intake ACURA INTEGRA 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1998, Model line: INTEGRA, Model: ACURA INTEGRA 1998Pages: 1680, PDF Size: 53.14 MB

Page 41 of 1680

ra

Engine

Engine Removal/lnstallation ............. 5-1

Cylinder Head/Valve Train ............... 6-1

Engine Block ......... ........7-1

Engine Lubrication .........8-1

Intake Manifold/Exhaust System ...... 9-1

Cooling ....... 10-1

Page 45 of 1680

En gine Remova l/l nstal lation

(cont'dl

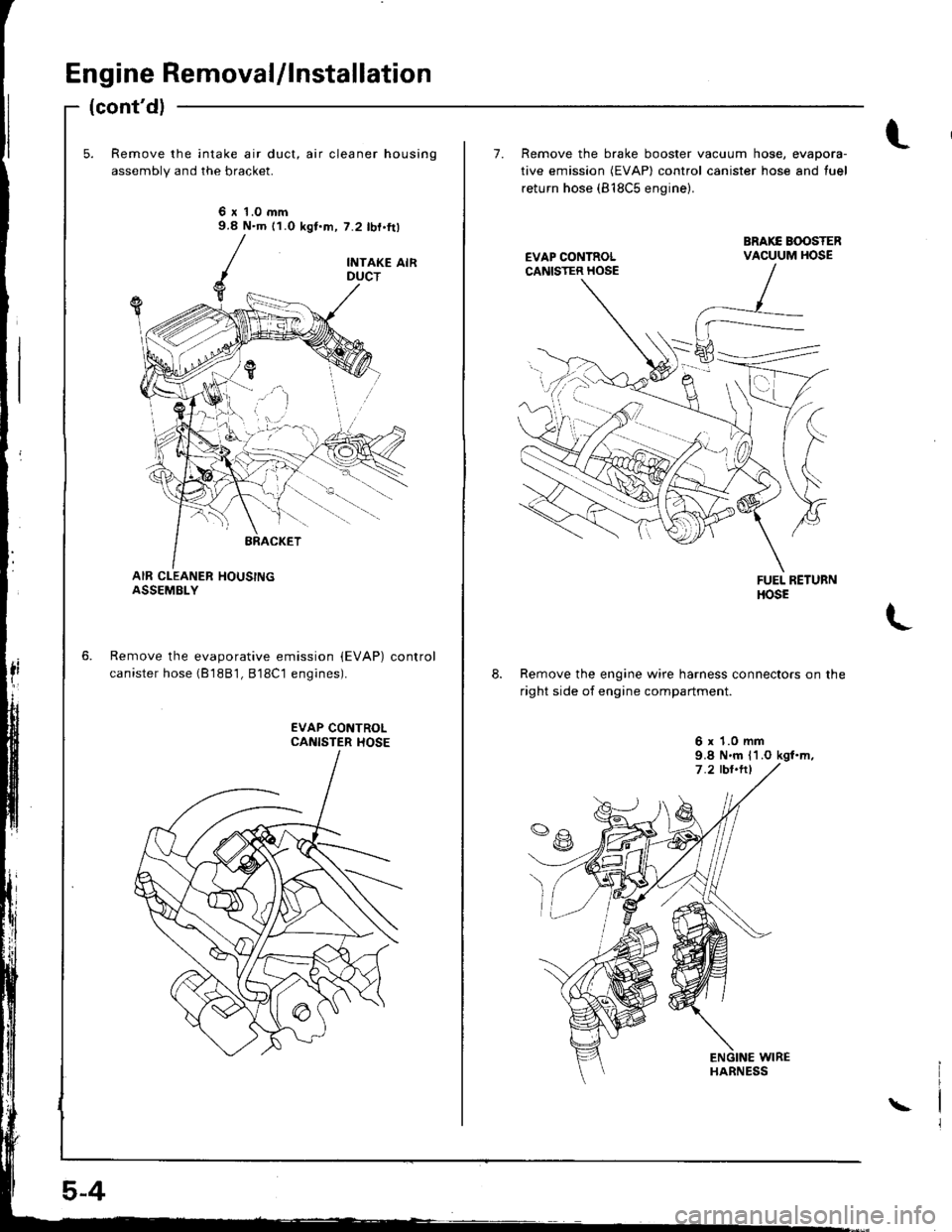

Remove the intake air duct, air cleaner housing

assembly and the bracket.

6 r 't.0 mm9.8 N.m (1.0 kgt.m, 7.2 lbf.ft)

Remove the evaporative emission {EVAP)

canister hose (B 18B1, B'18C1 eng;nes).

control

5-4

\

7. Remove the brake booster vacuum hose, evapora-

tive emission (EVAP) control canister hose and tuel

return hose (818C5 engine).

Remove the engine wire harness connectors on the

right side of engine compartment.

