weight ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 11 of 1640

Towing

If th e ca r need s t o b e towed , cal l a professiona l towin g

service . Neve r to w th e ca r behin d anothe r ca r wit h jus t

a rop e o r chain . I t i s ver y dangerous .

Ther e ar e thre e widel y use d method s o f towin g a car :

Flat-be d Equipmen t — Th e operato r load s th e ca r o n th e

bac k o f a truck . Thi s i s th e onl y recommende d wa y o f

towin g th e NS X & NSX-T .

Whee l Lif t Equipment— The to w truc k drive r use s tw o

pivotin g arm s whic h g o unde r th e tire s (fron t o r rear ) an d

lif t the m of f th e ground . Th e othe r tw o wheel s remai n

o n th e ground . Thi s towin g metho d i s no t recommend -

ed . Becaus e o f th e NS X & NSX-T' s lo w groun d clearance ,

th e bod y ca n b e damage d goin g ove r larg e bump s o r u p

inclines .

Sling-typ e Equipment— The tow truc k use s meta l chain s

wit h hook s o n th e ends . Thes e hook s g o aroun d part s

of th e fram e or suspensio n and th e cable s lift tha t end

of th e ca r of f th e ground . Damag e t o th e car' s suspen -

sio n an d bod y i s almos t certai n if thi s metho d o f towin g

i s attempted .

I f th e NS X & NSX- T canno t b e towe d b y flat-bed , i t

shoul d b e towe d wit h th e rea r wheel s of f th e ground .

If , du e t o damage , th e ca r mus t b e towe d wit h th e rea r

wheel s o n th e ground , d o th e following :

Manual Transmissio n

• Releas e th e parkin g brak e

• Shif t th e transmissio n t o Neutra l

Automati c Transmissio n

• Releas e th e parkin g brak e

• Star t th e engin e

• Shif t t o position , the n t o positio n

• Tur n of f th e engin e

NOTICE :

• Imprope r towin g preparatio n wil l damag e th e trans -

mission . Follo w th e abov e procedur e exactly . Th e ca r

mus t b e towe d o n a fla t be d if th e engin e wil l no t star t

o r th e transmissio n wil l no t shift .

• I t i s bes t t o to w th e ca r n o farthe r tha n 5 0 mile s (8 0

km) , an d kee p th e spee d belo w 3 5 mp h (5 5 km/h) .

• Tryin g t o lif t o r to w th e ca r b y th e bumper s wil l caus e

seriou s damage . Th e bumper s ar e no t designe d to sup -

por t th e car' s weight .

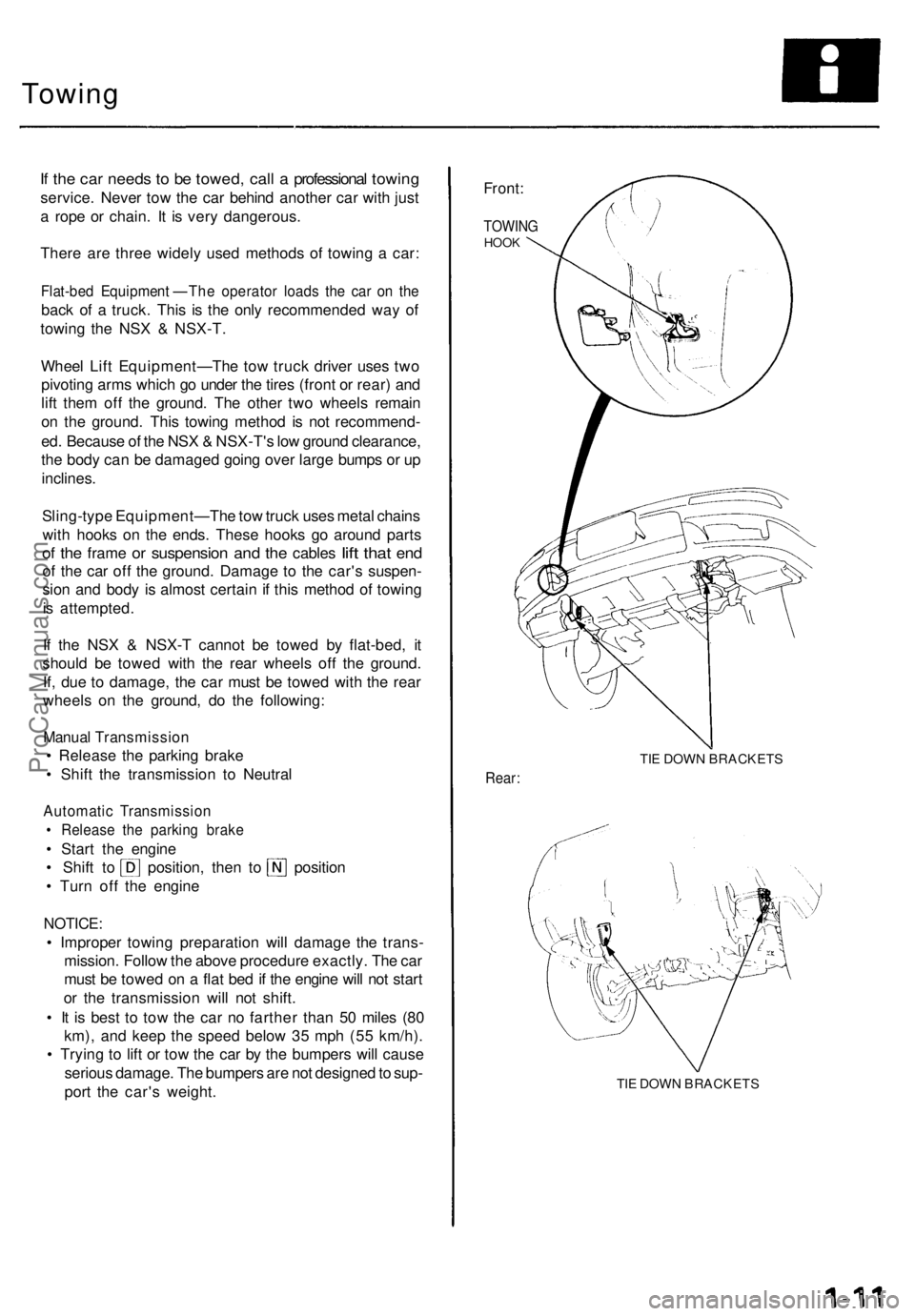

Front:

TOWIN GHOOK

TIE DOW N BRACKET S

Rear:

TIE DOW N BRACKET S

ProCarManuals.com

Page 44 of 1640

Towing

If th e ca r need s t o b e towed , cal l a professiona l towin g

service . Neve r to w th e ca r behin d anothe r ca r wit h jus t

a rop e o r chain . I t i s ver y dangerous .

