0.0/B inl

Service Limh:0.4 mm {0.02 in)

Double Cone Svnchro-to-Gea. Clgarance

Standard:

@r (Outer Synchro Ring to Synchro Conel

0.5 - 1.0 mm {0.02 - 0.04 in}

@: (synchro ConG to Gear)

0.5 - 1.0 mm (0.02 - 0.04 inl

@: lOute; Synchro Ring to Gearl

0.95 - 1.68 mm 10.037 - 0.066 inl

Servic€ Limit:

@: 0.3 mm (0.01 in)

@: 0.3 mm 10.01 in)

O: 0.6 mm {0.02 in}

lf the clearance js less than the service limit, reDlace

the synchro ring and synchro cone.

SYNCHRO SPRING

SYNCHRO RING

SYNCHRO CONE

I

SYNCHRO RING

13-35

Page 403 of 1680

Mainshaft Thrust Glearance

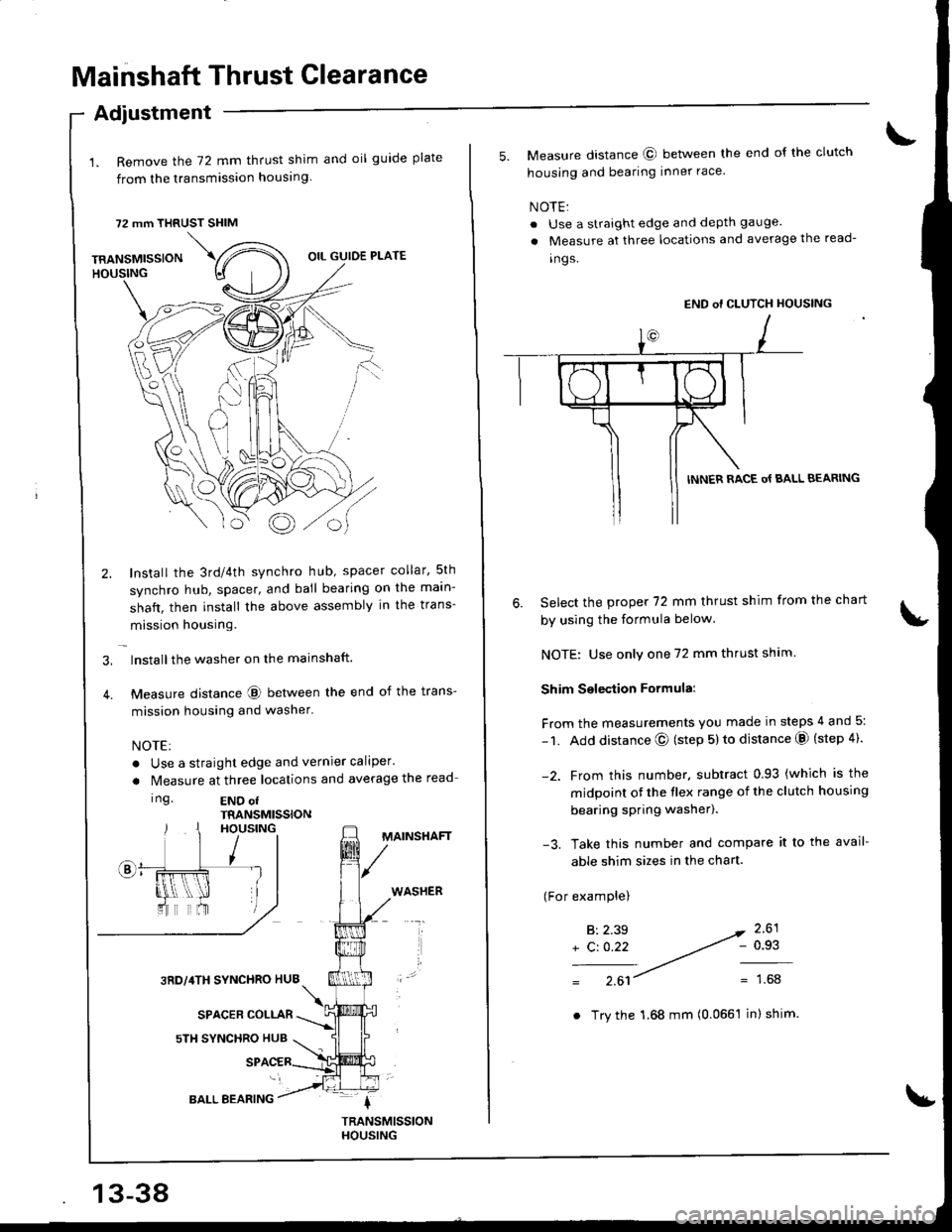

1. Remove the 72 mm thrust shim and oil guide plate

from the transmission housing

72 mm THRUST SHIM

Adiustment

TRANSMISSIONHOUSING

\,

Bo

OIL GUIDE PLATE

Install the 3rd/4th synchro hub, spacer collar,5th

synchro hub, spacer, and ball bearing on the maln-

shaft, then install the above assembly in the trans-

mission housing.

lnstallthe washer on the mainshaft.

Measure distance @ between the end of the trans-

mission housing and washer'

NOTE:

. Use a straight edge and vernier caliper'

a N4easure at three locations and average the read

Ing.END ofTRANSMISSIONHOUSING

3RD,/4TH SYNCHRO HUB

SPACER COLLAR

sTH SYNCHRO HUB

MAINSHAFT

WASHER

BALL BEARING

. Try the 1.68 mm (0.0661 inI shim.

5. Measure distance @ between the end of the clutch

housing and bearing inner race

NOTE:

. Use a straight edge and depth gauge

a Measure at three locations and average the read-

ings.

Select the prcpe( 72 mm thrust shim from the chart

by using the formula below.

NOTE: Use only one 72 mm thrust shim

Shim Selection Formula:

From the measurements you made in steps 4 and 5:

- 1. Add distance @ (step 5) to distance @ (step 4).

-2. Frcm this number. subtract 0.93 (which is the

midpoint ot the flex range of the clutch housing

bearing spring washer).

-3. Take this number and compare it to the avail-

able shim sizes in the chart.

(For examplel

6.