6 x 1.0 mm9.8 N.m l1.O kgl.m,

Page 64 of 1680

r.lJ

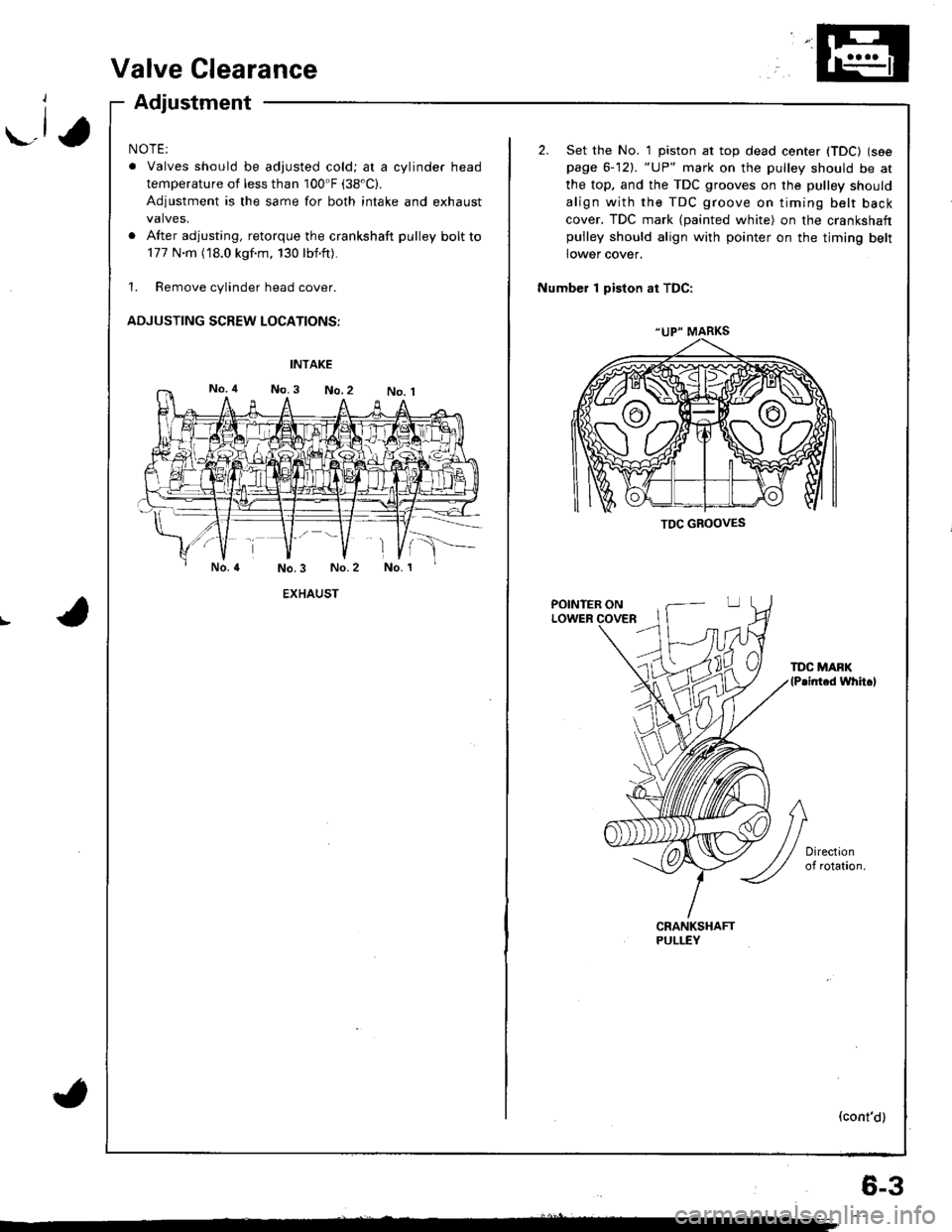

Valve Clearance

Adjustment

NOTE:

. Valves should be adjusted cold; at a cylinder head

temperature of less than 100'F (38"C).

Adjustment is the same for both intake and exhaust

valves.

. After adjusting, retorque the crankshaft pulley bolt to

177 N.m (18.0 kgf.m, 130 lbf'ft).

1. Remove cylinder head cover.

ADJUSTING SCREW LOCATIONS:

EXHAUST

(

"UP" MARKS

TDC GBOOVES

2. Set the No. 1 piston at top dead center (TDC) (see

page 6-12). "UP" mark on the pulley should be at

the top, and the TDC grooves on the pulley should

align with the TDC groove on timing belt back

cover. TDC mark (painted white) on the crankshaftpulley should align with pointer on the timing belt

lower cover.

Number 1 piston at TDC:

POINTER ONLOWER

TDC MAFK(P.inted whh.l

(cont'd)

