ecm ACURA INTEGRA 1998 Service Service Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1998, Model line: INTEGRA, Model: ACURA INTEGRA 1998Pages: 1680, PDF Size: 53.14 MB

Page 276 of 1680

PGM-FI System

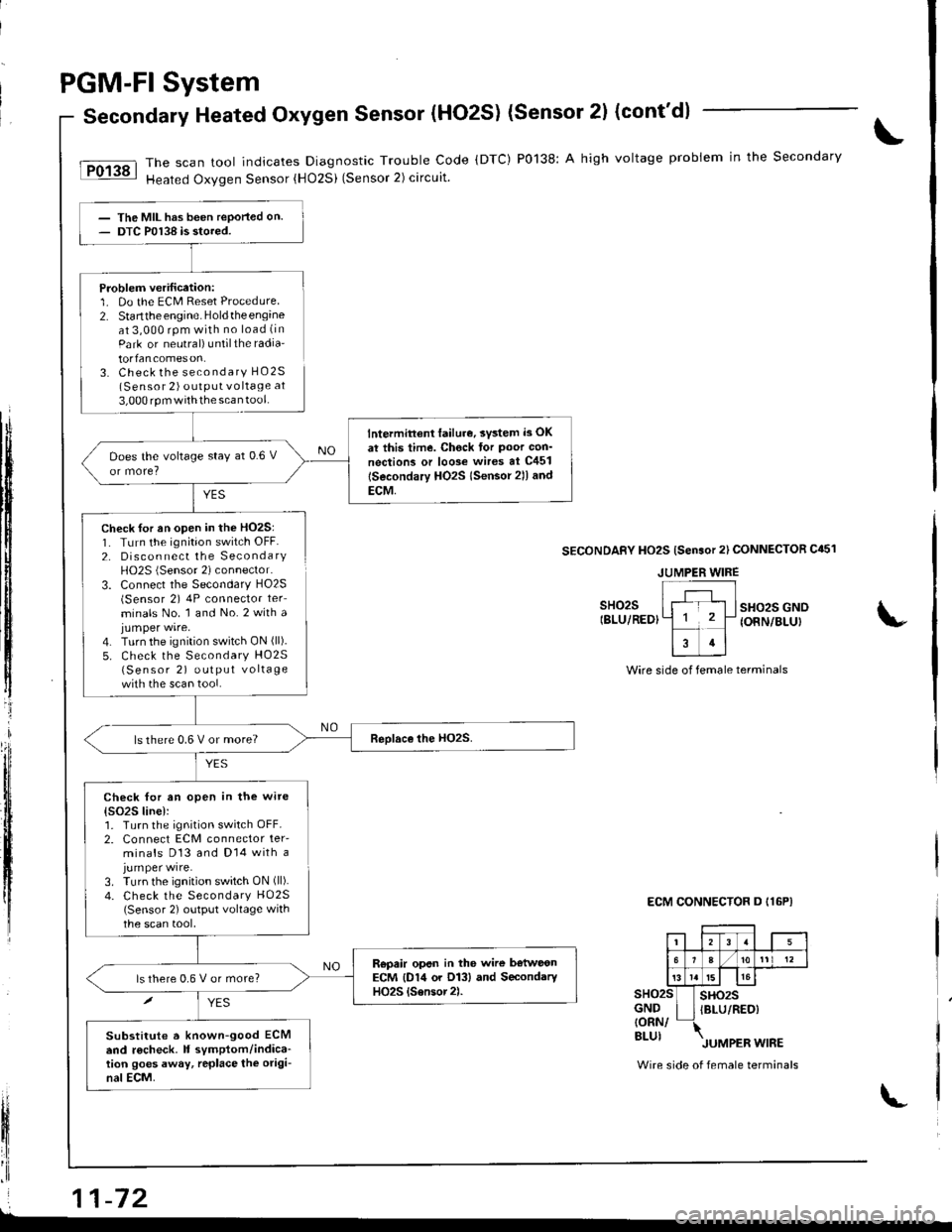

Secondary Heated Oxygen Sensor (HO2S) (Sensor 2l (cont'd)

The scan tool indicates Diagnostic Trouble Code (DTC) P0138: A high voltage probiem in the Secondary

Heated Oxygen Sensor {HO2Si (Sensor 2) circuit.

YES

The MIL has been reported on.DTC P0138 is stored.

Problem verification:1. Do the ECM Reset Procedure2. Startthe engine. Holdtheengineat 3,000 rpm with no load (in

Park or neutral) untilthe radia'

torfancomeson.3. Check the secondary HO2S(Sensor 2) outPUt vo ltage at

3,000 rpm withthe scan tool.

lntermittent lailur€, svsted i3 OK

at this time. Chock tor Poor con'

nections or loo3e wires at C451

lSecondary HO2s lsensor 2ll and

ECM,

Does the voltage stay at 0.6 V

ls there 0.6 V or more?

Check for an open in the wite

{s()2S line):1. Turn the ignition switch OFF.2. Connect ECM connector ter-minals D13 and Dl4 with ajumper wire.3. Turn the ignition switch ON (ll).

4. Check the Secondary HO25(Sensor 2) output voltage withthe scan tool,

Repair opsn in the wire b€tweonECM {D14 or O13} and SecondaryHO2S {Sensor2).ls there 0,6 V or more?

Substitute a known-good ECMend r6check. It symptom/indica-tion goes away, rcplace the origi-nal ECM.

tI

t$

ffi

tljl'l

t,

lfi

il

fl'I

Check for an open in the HO2S:1. TLrrn the ignition switch OFF.2. Disconnect the SecondaryH02S (Sensor 2) connector.

3. Connect the Secondary HO2S(Sensor 2) 4P connector ter_

minals No. 1 and No.2 with ajumper wire.4. Turn the ignition switch ON (ll).

5. Check the Secondary HO25(Sensor 2) output vo lta ge

with the scan tool.