B:2.39

+ C: 0.22- 0.93

1.68

END of CLUTCH HOUSING

INNER RACE o{ BALL BEARING

Page 422 of 1680

Description

Clutches

t

{

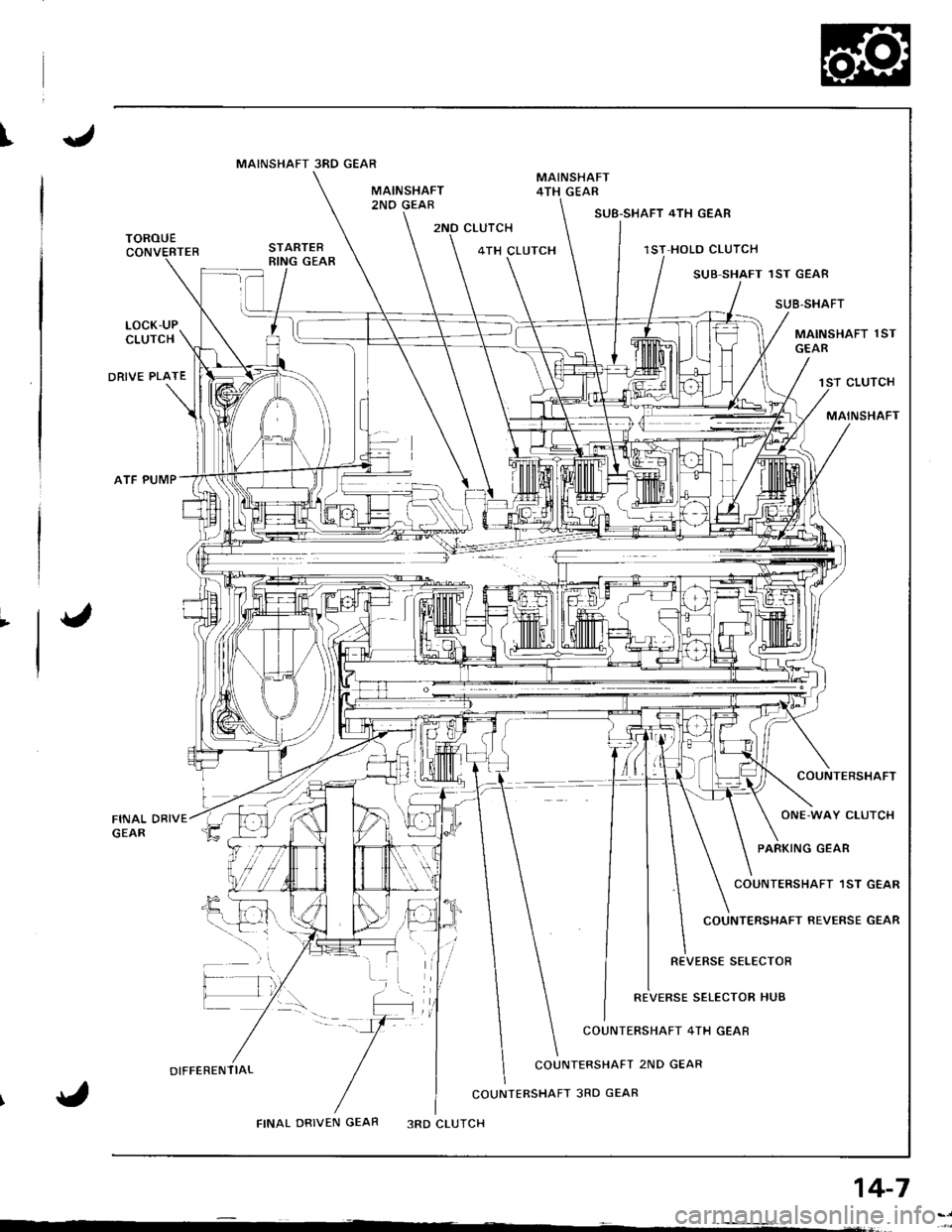

The four-speed automatic transmission uses hydraulically-actuated clutches to engage or disengage the transmission gears.

When hydraulic pressure is introduced into the clutch drum. the clutch piston is applied. This presses the friction discs

and steel plates together, locking them so they don't slip. Power is then transmitted through the engaged clutch pack

to its hub-mounted gear.

Likewise, when hydraulic pressure is bled from the clutch pack, the piston releases the friction discs and steel plates,

and they are free to slide past each other while disengaged. This allows the gear to spin independently on its shaft, trans-

mrrrng no power.

lsr Clutch

The 1 st clutch engages/disengages 1st gear, and is located at the end of the msinshaft, just behind the right side cover.

The 1st clutch is supplied hydraulic pressure by its ATF feed pipe within the mainshaft.

l st-hold clurch

The '1 st-hold clutch engages/disengages 'lst-hold or E] position, and is located at the middle of the sub-shaft. The 1st-

hold clutch is supplied hydraulic pressure by its ATF feed pipe within the sub-shaft.

2nd Clutch

The 2nd clutch engages/disengages 2nd gear, and is located at the middle of the mainshaft. The 2nd clutch is joined

back-to-back to the 4th clutch. The 2nd clutch is supplied hydraulic pressure through the mainshaft by a circuit connected

to the internal hydraulic circuit.

3rd ClutchThe 3rd clutch engages/disengages 3rd gear, and is located at the end of the counte.shaft, opposite the right side cover.

The 3rd clutch is supplied hydraulic pressure by its ATF feed pipe within the countershaft.

4th Clutch

The 4th clutch engages/disengages 4th gear, as well as reverse gear, and is located at the middle of the mainshaft.

The 4th clutch is joined back-to-back to the 2nd clutch. The 4th clutch is supplied hydraulic pressure by its ATF feed

oiDe within the mainshaft.

