frame ACURA INTEGRA 1998 Service Owner's Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1998, Model line: INTEGRA, Model: ACURA INTEGRA 1998Pages: 1680, PDF Size: 53.14 MB

Page 1043 of 1680

Evaporator

Replacement

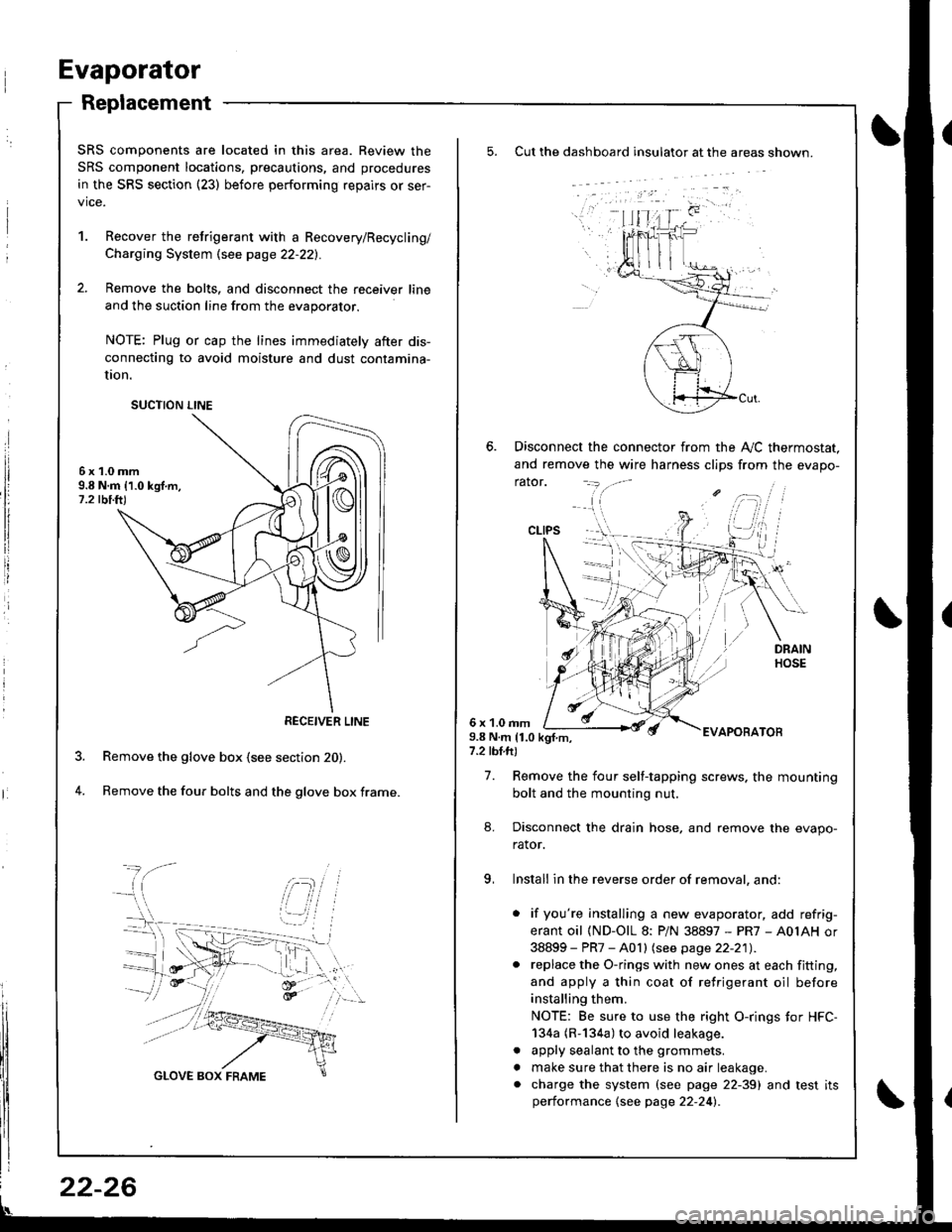

Cut the dashboard insulato. at the areas shown.

Disconnect the connector from the A,,/C thermostat.

and remove the wire harness clips from the evapo-

rator.

6 x 1.0 rnm9.8 N.m 11.0 kgf.m,7.2 tbl.ft)

EVAPOBATOB

7. Remove the four self-tapping screws. the mounting

bolt and the mounting nut.

8. Disconnect the drain hose, and remove the evapo-

rator.