SECONDAFY HO2S {Sensor 2l CONNECTOR C451

sHo2sIBLU/REDIsHo2s GNOIONN/BLUI

Wire side of female terminals

ECM CONNECTOR D I16P}

sHo2sGND{ORN/BLUI

sHo2sIBLU/RED)

Wire side of female terminals

JUMPER WIRE

i 11-72L

Page 277 of 1680

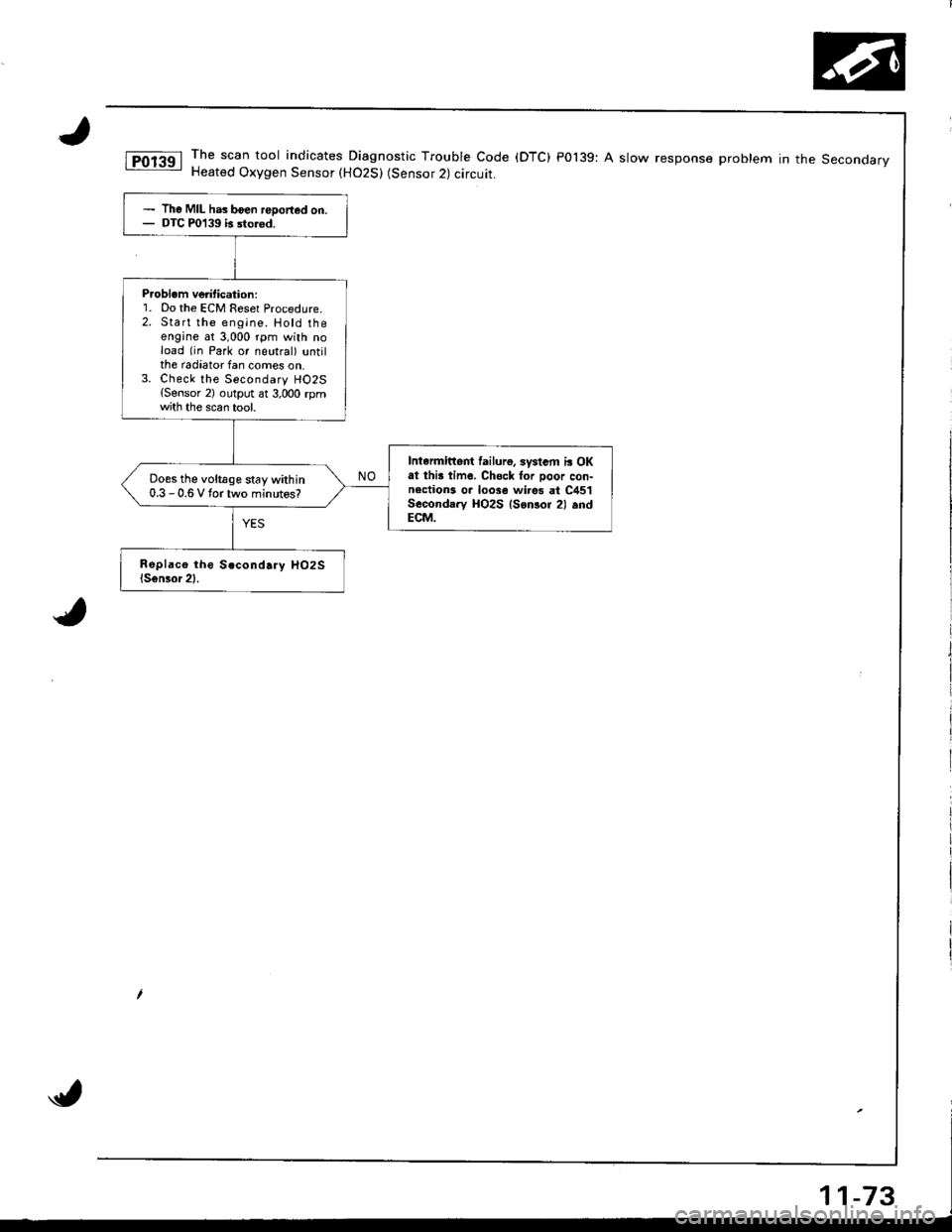

The scan tool indicates Diagnostic Trouble Code (DTC) P0139: A slow response problem in the SeconoarvHeated Oxygen Sensor (H02S) (Sensor 2) circuit.

The MIL has boen reDorted on.DTC P0139 b sto.od.

P.oblem ve tication:1. Do the ECM Reset Procedure.2. Start the engine. Hotd theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on,3. Check the Secondary HO2S{Sensor 2) output ar 3,000 rpmth the scan tool.

Intarmittert lailurg, systsm i! OKat thi! time. Chsck for Door con-nections o. loose wi.es at C451Secondary HO2S lsonsor 2) .ndECM.

Does the voltage stay within0.3 - 0.6 V tortwo minutos?

