exhaust ACURA INTEGRA 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1998, Model line: INTEGRA, Model: ACURA INTEGRA 1998Pages: 1680, PDF Size: 53.14 MB

Page 41 of 1680

ra

Engine

Engine Removal/lnstallation ............. 5-1

Cylinder Head/Valve Train ............... 6-1

Engine Block ......... ........7-1

Engine Lubrication .........8-1

Intake Manifold/Exhaust System ...... 9-1

Cooling ....... 10-1

Page 50 of 1680

7

30.Disconnect the primary heated oxygen sensor(Primary HO2S) connector, then remove exhaust

pipe A.

818C1 engine:PRIMARYHO2S

8 x 1.25 mm24 N.m 12.4 kgl.m.t7 rbt.fttReplace.

GASKETReplace.

Replace.

SELF-LOCKING I{UT8 r 1.25 mm16 N.m (1 .6 kgf .m,

12 tbt.frtBeplace.

EXHAUSTPIPE A

NUT10 x 1.25 mm54 N.m {5.5 kgt'.n, tlo lbt.ft}Replace.

81881, 818C5 engines:

PRIMARYHO25 CONNECTOF

GASKETReplace.

GASKETReplace.

S€LF.LOCKING NUT

8 x 1.25 mm16 N.m (1.6 kgf'm,12 tbt.fr)Replace.f{UT10 x 1.25 mm54 N.m {5.5 kgf'm,40 lbf.ftlReplace.

8 x 1.25 mm24 N.m (2.4 kgt.m,17 lbf.frlReplace.

31. Remove the shift rod and extension rod {Mff).

8 x 1.25 mm22 N'm 12.2 kgl.m, '16 lbt.ttl

32. Remove the shift cable (A,/T).

I x 1.25 mm22 N-l'. 12.2 kgl.m,16 lbf.frl

SHIFT CABLE

CONTROLLEVER

6 x 'l.O mm14 N.m {1.4 kgf.m, 10 lbt.ft}

SHIFT ROD

RETAINER

SHIFT CABLE

LOCK WASHER

{cont'd)

COVER

5-9

Page 64 of 1680

r.lJ

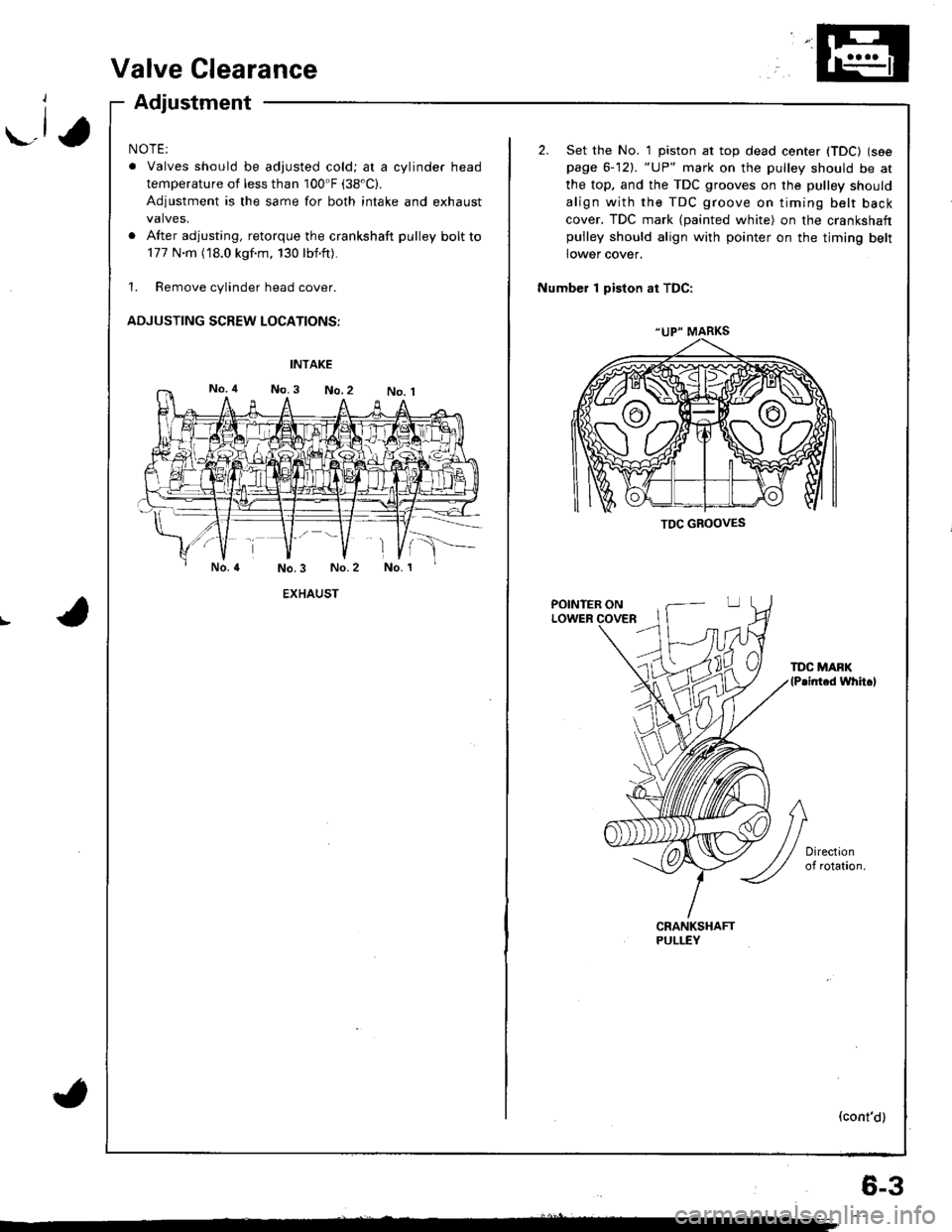

Valve Clearance

Adjustment

NOTE:

