brake sensor ACURA RL KA9 1996 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 356 of 1954

Cruise Control

Control Unit Input Test (cont'd)

Cavity Wire

Test condition

Test: Desired result

Possible cause if result is not obtained

3

13

7

6

14

12

2

5

10

9

11

1

BLK

LT GRN

LT GRN/BLK

LT GRN/RED

PNK

BLU/WHT

GRY

GRN/WHT

BLU/YEL

BRN

BRN/BLK

BRN/WHT

Under all conditions

Ignition switch ON (II) and

main switch ON

Resume button pushed

Cancel button pushed

Set button pushed

Cancel button pushed

Shift lever in , or

Ignition switch ON (II), and

main switch ON; raise the

front of the vehicle, and rotate

one wheel slowly while

holding the other wheel.

Ignition switch ON (II), main

switch ON; brake pedal

pressed, then released

Brake pedal pressed then

released

Ignition switch ON (II)

Under all conditions

Under all conditions

Under all conditions

Check for continuity to ground:

There should be continuity.

Check for voltage to ground:

There should be battery voltage.

Check for voltage to ground:

There should be battery voltage.

When testing terminal No. 7, there

should be no voltage on terminal No. 6.

Check for voltage to ground:

There should be battery voltage.

When testing terminal No. 7, there

should be voltage on terminal No. 6.

Check for voltage to ground:

There should be battery voltage.

When testing terminal No. 6, there

should be no voltage on terminal No. 7.

Check for voltage to ground:

There should be battery voltage.

When testing terminal No. 6, there

should be voltage on terminal No. 7.

Check for continuity to ground:

There should be continuity.

NOTE: There should be no continuity

when the shift lever is in other positions.

Check for voltage between the

BLU/ WHT and BLK terminals:

There should be cycle 0 - 5 V or

battery voltage.

Check for voltage to ground:

There should be 0 V with the pedal

pressed, and battery voltage with

the pedal released.

Check for voltage to ground:

There should be battery voltage with

the pedal pressed, and 0 V with the

pedal released.

Attach to ground:

The cruise light in the gauge assembly

should come on.

Check for resistance to ground:

There should be 80 -120

Check for resistance to ground:

There should be 70 -110

Check for resistance to ground:

There should be 40 - 60

• Poor ground (G401, G402)

• An open in the wire

• Blown No. 20 (20 A) fuse in the

under-dash fuse/relay box

• Faulty main switch

• An open in the wire

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty horn relay

• Faulty set/resume/cancel switch

• Faulty cable reel

• An open in the wire

• Short between LT GRN/BLK and

LT GRN/RED wires

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty horn relay

• Faulty set/resume/cancel switch

• Faulty cable reel

• An open in the wire

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty horn relay

• Faulty set/resume/cancel switch

• Faulty cable reel

• An open in the wire

• Short between LT GRN/BLK and

LT GRN/RED wires

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty horn relay

• Faulty set/resume/cancel switch

• Faulty cable reel

• An open in the wire

• Faulty A/T gear position switch

• Poor ground (G401, G402)

• An open in the wire

• Faulty vehicle speed sensor (VSS)

