length ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 294 of 1640

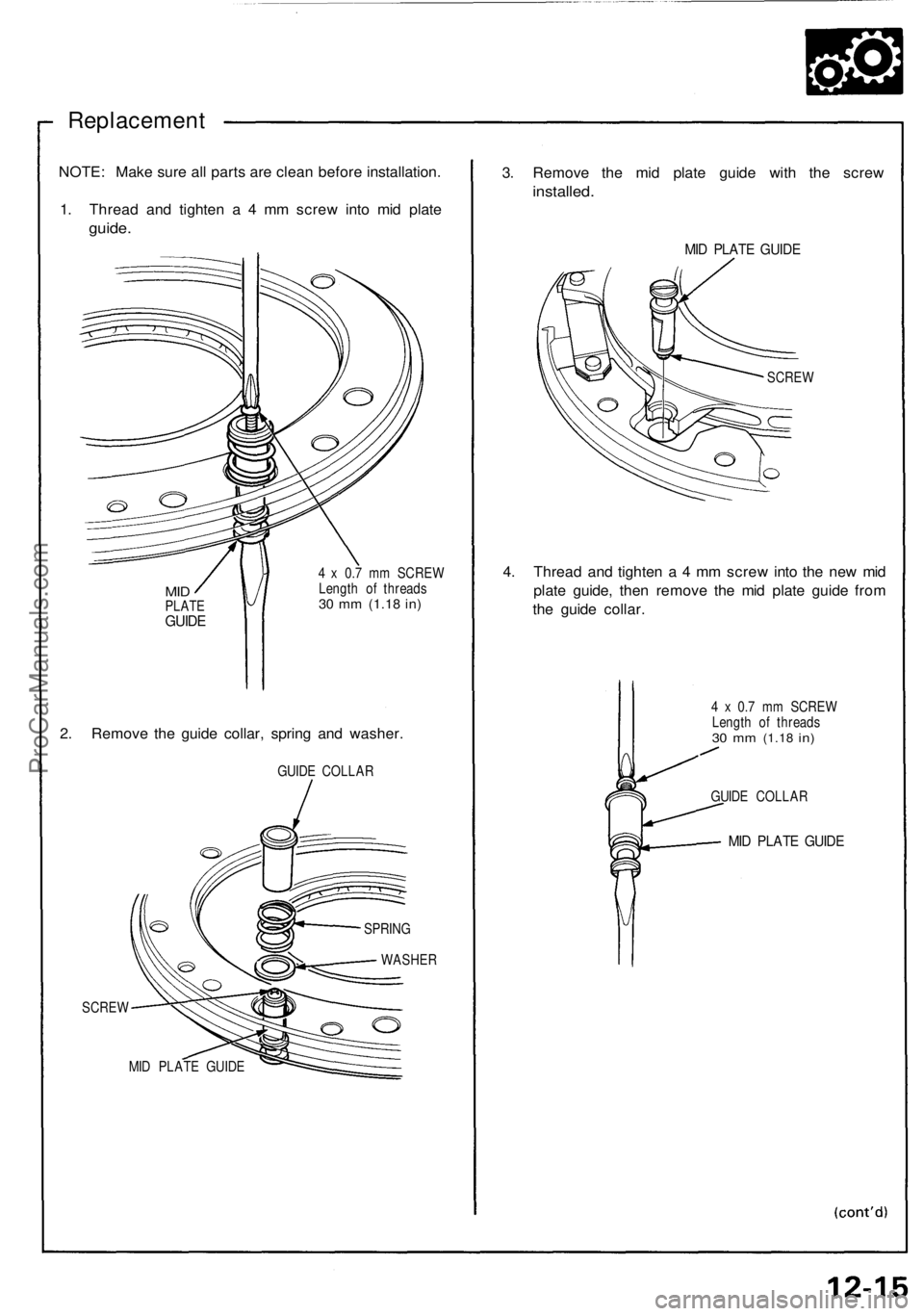

Replacement

NOTE: Make sure all parts are clean before installation.

1. Thread and tighten a 4 mm screw into mid plate

guide.

MID

PLATE

GUIDE

4 x 0.7 mm SCREW

Length of threads

30 mm

(1.18

in)

2. Remove the guide collar, spring and washer.

GUIDE COLLAR

SCREW

MID PLATE GUIDE

3. Remove the mid plate guide with the screw

installed.

MID PLATE GUIDE

SCREW

4. Thread and tighten a 4 mm screw into the new mid

plate guide, then remove the mid plate guide from

the guide collar.

4 x 0.7 mm SCREW

Length of threads

30 mm

(1.18

in)