Ther e ar e thre e widel y use d method s o f towin g a car :

Flat-be d Equipment—Th e operato r load s th e ca r o n th e

bac k o f a truck . This is th e onl y recommende d wa y o f

towin g th e NS X & NSX-T .

Whee l Lif t Equipment—Th e to w truc k drive r use s tw o

pivotin g arm s whic h g o unde r th e tire s (fron t o r rear ) an d

lif t the m of f th e ground . Th e othe r tw o wheel s remai n

o n th e ground . Thi s towin g metho d i s no t recommend -

ed . Becaus e o f th e NS X & NSX-T' s lo w groun d clearance ,

th e bod y ca n b e damage d goin g ove r larg e bump s o r u p

inclines .

Sling-typ e Equipment—Th e to w truc k use s meta l chain s

wit h hooks on th e ends . Thes e hook s g o aroun d part s

o f th e fram e o r suspensio n an d th e cable s lif t tha t en d

o f th e ca r of f th e ground . Damag e t o th e car' s suspen -

sio n an d bod y i s almos t certai n if thi s metho d o f towin g

i s attempted .

I f th e NS X & NSX- T canno t b e towe d b y flat-bed , i t

shoul d b e towe d wit h th e rea r wheel s of f th e ground .

If , du e t o damage , th e ca r mus t b e towe d wit h th e rea r

wheel s o n th e ground , d o th e following :

Manual Transmissio n

Release th e parkin g brak e

Shift th e transmissio n t o Neutra l

Automati c Transmissio n

Releas e th e parkin g brak e

Star t th e engin e

Shift t o position , the n t o positio n

Tur n of f th e engin e

NOTICE :

Improper towin g preparatio n wil l damag e th e trans -

mission . Follo w th e abov e procedur e exactly . Th e ca r

mus t b e towe d o n a fla t be d if th e engin e wil l no t star t

or th e transmissio n wil l no t shift .

It i s bes t t o to w th e ca r n o farthe r tha n 5 0 mile s (8 0

km) , an d kee p th e spee d belo w 3 5 mp h (5 5 km/h) .

Tryin g t o lif t o r to w th e ca r b y th e bumper s wil l caus e

seriou s damage . Th e bumper s ar e no t designe d to sup -

por t th e car' s weight .

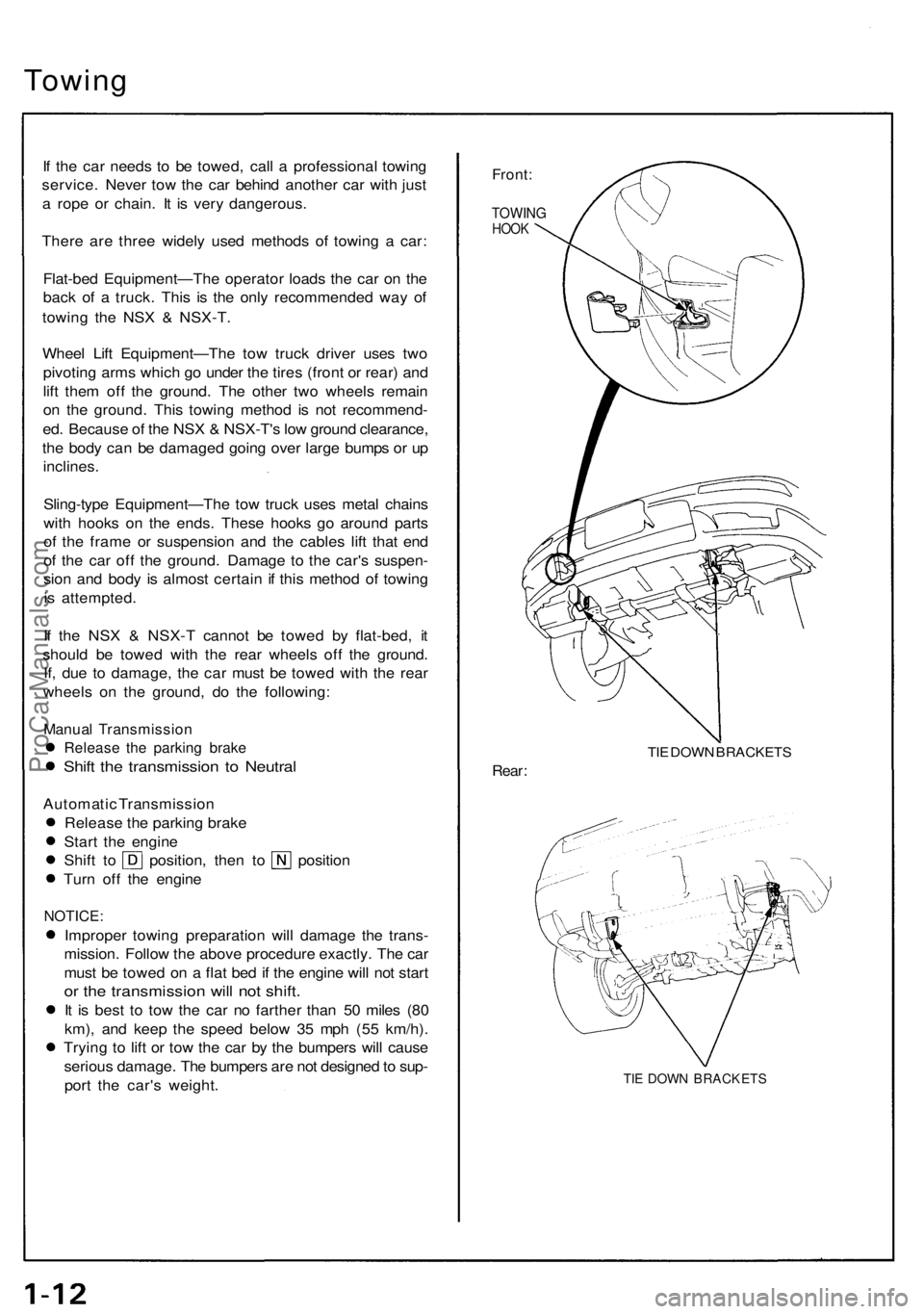

Front:

TOWIN GHOOK

TIE DOW N BRACKET S

Rear:

TIE DOW N BRACKET S

ProCarManuals.com

Page 131 of 1640

Main Bearing s

Clearanc e

1. T o chec k mai n bearing-to-journa l oi l clearance ,

remov e th e mai n cap s an d bearin g halves .

2 . Clea n eac h mai n journa l an d bearin g hal f wit h a

clea n sho p towel.

3 . Plac e on e stri p o f plastigag e acros s eac h mai n jour -

nal.

