rear ACURA INTEGRA 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1998, Model line: INTEGRA, Model: ACURA INTEGRA 1998Pages: 1680, PDF Size: 53.14 MB

Page 35 of 1680

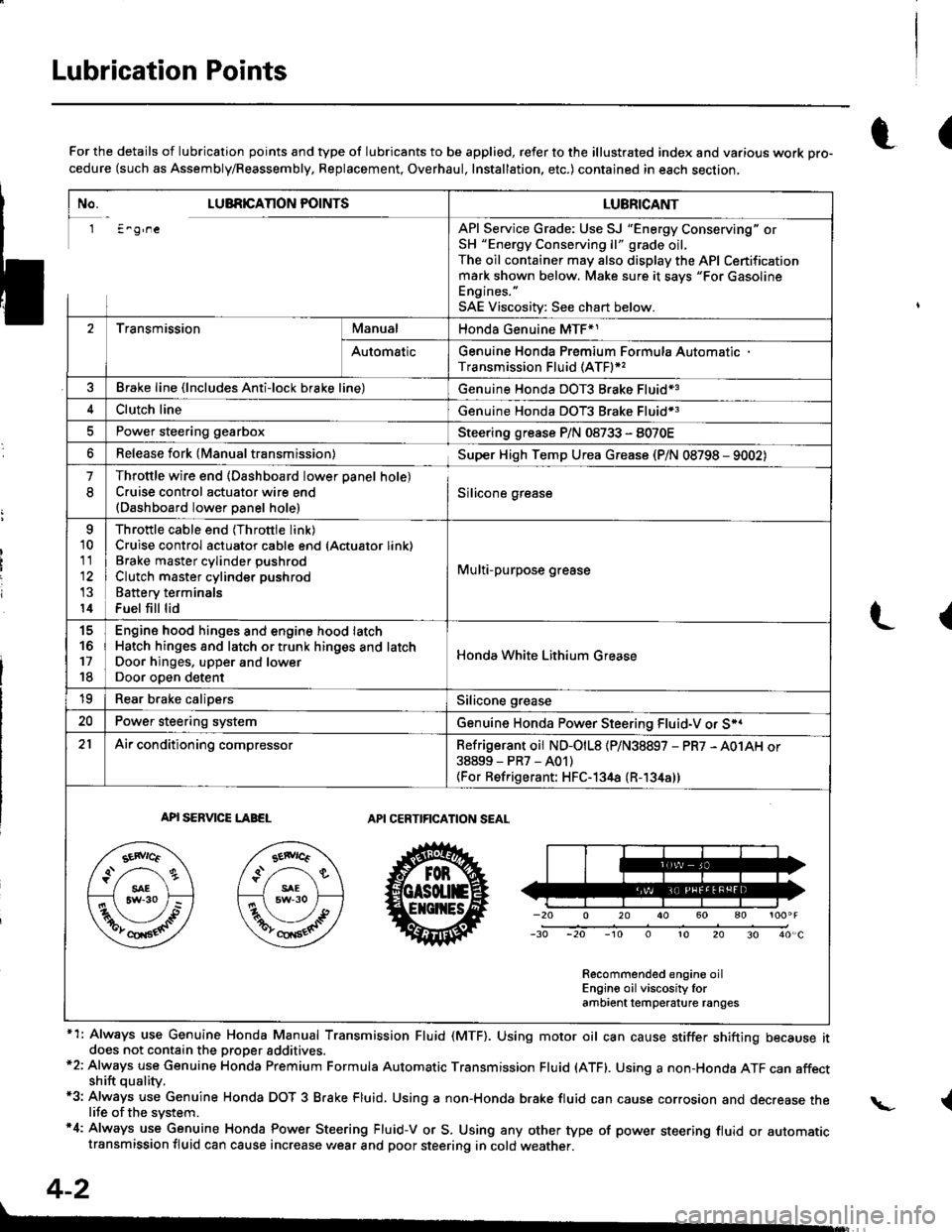

Lubrication Points

No. LUBRICAnON POINTSLUBRICANT

1 E^g,neAPI Service Grade: Use SJ "Energy Conserving" orSH "Energy Conserving ll" grade oil,The oil container may also display the API Certificationmark shown below. Make sure it savs "For GasolineEngines. "

SAE Viscositv: See chart below.

2TransmissionManualHonda Genuine MTF*1

AutomaticGenuine Honda Premium Formula AutomaticTransmission Fluid (ATF)*,

Brake line (lncludes Anti-lock brake line)Genuine Honda DOT3 Brake Fluid13

Clutch lineGenuine Honda DOT3 Brake Fluid*3

Power steering gearboxSteering grease P/N 08733 - 8070E

Release fork lManual transmission)Sup€r High Temp Urea Grease (P/N 08798 - 9002)

1

8

Throttle wire end (Dashboard lower oanel hole)Cruise control actuator wire end(Dashboard lower Danel hole)Silicone grease

o

10

11

14

Throttle cable end (Throttle link)Cruise control actuator cable end (Actuator link)Brake master cvlinder oushrodClutch master cylinder pushrod

Battery terminals

Fuel fill lid

Multi-purpose grease

to

17

18

Engin6 hood hinges and engine hood latchHatch hinges 8od latch or trunk hinges and latchDoor hjnges, upper and lowerDoor ooen detent

Honda White Lithium Grease

19Rear b.ake calipersSilicone grease

20Power steering systemGenuine Honda Power Steering Fluid-V or S*.

21Ai|' conditioning compressorRefrigerant oii ND-O|L8 {P/N38897 - PR7 - A01AH or38899-PR7-A01)(For Refrigerant: HFC-134a (R- 134a))

API SERVICE LABELAPI CERTIFICATION SEAL

Recommended engine oilEngin€ oil viscosity lorambrent lemperature ranges

r(For the details of lubrication points and type of lubricants to be applied, refer to the illustrated index and various work Dro-cedure (such as Assembly/Reassembly, Replacement, Overhaul, Installation. etc.) contained in each section,

*1: Always use Genuine Honda Manual Transmission Fluid (MTF). Using motor oil can cause stiffer shifting because itdoes not contain the proper addtuves.*2: Always use Genuine Honda Premium Formula Automatic Transmission Fluid (ATF). Using a non-Honda ATF can affectshift quality.*3: Always use Genuine Honda DOT 3 B.ake Fluid, Using a non-Honda brake fluid can cause corrosion and decrease thelife of the system.'4: Always use Genuine Honda Power Steering Fluid-V or S. Using any other type of power steering fluid or automatictransmission fluid can cause increase v,/ear and poor steering in cold weather.