Page 278 of 1680

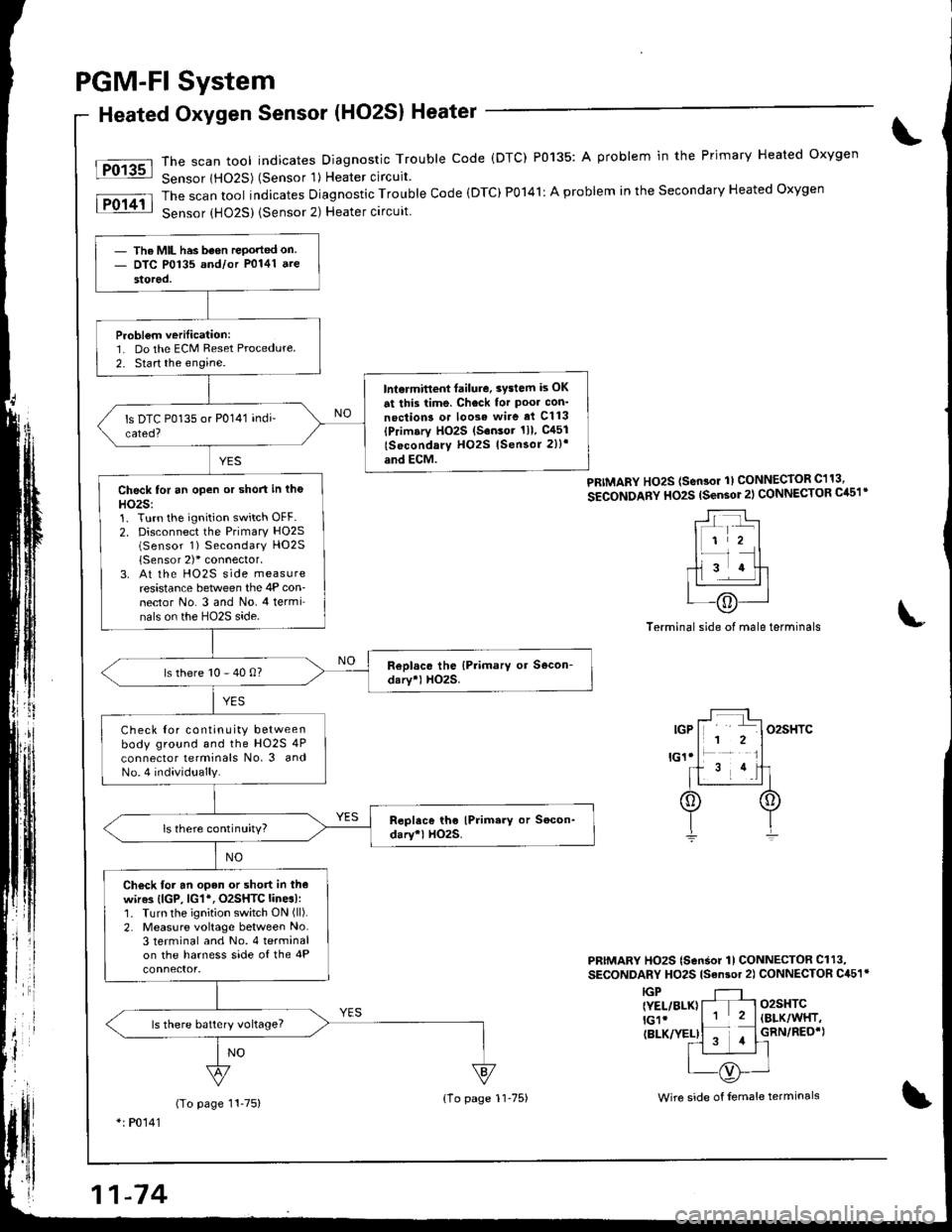

PGM-FI System

Heated Oxygen Sensor (HO2S) Heater

The scan tool indicates Diagnostic Trouble code (DTC) P0135: A problem in the Primary Heated oxygen

Sensor lHO2S) (Sensor 'l) Heater circuit

The scan tool indicates Diagnostic Trouble Code (DTC)P0141: A problem in the Secondary Heated Oxygen

Sensor {HO25) {Sensor 2) Heater circuit

Fo13sl

lFol4il

PRIMARY Ho2S (sen3or 1) CONNECToR C113,

SECONDARY HO2S (sensor 2l CONNECTOR Cil51'

Terminal side of male terminals

PRIMARY HO2S (SonSor 1l CONNECTOR Cl13,

SECONDARY HO2S lsan3or 2) CONNECTOR C451r

o2sHTC(BLK/WHT,

GRN/REO'}

IGP{YEL/BLK}lGlr(BLK/YEL)

(To page 11-75)*: P0141

- The MIL has been rePorted on- DTC P0135 and/or P0141 ate

stored.

Probl€m verilication:1. Do the ECM Reset Procedure

2. Start the engine.

lnt€rmitlent failure. 3vslem is OK

at this time. Check for Poo. con'

noction3 o. loose wire ai Cl13(Primary HO2S (S.nsor 1ll. gl51

lSocondary H02S lSensor 2))'

and ECM.

Check for an open or short in tho

HO2S:1. Turn the ignition switch OFF.2. Disconnect the Primary HO2S(Sensor 1) Secondary HO2S

{Sensor 2)'connector,3. At the HO2S side measureresistance between the 4P con-nector No. 3 and No. 4 terminals on the HO2S side.

ls there 10 - 40 0?

Check Ior continuity betweenbody ground and the HO2S 4P

connector lerminals No. 3 andNo.4 individually.

ls there continuity?

Ch€ck for an open or short in thewir63 (lGP, lG1*, O2SHTC lines):1. Turn the ignition switch ON (ll).

2. Measure voltage between No.3 terminal and No. 4 terminalon the harness side of the 4P

ls there batlery vohage?