9, Install in the reverse order of removal, and:

. if you're installing a new evaporator, add refrig-

erant oil (ND-OlL 8: PiN 38897 - PR7 - A0IAH or

38899 - PR7 - A0 I I lsee page 22-21) .. replace the O-rings with new ones at each fitting,

and apply a thin coat of refrigerant oil before

installing them.

NOTE: Be sure to use the right O-rings tor HFC-

134a (R-134a) to avoid leakage.

. apply sealant to the grommets.

. make sure that there is no air leakage.. charge the system (see page 22-39) and test itsperformance {see page 22-24l�.

CLIPS

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section {23) before performing repairs or ser-

vice.

1. Recover the retrigerant with a Recovery/Recycling/

Charging System \see page 22-221.

2. Remove the bolts, and disconnect the receiver line

and the suction line from the evaporator.

NOTE: Plug or cap the lines immediately after dis-

connecting to avoid moisture and dust contamina-

UOn.

6x1.0mm9.8 N.m 11.0 kgf.m,1.2 tbi.ft)

Remove the glove box (see section 20).

Remove the four bolts and the glove box frame.4.

SUCTION LINE

RECEIVER LINE

22-26

Page 1060 of 1680

Troubleshooting

Tips and Precautions (cont'd)

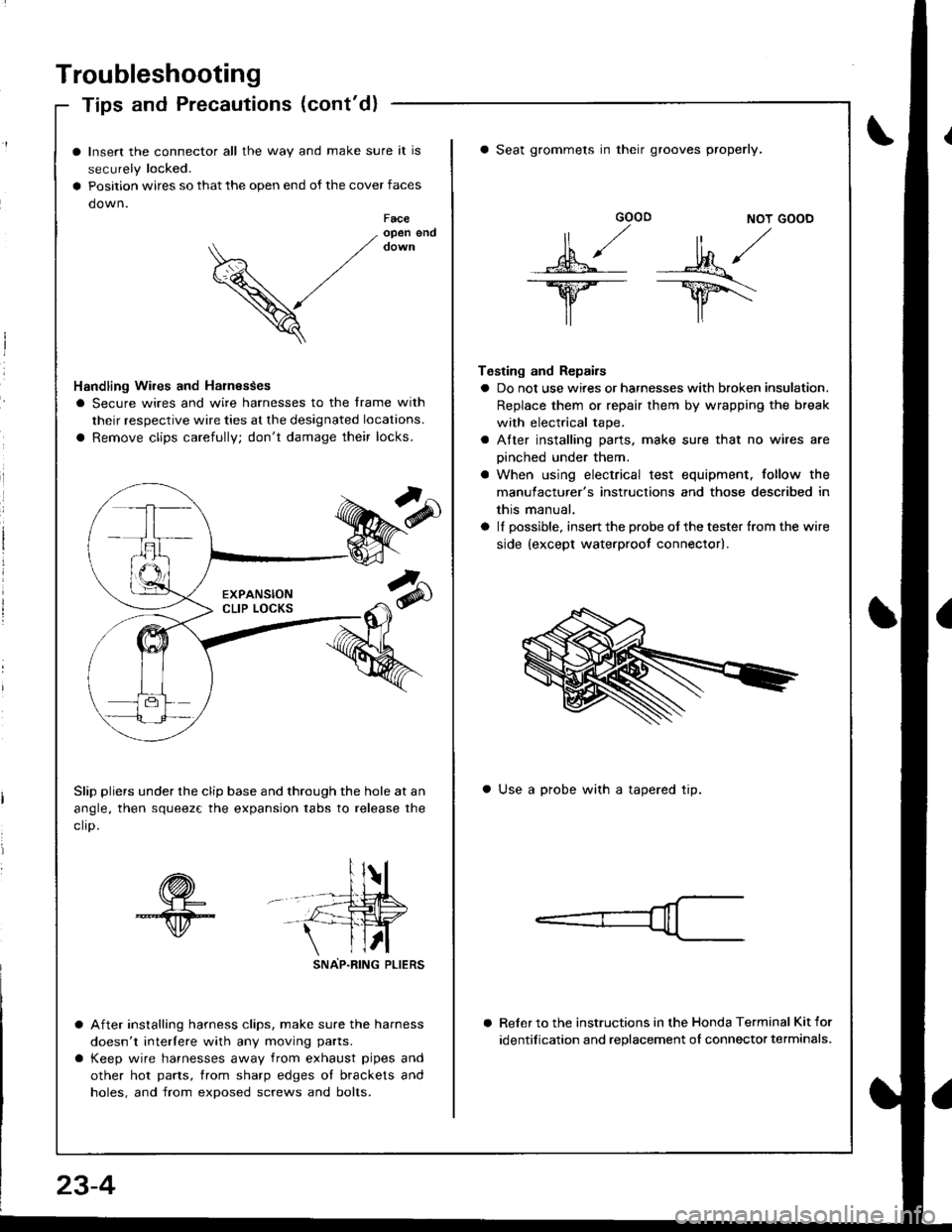

Insert the connector all the way and make sure it is

securely locked.