• An open in the wire

• Short to ground

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty brake switch

• An open in the wire

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty brake switch

• An open in the wire

• Blown bulb

• Faulty gauge circuit

• An open in the wire

• Faulty actuator solenoid

• An open in the wireProCarManuals.com

Page 558 of 1954

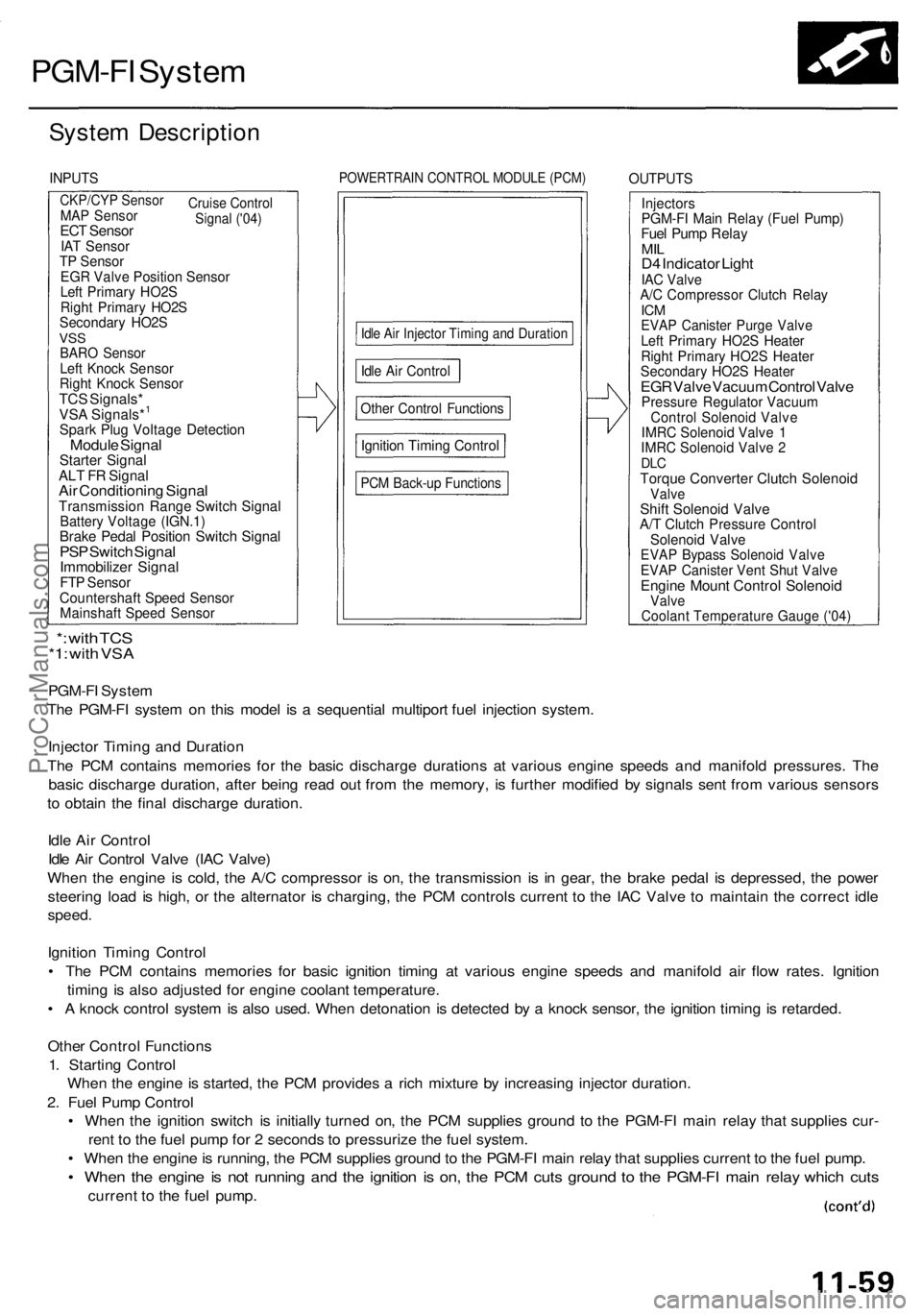

PGM-FI Syste m

System Descriptio n

INPUTSPOWERTRAI N CONTRO L MODUL E (PCM )OUTPUT S

CKP/CYP Senso r

Cruise

Control

Signal ('04)MA P Senso rECT Senso rIAT Senso rTP Senso rEGR Valv e Positio n Senso rLeft Primar y HO2 SRight Primar y HO2 SSecondar y HO2 SVSSBAR O Senso rLeft Knoc k Senso rRight Knoc k Senso rTCS Signals *VSA Signals*1

Spar k Plu g Voltag e Detectio nModule Signa lStarte r Signa lALT F R Signa lAir Conditionin g Signa lTransmissio n Rang e Switc h Signa lBattery Voltag e (IGN.1 )Brake Peda l Positio n Switc h Signa lPSP Switc h Signa lImmobilize r Signa lFTP Senso rCountershaf t Spee d Senso rMainshaf t Spee d Senso r