L(

{

4-2

Page 61 of 1680

I

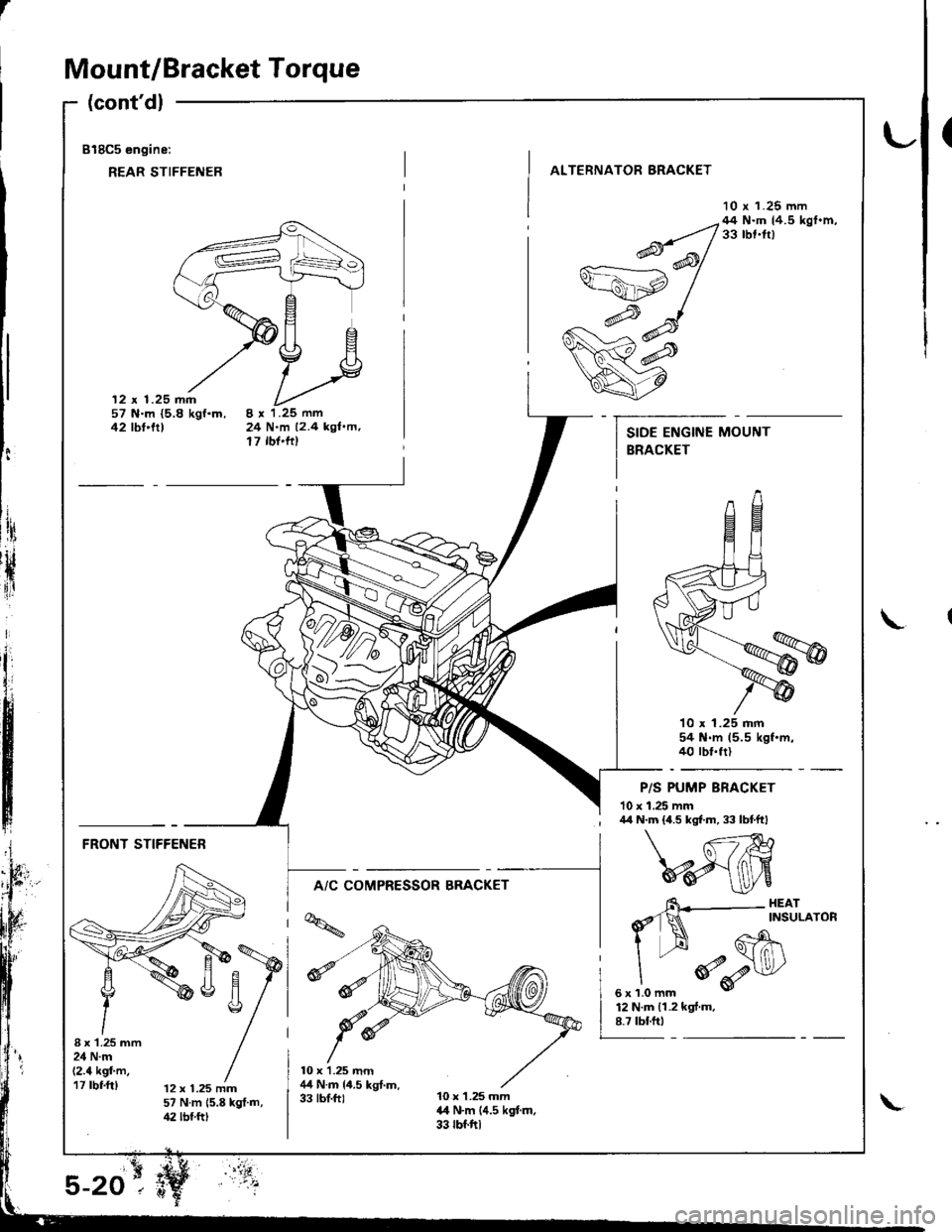

Mount/Bracket Torque

(cont'dl

818C5 engine:

REAR STIFFENER

(

ALTERNATOR BRACKET

10 r 1.25 mm

12 x 1.25 mm57 N.m {5.8 kgf.m,42 tbt'trt24 N.m 12.4 kgl.m,17 rbf'ftt

--q;;/44N'mtr.5kst'm'v=ahp /

w#

q7

10 x 1.25 mm54 N.m 15.5 kgf.m.40 rbt.frl

P/S PUMP BRACKET

10 x 1.25 mm

t:

ltri

rH

{ir

I\

; /r/r N.m {4.5 kgf.m, 33 lbtftl

FRONT STIFFENER

A/C COMPRESSOR BRACKET

I x'1.25 mm24 N.m(2.4 kgf'm,17 rbf.ft)12 x 1.25 mm57 N.m 15.8 kgt.m,42 lbf.ftt

6\--- HEAr

d'1N ^rNsuLAroR

I --H Gh\

"