Position wires so that the open end of the cover faces

down.Faceopen end

V

Handling Wires and Harnesses

I Secure wires and wire harnesses to the frame with

their respective wire ties at the designated locations.

a Remove clips carefully; don't damage their locks.

Slip pliers under the clip base and through the hole at an

angle, then squeez€ the expansion tabs to release the

clro.

sNAP-R|NG PLtERS

After installing harness clips, make sure the harness

doesn't interlere with any moving parts.

Keep wire harnesses away from exhaust pipes and

other hot parts, trom sharp edges ol brackets and

holes, and from exposed screws and bolts.

GOOD NOT GOOD

MA/

lr lr\

Testing and Repairs

a Do not use wires or harnesses with broken insulation.

Replace them or repair them by wrapping the break

with electrical tape.

a Atter installing parts. make sure that no wires are

oinched under them.

a When using electrical test equipment. follow the

manulacturer's instructions and those described in

this manual.

a lI possible, insert the probe of the tester {rom the wire

side {except waterproot connector).

a Seat grommets in their grooves properly.

a Use a probe with a tapered tip.

Reler to the instructions in the Honda Terminal Kit for

identification and replacement oI connector terminals.

23-4

Page 1070 of 1680

Connector ldentification and Wire Harness Routing

Starter Cables

Connectol ot

Terminal

Numbel of

CavitiesLocationConnects toNotes

Tl

r2

Right side of engine compartment

Right side oI engine compartment

Under-hood Iuse/relay box

Starter motor

oBatteryBattery positive terminal

Battely Ground Cable

Connector ol

Terminal

Numbel of

CavitiesLocationConnects toNotes

Right lront shock towerBody ground, via battery ground

caore

oBatteryBattery negative terminal

Engine Ground Cable A

Connector ol

Terminal

Number ol

CavitiesLocationConnects toNotes

T3Left side of engineValve cover

c2Left side oI engine compartmentBody ground. via engine ground

Engine Ground Cable B

Connector ol

Terminal

Numbel of

CavitiesLocationConnects toNot€s

r4Right side of engine compartmentTransmission housing

Right side of front frameBody ground, via engine ground

wire B

A/C Wire Harness

Connector or

Terminal

Number of

CavitiesLocationConnects toNotos

c 151

cl54

c156

8

2,l

Righr side of engine compartment

Left side of engine companment

Left side of engine compartment

Left side of engine compartment

Main wire harness (C207)