6-3

Page 65 of 1680

Valve Clearance

Adjustment (cont'dl

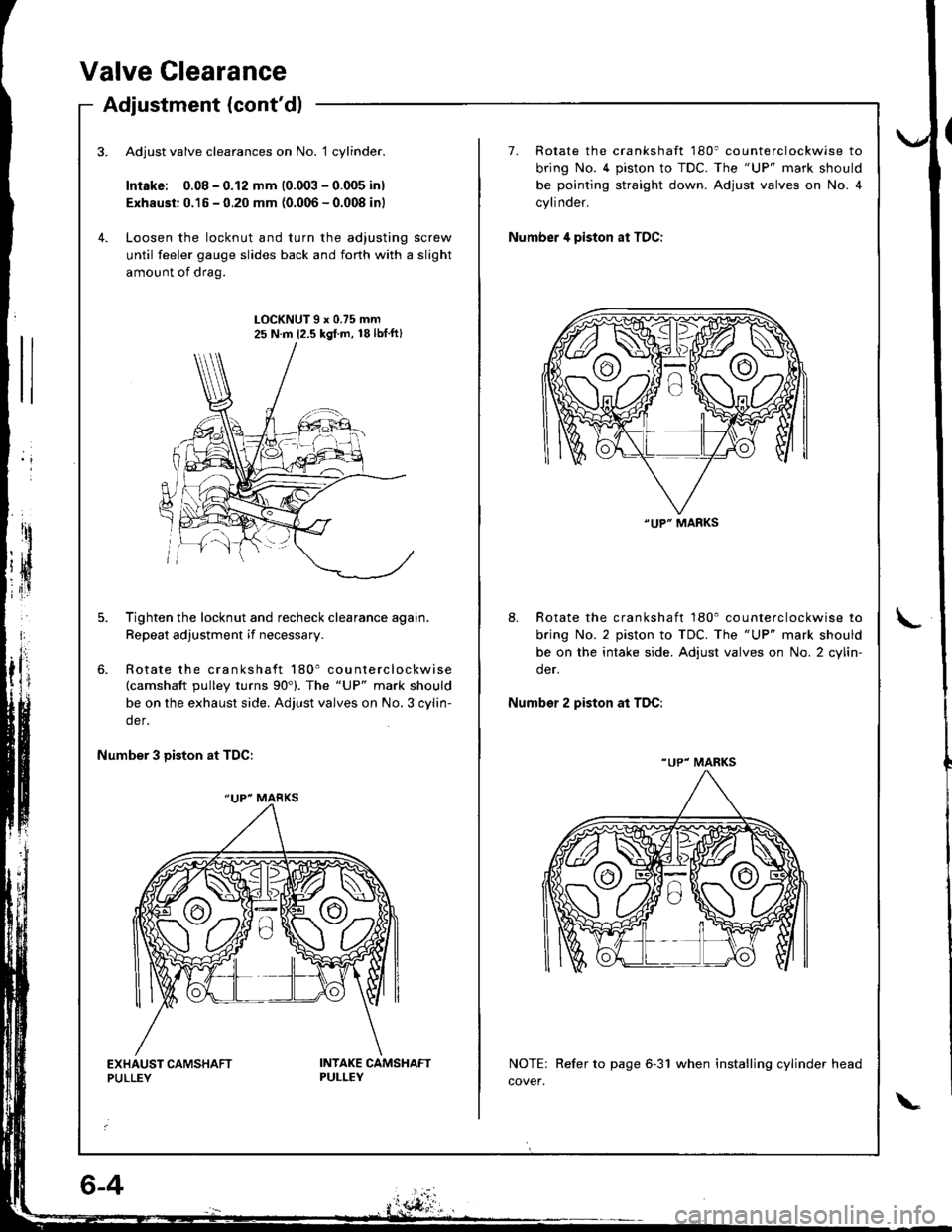

Adjust valve clearances on No. 1 cylinder.

Intske: 0.08 - 0.12 mm (0.003 - 0.005 inl

Exhaust: 0.15 - 0.20 mm (0.006 - 0.008 inl

Loosen the locknut and turn the adjusting screw

until feeler gauge slides back and forth with a slight

amount of drag.

7. Rotate the crankshaft 180' counterclockwise to

bring No. 4 piston to TDC. The "UP" mark should

be pointing straight down. Adjust valves on No. 4

cylinder.

Number 4 piston at TDC:

LOCKNUT9x0.75mm25 N.m {2.5 kgl.m, 18lbtft}

Tighten the locknut and recheck clearance again,

Repeat adjustment if necessary.

Rotate the crankshaft 180' counterclockwise(camshaft pulley turns 90'). The "UP" mark should

be on the exhaust side. Adjust valves on No,3 cylin-

der.

8. Rotate the crankshaft 180' counterclockwise to

bring No. 2 piston to TDC. The "UP" mark should

be on the intake side. Adjust valves on No. 2 cylin-

der.

Number 2 piston at TDC:

Number 3 Diston at TDC:

NOTE: Refer to page 6-31 when installing cylinder head

cover.