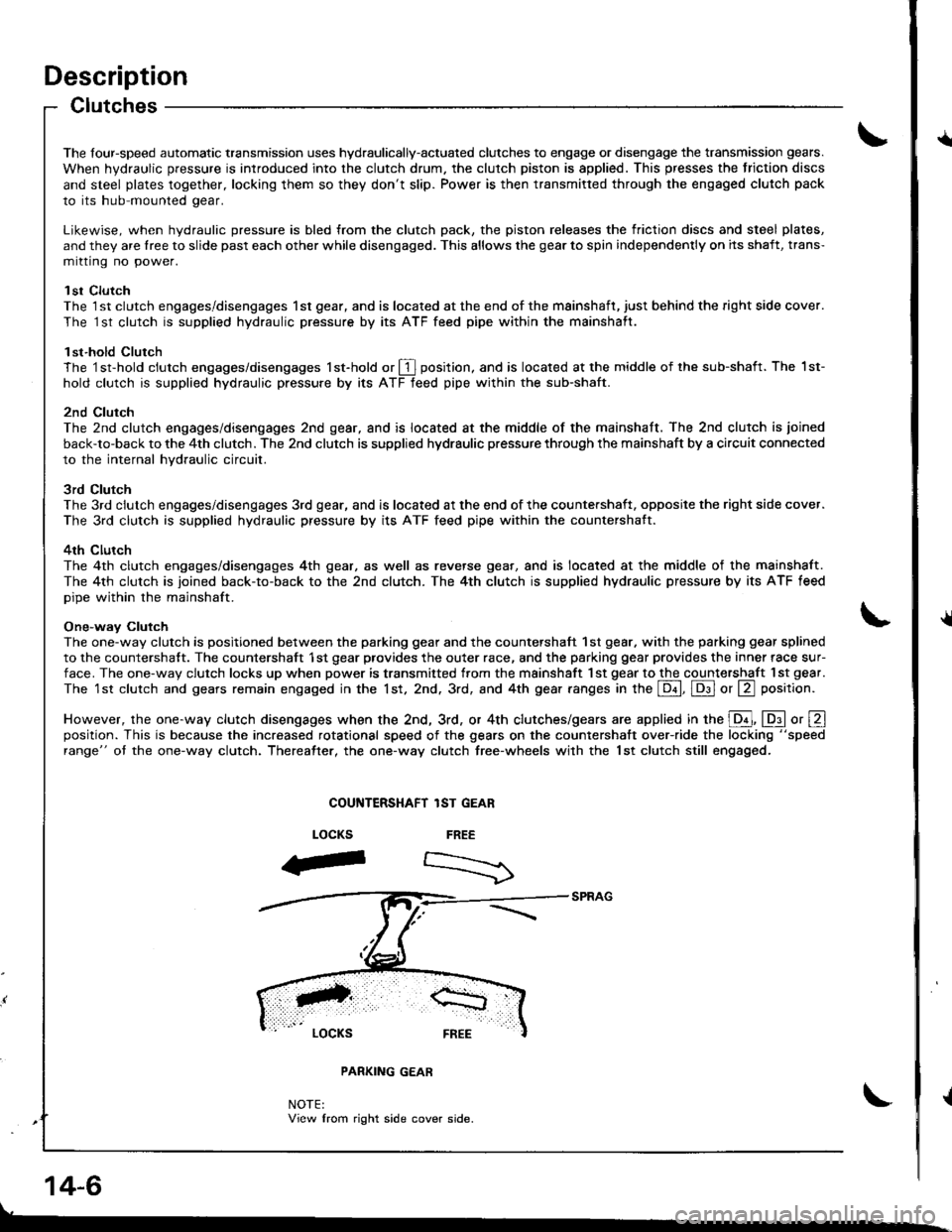

One-way Clutch

The one-way clutch is positioned between the parking gear and the countershaft 1st gear. with the parking gear splined

to the countershalt. The countershaft 1st gear provides the outer race, and the parking gear provides the inner race sur-

face. The one-way clutch locks up when power is transmitted from the msinshaft 1st gear to the countershaft I st gear.

The 1st clutch and gears remain engaged in the 1st, 2nd. 3rd, and 4th gear ranges in the Lqd, Lq9.l or La position.

However, the one-way clutch disengages when the 2nd, 3rd, or 4th clutches/gears are applied in the E, lDll o, Eposition. This is because the increased rotational speed of the gears on the countershatt over-ride the locking "speed

range" ot the one-way clutch. Thereatter, the one-way clutch free-wheels with the lst clutch still engaged.

COUiITERSHAFT lST GEAR

FREE

-".--)

LOCKS

F

LOCKS FREE

PARKING GEAR

NOTE:View from right side cover side.