. Valves should be adjusted cold; at a cylinder head

temperature of less than 100'F (38"C).

Adjustment is the same for both intake and exhaust

valves.

. After adjusting, retorque the crankshaft pulley bolt to

177 N.m (18.0 kgf.m, 130 lbf'ft).

1. Remove cylinder head cover.

ADJUSTING SCREW LOCATIONS:

EXHAUST

(

"UP" MARKS

TDC GBOOVES

2. Set the No. 1 piston at top dead center (TDC) (see

page 6-12). "UP" mark on the pulley should be at

the top, and the TDC grooves on the pulley should

align with the TDC groove on timing belt back

cover. TDC mark (painted white) on the crankshaftpulley should align with pointer on the timing belt

lower cover.

Number 1 piston at TDC:

POINTER ONLOWER

TDC MAFK(P.inted whh.l

(cont'd)

6-3

Page 65 of 1680

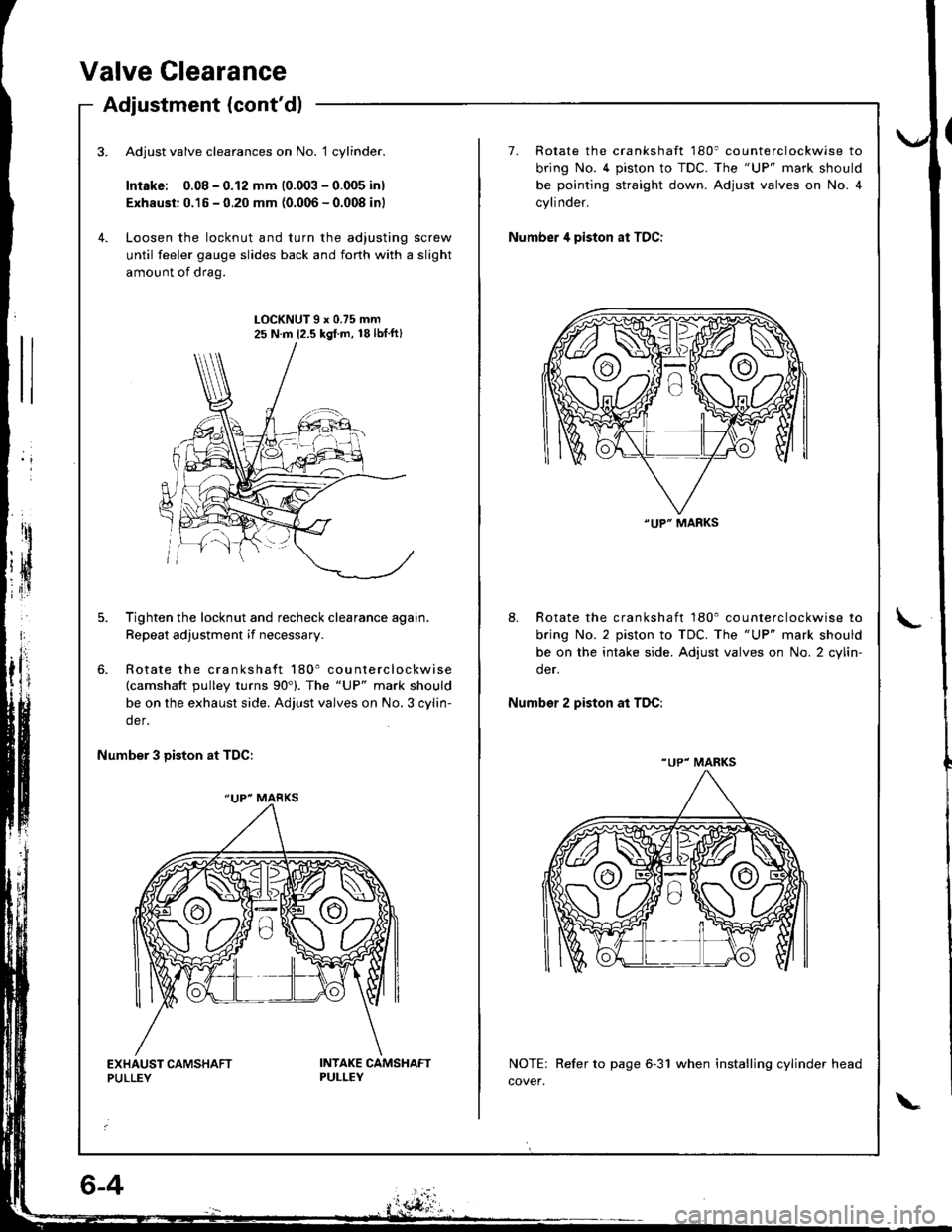

Valve Clearance

Adjustment (cont'dl

Adjust valve clearances on No. 1 cylinder.