Idle Ai r Injecto r Timin g an d Duratio n

Other Contro l Function s

Ignition Timin g Contro l

PCM Back-u p Function s

InjectorsPGM-FI Mai n Rela y (Fue l Pump )Fuel Pum p Rela yMILD4 Indicato r Ligh tIAC Valv eA/C Compresso r Clutc h Rela yICMEVA P Caniste r Purg e Valv eLeft Primar y HO2 S Heate rRight Primar y HO2 S Heate rSecondar y HO2 S Heate rEGR Valv e Vacuu m Contro l Valv ePressur e Regulato r Vacuu mControl Solenoi d Valv eIMRC Solenoi d Valv e 1IMR C Solenoi d Valv e 2DL CTorqu e Converte r Clutc h Solenoi dValveShift Solenoi d Valv eA/T Clutc h Pressur e Contro lSolenoid Valv eEVAP Bypas s Solenoi d Valv eEVAP Caniste r Ven t Shu t Valv eEngin e Moun t Contro l Solenoi dValve

PGM-F I Syste m

Th e PGM-F I syste m o n thi s mode l i s a sequentia l multipor t fue l injectio n system .

Injecto r Timin g an d Duratio n

Th e PC M contain s memorie s fo r th e basi c discharg e duration s a t variou s engin e speed s an d manifol d pressures . Th e

basi c discharg e duration , afte r bein g rea d ou t fro m th e memory , i s furthe r modifie d b y signal s sen t fro m variou s sensor s

t o obtai n th e fina l discharg e duration .

Idl e Ai r Contro l

Idl e Ai r Contro l Valv e (IA C Valve )

Whe n th e engin e i s cold , th e A/ C compresso r i s on , th e transmissio n i s i n gear , th e brak e peda l i s depressed , th e powe r

steerin g loa d i s high , o r th e alternato r i s charging , th e PC M control s curren t t o th e IA C Valv e t o maintai n th e correc t idl e

speed .

Ignition Timin g Contro l

• Th e PC M contain s memorie s fo r basi c ignitio n timin g a t variou s engin e speed s an d manifol d ai r flo w rates . Ignitio n

timin g i s als o adjuste d fo r engin e coolan t temperature .

• A knoc k contro l syste m is als o used . Whe n detonatio n i s detecte d b y a knoc k sensor , th e ignitio n timin g is retarded .

Othe r Contro l Function s

1 . Startin g Contro l

Whe n th e engin e is started , th e PC M provide s a ric h mixtur e b y increasin g injecto r duration .

2 . Fue l Pum p Contro l

• Whe n th e ignitio n switc h i s initiall y turne d on , th e PC M supplie s groun d t o th e PGM-F I mai n rela y tha t supplie s cur -

ren t t o th e fue l pum p fo r 2 second s t o pressuriz e th e fue l system .

• Whe n th e engin e is running , th e PC M supplie s groun d to th e PGM-F I mai n rela y tha t supplie s current to th e fue l pump .

• Whe n th e engin e is no t runnin g an d th e ignitio n i s on , th e PC M cut s groun d t o th e PGM-F I mai n rela y whic h cut s

curren t t o th e fue l pump .

*: wit h TC S*1: wit h VS A

Idle Ai r Contro l

Coolant Temperature Gauge ('04)

ProCarManuals.com

Page 730 of 1954

Grade Logic Control System

How it works:

The PCM compares actual driving conditions with driving conditions memorized in the PCM, based on the input from the

vehicle speed sensor, throttle position sensor, engine coolant temperature sensor, barometric pressure sensor, brake

pedal position switch signal and shift lever position signal, to control shifting while a vehicle is ascending or descending a

slope.ProCarManuals.com

Page 1114 of 1954

Troubleshooting

DTC 5 , 5-4 , 5-8 : Rea r Whee l Loc k

The AB S contro l uni t monitor s th e rea r whee l senso r signal s durin g th e regula r diagnosi s (durin g driving) . Thi s diagnosi s

is no t performe d whe n th e parkin g brak e signa l i s ON . Th e AB S contro l uni t turn s th e AB S indicato r ligh t o n if i t detect s n o

signal(s ) fro m th e rea r whee l sensor(s ) du e to , fo r example , rea r whee l lock .