NOTE : I f th e engine is stil l i n th e ca r whe n yo u bol t

th e mai n ca p dow n t o chec k clearance , th e weigh t

o f th e crankshaf t an d flywhee l wil l flatte n th e plasti -

gag e furthe r tha n jus t th e torqu e o n th e ca p bolts ,

an d giv e yo u a n incorrec t reading . Fo r a n accurat e

reading , suppor t th e cran k wit h a jac k unde r th e

counterweights , an d chec k onl y on e bearin g a t a

time .

4. Reinstal l th e bearings , cap s an d ca p bridge , the n

torqu e th e 9 m m bridg e bolt s t o 4 0 N- m (4. 0 kg-m ,

2 9 Ib-ft) . Torqu e th e 1 1 m m ca p bolt s t o 6 6 N- m

(6. 6 kg-m , 4 8 Ib-ft) .

5 . Torqu e th e sid e bolt s t o 5 0 N- m (5. 0 kg-m , 3 6 Ib -

ft).

6. Remov e th e bridge , cap s an d bearings , an d

measur e th e wides t par t o f th e plastigage .

Mai n Bearing-to-journa l Oi l Clearance :

Standar d

(New): 0.024-0.04 8 mm

(0.0009-0.001 9 in )

Servic e Limit : 0.05 0 m m (0.002 0 in )

PLASTIGAG E STRI P

7. I f th e plastigag e measure s to o wid e o r to o narrow ,

(remove th e engine if it' s stil l i n th e car) , remov e th e

crankshaft , an d remov e th e uppe r hal f o f th e bear -

ing . Instal l a new , complet e bearin g wit h th e sam e

colo r cod e (selec t th e colo r a s show n o n nex t page) ,

an d rechec k th e clearance .

CAUTION : D o no t file , shim , o r scrap e th e bear -

ing s o r th e cap s t o adjus t clearance .

8 . I f th e plastigag e show s th e clearanc e i s stil l incor -

rect , tr y th e nex t large r o r smalle r bearin g (th e colo r

liste d abov e o r belo w tha t one) , an d chec k again .

NOTE : I f th e prope r clearanc e canno t b e obtaine d

b y usin g th e appropriat e large r o r smalle r bearings ,

replac e th e crankshaf t an d star t over .

Connectin g

Rod Bearing s

Clearanc e

1. Remov e th e connectin g ro d ca p an d bearin g half .

2 . Clea n th e crankshaf t ro d journa l an d bearin g hal f

wit h a clea n sho p towel .

3 . Plac e plastigag e acros s th e ro d journal .

4 . Reinstal l th e bearin g hal f an d cap , an d torqu e th e

nut s a s show n o n pag e 7-19 .

NOTE : D o no t rotat e th e crankshaft during inspection .

5 . Remov e th e ro d ca p an d bearin g hal f an d measur e

th e wides t par t o f th e plastigage . Mak e sur e th e

clearanc e betwee n th e connectin g ro d an d th e

bearin g i s withi n th e standar d show n below .

Connectin g Ro d Bearing-to-Journa l Oi l Clearance :

Standar d (New) : 0.040—0.06 0 m m

(0.0016-0.002 4 in )

Servic e Limit : 0.06 0 m m (0.002 4 in )

PLASTIGAG E STRI P

6. I f th e plastigag e measure s to o wid e o r to o narrow ,

remov e th e uppe r hal f of the bearing , instal l a new ,

complet e bearin g wit h th e sam e colo r cod e (selec t

color a s show n o n nex t page) , an d rechec k th e

clearance .

CAUTION: D o no t file , shim , o r scrap e th e bearin g

o r th e cap s t o adjus t clearance .

7. I f th e plastigag e show s th e clearanc e i s stil l incor -

rect , tr y th e nex t large r o r smalle r bearin g (th e colo r

liste d abov e o r belo w tha t one) , an d chec k

clearanc e again .

NOTE : I f th e prope r clearanc e canno t b e obtaine d

b y usin g th e appropriat e large r o r smalle r bearings ,

replac e th e crankshaf t an d star t over .