A,/C pressure switch

Condenser fan motor

ly'C compressor clutch

Right side of front frame

Under-hood ABS Fuse/Relav Box Cable

Connector or

Telminal

Number of

CavitiesLocationConnects toNotes

T5Right side o'f engine compartmentUnderhood ABS fuse/relay box

@Right side oI engine compaftmentBattery positive terminal

23-14

Page 1226 of 1680

Headlight

Adjustment

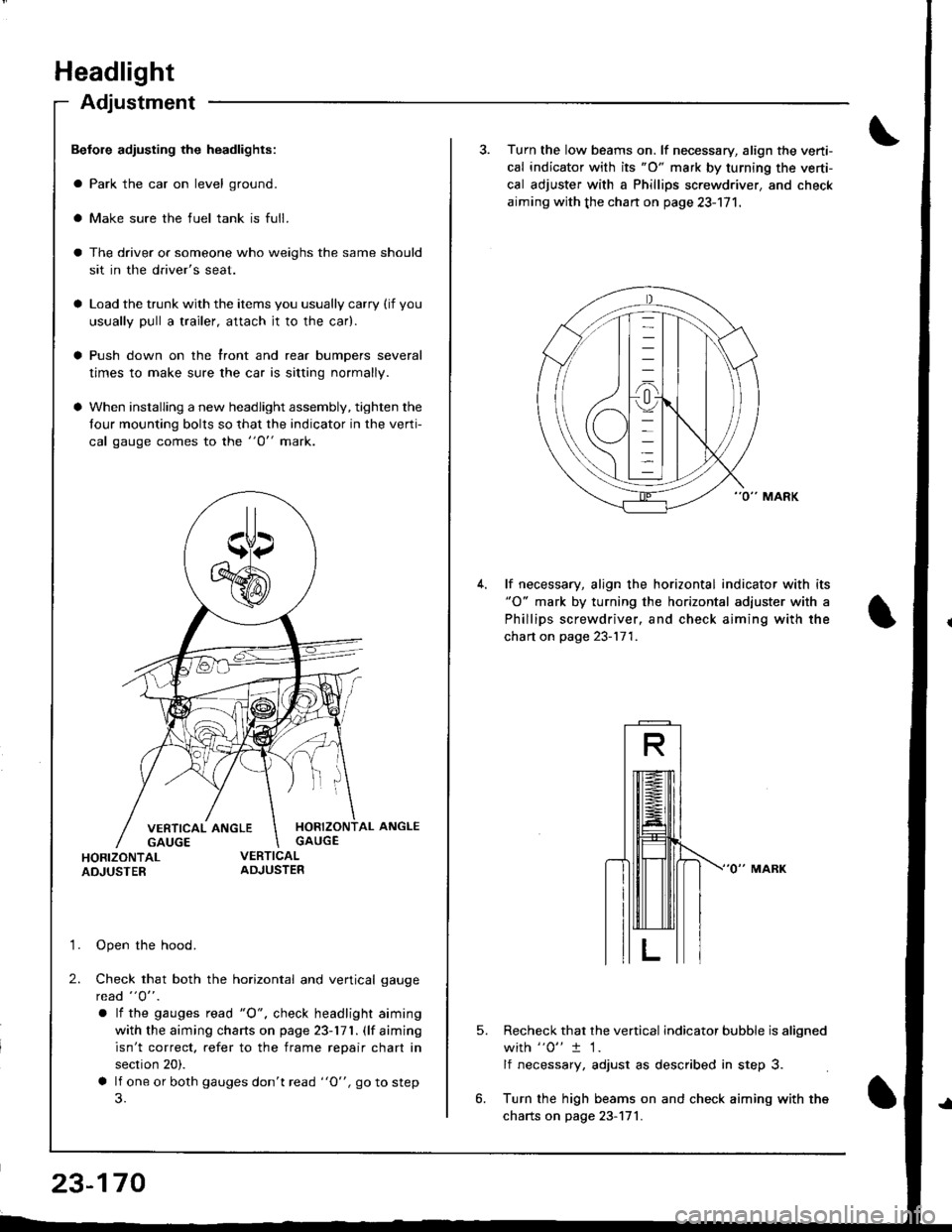

Befole adiusting the headlights:

a Park the car on level ground.

a Make sure the fuel tank is full.

The driver or someone who weighs the same should

sit in the driver's seat.

Load the trunk with the items you usually carry (if you

usually pull a trailer, attach jt to the car).

Push down on the front and rear bumpers several

times to make sure the car is sitting normally.

When installing a new headlight assembly, tighten the

four mounting bolts so that the indicator in the verti-

cal gauge comes to the "O" mark.

HORIZONTAL ANGLEGAUGE

HORIZONTALADJUSTER

'1. Open the hood.

2. Check that both the horizontal and vertical gauge

rcad "O" .

a lf the gauges tead "O", check headlight aiming

with the aiming charts on page 23-171. (lf aiming

isn't correct. refer to the frame repair chart in

section 20).

a lf one or both gauges don't read "O", go to step

23-170

3. Turn the low beams on. lf necessary, align the verti-

cal indicator with its "O" mark by turning the verti-

cal adjuster with a Phillips screwdriver, and check

aiming with the chan on page 23-171.

lf necessary, align the horizontal indicator with its"O" mark by turning the horizontal adjuster with a

Phillips screwdriver, and check aiming with the

chart on page 23-171.

5.Recheck that the vertical indicator bubble is aligned

with "0" t 1.

lf necessary, adjust as described in step 3.

Turn the high beams on and check aiming with the

charts on page 23-171.