Intske: 0.08 - 0.12 mm (0.003 - 0.005 inl

Exhaust: 0.15 - 0.20 mm (0.006 - 0.008 inl

Loosen the locknut and turn the adjusting screw

until feeler gauge slides back and forth with a slight

amount of drag.

7. Rotate the crankshaft 180' counterclockwise to

bring No. 4 piston to TDC. The "UP" mark should

be pointing straight down. Adjust valves on No. 4

cylinder.

Number 4 piston at TDC:

LOCKNUT9x0.75mm25 N.m {2.5 kgl.m, 18lbtft}

Tighten the locknut and recheck clearance again,

Repeat adjustment if necessary.

Rotate the crankshaft 180' counterclockwise(camshaft pulley turns 90'). The "UP" mark should

be on the exhaust side. Adjust valves on No,3 cylin-

der.

8. Rotate the crankshaft 180' counterclockwise to

bring No. 2 piston to TDC. The "UP" mark should

be on the intake side. Adjust valves on No. 2 cylin-

der.

Number 2 piston at TDC:

Number 3 Diston at TDC:

NOTE: Refer to page 6-31 when installing cylinder head

cover.

"UP" MARKS

"UP" MARKS

"UP" MARKS

Page 77 of 1680

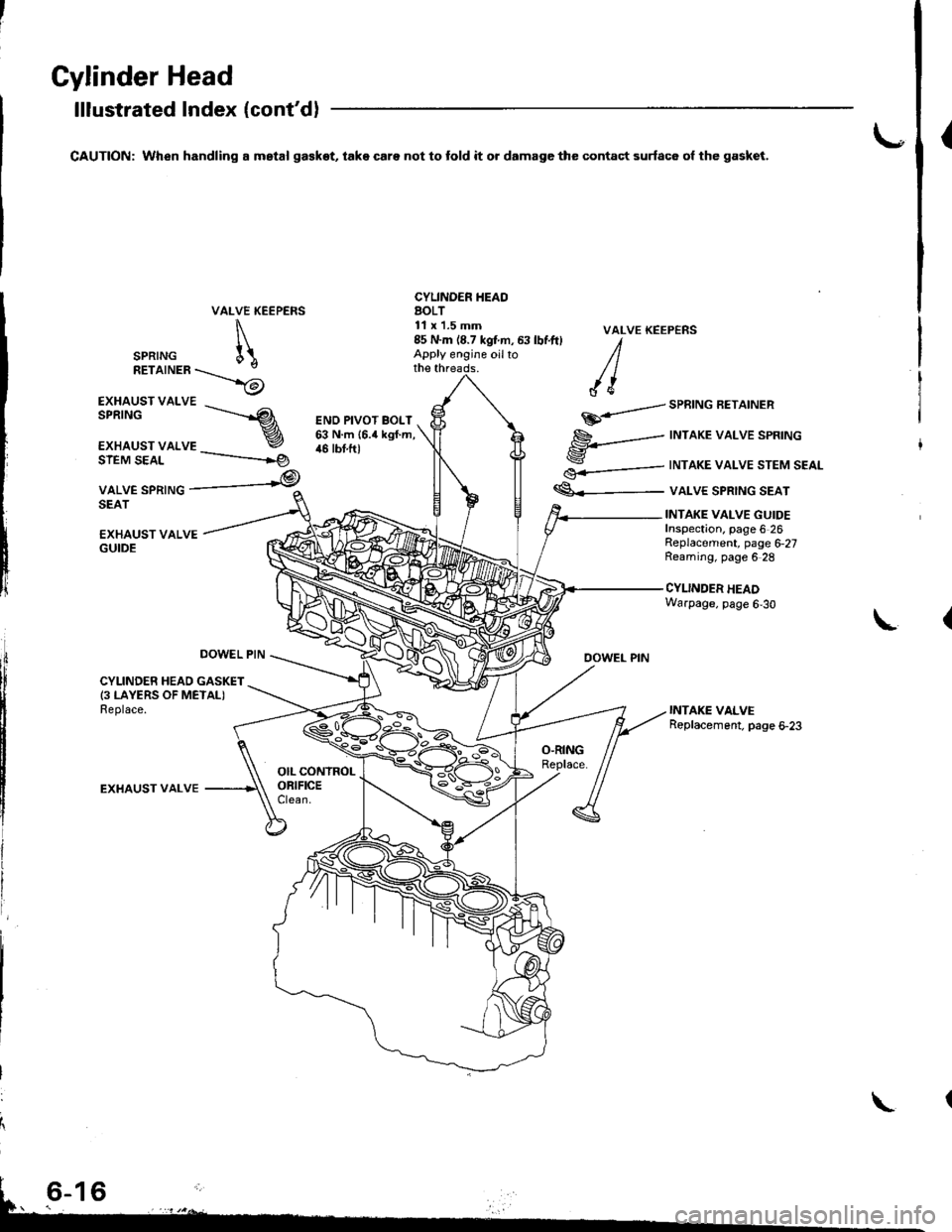

Gylinder Head

lllustrated Index (cont'd)