ProCarManuals.com

Page 307 of 1640

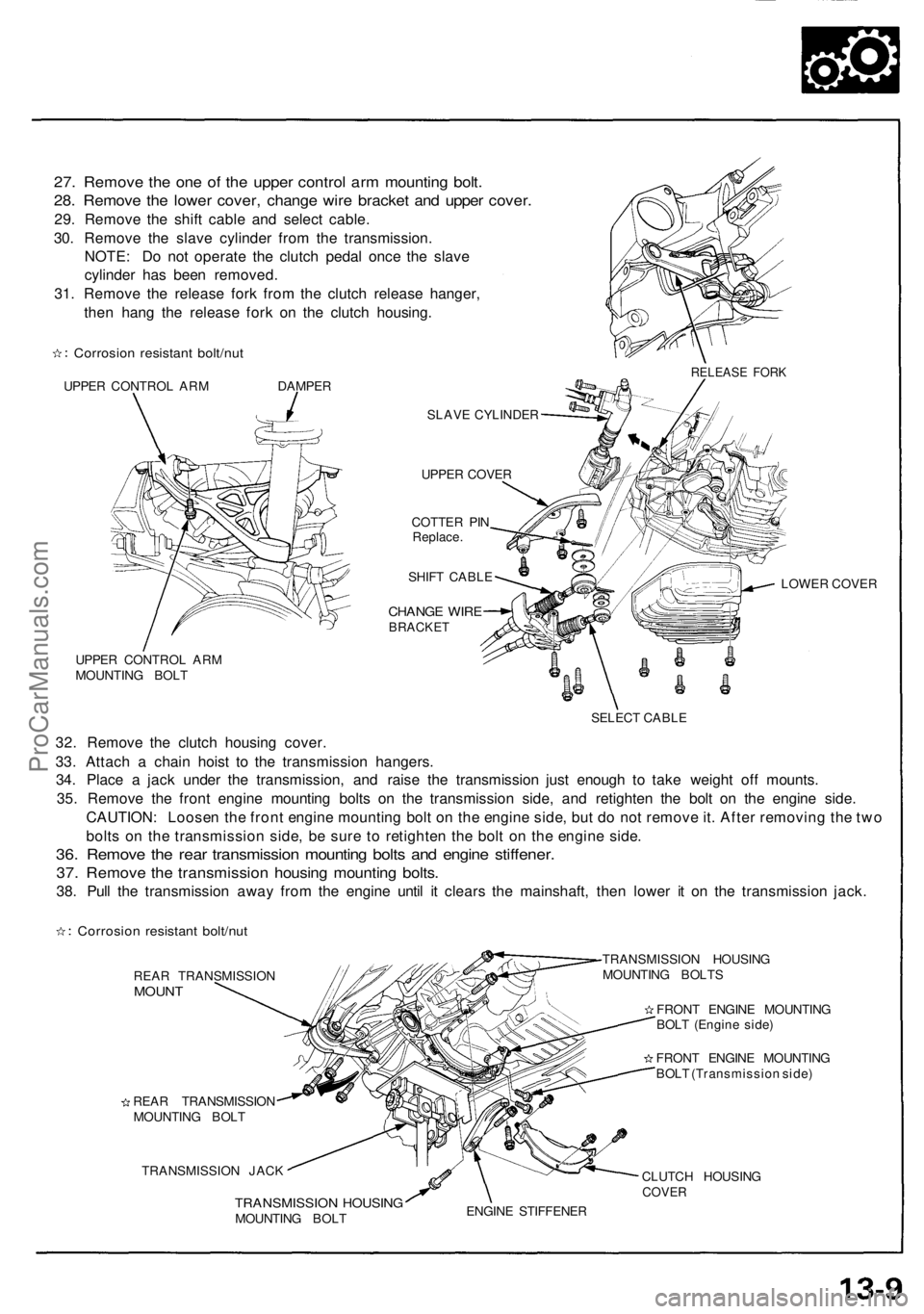

27. Remove the one of the upper control arm mounting bolt.

28. Remove the lower cover, change wire bracket and upper cover.

29. Remove the shift cable and select cable.

30. Remove the slave cylinder from the transmission.

NOTE: Do not operate the clutch pedal once the slave

cylinder has been removed.

31. Remove the release fork from the clutch release hanger,

then hang the release fork on the clutch housing.

Corrosion resistant bolt/nut

UPPER CONTROL ARM DAMPER

SLAVE CYLINDER

UPPER COVER

COTTER PIN

Replace.

SHIFT CABLE

CHANGE WIRE

BRACKET

UPPER CONTROL ARM

MOUNTING BOLT

LOWER COVER

SELECT CABLE

32. Remove the clutch housing cover.

33. Attach a chain hoist to the transmission hangers.

34. Place a jack under the transmission, and raise the transmission just enough to take weight off mounts.

35. Remove the front engine mounting bolts on the transmission side, and retighten the bolt on the engine side.

CAUTION: Loosen the front engine mounting bolt on the engine side, but do not remove it. After removing the two

bolts on the transmission side, be sure to retighten the bolt on the engine side.

36. Remove the rear transmission mounting bolts and engine stiffener.

37. Remove the transmission housing mounting bolts.

38. Pull the transmission away from the engine until it clears the mainshaft, then lower it on the transmission jack.

Corrosion resistant bolt/nut

REAR TRANSMISSION

MOUNT

REAR TRANSMISSION

MOUNTING BOLT

TRANSMISSION JACK

TRANSMISSION HOUSING

MOUNTING BOLTS

FRONT ENGINE MOUNTING

BOLT (Engine side)

FRONT ENGINE MOUNTING

BOLT (Transmission side)

TRANSMISSION HOUSING

MOUNTING BOLT

CLUTCH HOUSING

COVER

ENGINE STIFFENER

RELEASE FORKProCarManuals.com

Page 407 of 1640

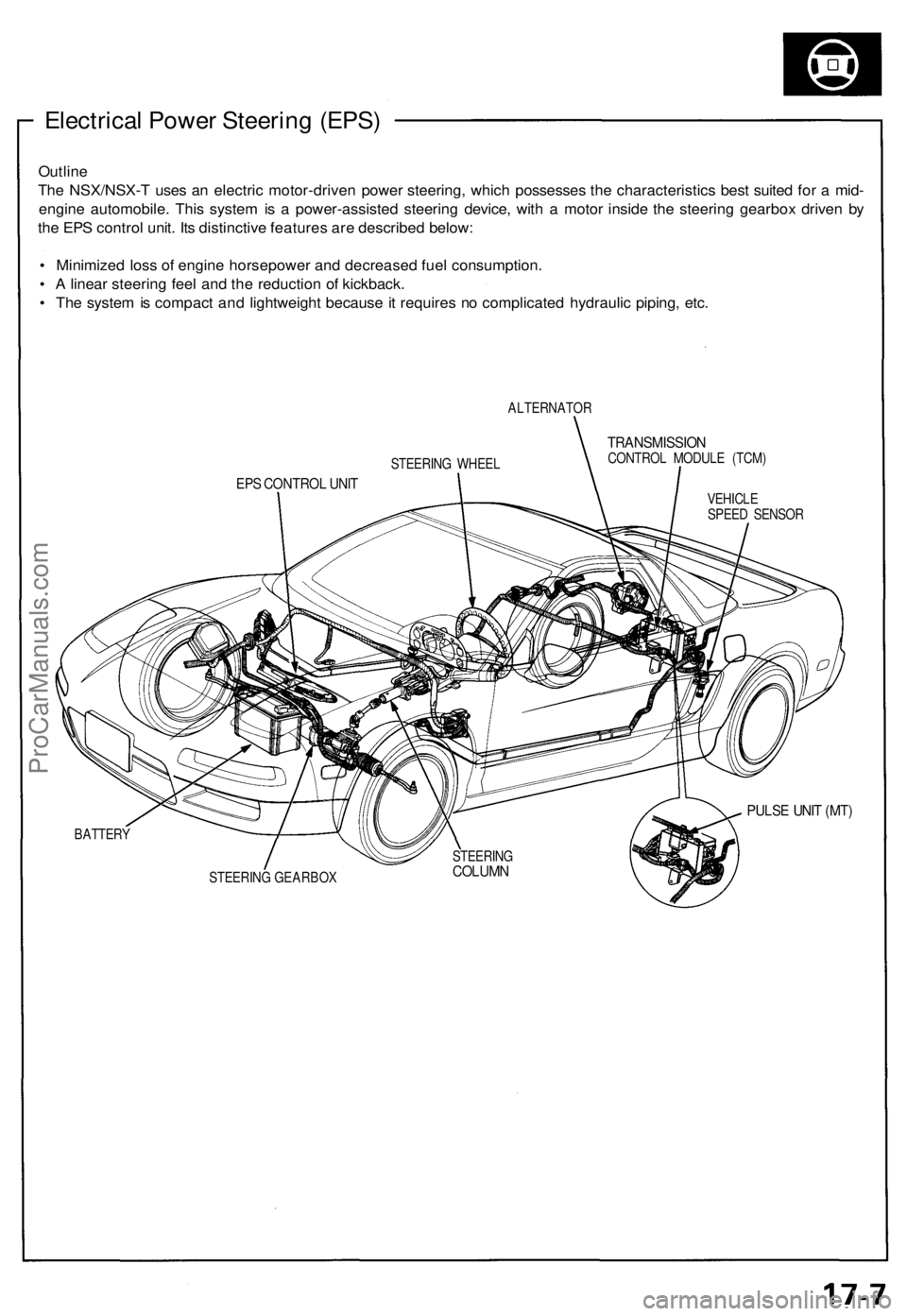

Electrical Power Steering (EPS)

Outline

The NSX/NSX-T uses an electric motor-driven power steering, which possesses the characteristics best suited for a mid-

engine automobile. This system is a power-assisted steering device, with a motor inside the steering gearbox driven by

the EPS control unit. Its distinctive features are described below:

• Minimized loss of engine horsepower and decreased fuel consumption.