*o-r$l/

sxrlomm v

12 N.m 11.2 kgf.m.8.7 tbf.ftt

Page 66 of 1680

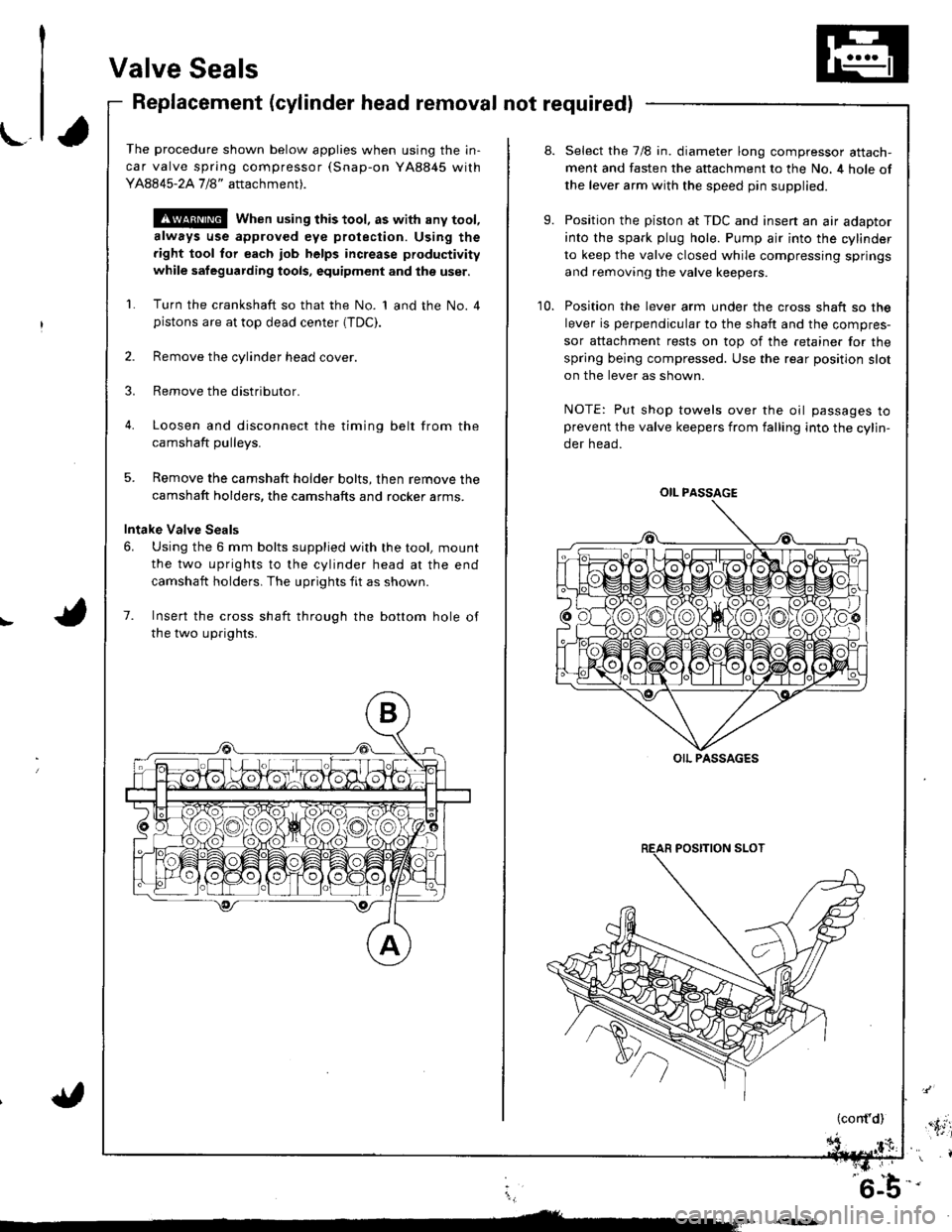

Valve Seals

Replacement (cylinder head removal not required)

The procedure shown below applies when using the in-

car valve spring compressor (Snap-on YA8845 with

Y AAA45-2A 1 /8" attachment).

!@@ When using this tool, as with any tool,

always use approved eye protection. Using the

fight tool tor each job helps increase productivity

while safeguarding tools, equipment and ihe user.

Turn the crankshaft so that the No. 1 and the No. 4pistons are at top dead center (TDC).

Remove the cylinder head cover.

Remove the distributor.

Loosen and disconnect the timinq belt from the

camshaft oullevs.

5. Remove the camshaft holder bolts, then remove the

camshaft holders, the camshafts and rocker arms.

Intake Valve Seals

6. Using the 6 mm bolts supplied with the tool, mount

the two uprights to the cylinder head at the end

camshaft holders. The uprights fit as shown.

7. Insert the cross shaft through the bottom hole of

the two uprights.

8.

9.

10.

Select the 7/8 in. diameter long compressor attach-

ment and fasten the attachment to the No. 4 hole of

the lever arm with the speed pin supplied.

Position the piston at TDC and insen an air adaptor

into the spark plug hole. Pump air into the cylinder

to keep the valve closed while compressing springs

and removing the valve keepers.

Position the lever arm under the cross shaft so the

lever is perpendicular to the shaft and the compres-

sor attachment rests on top of the retainer for the

spring being compressed. Use the rear position slot

on the lever as shown.

NOTE: Put shop towels over the oil passages toprevent the valve keepers from falling into the cylin-

der head.

OIL PASSAGE

OIL PASSAGES

(cont'd),'.itil

i,

'6-b-'