{1o page 1l-75)Wire side of female terminals

Page 279 of 1680

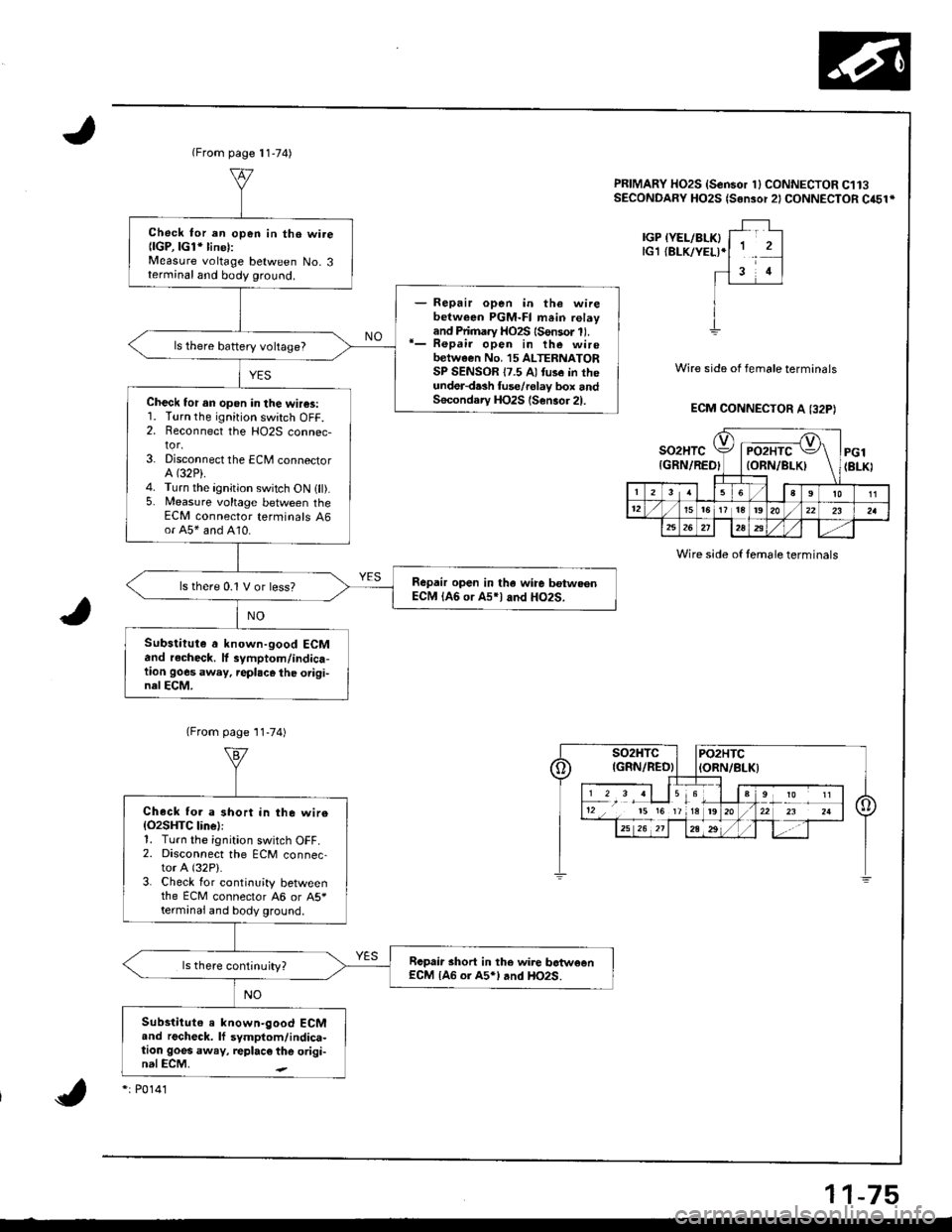

(From page 11-74)

Check tor an op6n in the wire{lGP, lGl* linel:Measure voltage between No. 3terminal and body ground.

Repair open in the wirebetween PGM-Fl mein relayand Pii.nary HO2S {Sonsor 11.Repair open in the wirebetween No. 15 ALTERNATORSP SENSOR 17.5 A) tuse in theund€r-d.sh fuse/rolav box andSecondary HO2S (S€n3or 21.

ls there battery vohage?

Check for an opon in the wh$:1. Turn the ignition switch OFF.2. Reconnect the HO2S connec-tor.3- Disconnect the ECM connectorA (32P).

4. Turn the ignition switch ON 1fl).5. Measure voltage between theECM connector terminals 46or A5* and A10.

Repair open in tha wire betw.enECM {A6 or A5rl and HO2S.ls there 0.1 V or less?

Substitute a known-good ECMand r.chcck. tf 3ymptom/indica-tion goes awey, repl.ce the odgi-nelECM.

PRIMARY HO2S {Sensor 1} CONNECTOR C113SECONDARY HO2S (Sensor 2ICONNECTOR C45tr

Wire side of female terminals

ECM CONNECTOR A I32P)

IGPlG1

so2HTC{GRN/RET

c

4tr

A, 4\'/ | PO2HTC \=/ \ltoRN/BLKt \-T--] \

PGl(BLK)

2a 1f lefil tt12't5t51? t8t92022 23

2526l2823

Wire side of temale terminals

(From page '11-74)

Check fo. a short in the wire(O2SHTC linel:1. Turn the ignition switch OFF.2. Disconnect the ECM connec-tor A (32P).

3. Check for continuity betweenthe ECM connector 46 or A5*termanai and body ground.

Rcpair short in the wire botweenECM IAG or A5*l .nd HO2S.ls there continuity?

Substituto a known-good ECMand recheck. lf symptom/indica-tion goes away, replac€ the origi-nalECM.

3 rl 15 6

15 15 17 lA

*r P0141

11-75

Page 284 of 1680

PGM.FI

Misfire

System

Detected in One Cylinder (cont'd)

)

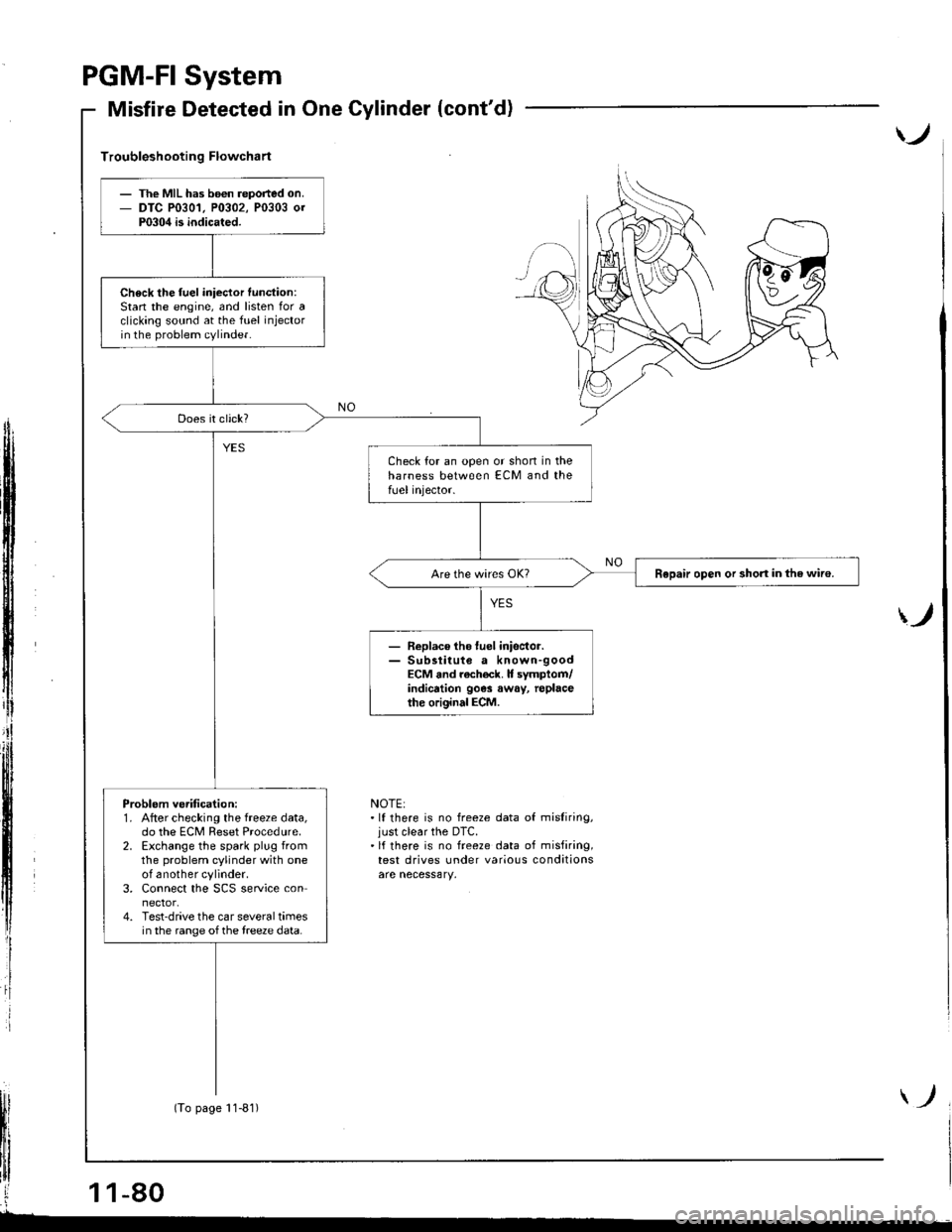

Troubleshooting Flowchart

ff

i

)

NOTE:.lf there is no freeze data of misliring,just clear the DTC.'lf there is no freeze data of misfiring,test drives under various conditions

The MIL has b6€n reported on.DTC P0301, P0302, P0303 0rP0304 is indicated.