CAUTION: When handling a mstal ga€kot, take care not to fold it o. damage the contact surfac6 ol the gasket.{

VALVE KEEPERS

\

SPRTNG [\RETaTNER\_>6

CYLINDER IIEAOAOLT11 x'1.5 mm

EXHAUST VALVE

EXHAUST VALSPRINGs------.--

r

€.-=---

€<_-

VALVE KEEP€NS

DOWEL PIN

SPRING AEIAINER

INTAKE VALVE SPRING

INTAKE VALVE STEM SEAL

VALVE SPRING SEAT

ENO PIVOT BOLT63 N.m {6.4 kgf.m,46 tbt.ftlSIEM SEAL

VALVE SPRINGSEAT

-----------rg

,@

EXHAUST VALVEGUIDE

INTAKE VALVE GUIDEInspection. page 6 26Replacement, page 6,27Reaming, page 6 28

CYLINDER HEADWarpage, page 6,30

L

DOWEL PIN

CYLINDER HEAD GASKET(3 LAYERS OF METALIReplace.

EXHAUST VALVE

85 N.m (8.7 kgtm, 63 lbf.ft) IApply engine oilto /lthe threads. / |

/ {e

\

Page 81 of 1680

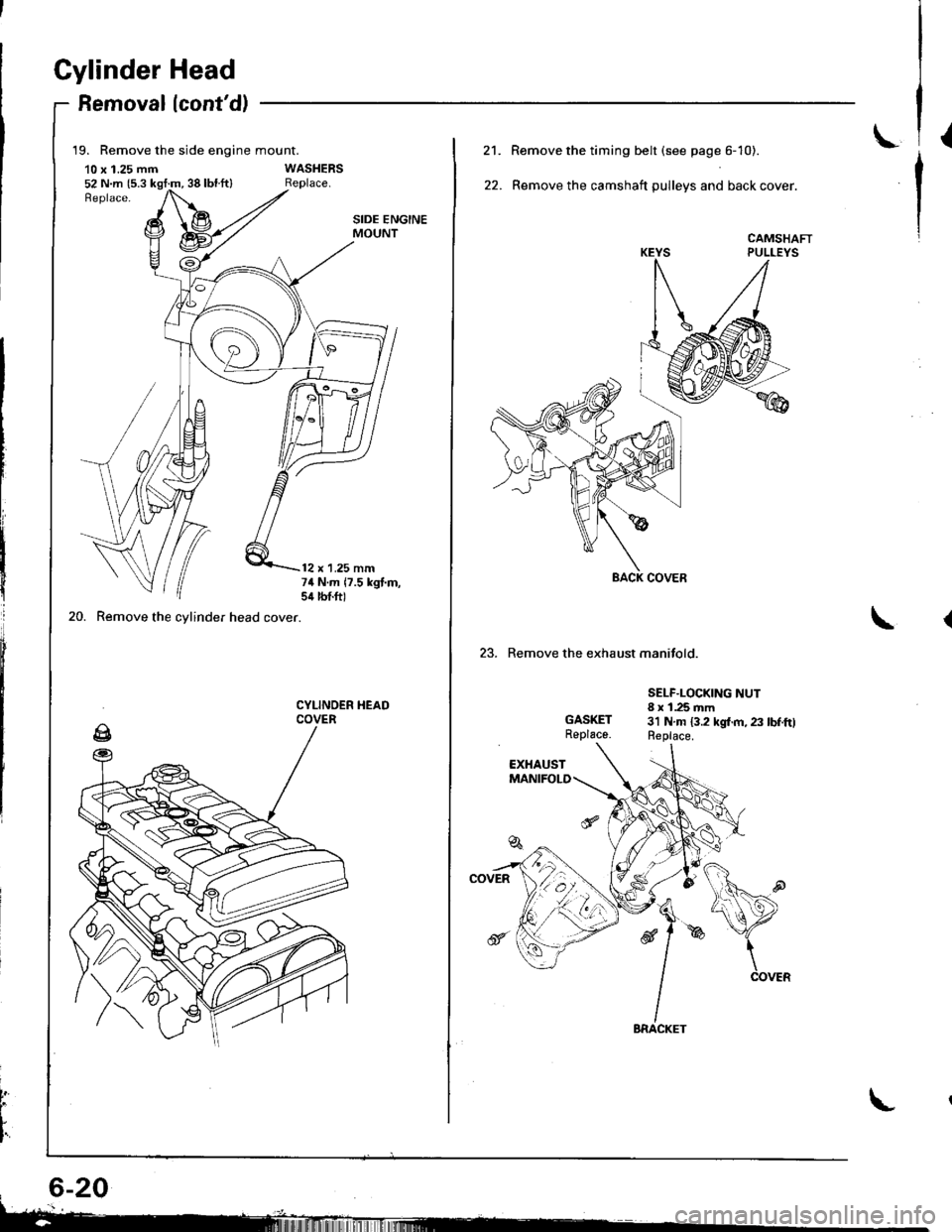

Gylinder Head

Removallcont'd)

19. Remove the side engine mount.

10 x 1.25 mm52 N.m {5.3 kgt:m, 38 lbl.ft}

20. Remove the cylinder head cover.

SIDE ENGINEMOUNT

12 x 1.25 mm74 N.m 17.5 kgt.m,sil lbtft)

CYLINOER HEADCOVER

t

L

I'

L21.