Page 1392 of 1680

How To Use This Manual

Symbols

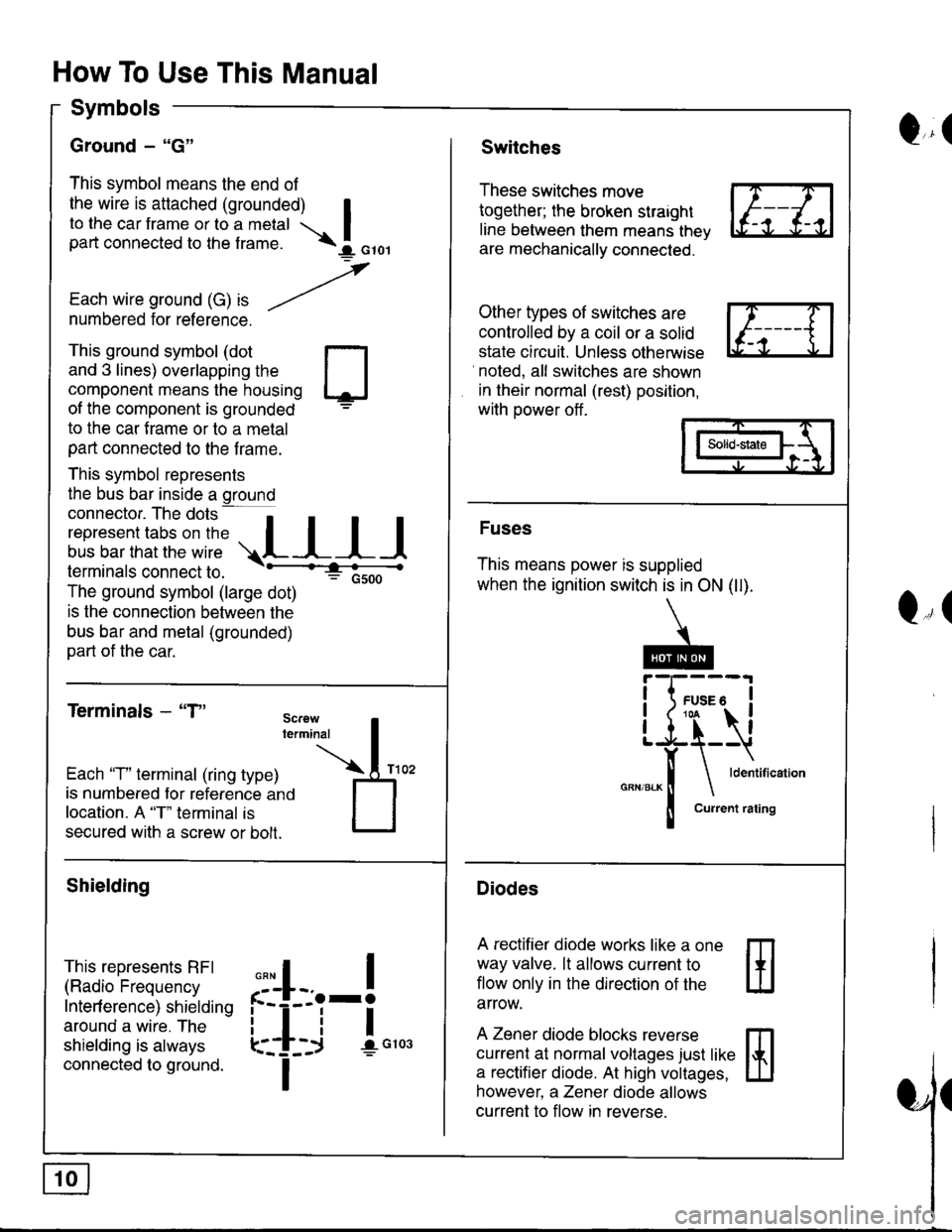

Ground - "G"

This symbol means the end of

the wire is attached (grounded) Ito the car frame or to a metal Ipart connected to the f rame. \I orol

,

Each wire ground (G) ," -/numbered for reference.

Q,(Switches

These switches move

together; the broken straight

line between them means thev

are mechanically connected.

Other types of switches are

controlled by a coil or a solid

state circuit. Unless otherwise

noted, all switches are shown

in their normal (rest) position,

with power off .

This ground symbol (dot

and 3 lines) overlapping the

component means the housing

of the component is grounded

to the car f rame or to a metal

part connected to the f rame.

This symbol represents

the bus bar inside a ground

connector. The dots a

i"r*"""*nn"l,':" .,.L I I I

lermtnals connectto. -'--'-:t"'--------<

The ground symbol (large dot)

: Gsoo

is the connection between the

bus bar and metal (grounded)

part of the car.

Terminals - "T"

m

ffi

Solid-state

Fuses

This means power is supplied

when the ignition switch is in ON (ll).

Diodes

A rectifier diode works like a one

way valve. lt allows current to

flow only in the dlrection of the

arrow.

A Zener diode blocks reverse

currenl at normal voltages just like

a rectifier diode. At high voltages,

however, a Zener diode allows

current to flow in reverse.

Q,(

Each 'T" terminal (ring type)

is numbered for reference ano

location. A "T" terminal is

secured with a screw or bolt.

Shielding

This represents RFI

(Radio Frequency

Interf erence) shielding

around a wire. The

shielding is always

connected to ground.

,,,

n

:'iL.-!

L-_+i !",*

I