• A linear steering feel and the reduction of kickback.

• The system is compact and lightweight because it requires no complicated hydraulic piping, etc.

ALTERNATOR

TRANSMISSION

CONTROL MODULE (TCM)

EPS CONTROL UNIT

VEHICLE

SPEED SENSOR

PULSE UNIT (MT)

BATTERY

STEERING GEARBOX

STEERING WHEEL

STEERING

COLUMNProCarManuals.com

Page 449 of 1640

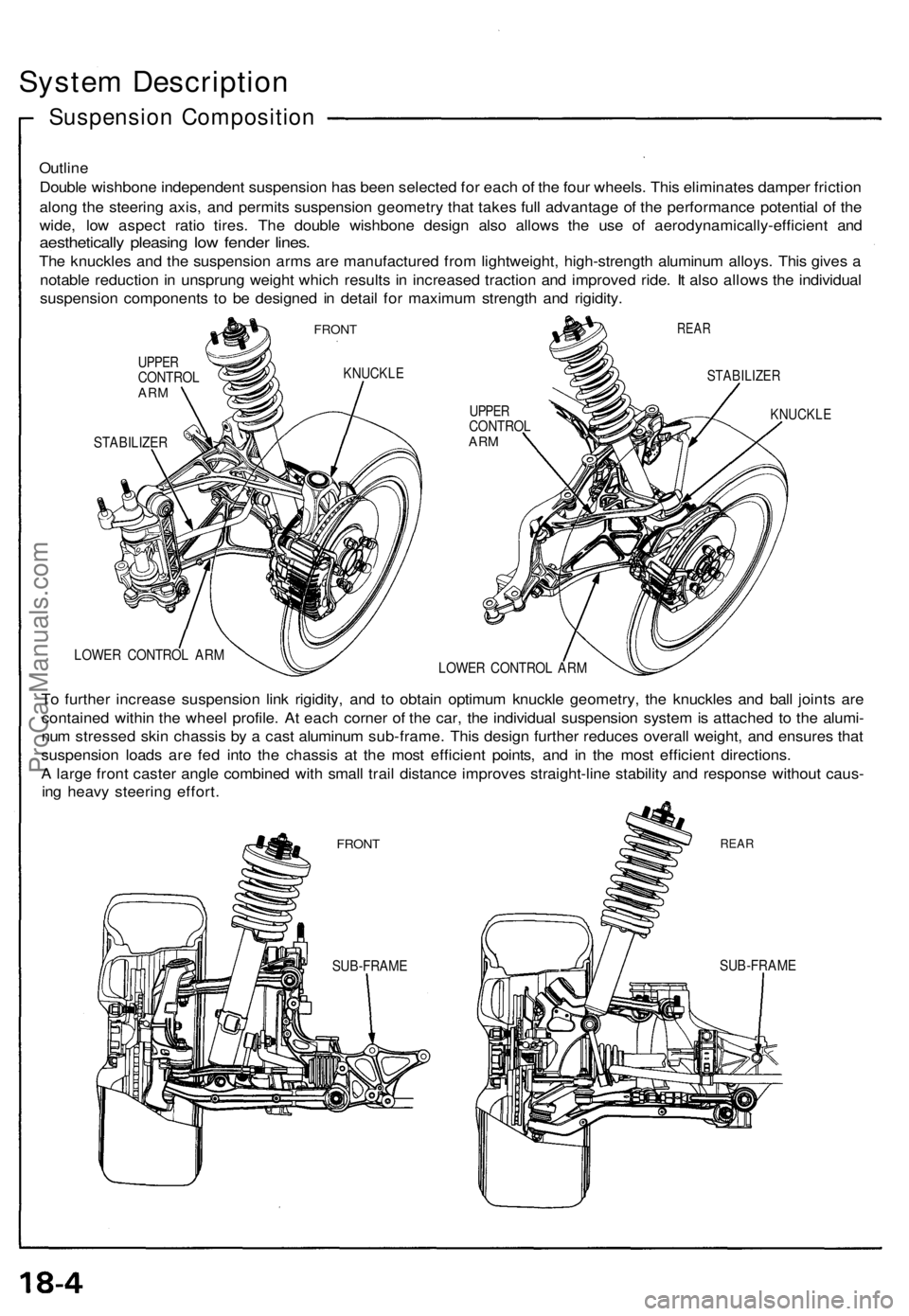

System Description

Suspension Composition

Outline

Double wishbone independent suspension has been selected for each of the four wheels. This eliminates damper friction

along the steering axis, and permits suspension geometry that takes full advantage of the performance potential of the

wide, low aspect ratio tires. The double wishbone design also allows the use of aerodynamically-efficient and

aesthetically pleasing low fender lines.

The knuckles and the suspension arms are manufactured from lightweight, high-strength aluminum alloys. This gives a

notable reduction in unsprung weight which results in increased traction and improved ride. It also allows the individual

suspension components to be designed in detail for maximum strength and rigidity.

FRONT

UPPER

CONTROL

ARM

KNUCKLE

STABILIZER

REAR

UPPER

CONTROL

ARM

STABILIZER

KNUCKLE

LOWER CONTROL ARM

LOWER CONTROL ARM

To further increase suspension link rigidity, and to obtain optimum knuckle geometry, the knuckles and ball joints are

contained within the wheel profile. At each corner of the car, the individual suspension system is attached to the alumi-

num stressed skin chassis by a cast aluminum sub-frame. This design further reduces overall weight, and ensures that

suspension loads are fed into the chassis at the most efficient points, and in the most efficient directions.

A large front caster angle combined with small trail distance improves straight-line stability and response without caus-

ing heavy steering effort.