22.

Remove the timing belt (see page 6- 10).

Remove the camshaft pulleys and back cover.

CAMSHAFTPULLEYS

23. Remove the exhaust manifold.

GASKETReplace.

SELF.LOCKING NUT8 x 1.25 mm3'l N.m 13.2 kgl.m, 23 lbf.ftlReplace.

Page 84 of 1680

\-

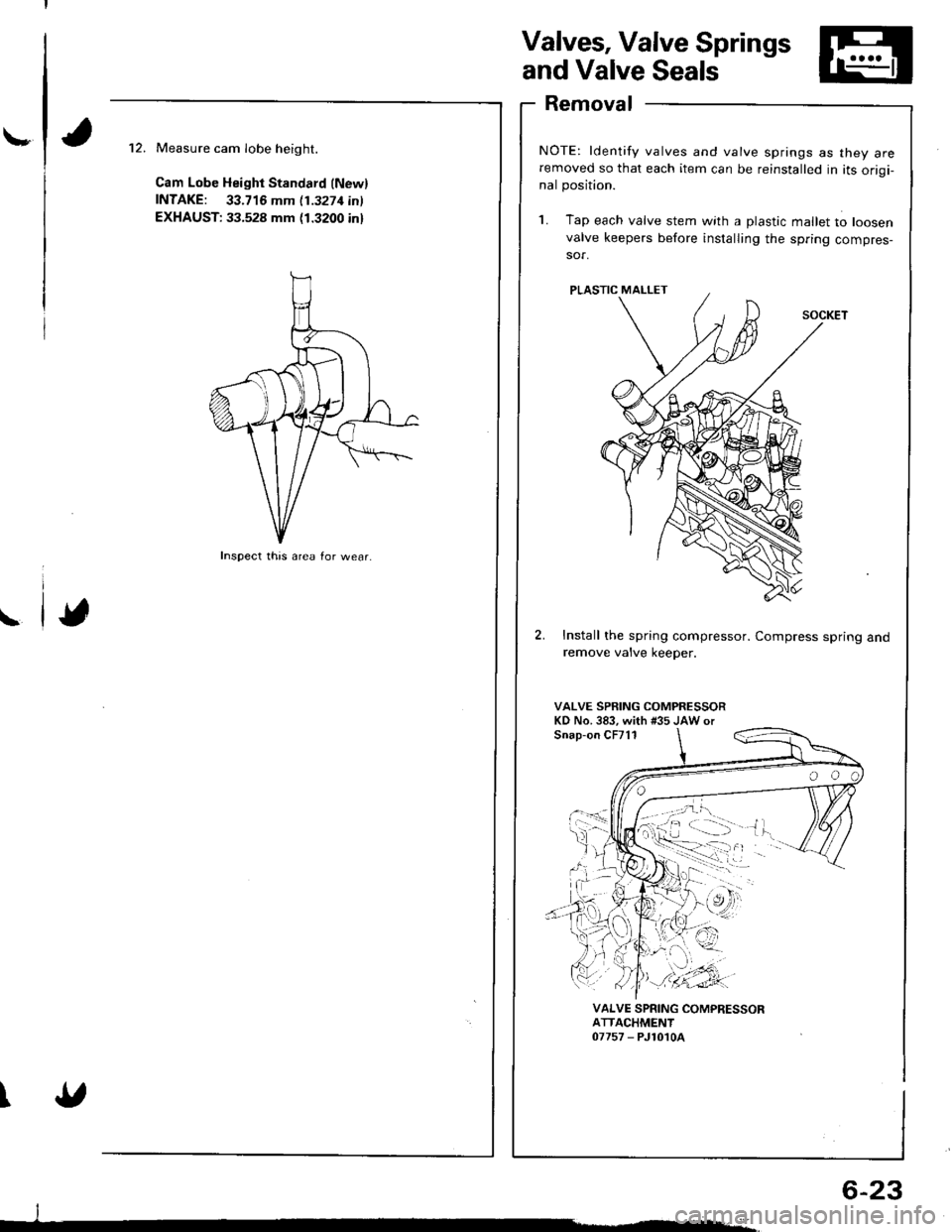

Valves, Valve Springs

and Valve Seals

Removal

NOTE: ldentify valves and valve springs as they areremoved so that each item can be reinstalled in its origi-nal position.

1. Tap e€ch valve stem with a plastic mallet to loosen

valve keepers before installing the spring compres-sor.

Install the spring compressor. Compress spring andremove valve keeper.

VALVE SPRING COMPRESSORKD No.383, with #35 JAW orSnap-on CF711

Measure cam Iobe height.

Cam Lobe Height Standard (Newl

fNTAKE: 33.716 mm 11.3271inl

EXHAUST: 33.528 mm (1.3200 inl

\

\

VALVE SPRING COMPRESSORATTACHMENT07757 - PJ1010A

Inspect this area for wear.