14-6

Page 423 of 1680

I

2NO CLUTCHSUB-SHAFT 4TH GEAR

1ST HOLO CLUTCH

SUB SHAFT 1ST GEAE

SUB,SHAFT

MAINSHAFT 1ST

CLUTCH

MAINSHAFT

COUNTERSHAFT

ONE.WAY CLUTCH

PARKING GEAR

COUNTERSHAFT 1ST GEAR

COUNTERSHAFT REVERSE GEAR

REVERSE SELECTOR

SELECTOR HUB

TOROUE4TH CLUTCH

LOCK-UPCLUTCH

DRIVE PLATE

ATF PUMP

COUNTERSHAFT 4TH GEAR

DIFFERENTIALCOUNTERSHAFT 2ND GEAR

COUNIERSHAFT 3RD GEAR

FINAL DRIVEN GEAR3RD CLUTCH

14-7

MAINSHAFT 3RD GEAR

Page 425 of 1680

![ACURA INTEGRA 1998 Service User Guide l

t

LNI Position

Hydraulic pressure is not applied to the clutches. Power is not transmitted to the countershaft.

[] Position

Hydrsulic pressure is not applied 10 the clutches. Power is not transmitt ACURA INTEGRA 1998 Service User Guide l

t

LNI Position

Hydraulic pressure is not applied to the clutches. Power is not transmitted to the countershaft.

[] Position

Hydrsulic pressure is not applied 10 the clutches. Power is not transmitt](/img/32/56983/w960_56983-424.png)

l'

t

LNI Position

Hydraulic pressure is not applied to the clutches. Power is not transmitted to the countershaft.

[] Position

Hydrsulic pressure is not applied 10 the clutches. Power is not transmitted to the countershaft.

The countershaft is locked by the parking brake pawl interlocking the parking gear.

TOROUE CONVERTEB

PARKING GEAR

REVERSE SELECTOR

REVERSE GEAR

REVERSE SEI.ECTORHUB

SERVO VALVE/SHIFT FORK SHAFT

{cont'd)