GUIDE COLLAR

MID PLATE GUIDE

SPRING

WASHERProCarManuals.com

Page 444 of 1640

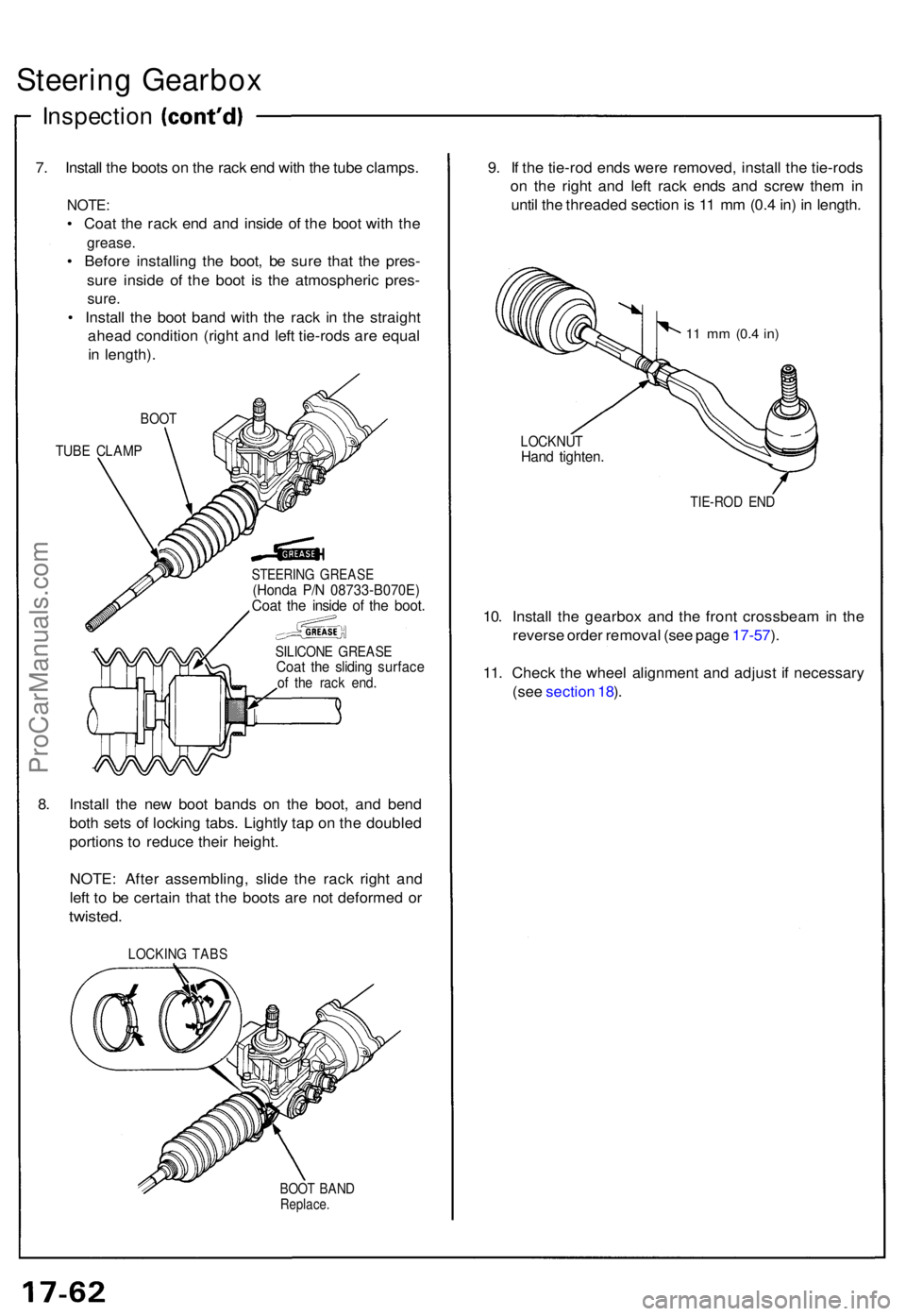

Steering Gearbo x

Inspectio n

7. Instal l th e boot s o n th e rac k en d wit h th e tub e clamps .

NOTE:

• Coa t th e rac k en d an d insid e o f th e boo t wit h th e

grease .

• Befor e installin g th e boot , b e sur e tha t th e pres -

sur e insid e o f th e boo t i s th e atmospheri c pres -

sure.

• Instal l th e boo t ban d wit h th e rac k i n th e straigh t

ahea d conditio n (righ t an d lef t tie-rod s ar e equa l

i n length) .

BOOT

TUBE CLAM P

STEERIN G GREAS E(Honda P/ N 08733-B070E )Coat th e insid e o f th e boot .

SILICON E GREAS ECoat th e slidin g surfac eof th e rac k end .

8. Instal l th e ne w boo t band s o n th e boot , an d ben d

bot h set s o f lockin g tabs . Lightl y ta p o n th e double d

portion s t o reduc e thei r height .

NOTE : Afte r assembling , slid e th e rac k righ t an d

lef t t o b e certai n tha t th e boot s ar e no t deforme d o r

twisted .

LOCKIN G TAB S

BOOT BAN DReplace .

9. I f th e tie-ro d end s wer e removed , instal l th e tie-rod s

o n th e righ t an d lef t rac k end s an d scre w the m in

unti l th e threade d sectio n is 1 1 m m (0. 4 in ) i n length .

11 m m (0. 4 in)

LOCKNU THand tighten .

TIE-RO D EN D

10. Instal l th e gearbo x an d th e fron t crossbea m in th e

revers e orde r remova l (se e pag e 17-57 ).

11 . Chec k th e whee l alignmen t an d adjus t i f necessar y

(se e sectio n 18 ).