FRONT

REAR

SUB-FRAME

SUB-FRAMEProCarManuals.com

Page 460 of 1640

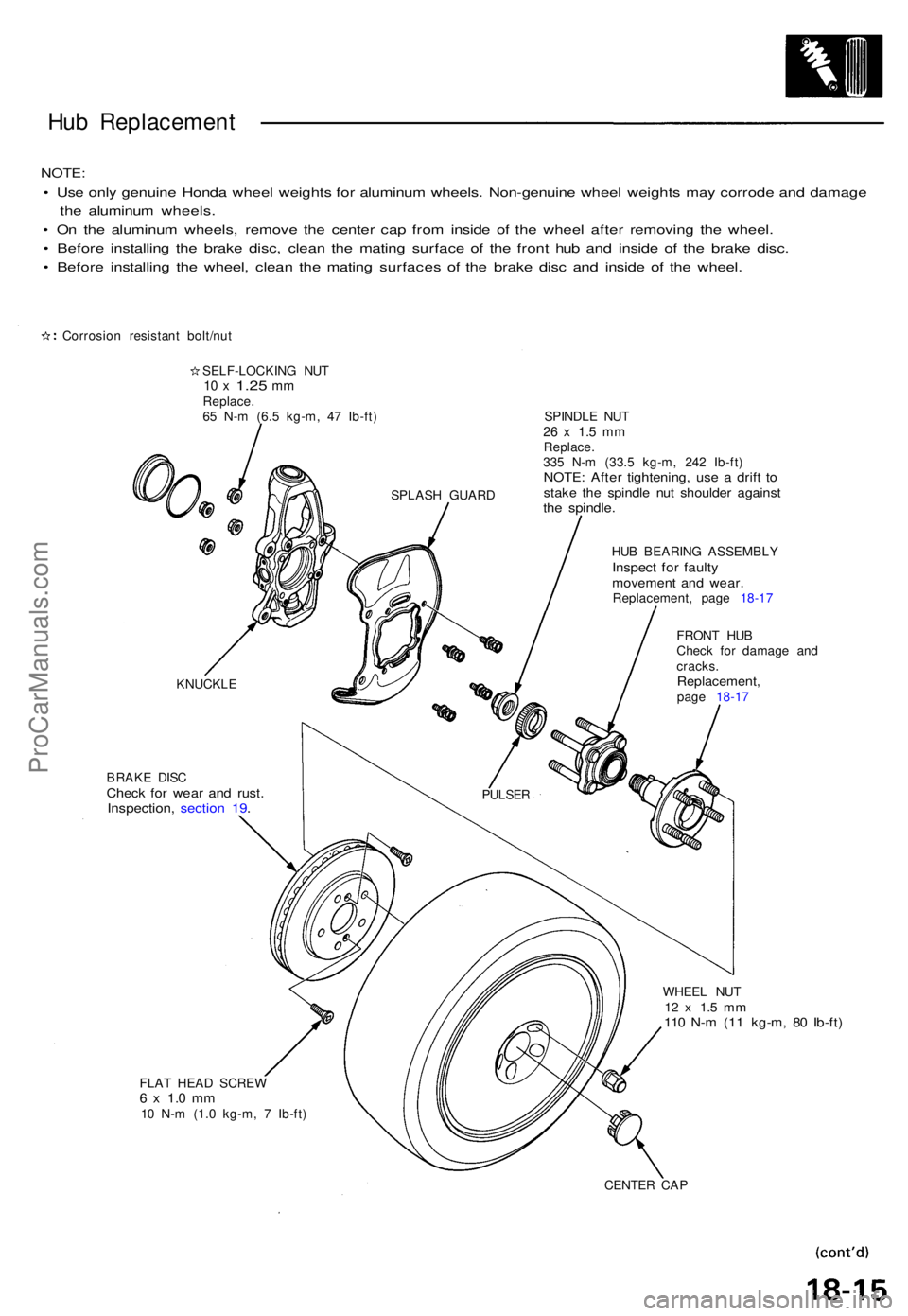

Hub Replacemen t

NOTE:

• Us e onl y genuin e Hond a whee l weight s fo r aluminu m wheels . Non-genuin e whee l weight s ma y corrod e an d damag e

th e aluminu m wheels .

• O n th e aluminu m wheels , remov e th e cente r ca p fro m insid e o f th e whee l afte r removin g th e wheel .

• Befor e installin g th e brak e disc , clea n th e matin g surfac e o f th e fron t hu b an d insid e o f th e brak e disc .

• Befor e installin g th e wheel , clea n th e matin g surface s of the brak e dis c an d insid e o f th e wheel .

Corrosio n resistan t bolt/nu t

SELF-LOCKIN G NU T

10 x 1.2 5 mmReplace .

6 5 N- m (6. 5 kg-m , 4 7 Ib-ft ) SPINDL E NU T

26 x 1. 5 m mReplace .

33 5 N- m (33. 5 kg-m , 24 2 Ib-ft )

NOTE : Afte r tightening , us e a drif t t ostak e th e spindl e nu t shoulde r agains tthe spindle .

HUB BEARIN G ASSEMBL YInspect fo r fault ymovemen t an d wear .Replacement , pag e 18-1 7

BRAK E DIS C

Chec k fo r wea r an d rust .Inspection , sectio n 19 .

FRON T HU B

Chec k fo r damag e an d

cracks .

Replacement ,page 18-1 7

WHEE L NU T

12 x 1. 5 m m110 N- m (1 1 kg-m , 8 0 Ib-ft )

FLAT HEA D SCRE W6 x 1. 0 m m10 N- m (1. 0 kg-m , 7 Ib-ft )