"UP" MARKS

"UP" MARKS

"UP" MARKS

Page 66 of 1680

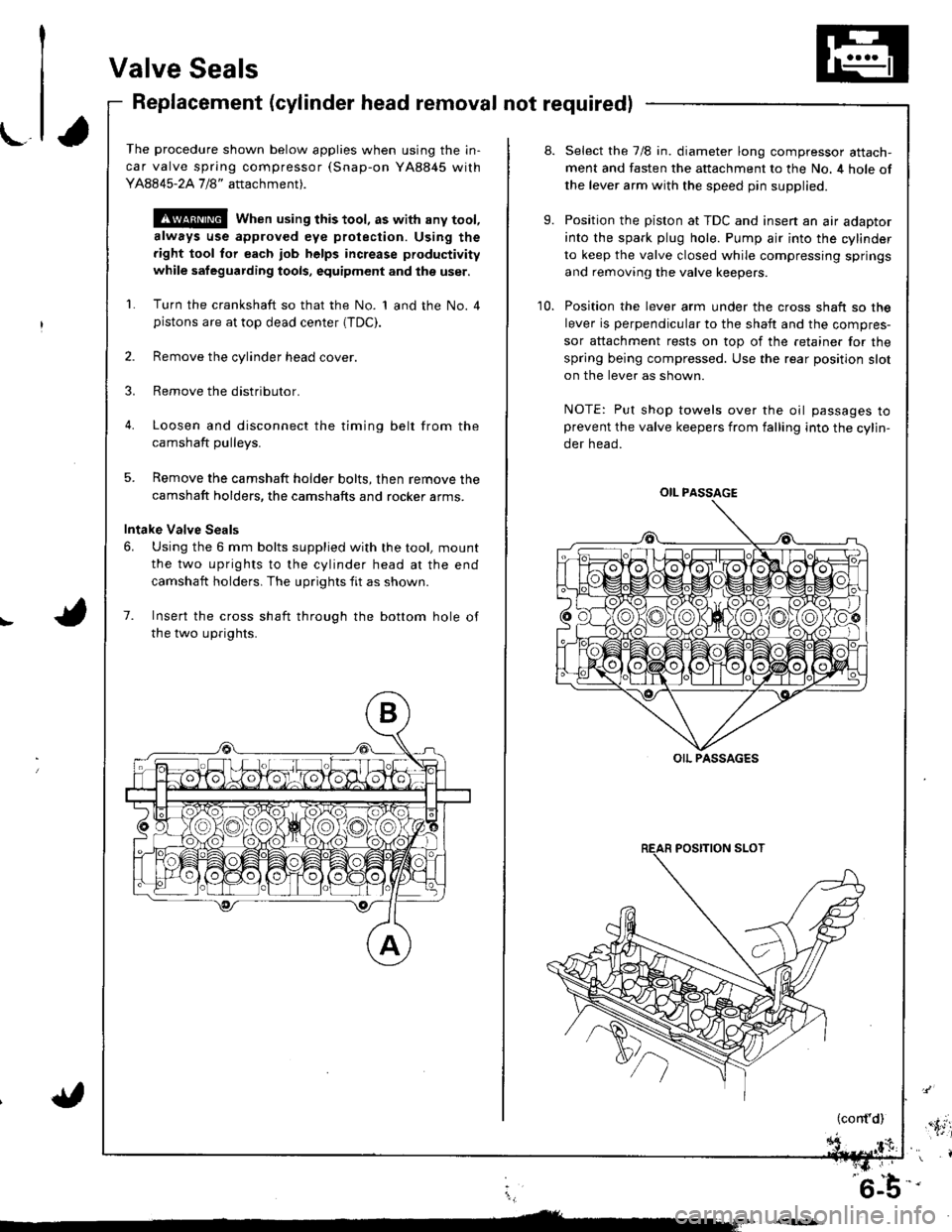

Valve Seals

Replacement (cylinder head removal not required)

The procedure shown below applies when using the in-

car valve spring compressor (Snap-on YA8845 with

Y AAA45-2A 1 /8" attachment).

!@@ When using this tool, as with any tool,

always use approved eye protection. Using the

fight tool tor each job helps increase productivity

while safeguarding tools, equipment and ihe user.

Turn the crankshaft so that the No. 1 and the No. 4pistons are at top dead center (TDC).

Remove the cylinder head cover.

Remove the distributor.

Loosen and disconnect the timinq belt from the

camshaft oullevs.

5. Remove the camshaft holder bolts, then remove the

camshaft holders, the camshafts and rocker arms.

Intake Valve Seals

6. Using the 6 mm bolts supplied with the tool, mount

the two uprights to the cylinder head at the end

camshaft holders. The uprights fit as shown.

7. Insert the cross shaft through the bottom hole of

the two uprights.

8.

9.

10.

Select the 7/8 in. diameter long compressor attach-

ment and fasten the attachment to the No. 4 hole of

the lever arm with the speed pin supplied.

Position the piston at TDC and insen an air adaptor

into the spark plug hole. Pump air into the cylinder

to keep the valve closed while compressing springs

and removing the valve keepers.

Position the lever arm under the cross shaft so the

lever is perpendicular to the shaft and the compres-

sor attachment rests on top of the retainer for the

spring being compressed. Use the rear position slot

on the lever as shown.

NOTE: Put shop towels over the oil passages toprevent the valve keepers from falling into the cylin-

der head.

OIL PASSAGE

OIL PASSAGES

(cont'd),'.itil

i,

'6-b-'

Page 77 of 1680

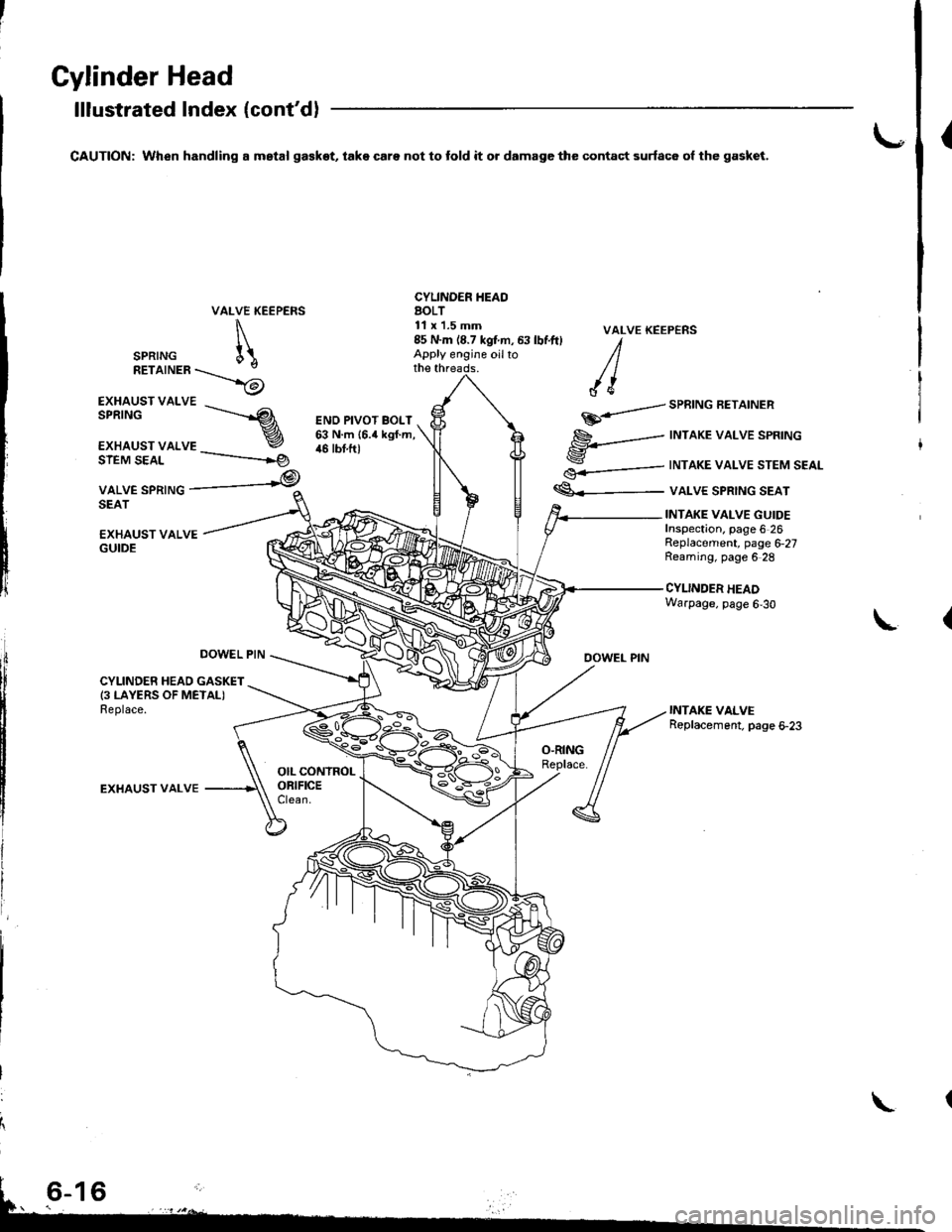

Gylinder Head

lllustrated Index (cont'd)