ProCarManuals.com

Page 457 of 1640

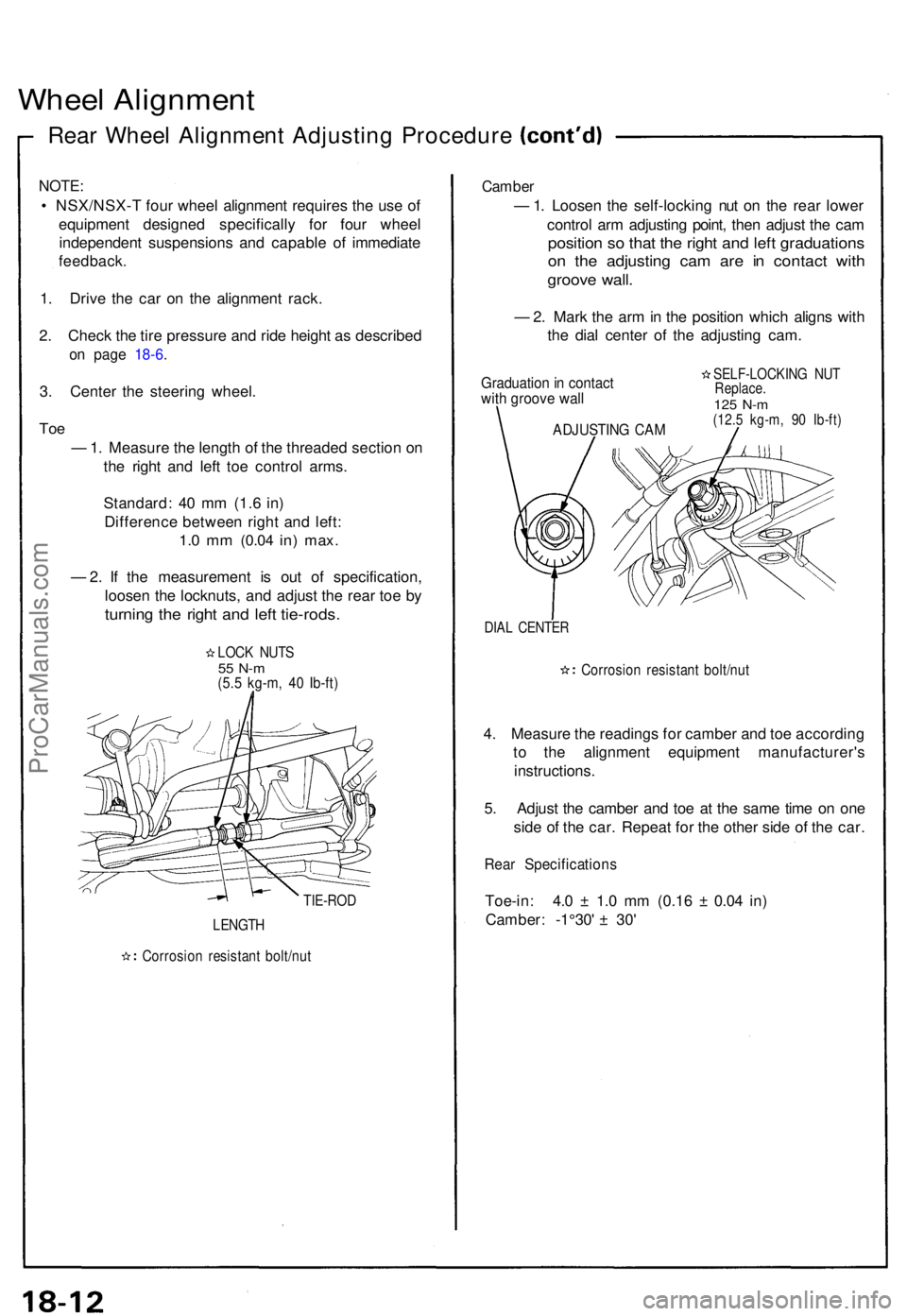

Wheel Alignmen t

Rear Whee l Alignmen t Adjustin g Procedur e

NOTE:

• NSX/NSX- T fou r whee l alignmen t require s th e us e o f

equipmen t designe d specificall y fo r fou r whee l

independen t suspension s an d capabl e o f immediat e

feedback.

1. Driv e th e ca r o n th e alignmen t rack .

2 . Chec k th e tir e pressur e an d rid e heigh t a s describe d

on pag e 18-6 .

3. Cente r th e steerin g wheel .

Toe

— 1. Measur e th e lengt h o f th e threade d sectio n o n

th e righ t an d lef t to e contro l arms .

Standard : 4 0 m m (1. 6 in )

Differenc e betwee n righ t an d left :

1.0 m m (0.0 4 in) max .

— 2. I f th e measuremen t i s ou t o f specification ,

loose n th e locknuts , an d adjus t th e rea r to e b y

turnin g th e righ t an d lef t tie-rods .

LOCK NUT S55 N- m(5.5 kg-m , 4 0 Ib-ft )

TIE-RO D

LENGTH

Corrosio n resistan t bolt/nu t

Camber

— 1. Loose n th e self-lockin g nu t o n th e rea r lowe r

contro l ar m adjustin g point , the n adjus t th e ca m

positio n s o tha t th e righ t an d lef t graduation s

on th e adjustin g ca m ar e i n contac t wit h

groov e wall .

— 2. Mar k th e ar m in th e positio n whic h align s wit h

th e dia l cente r of the adjustin g cam .

Graduatio n in contac twith groov e wall

SELF-LOCKIN G NU TReplace .125 N- m(12. 5 kg-m , 9 0 Ib-ft )

DIAL CENTE R

Corrosio n resistan t bolt/nu t

4. Measur e th e reading s fo r cambe r an d to e accordin g

t o th e alignmen t equipmen t manufacturer' s

instructions .

5 . Adjus t th e cambe r an d to e a t th e sam e tim e o n on e

sid e o f th e car . Repea t fo r th e othe r sid e of the car .

Rear Specification s

Toe-in: 4. 0 ± 1. 0 m m (0.1 6 ± 0.0 4 in )

Camber : - 1°30 ' ± 30'

ADJUSTIN G CA M

ProCarManuals.com

Page 643 of 1640

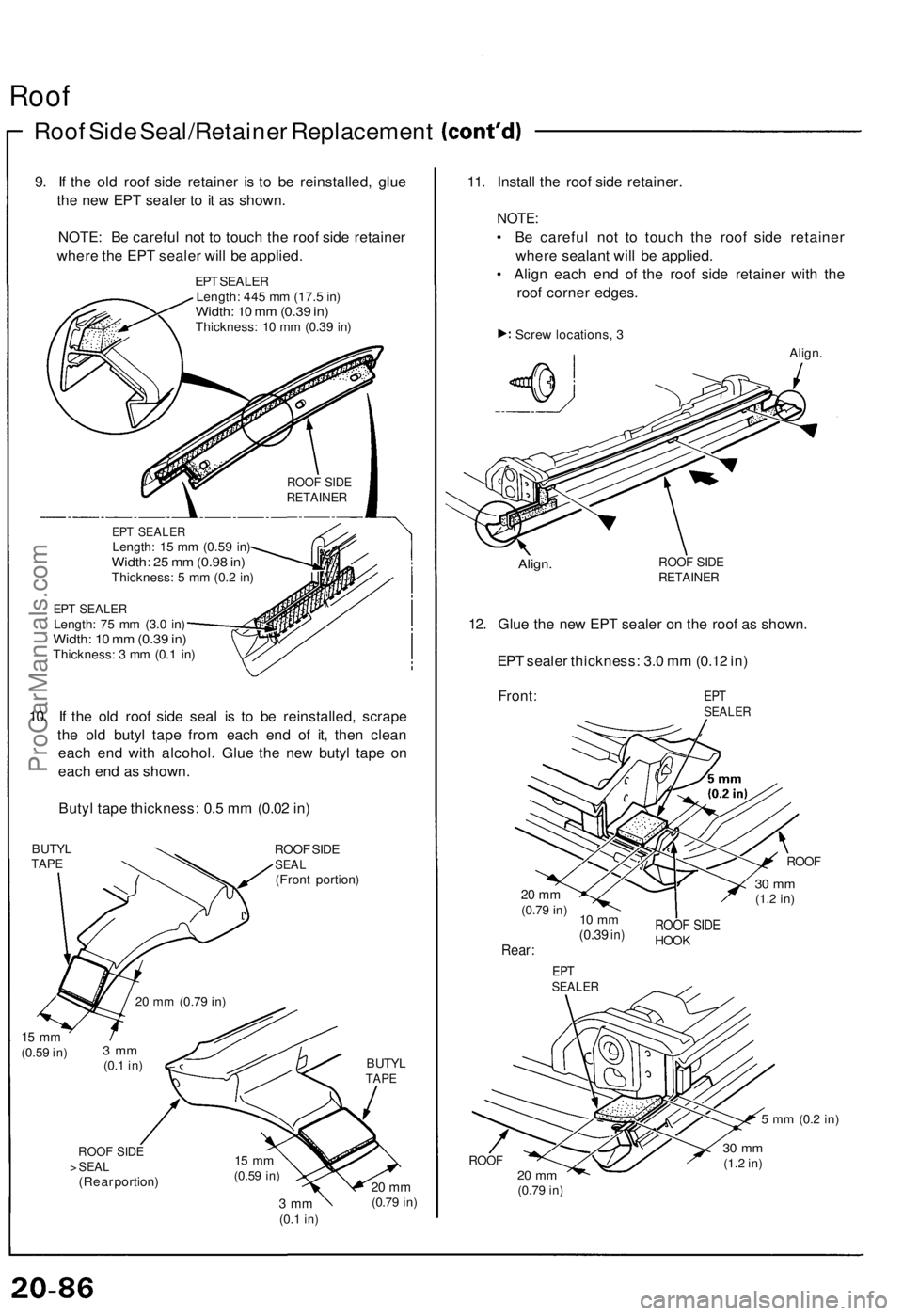

Roof

Roof Side Seal/Retainer Replacement

9. If the old roof side retainer is to be reinstalled, glue

the new EPT sealer to it as shown.