14-9

Page 427 of 1680

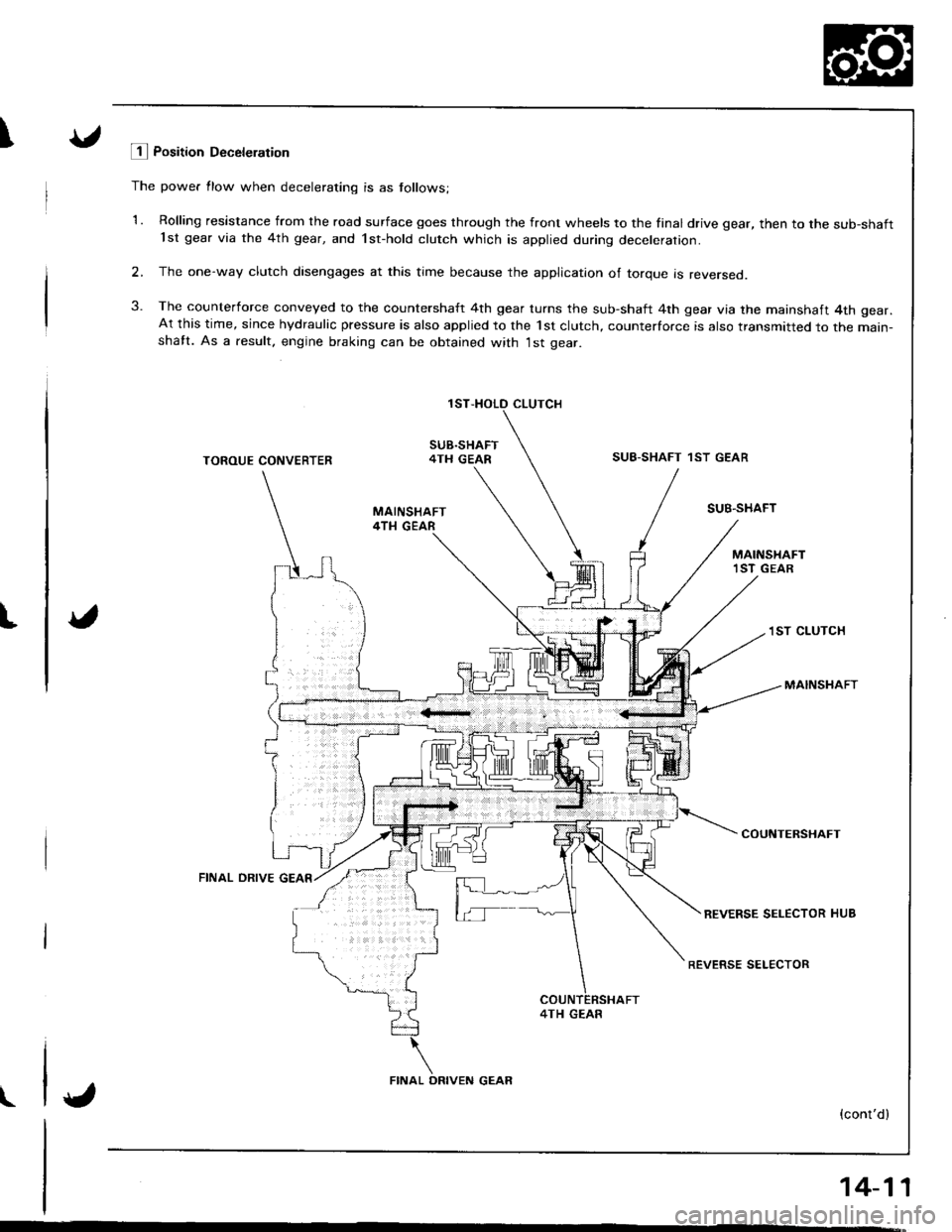

\E Position Deceleration

The power flow when decelerating is as follows;

1. Rolling resistance from the road surface goes through the front wheels to the final drive gear, then to the sub-shaft'lst gear via the 4th gear, and 1st-hold clutch which is applied during decelerarion.

2, The one-way clutch disengages at this time because the application of torque is reversed.

3. The counterforce conveyed to the countershaft 4th gear turns the sub-shaft 4th gear via the mainshaft 4th gear.At this time, since hydraulic pressure is also applied to the 1st clutch, counterforce is also transmitted to the main-shatt. As a.esult. engine braking can be obtained with 1st gear.