CAUTION: When handling a mstal ga€kot, take care not to fold it o. damage the contact surfac6 ol the gasket.{

VALVE KEEPERS

\

SPRTNG [\RETaTNER\_>6

CYLINDER IIEAOAOLT11 x'1.5 mm

EXHAUST VALVE

EXHAUST VALSPRINGs------.--

r

€.-=---

€<_-

VALVE KEEP€NS

DOWEL PIN

SPRING AEIAINER

INTAKE VALVE SPRING

INTAKE VALVE STEM SEAL

VALVE SPRING SEAT

ENO PIVOT BOLT63 N.m {6.4 kgf.m,46 tbt.ftlSIEM SEAL

VALVE SPRINGSEAT

-----------rg

,@

EXHAUST VALVEGUIDE

INTAKE VALVE GUIDEInspection. page 6 26Replacement, page 6,27Reaming, page 6 28

CYLINDER HEADWarpage, page 6,30

L

DOWEL PIN

CYLINDER HEAD GASKET(3 LAYERS OF METALIReplace.

EXHAUST VALVE

85 N.m (8.7 kgtm, 63 lbf.ft) IApply engine oilto /lthe threads. / |

/ {e

\

Page 79 of 1680

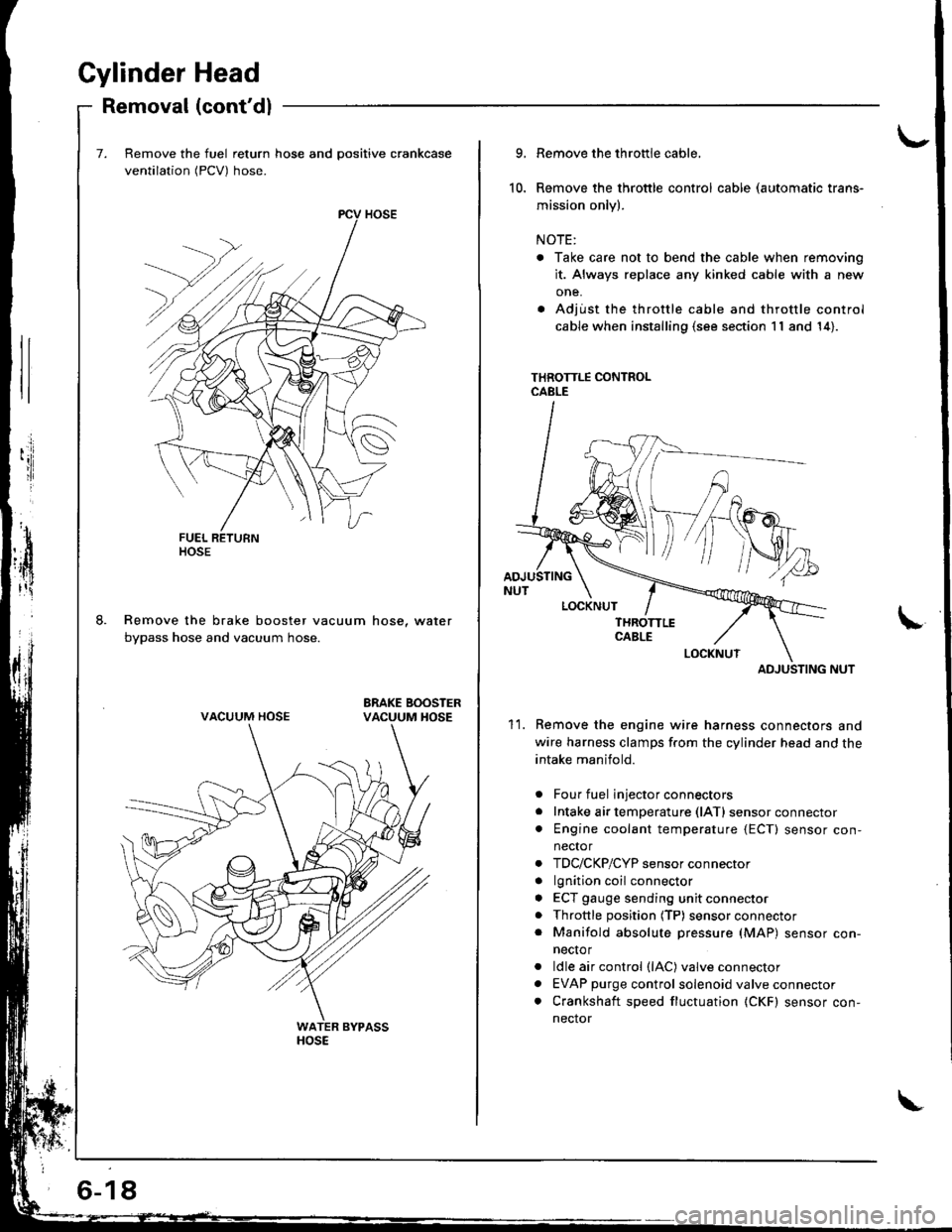

Gylinder Head

Removal (cont'dl

Remove the fuel return hose and positive crankcase

ventilation (PCV) hose.