NOTE: Be careful not to touch the roof side retainer

where the EPT sealer will be applied.

EPT SEALER

Length: 445 mm (17.5 in)

Width: 10 mm (0.39 in)

Thickness: 10 mm (0.39 in)

EPT SEALER

Length: 15 mm (0.59 in)

Width: 25 mm (0.98 in)

Thickness: 5 mm (0.2 in)

EPT SEALER

Length: 75 mm (3.0 in)

Width: 10 mm (0.39 in)

Thickness: 3 mm (0.1 in)

10. If the old roof side seal is to be reinstalled, scrape

the old butyl tape from each end of it, then clean

each end with alcohol. Glue the new butyl tape on

each end as shown.

Butyl tape thickness: 0.5 mm (0.02 in)

BUTYL

TAPE

ROOF SIDE

SEAL

(Front portion)

15 mm

(0.59

in)

BUTYL

TAPE

ROOF SIDE

> SEAL

(Rear portion)

3 mm

(0.1

in)

20 mm

(0.79

in)

11. Install the roof side retainer.

NOTE:

• Be careful not to touch the roof side retainer

where sealant will be applied.

• Align each end of the roof side retainer with the

roof corner edges.

Screw locations, 3

Align.

Align.

ROOF SIDE

RETAINER

12. Glue the new EPT sealer on the roof as shown.

EPT sealer thickness: 3.0 mm (0.12 in)

Front:

EPT

SEALER

ROOF

20 mm

(0.79

in)

30 mm

(1.2

in)

10 mm

(0.39

in)

Rear:

ROOF SIDE

HOOK

EPT

SEALER

5 mm

(0.2

in)

ROOF

20 mm

(0.79

in)

30 mm

(1.2

in)

3 mm

(0.1

in)

20 mm

(0.79

in)

15 mm

(0.59

in)

ROOF SIDE

RETAINERProCarManuals.com

Page 753 of 1640

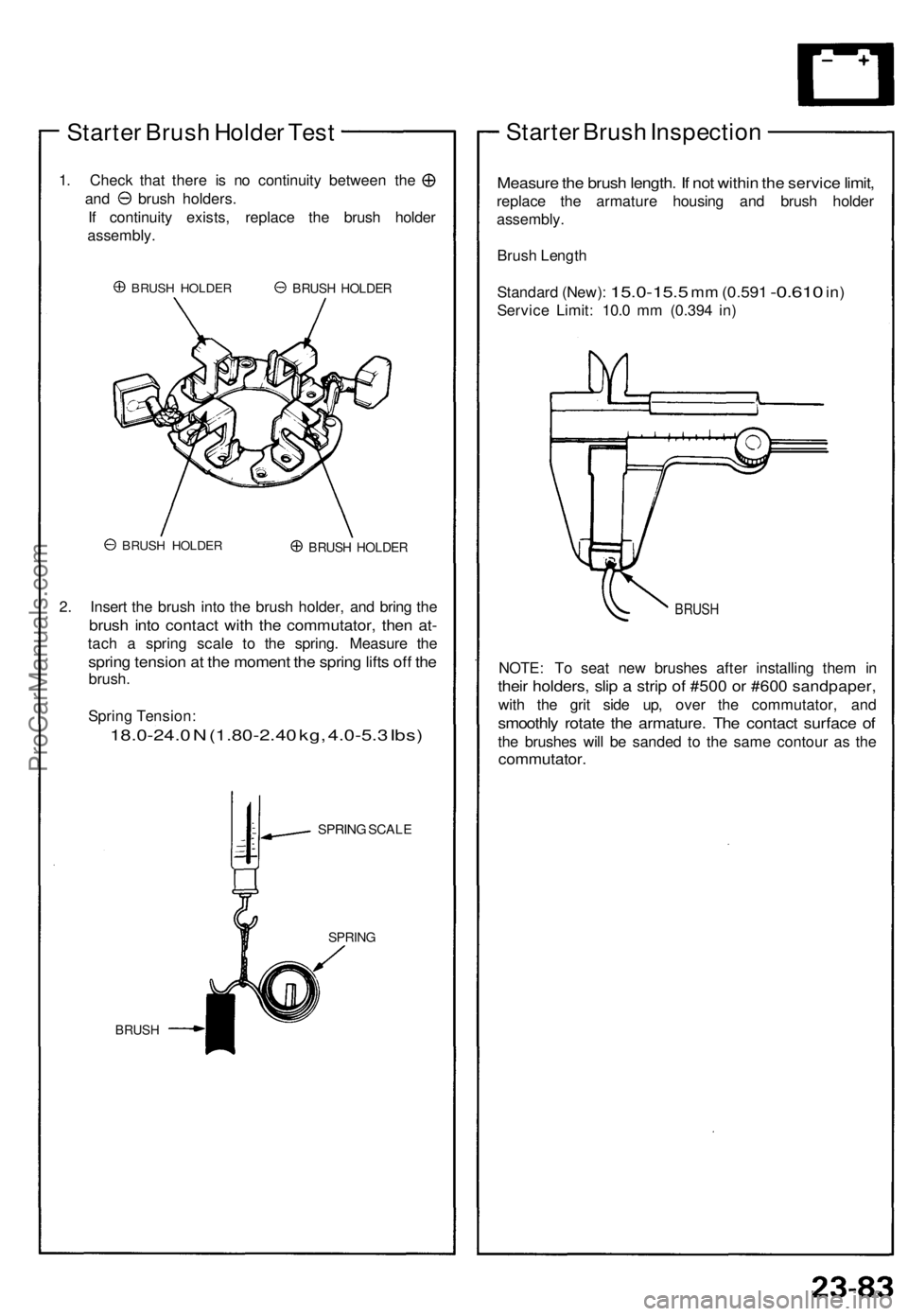

Starter Brush Holder Test

1. Check that there is no continuity between the

and brush holders.