Page 165 of 1680

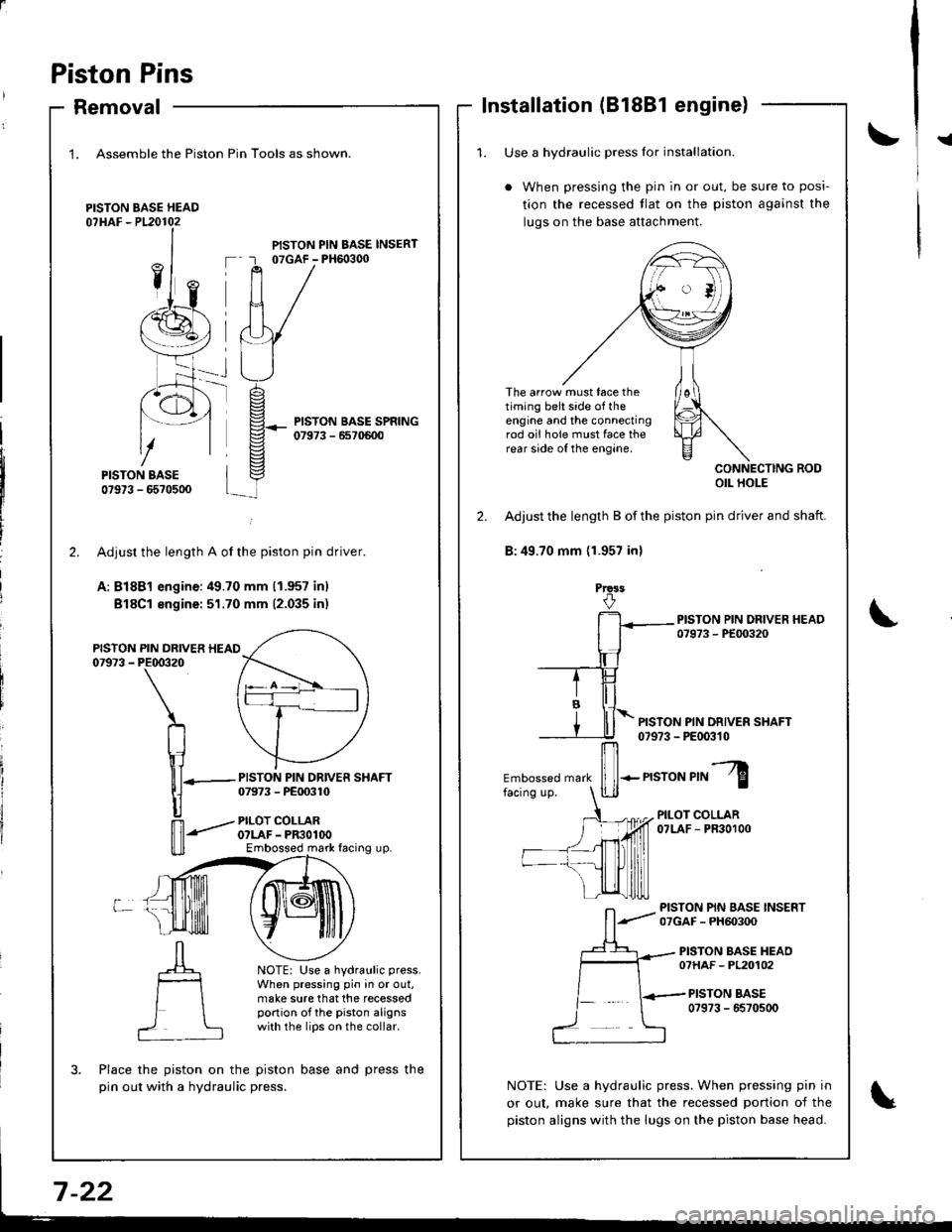

Piston Pins

Removal

1. Assemble the Piston

PISTON BASE HEAD07HAF - P120102

Pin Tools as shown.

PISTON PIN BASE INSERT07GAF - PH6o3q)

PISTON BASE SPRING07973 - 6570600

-rt_

2.

PISTON07973 -

L

PISTON PIN DRIVER SHAFT07973 - PE00310

PILOT COLLARO?LAF - PR3OlOOEmbossed mark facing up.

NOTE: Use a hydraulic press.

When pressing pin in or out,make sure that the recessedportion of the piston alignswith the lips on the collar.

?

Adjusr the length A of the piston pin driver.

A: Bl8Bl engine:49.70 mm (1.957 inl

Bl8Cl engine: 51.70 mm (2.035 inr

PIN DRIVER HEAIPE00320

\

n

\1lll-

|]

n'-"'

Place the piston on the piston base and press the

pin out with a hydraulic press.

Installation (81881 engine)

!{1. Use a hvdraulic Dress lor installation.

When pressing the pin in or out, be sure to posi-

tion the recessed tlat on the piston against the

luqs on the base attachment.

The arrow must face thetiming belt side of theengine and the connectingrod oii hole must face therear side of the engine.

CONNECTING RODOIL HOLE

2. Adjust the length B of the piston pin driver and shaft.

B:49.70 mm (1.957 inl

Prca3

PISTON PIN DRIVER SHAFT07973 - PE00310

Embossed mark

ffi-n"ro"r,"l

PILOT COLLAR07LAF - PR30100

PISTON PIN BASE INSERT07GAF - PH60300

PISTON BASE HEAO07HAF - PL20102

PISTON BASE0?973 - 6570500

NOTE: Use a hydraulic press. When pressing pin in

or out, make sure that the recessed portion of the

piston aligns with the lugs on the piston base head.

Page 234 of 1680

![ACURA INTEGRA 1998 Service Repair Manual System Description

System Connectors [Dash and Floor] (contd]

c405SERVICECHECK

c410(ECM.DICilo9{ECM-C)tL

REAR WIREHARNESS

,n

, ?l

1 1-30

L ACURA INTEGRA 1998 Service Repair Manual System Description

System Connectors [Dash and Floor] (contd]

c405SERVICECHECK

c410(ECM.DICilo9{ECM-C)tL

REAR WIREHARNESS

,n

, ?l

1 1-30

L](/img/32/56983/w960_56983-233.png)

System Description

System Connectors [Dash and Floor] (cont'd]