;;:'

, -:.. "

'orl

._vn-'r'.'i),

I

6-23

Page 85 of 1680

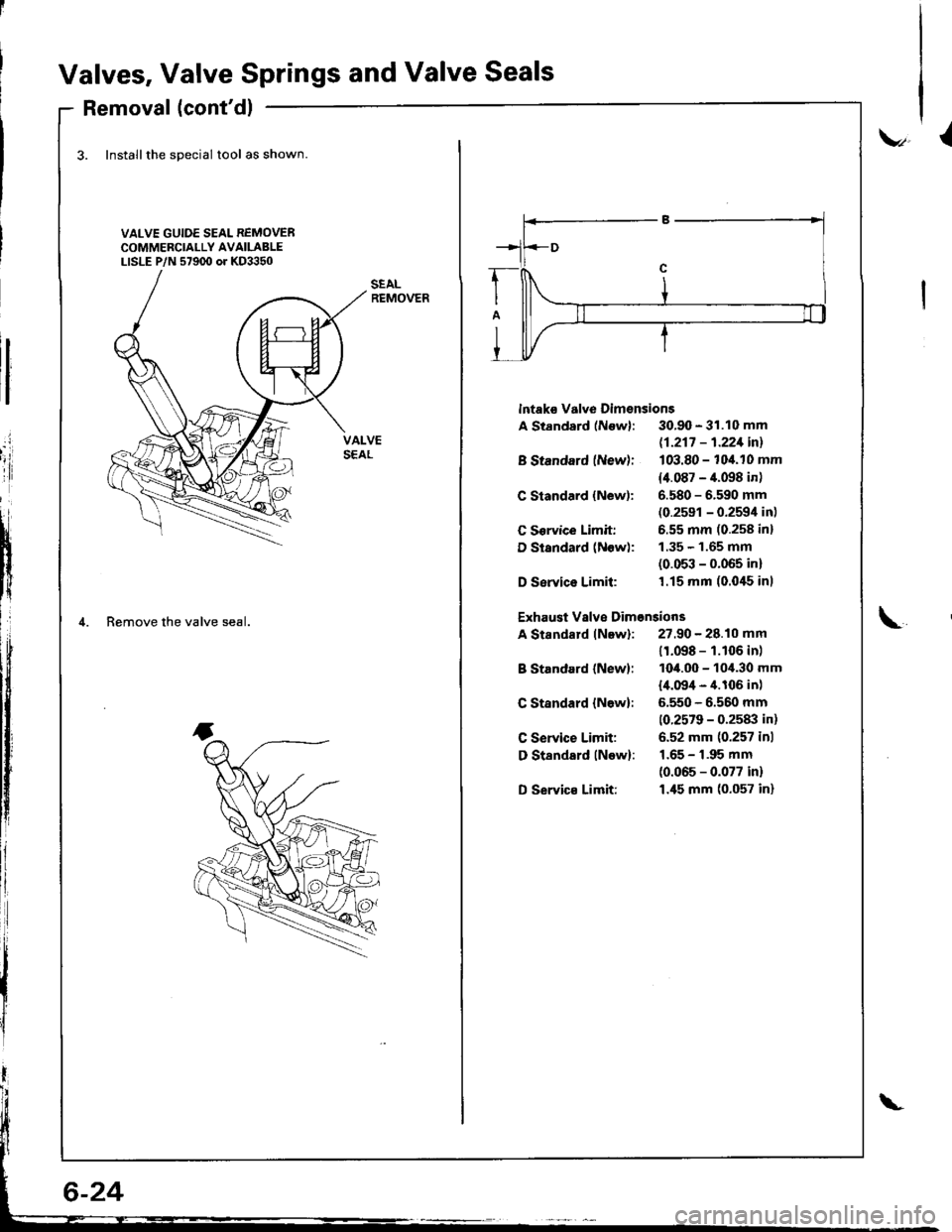

Valves, Valve Springs and Valve Seals

Removal (cont'dl

3. Installthe special tool as shown

VALVE GUIDE SEAL REMOVERCOMMERCIALLY AVAILABLELISLE P/N 57900 or KD3350

.i

'iii

tI

i{

lf

4. Remove the valve seal.

v,l

lntaks valve Dimsnsions

A Standard (Newl: 30.90 - 31.10 mm

B Standard (New):

C Standard {New):

C Sorvice Limit:

D Standard (Now):

D Service Limil:

B Standard (New):

C Standard {N6w}:

C Service Limit:

D Standsrd lNow):

D Servic€ Limit:

11-217 - 1.221inl

103.80 - 104.10 mm

14.087 - 4.098 in)

6.580 - 6.590 mm(0.2591 - 0.2594 in)

6.55 mm (0.258 inl

1.35 - 1.65 mm(0.053 - 0.065 in)'1.15 mm (0.0'15 inl

Exhaust Vslve Dimonsions

A Standard lNew): 27.90 - 28.10 mm\

11.098 - 1.106 in)

1O4.OO - 10,1.30 mm

l,[.09/t - 4.106 in)

5.550 - 6.560 mm

10.2579 - 0.2583 in)

6.52 mm (0.257 inl

1.65 - 1.95 mm

(0.065 - 0.077 in)