If continuity exists, replace the brush holder

assembly.

BRUSH HOLDER

BRUSH HOLDER

BRUSH HOLDER

2. Insert the brush into the brush holder, and bring the

brush into contact with the commutator, then at-

tach a spring scale to the spring. Measure the

spring tension at the moment the spring lifts off the

brush.

Spring Tension:

18.0-24.0 N (1.80-2.40 kg, 4.0-5.3 Ibs)

SPRING SCALE

BRUSH

SPRING

Starter Brush Inspection

Measure the brush length. If not within the service limit,

replace the armature housing and brush holder

assembly.

Brush Length

Standard (New):

15.0-15.5

mm

(0.591

-0.610

in)

Service Limit: 10.0 mm (0.394 in)

BRUSH

NOTE: To seat new brushes after installing them in

their holders, slip a strip of #500 or #600 sandpaper,

with the grit side up, over the commutator, and

smoothly rotate the armature. The contact surface of

the brushes will be sanded to the same contour as the

commutator.

BRUSH HOLDERProCarManuals.com

Page 774 of 1640

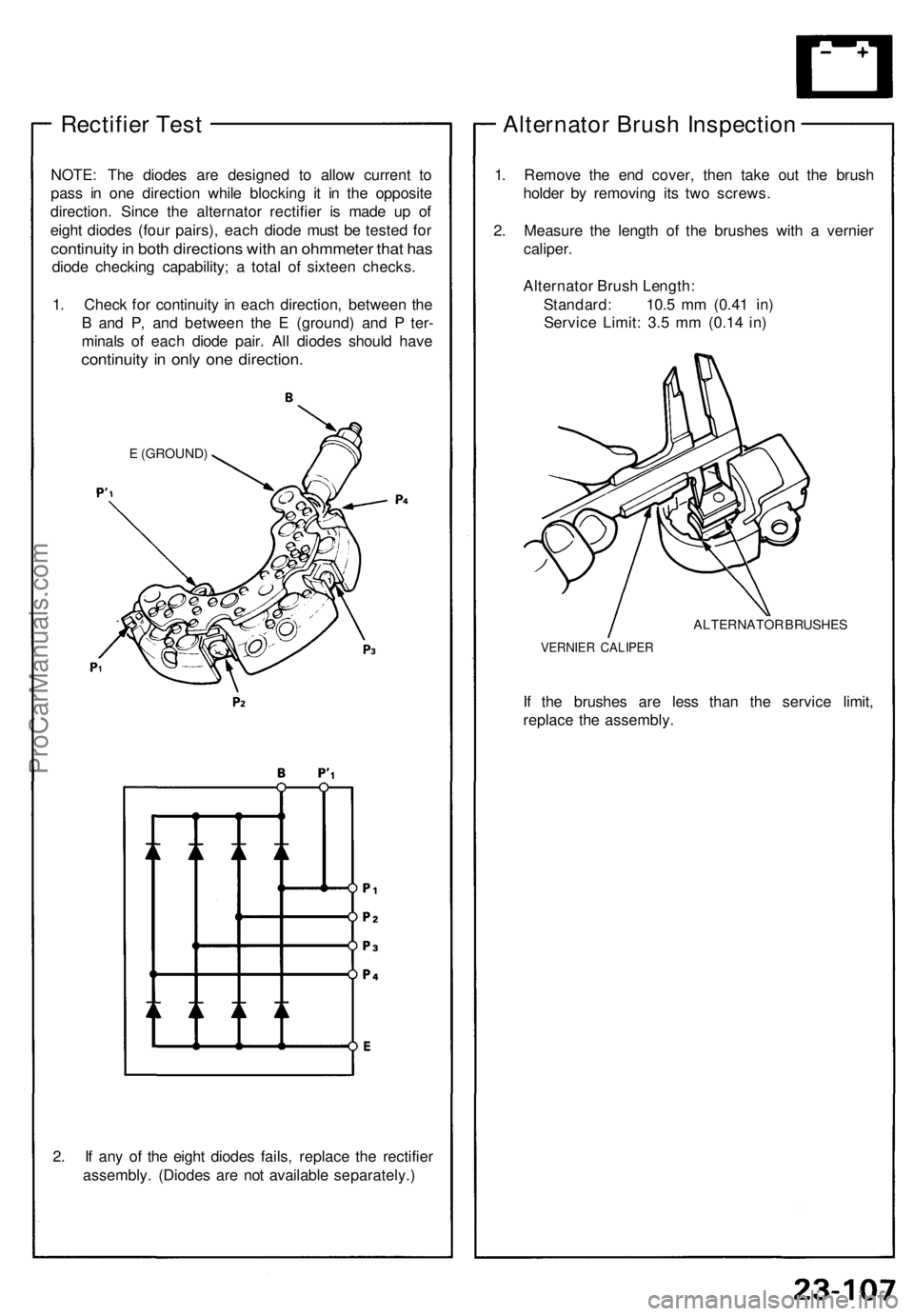

Rectifier Test

NOTE: The diodes are designed to allow current to

pass in one direction while blocking it in the opposite

direction. Since the alternator rectifier is made up of

eight diodes (four pairs), each diode must be tested for

continuity in both directions with an ohmmeter that has

diode checking capability; a total of sixteen checks.

1. Check for continuity in each direction, between the

B and P, and between the E (ground) and P ter-

minals of each diode pair. All diodes should have

continuity in only one direction.

E (GROUND)

2. If any of the eight diodes fails, replace the rectifier

assembly. (Diodes are not available separately.)

Alternator Brush Inspection

1. Remove the end cover, then take out the brush

holder by removing its two screws.

2. Measure the length of the brushes with a vernier

caliper.