c405SERVICECHECK

c410(ECM.DICilo9{ECM-C)tL

REAR WIREHARNESS

,n

, ?l

1 1-30

L

Page 289 of 1680

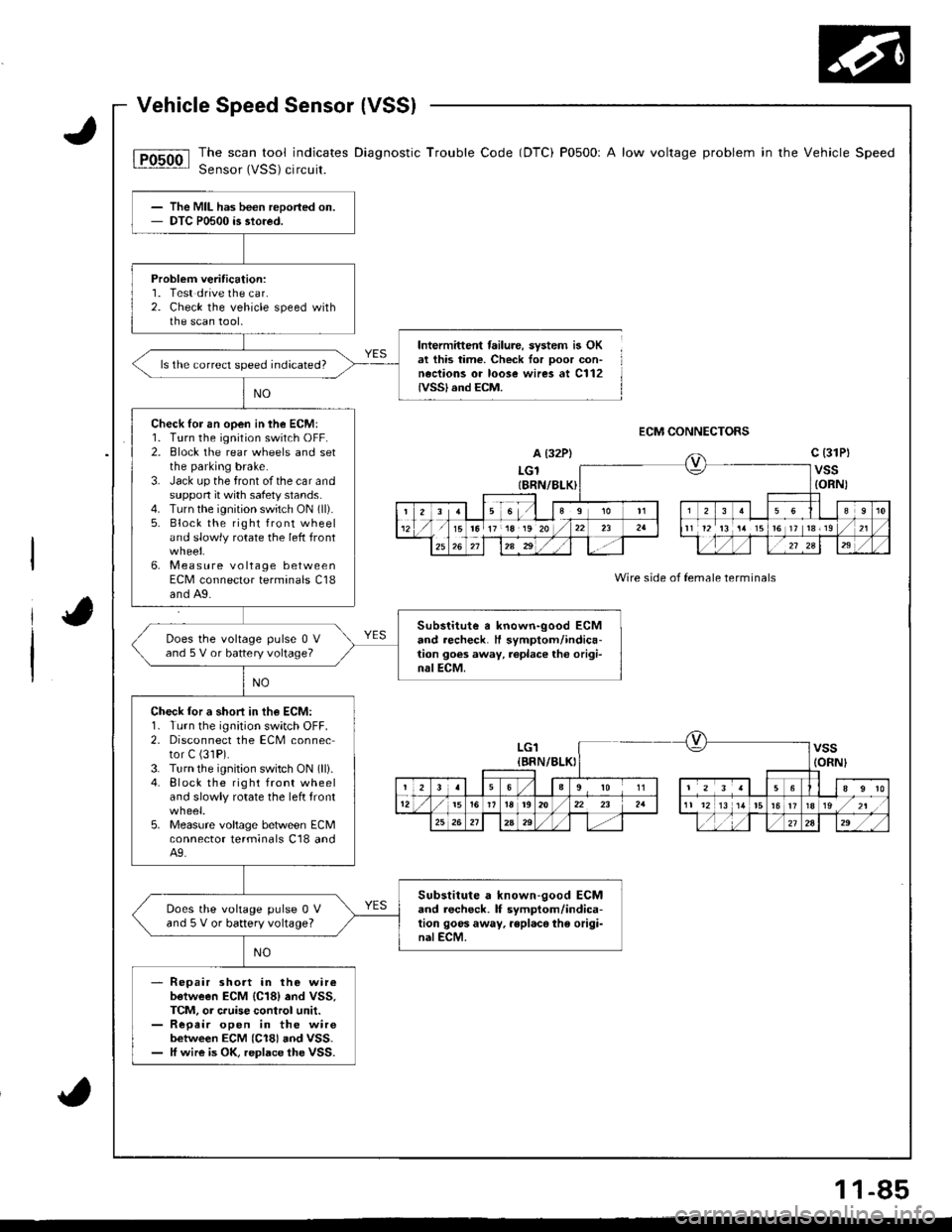

The scan tool indicates Diagnostic Trouble Code (DTC) P0500r A low voltage problem in the Vehicle Speed

Sensor (VSS) circuit.

Intermittent failure, system is OKat this time. Check for ooor con-neciions or loose wires at C112IVSSI and ECM.

ECM CONNECTORS

A (32P)

LGlIBRN/8LK)

c (31Pt

vss{ORN)

Wire side of female terminals

The MIL has been reported on.DTC P0500 is stored.

Probleft veritication:1. Test drive the car.2. Check the vehicle speed withthe scan tool,

ls the correct speed indicated?

Check lor an open in the ECM:1. Turn the ignition switch OFF.2. Block the rear wheels and setthe parking brake.3. Jack up the front of the car andsuppon it with safety stands.4. Turn the ignition switch ON (ll).

5. Block the right front wheeland slowly rotate the left front

6. Measure voltage betweenECM connector terminals C18and A9.

Substitute a known-good ECMand recheck. H symptom/indica-tion goes away, replace tho origi-nalECM.

Does the voltage pulse 0 Vand 5 V or battery voltage?

Check lor a shori in th€ ECM:1. Turn the ignition switch OFF.2. Disconnect the ECM connector C (31P).

3. Turn the ignition switch ON (lli.4. Block the right front wheeland slowly rotate the left front

5. Measure voltage between ECMconnector lerminals C18 andA9.

Substitute a known-good ECMand lecheck. lf symptom/indica-tion goos away. rsplaco the origi-nalECM.

Does the vohage pulse 0 Vand 5 V or battery voltage?

Repair short in the wireb€tween ECM {C18} end VSS,TCM, or cruise control unit.Repeir open in the wirebetween ECM (C18) aod VSS.ff wire is OK, replace the VSS.

ra 17 18 19 20t6 ]t 13r19

LG1{BRN/BLKIvss(ORNI

23563910 1156

12i5r92022 23 2a11 1213 1/tr6ts/zt

25262Aa9,/2724," ,/ ,,:

1 1-85

Page 302 of 1680

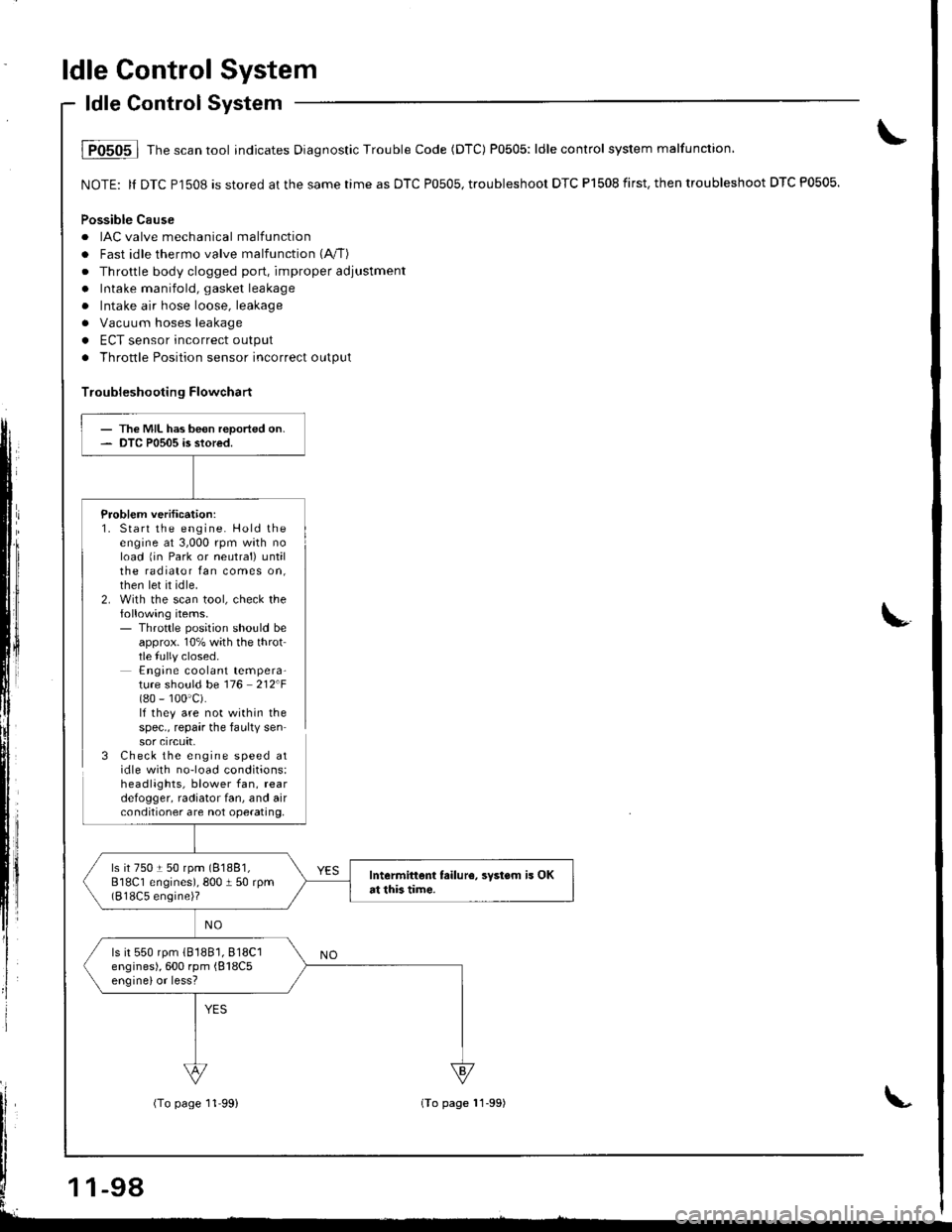

ldle Control System

ldle Control System

i P0505 | fne scan tool indicates Diagnostic Trouble Code (DTC) P0505: ldle control system malfunction,

NOTE: ll DTC Pl508 is stored at the same time as DTC P0505, troubleshoor DTC P1508 first. then troubleshoot DTC P0505.