CENTER CA P

KNUCKL

E

PULSER

SPLAS H GUAR D

ProCarManuals.com

Page 476 of 1640

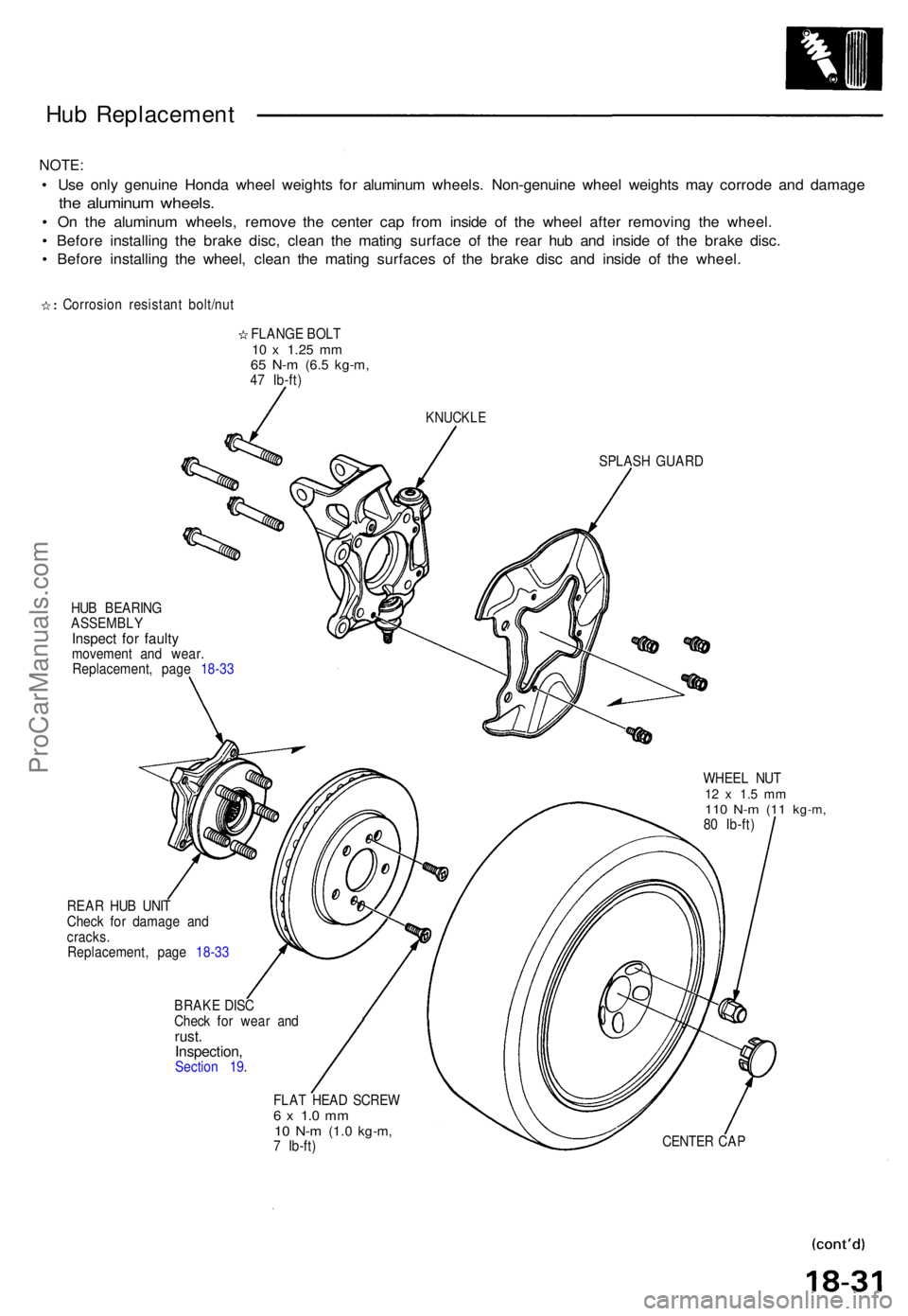

Hub Replacemen t

NOTE:

• Us e onl y genuin e Hond a whee l weight s fo r aluminu m wheels . Non-genuin e whee l weight s ma y corrod e an d damag e

the aluminu m wheels .

• O n th e aluminu m wheels , remov e th e cente r cap from insid e o f th e whee l afte r removin g th e wheel .

• Befor e installin g th e brak e disc , clea n th e matin g surfac e o f th e rea r hu b an d insid e o f th e brak e disc .

• Befor e installin g th e wheel , clea n th e matin g surface s o f th e brak e dis c an d insid e o f th e wheel .

Corrosio n resistan t bolt/nu t

FLANG E BOL T

10 x 1.2 5 mm65 N- m (6. 5 kg-m ,47 Ib-ft )

KNUCKL E

SPLASH GUAR D

HU B BEARIN G

ASSEMBL YInspect fo r fault ymovemen t an d wear .

Replacement , pag e 18-3 3

WHEEL NU T

12 x 1. 5 m m110 N- m (1 1 kg-m ,80 Ib-ft )

REA R HU B UNI T

Chec k fo r damag e an d

cracks .

Replacement , pag e 18-3 3

BRAK E DIS C

Chec k fo r wea r an d

rust .Inspection ,Section 19 .

FLAT HEA D SCRE W

6 x 1. 0 m m10 N- m (1. 0 kg-m ,7 Ib-ft ) CENTE

R CA P

ProCarManuals.com

Page 966 of 1640

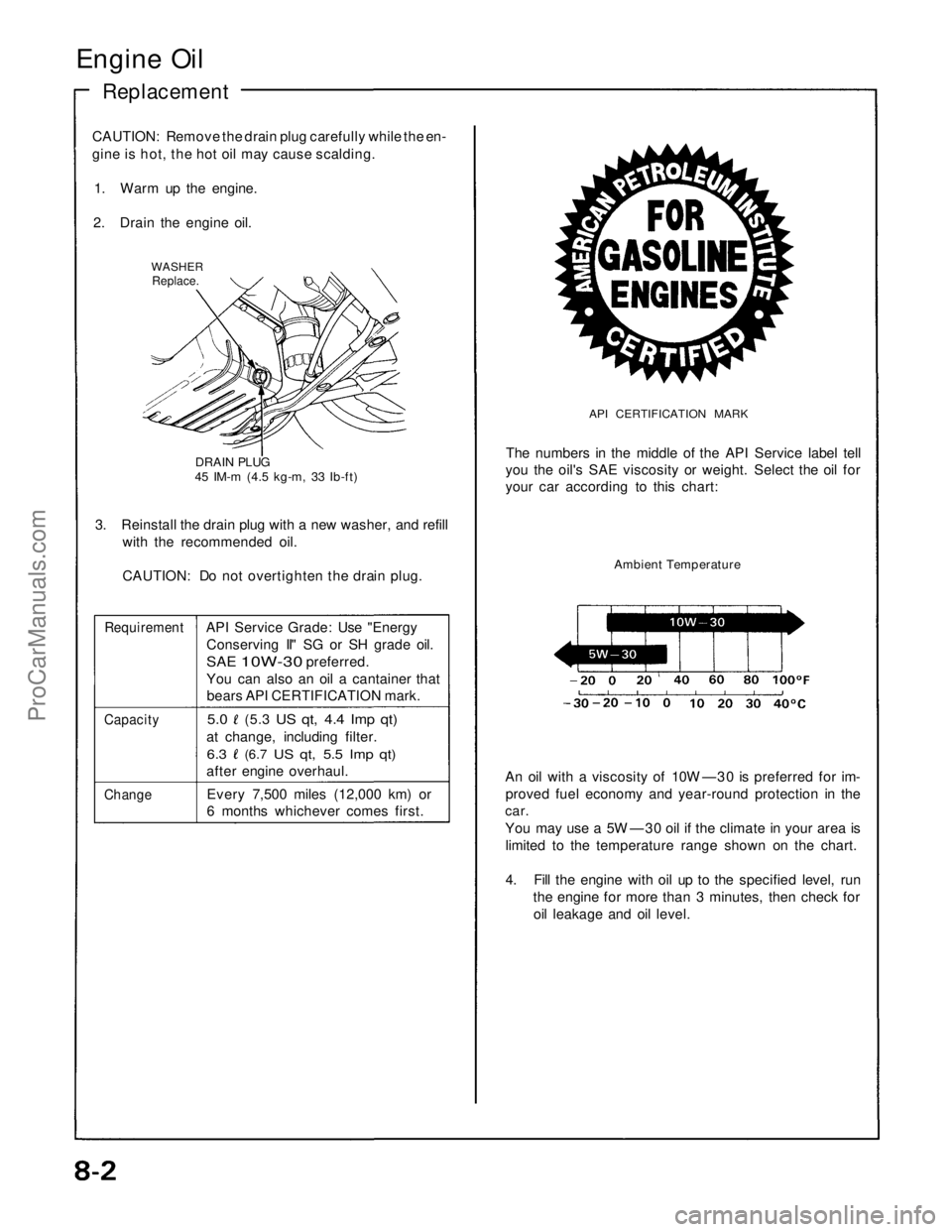

Engine Oil

Replacement

CAUTION: Remove the drain plug carefully while the en-

gine is hot, the hot oil may cause scalding.