Alternator Brush Length:

Standard: 10.5 mm (0.41 in)

Service Limit: 3.5 mm (0.14 in)

ALTERNATOR BRUSHES

VERNIER CALIPER

If the brushes are less than the service limit,

replace the assembly.ProCarManuals.com

Page 1032 of 1640

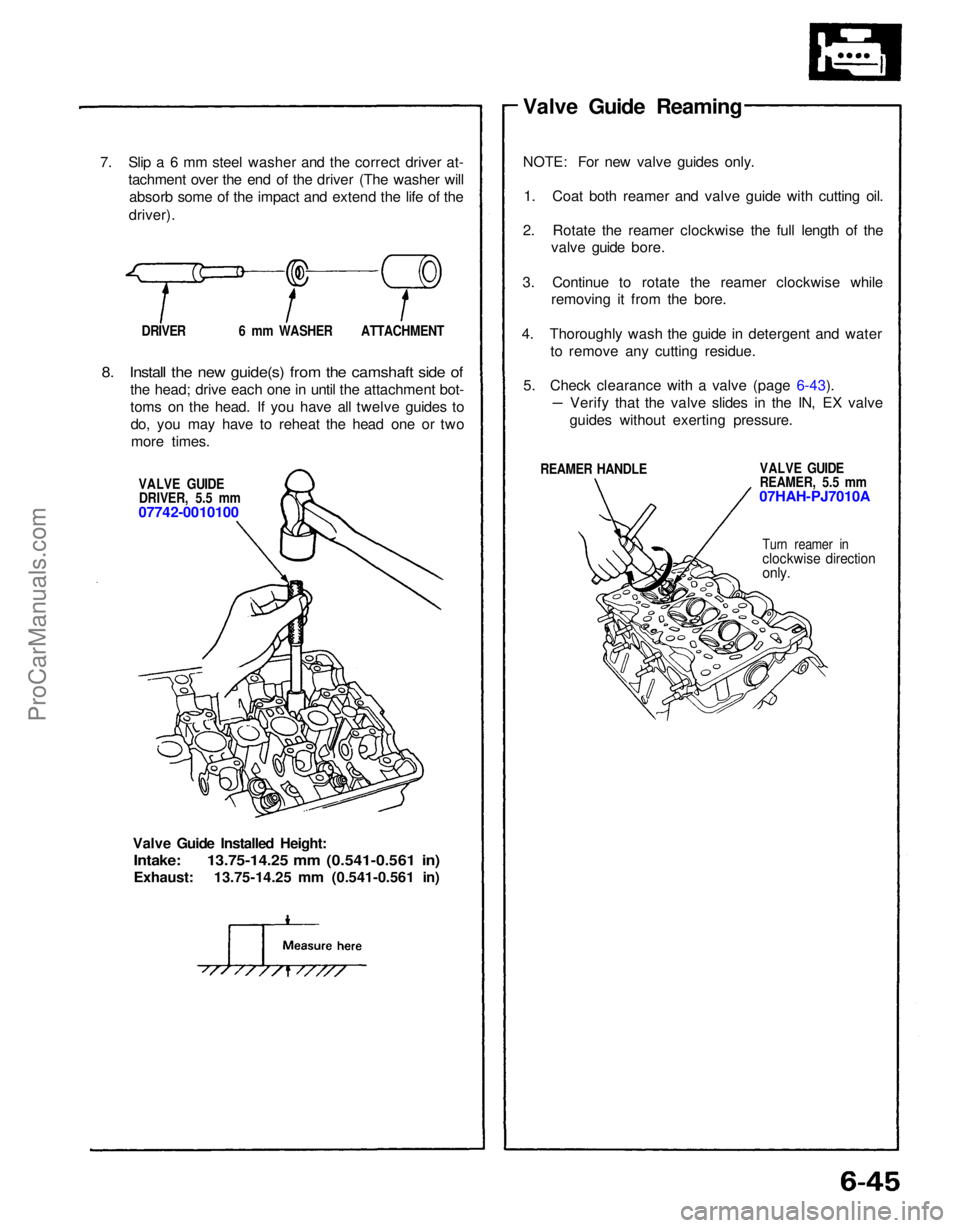

7. Slip a 6 mm steel washer and the correct driver at-

tachment over the end of the driver (The washer willabsorb some of the impact and extend the life of the

driver).

DRIVER 6 mm WASHER ATTACHMENT

8. Install the new guide(s) from the camshaft side of

the head; drive each one in until the attachment bot-

toms on the head. If you have all twelve guides todo, you may have to reheat the head one or twomore times.

VALVE GUIDEDRIVER, 5.5 mm

07742-0010100

Valve Guide Installed Height:

Intake: 13.75-14.25 mm (0.541-0.561 in)

Exhaust: 13.75-14.25 mm (0.541-0.561 in) Valve Guide Reaming

NOTE: For new valve guides only.

1. Coat both reamer and valve guide with cutting oil.

2. Rotate the reamer clockwise the full length of the valve guide bore.

3. Continue to rotate the reamer clockwise while removing it from the bore.

4. Thoroughly wash the guide in detergent and water to remove any cutting residue.

5. Check clearance with a valve (page 6-43).

REAMER HANDLE VALVE GUIDE

REAMER, 5.5 mm

07HAH-PJ7010A

Turn reamer in

clockwise direction

only.