Possible Cause

. IAC valve mechanical malfunctiorr

. Fast idle thermo valve malfunction (A"/T)

. Throttle body clogged port, improper adjustment

. Intake manifold, gasket leakage

. Intake air hose loose, leakage

a Vacuum hoses leakage

. ECT sensor incorrect output

. Throttle Position sensor incorrect output

Troubleshooting Flowchart

Problem verification:1. Start the engine. Hold theengine at 3,000 rpm wath noload 1in Park or neutral) untilthe radiator fan comes on,then let it idle.2. With the scan tool, check thefollowing items.- Throttle position should beapprox. 10% with the throttle fully closed.Engine coolant tempera-ture should be 116 212F(80 - 100'c).lf they are not within thespec., repair the faulty sensor crrcuft,3 Check the engine speed atidle with no-load conditions:headlights, blower fan, reardefogger, radiator fan, and airconditioner are not operating,

- The MIL has been reported on.- DTC P0505 is stored.

ls it 750 t 50 rpm (81881,

818C1 engines), 800 I 50 rpm(818C5 engine)?

Intermittent failur6, svstsm is OKat this tim€.

ls it 550 rpm (81881,818C1

engines), 600 rpm {818C5enginelor less?

-98

(To page 11'99)(To page 11-99)

Page 305 of 1680

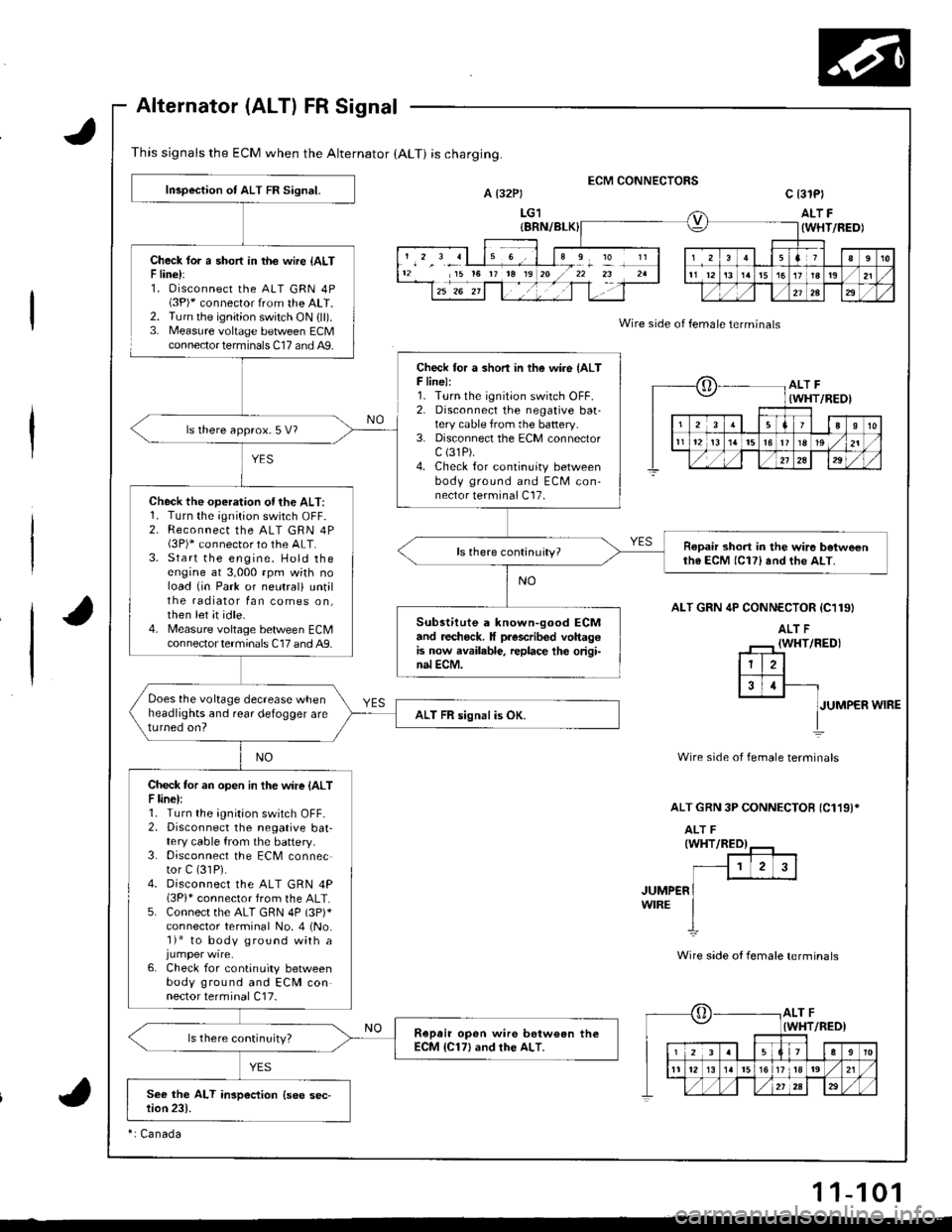

This signals the ECM when the Alternator (ALT) is charging.

Alternator (ALT) FR Signal

Check lor a short in th€ wire {ALTF line):1. Oisconnect the ALT GRN 4P(3P)* connector from the ALT.2. Turn the ignition switch ON {ll).3. Measure voltage between ECMconnector terminals C17 and A9.

ECM CONNECTORSA t32Pt

LG1

c 13lPl

ALT F(WHT/FEDI

Wire side of female terminals

ALT GRN 4P CONN€CTOR {C119}

JUMPER WIRE

Wire side of female terminals

ALT GRN 3P CONNECTOB {C119)*

JUMP€RWIRE

Wire side ot female terminals

12 15 t6 rr t8 19I

?

oALT F(WHT/REOI

23aI10

t112t3t5l6r819 ,/21

./,/,/2a29

[,ALT FIWHT/RED)

12339

11 12l517 tla19 ,/21

Inspection of ALT FR Signal.

Check for a shon in the wire {ALTF line):1. Turn the ignition switch OFF.2. Disconnecl the negative baatery cable from the battery.3. Disconnect the ECM connectorc (31P).