Remove the brake booster vacuum hose, water

bypass hose and vacuum hose.

ltosE

VACUUM HOSE

6-18

10.

9.

11.

Remove the throttle cable,

Remove the throttle control cable (automatic trans-

mission only).

NOTE:

. Take care not to bend the cable when removing

it. Always replace any kinked cable with a new

one.

. Adjust the throttle cable and throttle control

cable when installing (s€e section 11 and 14).

THROTTLE CONTROLCABLE

ADJUSTING NUT

Remove the engine wire harness connectors and

wire harness clamps f.om the cylinder head and the

intake manifold.

Four fuel injector connectors

Intake air temperature (lATl sensor connector

Engine coolant temperature {ECT) sensor con,

nector

TDC/CKP/CYP sensor connector

lgnition coil connector

ECT gauge sending unit connector

Throttle position (TP) sensor connector

Manifold absolute pressure (MAP) sensor con-

necto r

ldle air control (lAC) valve connector

EVAP purge control solenoid valve connector

Crankshaft speed fluctuation (CKF) sensor con-

nector

a

a

a

a

a

a

a

a

ADJUSTING

Page 86 of 1680

\-

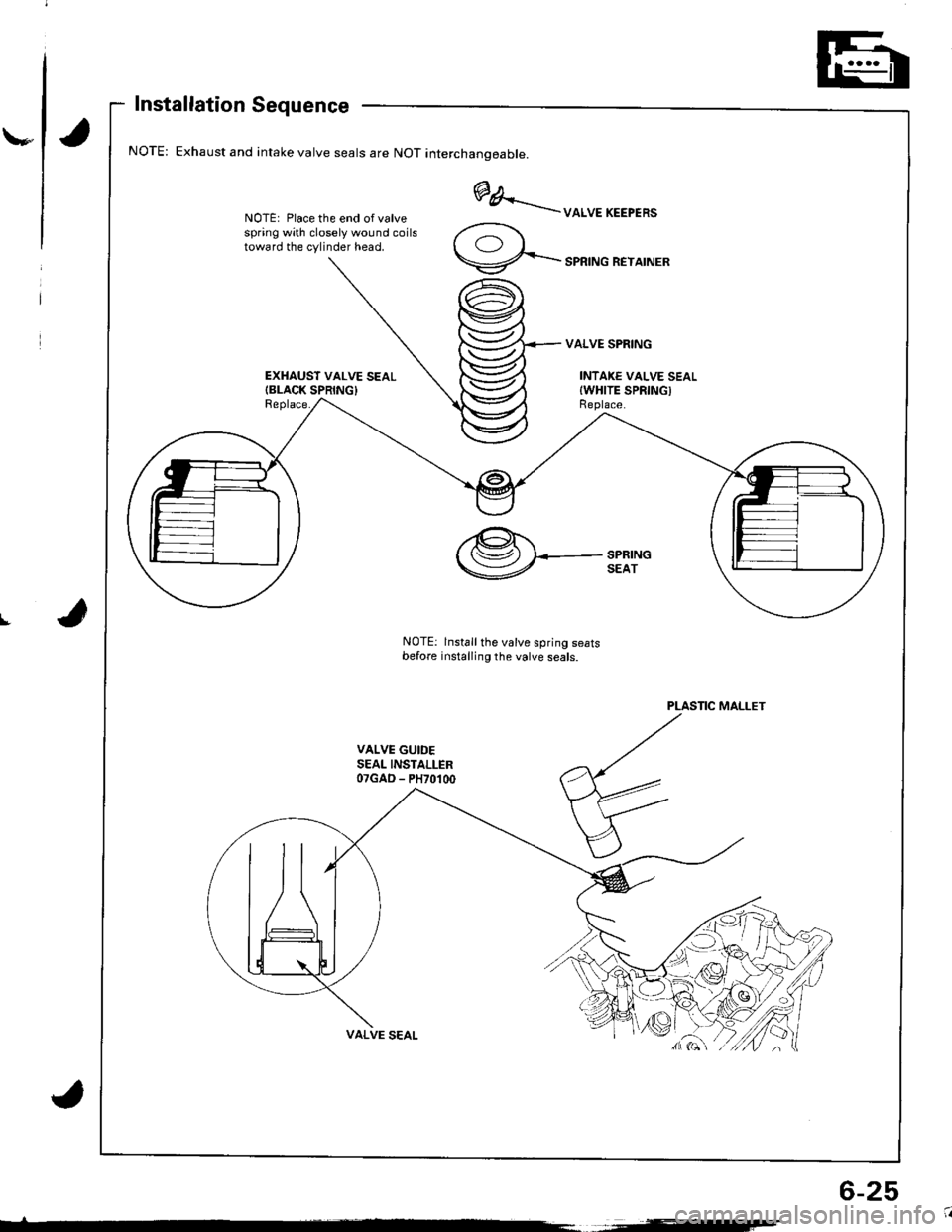

Installation Sequence

Exhaust and intake valve seals are NOT interchanoeable.

NOTE: Place the end of valvespring with closely wound coilstoward the cylinder head.

EXHAUST VALVE SEALIBLACK SPRING}Replace.

@A..'..--uoruEKEEPER'

9-...-'PRTNGREYATNER

VALVE SPRING

INTAKE VALVE SEALIWHITE SPRINGIReplace.

I

PLASTIC MALLET

VALVE GUIDESEAL INSTALLER07GAD - PH70100

,@.t.'( (Sz) I<-- SPRING

V SEAT

NOTE: lnstall the valve spring seatsbefore installing the valve seals.