Verify that the valve slides in the IN, EX valve

guides without exerting pressure.ProCarManuals.com

Page 1033 of 1640

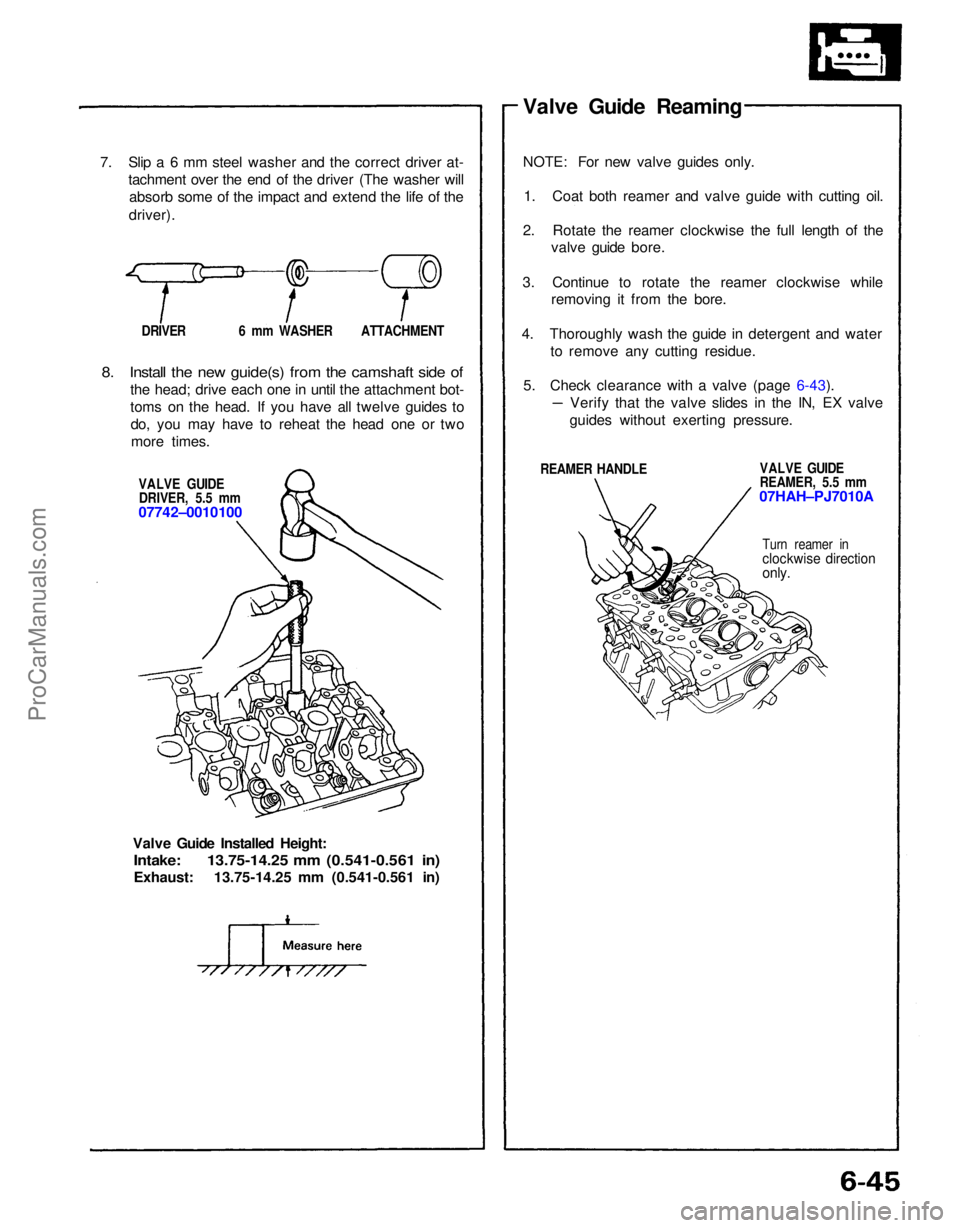

7. Slip a 6 mm steel washer and the correct driver at-

tachment over the end of the driver (The washer willabsorb some of the impact and extend the life of the

driver).

DRIVER 6 mm WASHER ATTACHMENT

8. Install the new guide(s) from the camshaft side of

the head; drive each one in until the attachment bot-

toms on the head. If you have all twelve guides todo, you may have to reheat the head one or twomore times.

VALVE GUIDEDRIVER, 5.5 mm

07742–0010100

Valve Guide Installed Height:

Intake: 13.75-14.25 mm (0.541-0.561 in)

Exhaust: 13.75-14.25 mm (0.541-0.561 in) Valve Guide Reaming

NOTE: For new valve guides only.

1. Coat both reamer and valve guide with cutting oil.

2. Rotate the reamer clockwise the full length of the valve guide bore.

3. Continue to rotate the reamer clockwise while removing it from the bore.

4. Thoroughly wash the guide in detergent and water to remove any cutting residue.

5. Check clearance with a valve (page 6-43).

REAMER HANDLE VALVE GUIDE

REAMER, 5.5 mm

07HAH–PJ7010A

Turn reamer in

clockwise direction

only.

Verify that the valve slides in the IN, EX valve

guides without exerting pressure.ProCarManuals.com

Page 1078 of 1640

Troubleshooting

Self-diagnostic Procedures

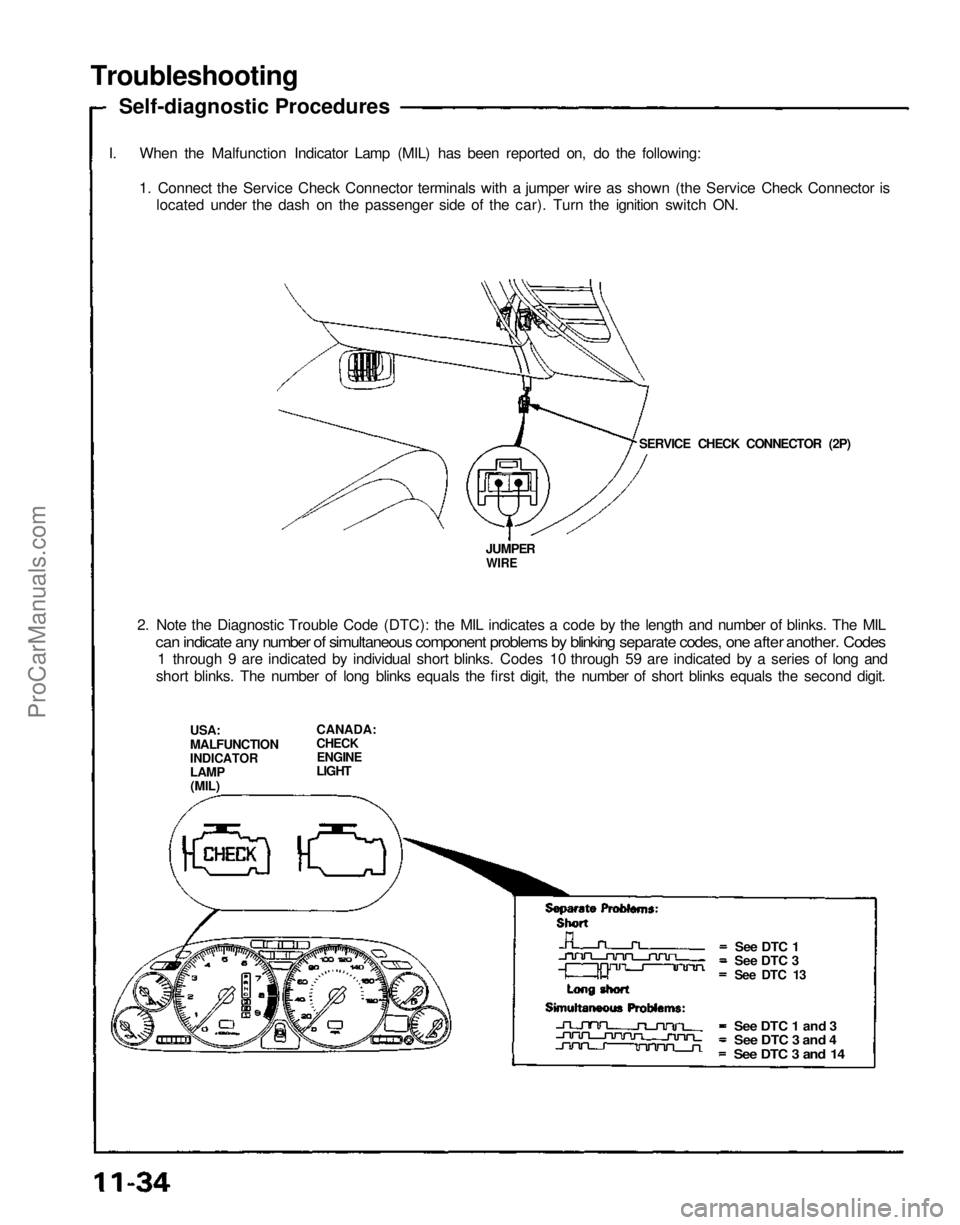

I. When the Malfunction Indicator Lamp (MIL) has been reported on, do the following: 1. Connect the Service Check Connector terminals with a jumper wire as shown (the Service Check Connector islocated under the dash on the passenger side of the car). Turn the ignition switch ON.