4. Check for continuity betweenbody ground and ECM con-nector terminal C17.

ls there approx.5 V?

Check the operation ofthe ALT:1. Turn the;Onition switch OFF-2. Reconnect the ALT GRN 4P(3P)* connector to the ALT.3. Start the engine. Hold theengine at 3,000 rpm wkh noload {in Park or neutral) untilthe radiator fan comes on,then let it idle.4. Measure voltage bet/veen ECMcon nector termina ls C17 and A9.

Ropair short in the wir6 betweenth6 ECM (C17) and the ALT.

Substitute a known-good ECMand recheck. It prescribed voltagGis now available, replace th€ origi-nal ECM.

Does the voltage decrease whenheadlights and rear defogger areturned on?ALT FR signal is OK.

Check tor an open in the wire {ALTF line):1. Turn the ignition switch OFF-2. Disconnect the negative bat-tery cable from the battery.3. Disconnect the ECM connector C (31P).

4. Disconnect the ALT GRN 4P(3Pi* connector from the ALT.5. Connect the ALT GRN 4P (3p)*

connector terminal No. 4 (No.'l)* to body ground with a

6. Check for continuity betweenbody ground and ECM connector terminal C17.

Ropair open wire bstw€an theECM {C17} and rhe ALT.ls there continuity?

ri Canada

11-101

Page 315 of 1680

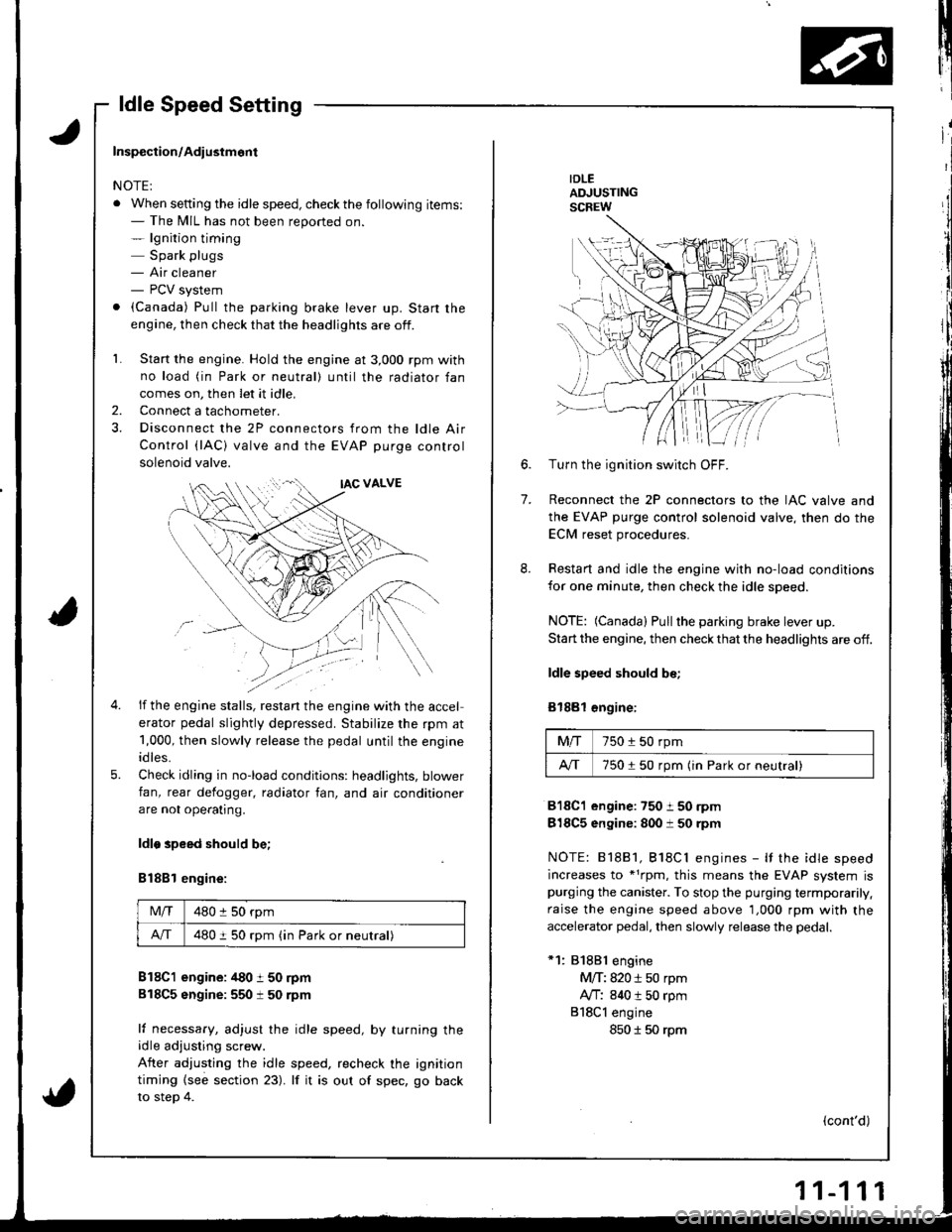

ldle Speed Setting

IDLEADJUSTINGSCREW

7.

6.Turn the ignition switch OFF.

Reconnect the 2P connectors to the IAC valve and

the EVAP purge control solenoid valve, then do the

ECM reset procedures.

Restart and idle the engine with no-load conditions

for one minute, then check the idle speed.

NOTE: (Canada) Pullthe parking brake lever up.

Start the engine, then check that the headlights are off.

ldle speed should be;

Bl88l €ngine:

Mfi750 i 50 rpm

A/T750150 rpm (in Park or neutral)

818C1 engine:750 i 50 rpm

818C5 engine: 800 i 50 rpm

NOTE: 81881, Bl8Cl engines - It the idle speed

increases to *1rpm, this means the EVAP system ispurging the canister. To stop the purging termporarily.

raise the engine speed above 1,000 rpm with the

accelerator pedal, then slowly release the pedal.

*1: 81881 engine

M/T: 820 i 50 rpm

Ay'T: 840 t 50 rpm

818Cl engine

850 I 50 rpm

(cont'd)

Inspection/Adiustmont

NOTE:

. When setting the idle speed, checkthe following items:- The MIL has not been reported on.- lgnition timing

Spark plugs- Air cleaner- PCV system

. (Canada) Pull the parking brake lever up. Start the

engine, then check that the headlights are off.

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle,

Connect a tachometer.