CLUTCH

SUB.SHAFT4TH GEARSUB-SHAFT 1ST GEAR

t

TOROUE CONVERTER

FINAL ORIVE

SUB.SHAFT

1ST CLUTCH

MAINSHAFT

COUNTERSHAFT

REVERSE SELECTOR HUB

REVERSE SELECTOR

4TH GEAR

(cont'dl

14-11

\

FINAL ORIVEN GEAR

Page 433 of 1680

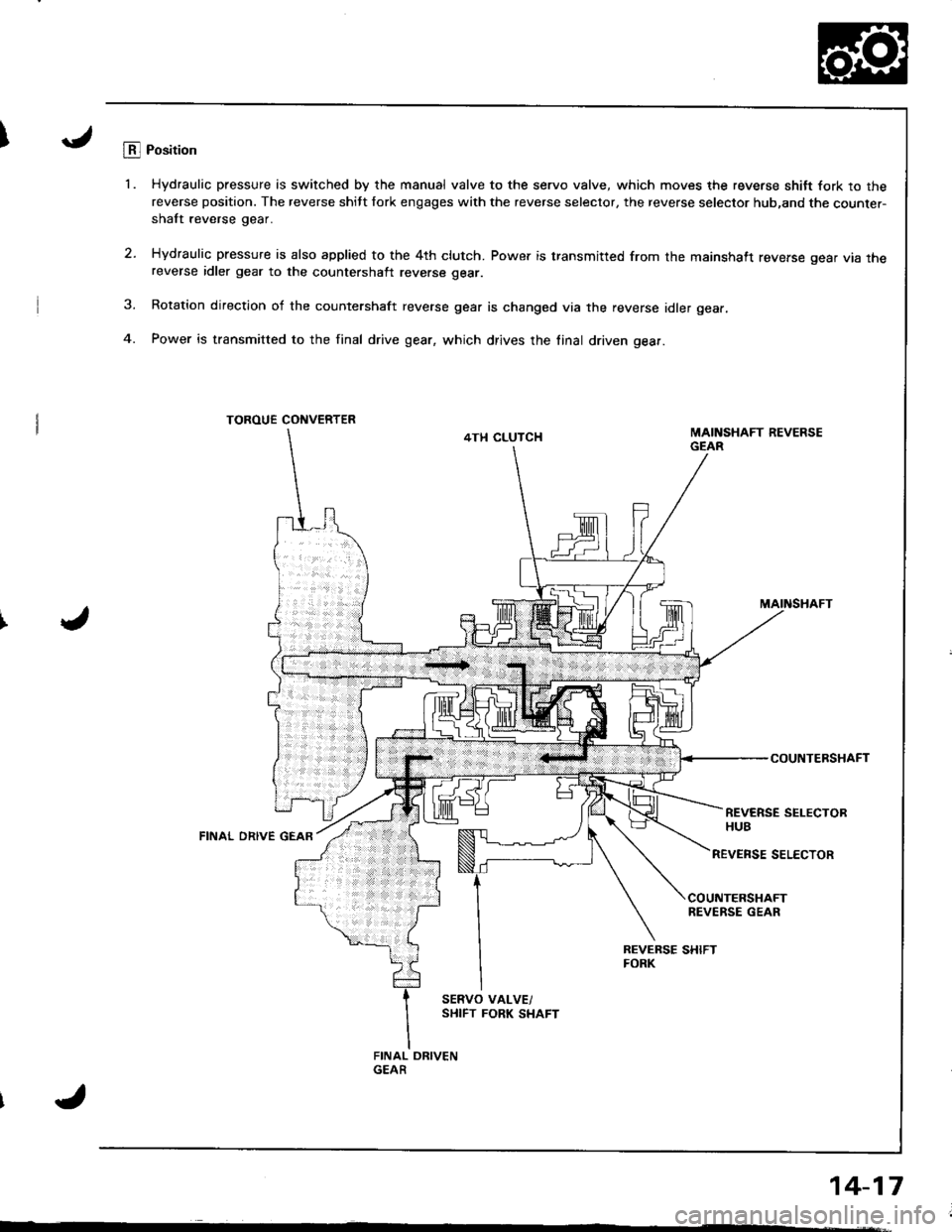

ILB.l Position

'1. Hydraulic pressure is switched by the manual valve to the servo valve, which moves the reverse shitt fork to thereverse position. The reverse shitt fork engages with the reverse selector, the reverse selector hub,and the counter-shaft reverse gear.

2. Hydraulic pressure is also applied to the 4th clutch. Power is transmitted from the mainshaft reverse gear vta rnereverse idler gear to the countershalt reverse gear.

3. Rotation direction of the countershaft reverse gear is changed via the reverse idler gear.

4. Power is transmitted to the final drive gear, which drives the linal driven gear.

TOROUE CONVERTER

4TH CLUTCH

MAINSHAFT

COUNTERSHAFT

REVERSE SELECTORHUBFINAL ORIVE GEAR

REVENSE SELECTOR

COUNTERSHAFTREVERSE GEAR

Page 508 of 1680

![ACURA INTEGRA 1998 Service User Guide The following symptoms can be caused

by improper repair or assembly

Checkthese items on the

PROBABLE CAUSE DUE TO

IMPROPER REPAIR Llst

Items on the

NOTES List

Vehicle creeps in E] position.R1, R2