Check the fuel iniector function:Stan the engine, and listen for aclicking sound at the fuel injectorin the problem cylinder.

Check for an open or shon in theharness between ECM and thefUel injector.

Repair open or short in the wiro.

- Replace tho luel inisctor.- Sub3titute a known-goodECM and rach€ck. It symptom/indicrtion 90e3 away, replacethe original ECM.

Problem ve.ification:1. After checking the freeze data,do the ECM Reset Procedure.2. Exchange the spark plug fromthe problem cylinder with oneof another cylinder.3. Connect the SCS service connector.4. Test-drive the car several timesin the range of the treeze data.

(To page 11-81)

Page 286 of 1680

I

PGM-FI System

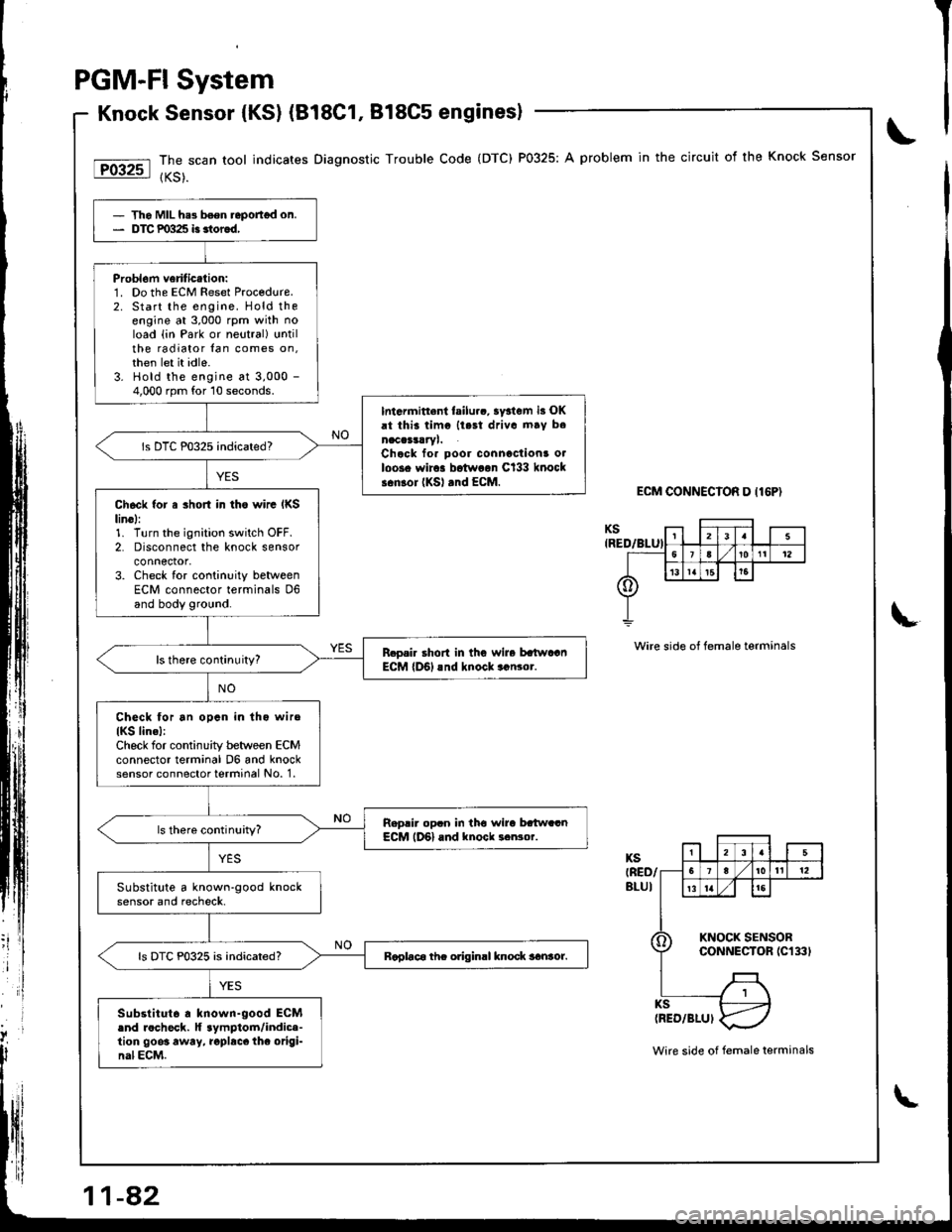

Knock Sensor {KSl (B18C1, 818C5 enginesl

The scan tool indicates Diagnostic Trouble Code (DTC) P0325: A problem in the circuit of the Knock Sensor

{KS).

ECM CONNECIOR D I16P)

Wire side of female terminals

- Tho MIL he3 b6en.eportgd on.- DTC P0325 i3 3tor6d,

Probl6m veriticalion:1. Do the ECM Reset Proc€dure.2. Start the engine. Hold theengine at 3,000 rpm with noload {in Park or neutral} untilthe radiator lan comes on,then let it idle.3. Hold the engine at 3,000 -

4,000 rpm for 10 seconds.

Intarmitt.nl failurc, ay3tem i3 OKrt thii timc llest driva mav b.naccrsrryl.Chcck for poor connactions o.loos. wir.. botw..n Cl33 knocks.nlor (KSl rnd EcM.

Ch6ck {or a 3hort in tho wirc IKSlin6l:1. Turn the ignition switch OFF.2. Disconnect the knock sensorconnector,3. Check for continuity betweenECM connector terminals D6and body ground.