SERVICE CHECK CONNECTOR (2P)

JUMPER

WIRE

2. Note the Diagnostic Trouble Code (DTC): the MIL indicates a code by the length and number of blinks. The MIL

can indicate any number of simultaneous component problems by blinking separate codes, one after another. Codes

1 through 9 are indicated by individual short blinks. Codes 10 through 59 are indicated by a series of long and

short blinks. The number of long blinks equals the first digit, the number of short blinks equals the second digit.

USA:

MALFUNCTION

INDICATOR

LAMP

(MIL) CANADA:

CHECK

ENGINE

LIGHT

See DTC 1

See DTC 3

See DTC 13

See DTC 1 and 3

See DTC 3 and 4

See DTC 3 and 14ProCarManuals.com

Page 1248 of 1640

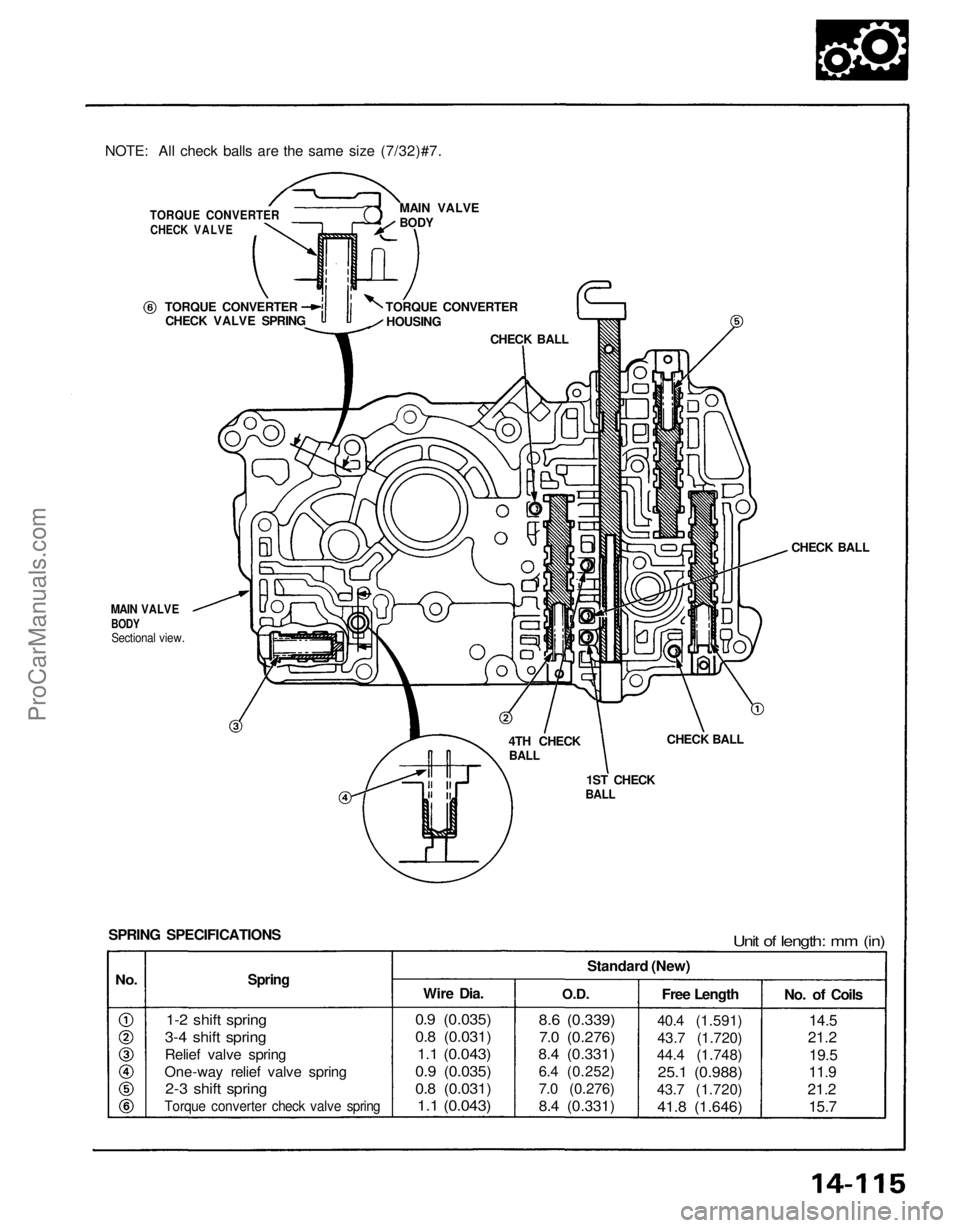

NOTE: All check balls are the same size (7/32)#7.

TORQUE CONVERTER

CHECK VALVE

TORQUE CONVERTER

CHECK VALVE SPRING TORQUE CONVERTER

HOUSING

CHECK BALL

MAIN VALVE

BODY

CHECK BALL

CHECK BALL

1ST CHECK

BALL

4TH CHECK

BALL

Unit of length: mm (in)

SPRING SPECIFICATIONS

Spring

No.

1-2 shift spring

3-4 shift spring

Relief valve spring

One-way relief valve spring

2-3 shift spring

Torque converter check valve spring

Wire Dia.

O.D.Standard (New)

Free Length

0.9 (0.035)

0.8 (0.031)

1.1 (0.043)

0.9 (0.035)

0.8 (0.031)

1.1 (0.043)

8.6 (0.339)

7.0 (0.276)

8.4 (0.331)

6.4 (0.252)

7.0 (0.276)

8.4 (0.331)

40.4 (1.591)

43.7 (1.720)

44.4 (1.748)

25.1 (0.988)

43.7 (1.720)

41.8 (1.646)

No. of Coils

14.5

21.2

19.5

11.9

21.2 15.7

MAIN VALVE

BODY

Sectional view.

ProCarManuals.com