6-25

Page 90 of 1680

\

Valve Seats

Reconditioning

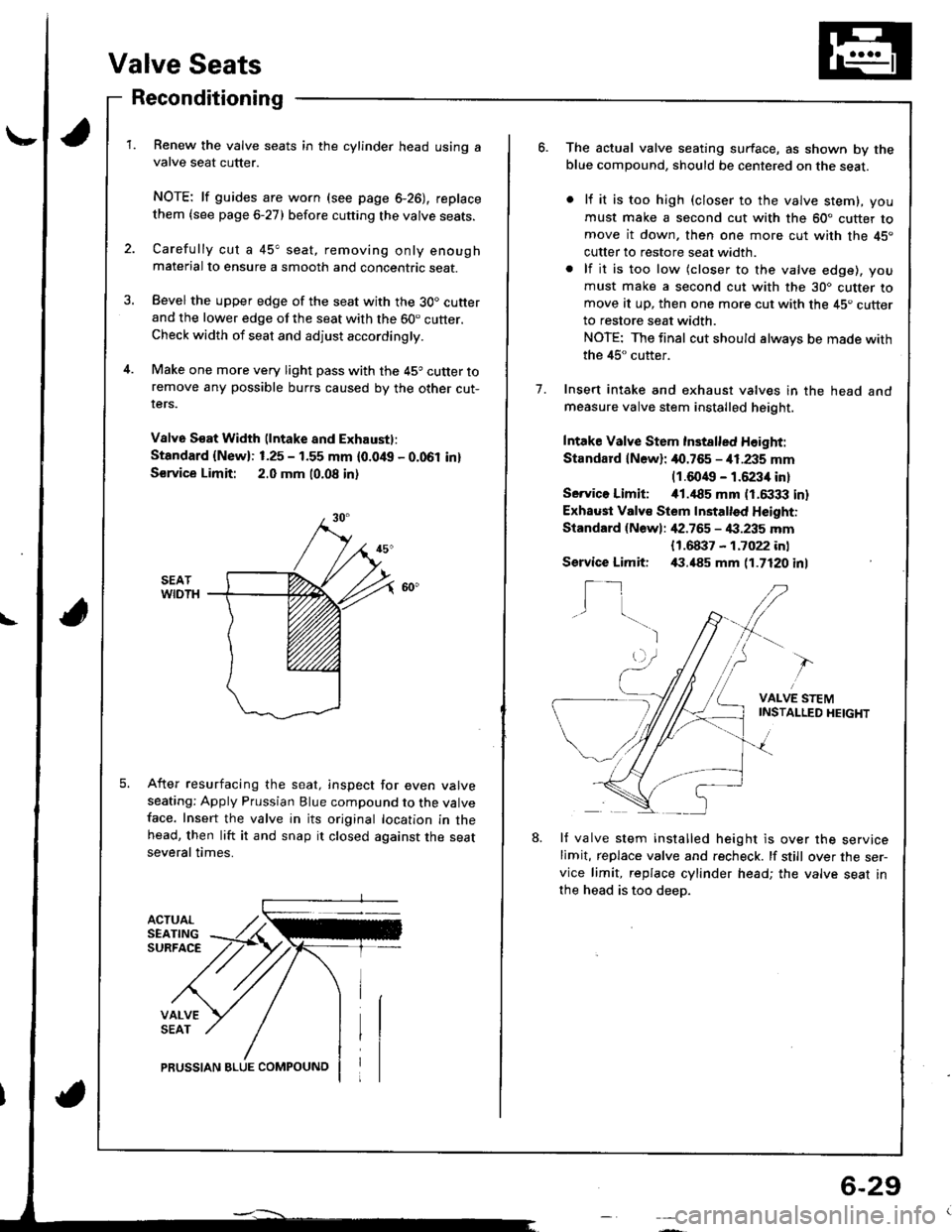

ACTUALSEATINGSURFACE

VALVESEAT

Renew the valve seats in the cylinder head using avalve seat cutter.

NOTE: lf guides are worn (see page 6-26), replace

them {see page 6-27) before cutting the valve seats.

Carefully cut a 45" seat, removing only enoughmaterial to ensure a smooth and concentric seat.

Bevel the upper edge of the seat with the 30. cutterand the lower edge of the seat with the 60. cutter.Check width of seat and adjust accordingly.

Make one more very light pass with the 45o cutter toremove any possible burrs caused by the other cut-rers.

V8lv6 S€at Width (lntake and Exhaustl:

Standard {New}: 1.25 - 1.55 mm {0.0/t{, - 0.061 in}

S€rvice Limit: 2.0 mm 10.08 in)

After resurfacing the seat, inspect for even valveseating: Apply Prussian Blue compound to the valveface. Insert the valve in its original location in thehead, then lift it and snap it closed against the seatseveral times.

PRUSSIAN BLUE COMPOUNO

6-29

o.The actual valve seating surface, as shown by theblue compound, should be centered on the seat.

lf it is too high (closer to the valve stem), you

must make a second cut with the 60" cutter tomove it down, then one more cut with the 45"

cutter to restore seat width.

lf it is too low (closer to the valve edge), you

must make a second cut with the 30. cutter tomove at up, then one more cut with the 45. cutterto restore seat width.

NOTE: The final cut should always be made with

the 45" cutter.

Insert intake and exhaust valves in the head andmeasure valve stem installed height.

Intake Valve Stem Inst8lled Height:

Standard lN6wl: 40.765 - i11.235 mm(1.6049 - 1.6234 in)

Servico Limiti i01.,|85 mm (1.6333 in)

Exhaust Valv€ Stem Installed Height:

Standard {Newl: ,[2.765 - 4:1.235 mm

1.

{1.68i}7 - 1.7022 inl,(1.485 mm 11.7120 inlService Limit:

I_1I

VALVE STEMINSTAI-LED HEIGHT

8.lf valve stem installed height is over the servicelimit, replace valve and recheck. lf still over the ser-vice limit, replace cylinder head; the valve seat in

the head is too deep.