R.o.i. short in thG wire batwaanECM lD6l rnd knock..n3or.

Check for an opcn in lho wiro

IKS lin.l:Check for continuity between ECMconnector terminal D6 and knocksensor connector terminal No. 1.

Reprir op.n in tho wira bttw..nECM lD6l and knock ..Nor.

Substitute a known-good knocksensor and recheck.

Raplac6 thc odginrl knock sanror.ls DTC P0325 is indicated?

Substitut6 . known-good ECM.nd rocheck. lf aymptom/indic.-tion 9003 away, .opbcc thc origi-nal ECM.Wire side of female terminals

Page 287 of 1680

t@

tFffi6l

F136il

l-P1362l

Fi3BTl

tFE82-l

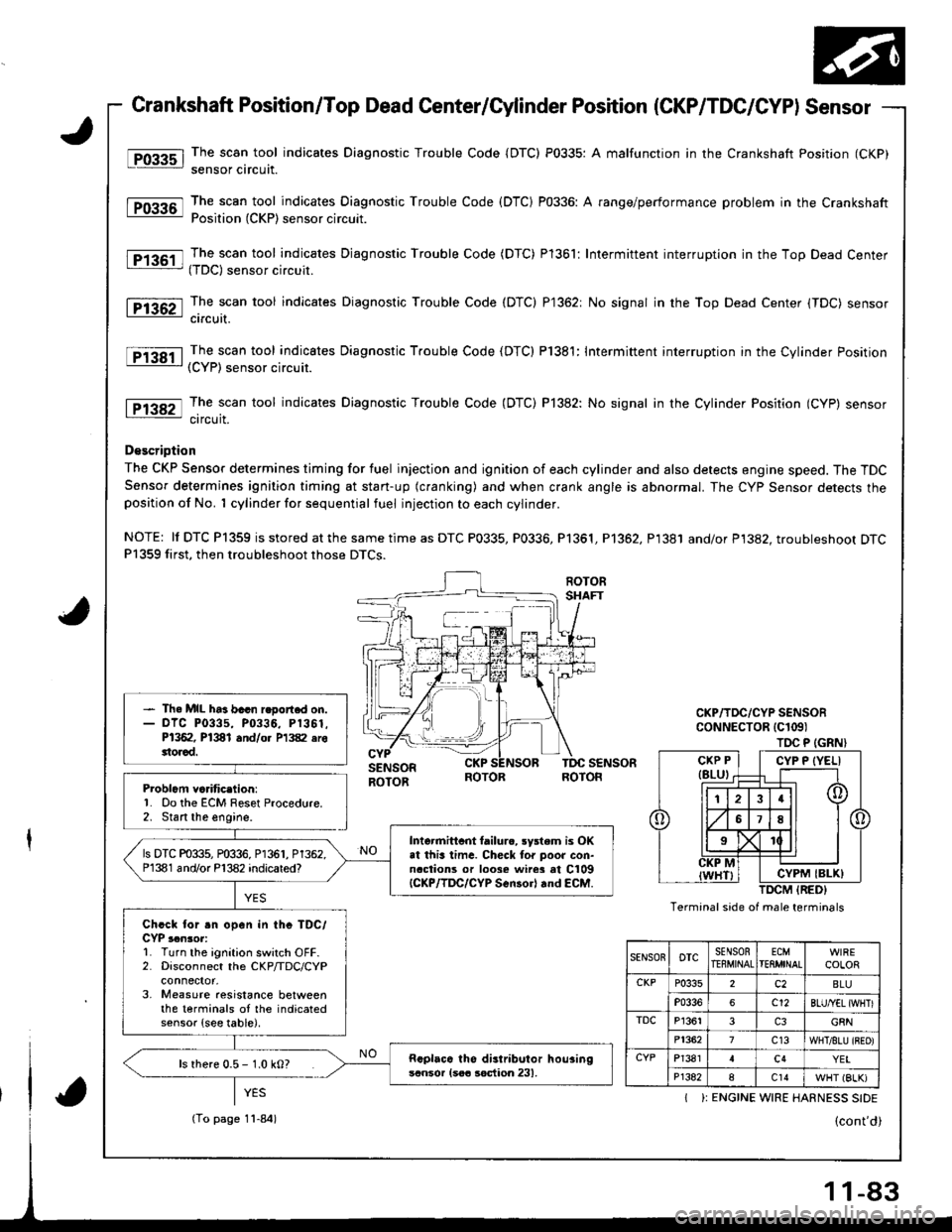

Crankshaft Position/Top Dead Center/Cylinder Position (CKP/TDC/CYPI Sensor

The scan tool indicates Diagnostic Trouble Code {DTC) P0335: A malfunction in the Crankshaft Position (CKP)

sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P0336: A range/performance problem in the CrankshaftPosition (CKP) sensor circuit.

The scan tool indicates Djagnostic Trouble Code (DTC) Pl361: Intermittent interruption in the Top Dead Center(TDC) sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1362: No signal in the Top Dead Center (TDC) sensorcircuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1381: Intermittent interruption in the Cylinder Position(CYP) sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P]382: No signal in the Cylinder Position (CYP) sensorcircuit.

D€scription

The CKP Sensor determines timing for fuel injection and ignition of each cylinder and also detects engine speed. The TDCSensor determines ignition timing at stan-up (cranking) and when crank angle is abnormal. The Cyp Sensor detects theposition of No. 1 cylinder for sequential fuel injection to each cylinder.

NOTE: ll DTC P1359 is stored at the same time as DTC P0335, P0336, Pl361, P1362, P1381 and/or P1382. troubleshoot DTCP1359 first, then troubleshoot those DTCS.

Problcm va.itic.lion:'1. Do the ECM Reset Procedure.2. Stan the engine.

- Th. MIL ha3 bacn r.oort.d on.- olc P0335, P0336, P1361.P1362, P1381 and/o. P1382 erottorad.

Intormittcnt tailurc, rystem is OKat this lima. Checl tor poor con-naclions or loose wire3 at C109{CKP/lDC/CYP Scn30rl rnd €CM.

ls DTC P0335, P0336, P1361, P1362.P1381 and/or P'l382 indicared?

Chcck for .n open in thc TDC/CYP ,.n3or:L Turn the ignition switch OFF.2. Disconnect the CKP/TDC/CYP

3, Measure aesistance betweenthe terminals oI the indicatedsensor {see table).