Disconnect the 2P connectors from the ldle Air

Control (lAC) valve and the EVAP purge control

solenoid valve.

2.

5.

if the engine stalls, restan the engine with the accel

erator pedal slightly depressed. Stabilize the rpm at

1,000, then slowly release the pedal until the engine

idles.

Check idling in no-load conditions: headlights, blower

fan, rear defogger, radiator fan, and air conditioner

are not ope€tlng.

ldlo speed should be;

B188l engine:

Mlf480 :l 50 rpm

A/T480 i 50 rpm (in Park or neutral)

B18C1 engine: /t80 t 50 rpm

818C5 sngine:550 t 50 rpm

lf necessary, adjust the idle speed, by turning theidle adjusting screw.

After adjusting the idle speed, recheck the ignition

timing {see section 23). lf it is out of spec, go back

to steo 4.

Page 327 of 1680

'*

1i

v3

I

l

i

I

1.

Testing

!@ Do not smoke during tho t€st. Keep open

flame away from your work area.

lf you suspect a problem with the fuel pump, check that

the fuel pump actually runs; when it is ON, you will hear

some noise it you hold your ear to the fuel fill pon with

the fuel fill cap removed. The fuel pump should run for

two seconds, when ignition switch is first turned on. lf

the fuel pump does not make noise, check as followsl

Remove the rear seat (see section 20).

Remove the access panel.

Disconnect the 2P connector from the tuel pump.

CAUTION: Be sure to turn the ignition switch OFF

before disconnecting the wires,

Connect the PGM-Fl main relay 7P connector termi-

nals No. 4 and No. 5 with a jumper wire.

PGM-FI MAIN RELAY CONNECTOR {C,14:}l

2.

3.

4.

5.

FUEL PUMP

{YEL/GRNI

IGN, 1

IYEL/GRN)

JUMPER WIRE

Wire side of female terminals

Check that battery voltage is available between the

fuel unit sub-harness connector terminal No. 2 and

body ground when the ignition switch is turned ON(

).

Wire side of female terminals

lf battery voltage is available, check the fuel

pump ground. lf the ground is OK. replace the

fuel pump.

lf there is no voltage, check the wire harness (see

page 11'125).

FUEL PUMPCoNNECTOR 1C510)

L]l

lrl-r

6l FUEL PUMP

\:/ (YEL/GRNI

4.

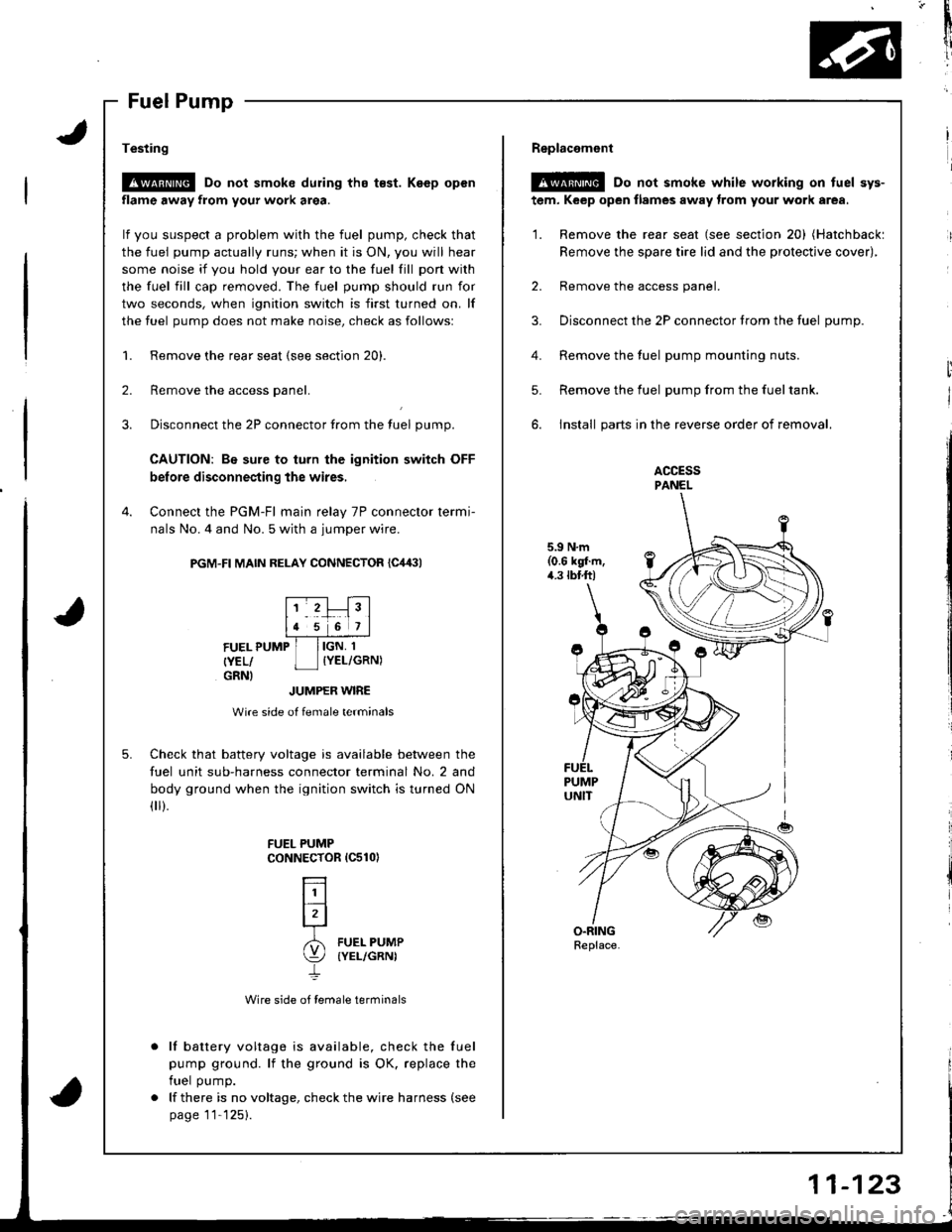

Replacemont

@ Do not smoke while working on tuel sys-

tem, Keep open flames away trom your work area.

'1. Remove the rear seat (see section 20) (Hatchbackl

Remove the spare tire lid and the protective cover),

2. Remove the access panel.

3. Disconnect the 2P connector trom the fuel oumD.

Remove the fuel pump mounting nuts.

Remove the fuel pump from the fueltank.

install parts in the reverse order of removal.

ACCESSPANEL

5.9 N.m(0.6 kgl.m,4.3 tbtft)

5.

Replace.