1.45 mm (0.057 in)

Page 86 of 1680

\-

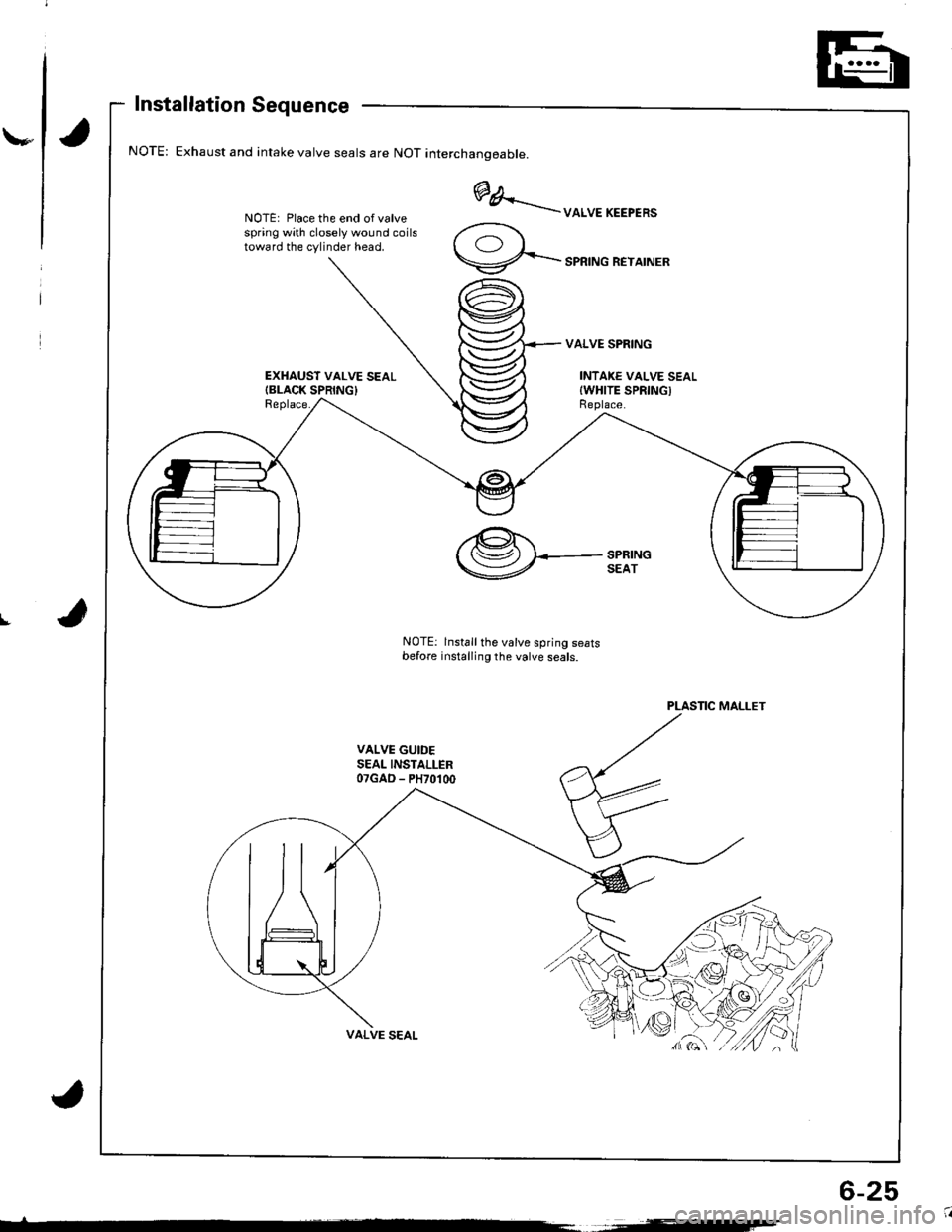

Installation Sequence

Exhaust and intake valve seals are NOT interchanoeable.

NOTE: Place the end of valvespring with closely wound coilstoward the cylinder head.

EXHAUST VALVE SEALIBLACK SPRING}Replace.

@A..'..--uoruEKEEPER'

9-...-'PRTNGREYATNER

VALVE SPRING

INTAKE VALVE SEALIWHITE SPRINGIReplace.

I

PLASTIC MALLET

VALVE GUIDESEAL INSTALLER07GAD - PH70100

,@.t.'( (Sz) I<-- SPRING

V SEAT

NOTE: lnstall the valve spring seatsbefore installing the valve seals.