Vehi ACURA INTEGRA 1998 Service User Guide The following symptoms can be caused

by improper repair or assembly

Checkthese items on the

PROBABLE CAUSE DUE TO

IMPROPER REPAIR Llst

Items on the

NOTES List

Vehicle creeps in E] position.R1, R2

Vehi](/img/32/56983/w960_56983-507.png)

The following symptoms can be caused

by improper repair or assembly

Checkthese items on the

PROBABLE CAUSE DUE TO

IMPROPER REPAIR Llst

Items on the

NOTES List

Vehicle creeps in E] position.R1, R2

Vehicle does not move in l&l or Lql position.R4

Transmittion locks up in E] position.R3, R12

Excessive drag in transmission.R6K,R

Excessive Vibration, rpm related.R7

Noise with wheels moving only.R5

Msin soal pops out,R8

Various shifting problems.R9, R1O

Harsh upshifts.Rl l

Symptom-to-Gomponent Ghart

Hydraulic System (cont'd)

14-92

\.J

v.4

\/J

PROBABLE CAUSE DUE TO IMPROPER REPAIR

R1lmproper clutch clearance.

R2.lmproper gear clearance.

R3.Parking brake lever installed upside down.

R4.One-way (sprag) clutch installed upside down.

R5.Reverse selector hub installed uoside down.

R6.ATF pump binding.

R7.Torque converter not fully seated in ATF pump.

R8.Main seal improperly installed.

R9.Springs improperly installed.

R10.Valves improperly installed.

R11Ball check valves not installed.

R12.Shift tork bolt not installed.