Rcplaca tho distributor hou3ingscnsor {soa soction 231,ls rhere 0.5 - 1.0 kO?

TOC P (GRN}

Termanal side of male terminals

CYP P {YELI

CYPM IBLK)

SENSOnoTcSENSORTEEMINALECMTEflMINALCOLOR

CKPP0335c2BLU

P0336c12BLU/YEL {WHTI

TDCP13613G8N

P13627c13WHT/8LU {BEO)

CYPP13814c4YEI

P1382ac14WHT (BLK)

I ): ENGINE WIRE HARNESS SIDE

(To page 11-84)

-83

Page 288 of 1680

PGM-FI System

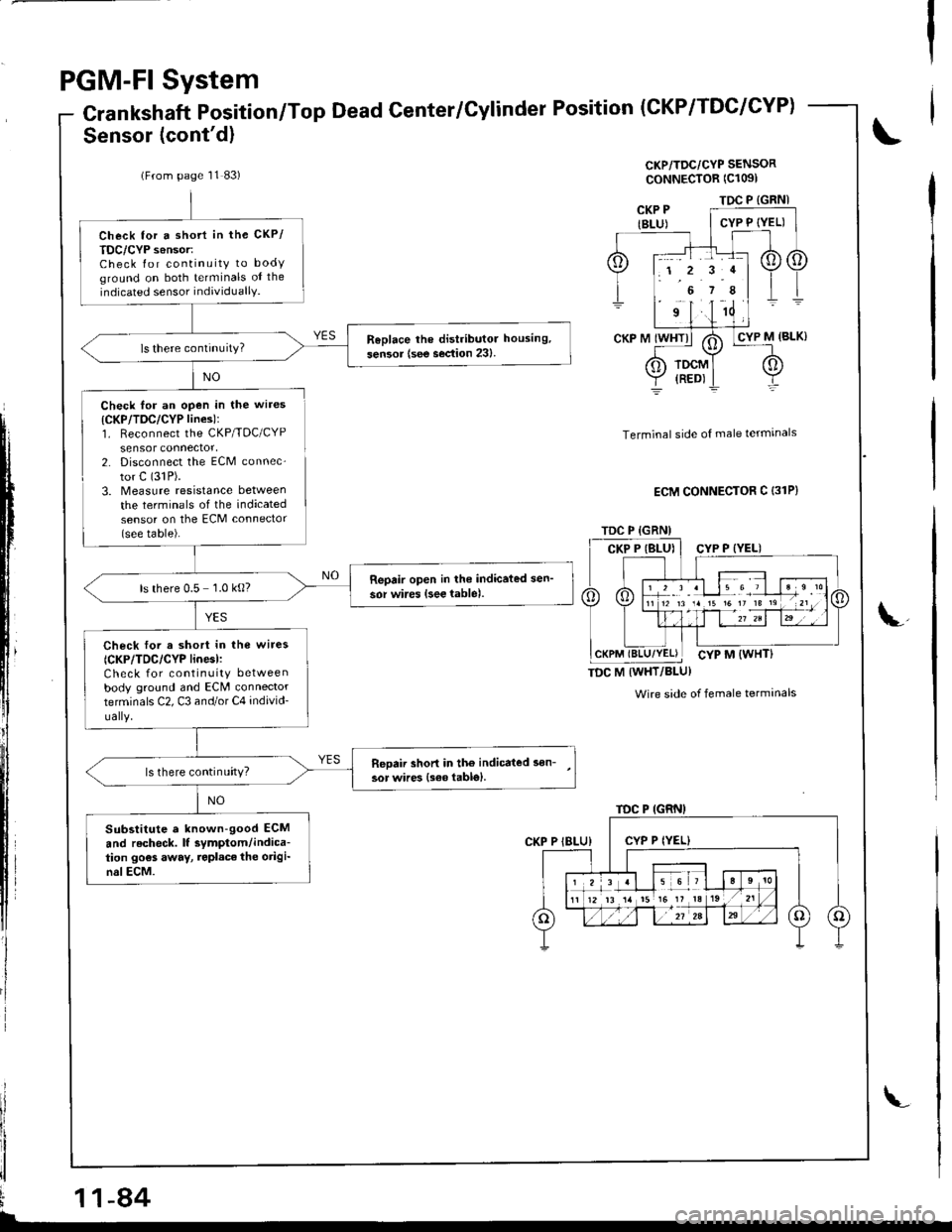

Crankshaft Position/Top Dead Center/Cylinder Position

Sensor (cont'd)

(CKP/TDC/CYP)

CKP/TDC/CYP SENSOR

ooNNECTOR (Cl091

NO

il

,ll

I

Check for an open in the wires

{CKP/TDC/CYP lines):1. Reconnect the CKP/TDC/CYPsensor connector,2. Disconnect the ECM connec-

tor C (31P).

3. Measure resrstance between

the terminals of the indicatedsensor on the ECM connector(see table).

Terminal side of male termrnals

ECM CONNECTOR C {31P}

TDC M IWHT/BLU}

Wire side of female terminals

i

ii!\

(From page 11 83)

Check tor a shott in the CKP/

TDC/CYP s6nsor:Check for continuity to bodyground on both terminals oI the

indicated sensor individuallY.

ReDlace lhe distributor housing,

sen3or {see section 23}.

Reoair open in lhe indicated sen'

sor wires {see lable).ls there 0.5 1.0 kg?

Check lor a short in the wire3

{CKP/TDC/CYP linesl:Check for continuity betweenbody ground and ECM connectorterminals C2, C3 and/or C4 individ-

ually.

Reoaii shon in tho indicated son-

3or wires {s€6 table}.ls there continuity?

Substitute a known-good ECM

and recheck. lf symptom/indica-tion go€s away, repl.ce the origi-nslECM.