1. Warm up the engine.

2. Drain the engine oil.

WASHER

Replace.

DRAIN PLUG

45 IM-m (4.5 kg-m, 33 Ib-ft)

3. Reinstall the drain plug with a new washer, and refill

with the recommended oil.

CAUTION: Do not overtighten the drain plug.

Requirement

API Service Grade: Use "Energy

Conserving II" SG or SH grade oil.

SAE

10W-30

preferred.

You can also an oil a cantainer that

bears API CERTIFICATION mark.

Capacity

5.0

(5.3

US qt, 4.4 Imp qt)

at change, including filter.

6.3

(6.7

US qt, 5.5 Imp qt)

after engine overhaul.

Change

Every 7,500 miles (12,000 km) or

6 months whichever comes first.

API CERTIFICATION MARK

The numbers in the middle of the API Service label tell

you the oil's SAE viscosity or weight. Select the oil for

your car according to this chart:

Ambient Temperature

An oil with a viscosity of 10W —30 is preferred for im-

proved fuel economy and year-round protection in the

car.

You may use a 5W —30 oil if the climate in your area is

limited to the temperature range shown on the chart.

4. Fill the engine with oil up to the specified level, run

the engine for more than 3 minutes, then check for

oil leakage and oil level.ProCarManuals.com

Page 978 of 1640

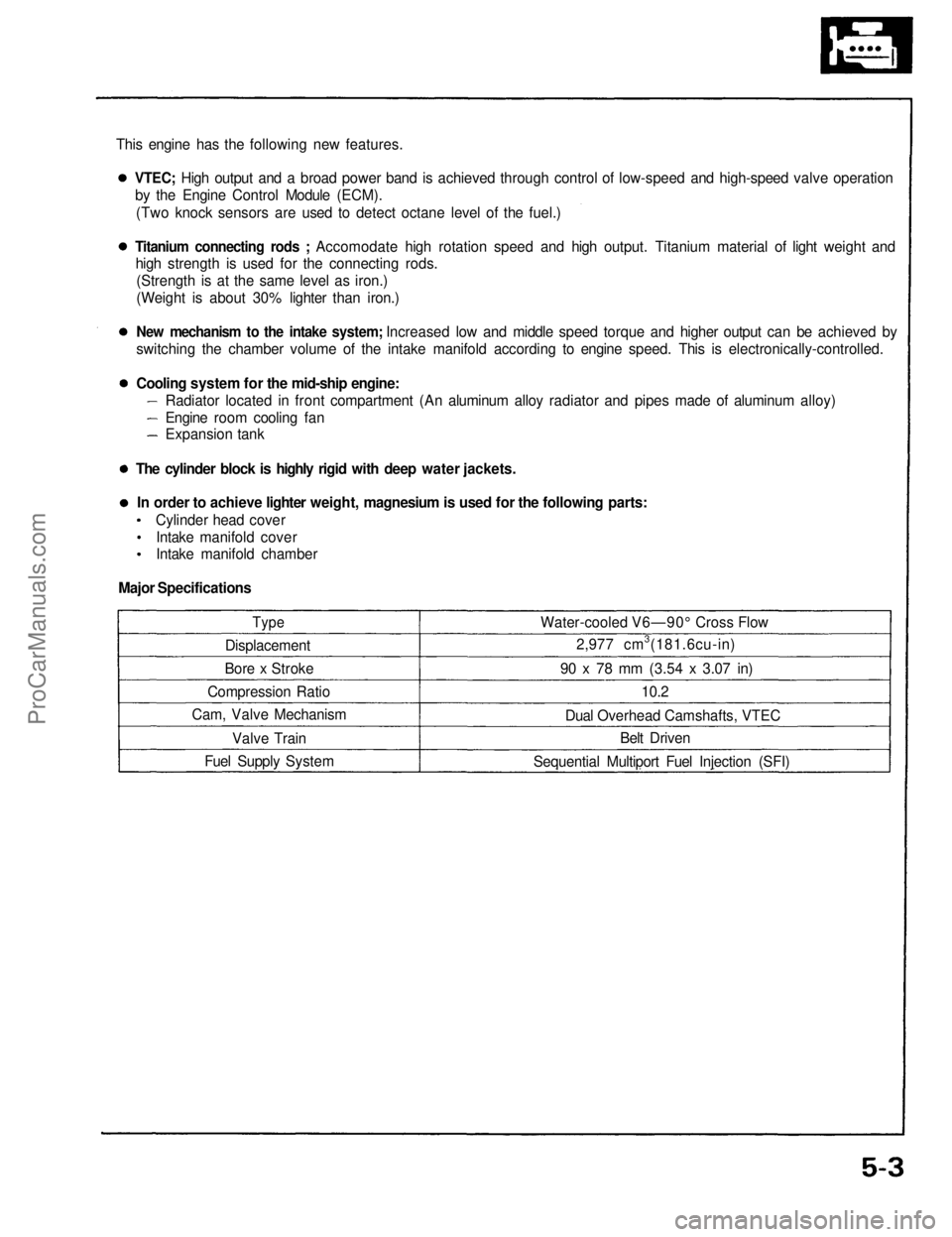

This engine has the following new features.

Type

Displacement

Bore x Stroke

Compression Ratio

Cam, Valve Mechanism

Valve Train

Fuel Supply System Water-cooled V6—90° Cross Flow

2,977 cm3(181.6cu-in)

90 x 78 mm

(3.54

x

3.07

in)

10.2

Dual Overhead Camshafts, VTEC Belt Driven

Sequential Multiport Fuel Injection (SFI)VTEC; High output and a broad power band is achieved through control of low-speed and high-speed valve operation

by the Engine Control Module (ECM).

(Two knock sensors are used to detect octane level of the fuel.)

Titanium connecting rods ; Accomodate high rotation speed and high output. Titanium material of light weight and

high strength is used for the connecting rods.

(Strength is at the same level as iron.)

(Weight is about 30% lighter than iron.)

New mechanism to the intake system; Increased low and middle speed torque and higher output can be achieved by

switching the chamber volume of the intake manifold according to engine speed. This is electronically-controlled.

Cooling system for the mid-ship engine:

Radiator located in front compartment (An aluminum alloy radiator and pipes made of aluminum alloy)

Engine room cooling fan

Expansion tank

The cylinder block is highly rigid with deep water jackets. In order to achieve lighter weight, magnesium is used for the following parts: Cylinder head coverIntake manifold cover

Intake manifold chamber

Major SpecificationsProCarManuals.com