Page 92 of 1680

\-

L

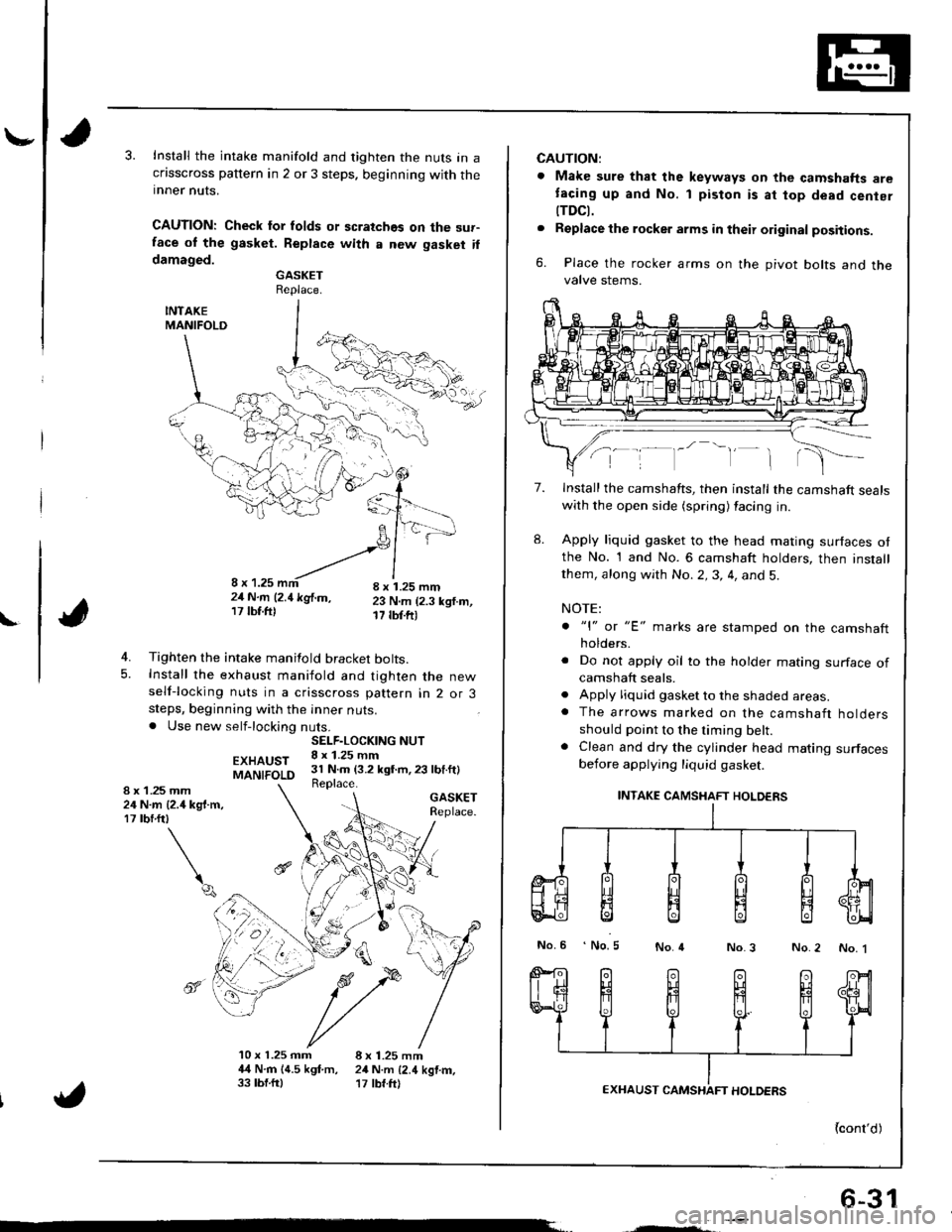

Install the intake manifold and tighten the nuts in acflsscross pattern in 2 or 3 steps. beginning with theinner nuts.

CAUTION: Check lor folds or scratches on the sur-face ol the gasket. Replace with a new gasket ildamaged.GASKETReplace.

INTAKEMANIFOLD

4. Tighten the intake manifold bracket bolts.5. Install the exhaust maniiold and tighten the newself-locking nuts in a crisscross pattern in 2 or 3steps, beginning with the inner nuts.. Use new self-locking nuts.

EXHAUSTMANIFOLD

GASKETReplace.

4

10 x 1.25 mm 8 x 1.25 mm4,{ N.rn 14.5 kgf.m, 24 N.m {2.4 kgtm,33 tbf.ftl '17 tbf.ft)

SELF.LOCKING NUT8 x 1.25 mm31 N.m (3.2 kgt m,23 lbf.ft)Replace.1 .25 mmN.m {2.4 kg{.m,rbrftt

\q

8x2417

",', r, ^-'-"-!,1,,,';-21N.m l2.1kglm, 23 N.m (2.3 ksf.m,17lbf.ftl 17 tbf.ftr

6-31

CAUTION:

. Make sure that the keyways on the camshafts aretacing up and No. 1 piston is at top dead cenier

tTDCt.. Replacethe rocker arms in their original positions.

6. Place the rocker arms on the pivot bolts and thevalve stems.

7.

8.

Install the camshafts, then install the camshaft sealswith the open side (spring) facing in.

Apply liquid gasket to the head mating surfaces otthe No. 1 and No. 6 camshaft holders, then installthem, along with No.2,3, 4, and 5.

NOTE:

. "l" or "E' marks are stamped on the camshaftholders.

. Do not apply oil to the holder mating surface ofcamshaft seals.. Apply liquid gasket to the shaded areas.. The arrows marked on the camshaft holdersshould point to the timing belt.. Clean and dry the cylinder head mating surfacesbefore applying liquid gasket.

INTAKE CAMSHAFT HOLDERS

No.6 No.5No.4No.3 No.2 No. 1

{cont'd)