6-25

Page 87 of 1680

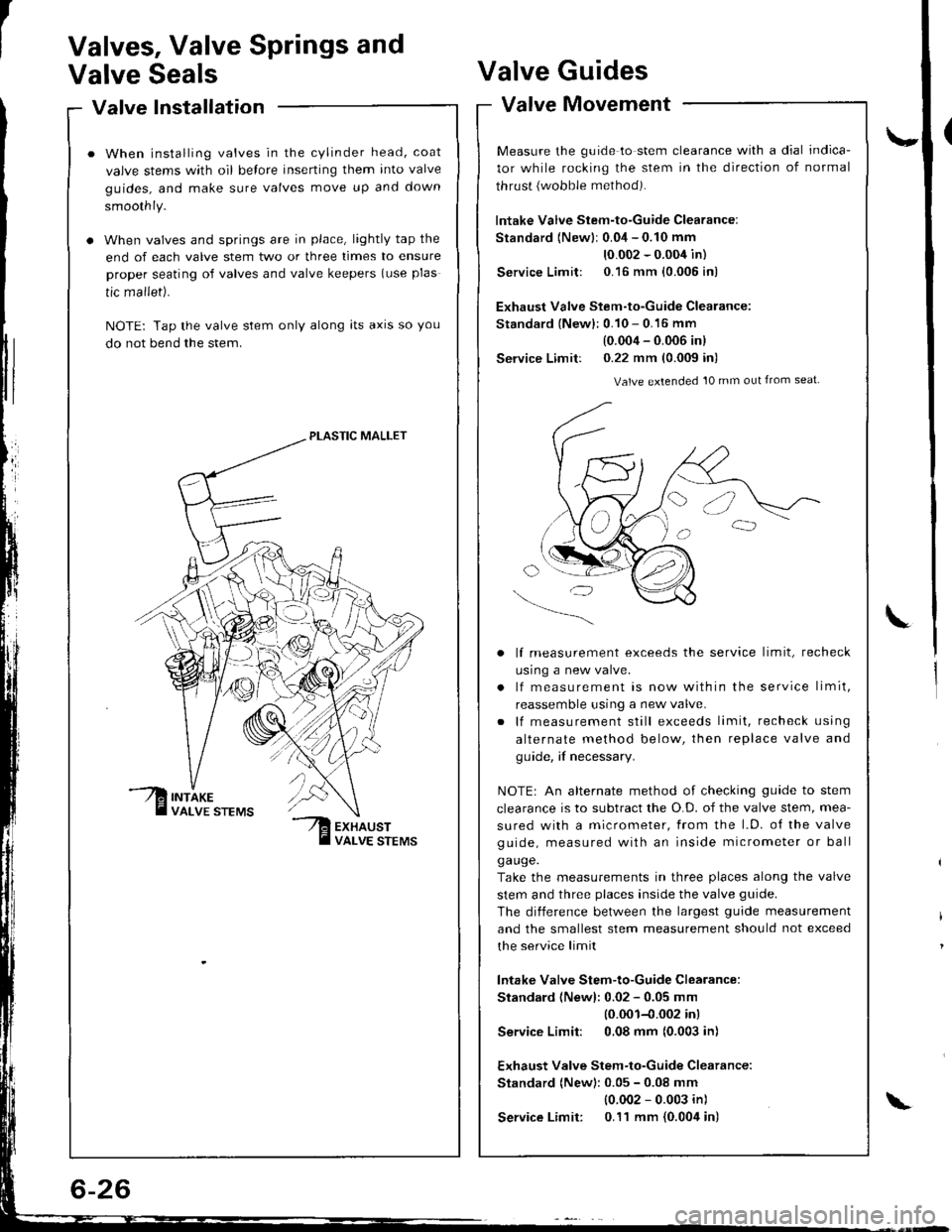

Valve Installation'alve Inslallauon -

When installing valves in the cylinder head, coat

valve stems with oil belore inserting them into valve

guides, and make sure valves move up and down

smoothly.

When valves and springs are in place, lightly tap the

end of each valve stem two or three times to ensure

proper seating of valves and valve keepers (use plas

tic mallet).

NOTE: Tap the valve stem only along lts axrs so you

do not bend the stem.

PLASTIC MALLET

Valves, Valve Springs and

Valve SealsValve

Valve

Guides

Movement

\-

L

valve tvtovemenr -

Measure the guide to stem clearance with a dial indica-

tor while rocking the stem in the direction of normal

thrust {wobble method).

lntake Valve Stem-to-Guide Clearance:

Standard {Newlr 0.04 - 0.10 mm

10.002 - 0.004 in)

Service Limit: 0.16 mm {0.005 in)

Exhaust Valve Stem-to-Guide Clearance:

Standard {New}: 0.10 - 0.16 mm

(0.004 - 0.006 inl

Service Limit: 0.22 mm (0.009 in)

Valve extended 10 mm out from seat

lf measurement exceeds the service limit, recheck

usrng a new valve.

lf measurement is now within the service limit,

reassemble using a new valve.

lf measurement still exceeds limit, recheck using

alternate method below, then replace valve and

guide, if necessary.

NOTEr An alternate method of checking guide to stem

clearance is to subtract the O.D. of the valve stem, mea-

sured with a micrometer, from the l.D. o{ the valve

guide, measured with an inside micrometer or ball

ga uge.

Take the measurements in three places along the valve

stem and three places inside the valve guide.

The diiference between the largest guide measurement

and the smallest stem measurement should not exceed

the service limit

lntake Valve Stem-to-Guide Clearance:

Standard (Newl: 0.02 - 0.05 mm

10.001-{.002 inl

Service Limit: 0,08 mm (0.003 in)

Exhaust Valve Stem-to-Guide Clearance:

Standard (New): 0.05 - 0.08 mm

{0.002 - 0.003 in)

Service Limit: 0.11 mm {0.004 in)\