TDC P {GRNI

TDC P (GRN)

1 2 r .l le 6 7

TDC P {GRN)

1 2 3 al 15 6 ,

12 13 14 t5 16 It 13

11-84

Page 289 of 1680

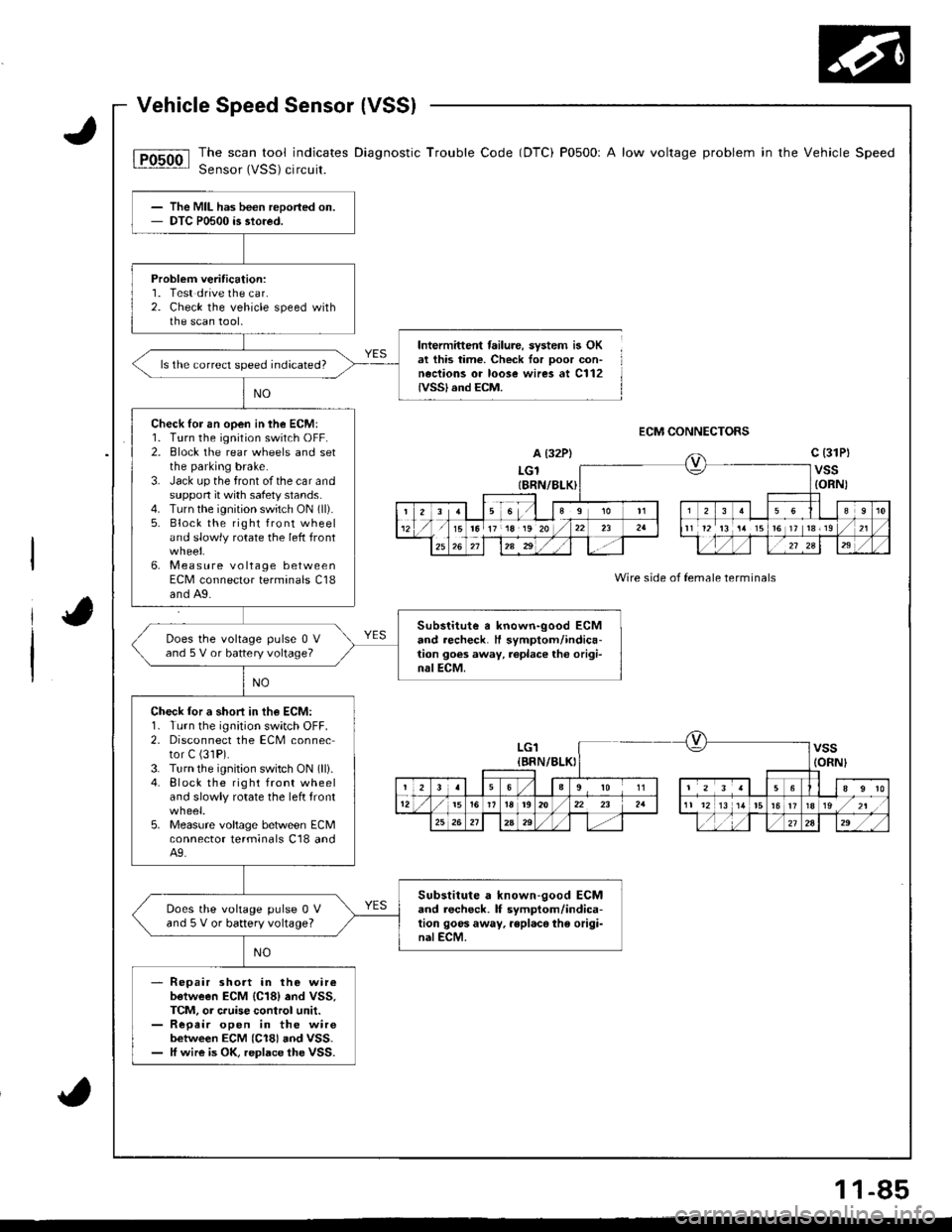

The scan tool indicates Diagnostic Trouble Code (DTC) P0500r A low voltage problem in the Vehicle Speed

Sensor (VSS) circuit.

Intermittent failure, system is OKat this time. Check for ooor con-neciions or loose wires at C112IVSSI and ECM.

ECM CONNECTORS

A (32P)

LGlIBRN/8LK)

c (31Pt

vss{ORN)

Wire side of female terminals

The MIL has been reported on.DTC P0500 is stored.

Probleft veritication:1. Test drive the car.2. Check the vehicle speed withthe scan tool,

ls the correct speed indicated?

Check lor an open in the ECM:1. Turn the ignition switch OFF.2. Block the rear wheels and setthe parking brake.3. Jack up the front of the car andsuppon it with safety stands.4. Turn the ignition switch ON (ll).

5. Block the right front wheeland slowly rotate the left front

6. Measure voltage betweenECM connector terminals C18and A9.

Substitute a known-good ECMand recheck. H symptom/indica-tion goes away, replace tho origi-nalECM.

Does the voltage pulse 0 Vand 5 V or battery voltage?

Check lor a shori in th€ ECM:1. Turn the ignition switch OFF.2. Disconnect the ECM connector C (31P).

3. Turn the ignition switch ON (lli.4. Block the right front wheeland slowly rotate the left front

5. Measure voltage between ECMconnector lerminals C18 andA9.

Substitute a known-good ECMand lecheck. lf symptom/indica-tion goos away. rsplaco the origi-nalECM.

Does the vohage pulse 0 Vand 5 V or battery voltage?

Repair short in the wireb€tween ECM {C18} end VSS,TCM, or cruise control unit.Repeir open in the wirebetween ECM (C18) aod VSS.ff wire is OK, replace the VSS.

ra 17 18 19 20t6 ]t 13r19

LG1{BRN/BLKIvss(ORNI

23563910 1156

12i5r92022 23 2a11 1213 1/tr6ts/zt

25262Aa9,/2724," ,/ ,,:

1 1-85

Page 290 of 1680

PGM-FI System

Barometric Pressure {BARO) Sensor

rrt*l ;:"""::::[Ti5li"$::::#nostic

rroubre code (Drc) P1106: A ranse/performance p'oblem in the Barometric\

,xl

lu,

i-

- The MIL h.3 bean roportad on.- DTC Pl106 i3 3tolod.

Problom Ye.ification:1. Dotho ECM resot procedure.

2. Start the engine. Hold the

ongine at 3,000 rpm with no

load (in Park or neutral) until

the mdiator lan comes on, thenlet h idle.3. Connect the SCS service con-

nector,4. Test-drive with the A,/T in E]position (M/T in 4th goar).

5. Accolerate for five seconds

using wide open throttle.

Int imitt.nt f.llur., .y!t.m ir OKrt thi. tim..ls DTC P1106 indicated?

Substltuto r known-good EGM

and rech.ck. tf rymptom/indic..lion gooa rway, raplaca thc origi_n.l ECM.

11-86

\.