Possibl e causes :

Wheel spi n durin g cornerin g

Open circuit , interna l shor t o r shor t t o th e bod y groun d in th e whee l senso r syste m

Rear brak e dra g

Modulato r doe s no t decreas e pressur e properl y

Faulty AB S contro l uni t

— Whe n vehicl e i s driven , ABSindicato r ligh t i s ON .— Wit h th e SC S servic e connec -tor connecte d (se e pag e 19-40 ),DTC s 5 , 5- 4 and/o r 5- 8 ar e indi -

cated .

Chec k th e PAR K circuit :

1. Tur n th e ignitio n switc h O N (II) .2. Pres s th e parking brake pedal .

Doe s th e brak e syste m ligh t

com e on ? Parkin

g brak e switc h stuc k OFF .

Repai r ope n circui t betwee n th e

under-das h fuse/rela y bo x an d

parkin g brak e switch .

NOTE:The self-diagnosi s o f th e whee l senso r i s per -forme d i n thi s step .

Test-driv e wit h th e parkin g brak e released .

Does th e AB S indicato r ligh tcom e on ?

Chec k fo r rea r brak e drag :

1 . Rais e th e rea r o f th e vehicle ,

and suppor t i t wit h safet ystands (se e sectio n 1 ).2 . Spi n th e lef t and/o r righ t rea rwhee l an d chec k fo r brak e

drag . I

s cod e 4- 4 o r 4- 8 indicated ?

Perform th e troubleshootin g fo rthe rea r whee l sensor .

Perfor m th e appropriat e trouble -

shootin g fo r th e code .

Doe s th e brak e drag ?

Repair th e rea r brak e drag .

Check th e AB S functio n (se epage 19-95 ).

Th e probabl e caus e wa s tha t

tractio n wa s los t du e t o exces -

siv e cornerin g speed , etc .

Chec

k th e self-diagnosis :

Test-driv e th e vehicl e a t speed s

of 6 mp h (1 0 km/h ) o r more .

Confir m th e DT C (se e pag e 19-40 ).

ProCarManuals.com

Page 1153 of 1954

Anti-lock Brake System (ABS)

Features/Construction (cont'd)

ABS Control

The ABS control unit detects the wheel speed based on the wheel sensor signal it received, then it calculates the vehicle

speed based on the detected wheel speed. The control unit detects the vehicle speed during deceleration based on the

rate of deceleration.

The ABS control unit calculates the slip rate of each wheel, and it transmits the control signal to the modulator unit

solenoid valve when the slip rate is high.

The pressure reduction control has 3-modes: pressure reduction, pressure retaining, and pressure intensifying.

ABS CONTROL UNITProCarManuals.com

Page 1196 of 1954

TCS CONTROL UNIT 20P CONNECTOR

Wire side of female terminals

VB: Battery Voltage

Terminal

number

1

2

4

5

6

9

10

11

12

13

14

15

16

17

20

Wire

color

BLK/YEL

GRN/RED

BLU

PNK/BLU

BLK/WHT

BLK

BRN/WHT

GRN/WHT

BLU

GRN/ORN

BLK/ORN

BRN/BLK

WHT/BLU

BLU/GRY

GRN

BRN

Terminal sign

(Terminal name)

IG1

(Ignition 1)

PARK

(Parking)

SCS

(Service check

signal)

STR-GND

(Steering ground)

AT-SHIFT

(AT shift)

FSR

(Fail-safe relay)

PMG

(Power motor

Ground)

VPM

(Voltage power

motor)

STOP

(Stop)

NEP (Engine

speed pulse)

BARO

(Barometric)

TC-FC

(Traction control

fuel cut)

LG2

(Logic ground 2)

STR-VCC (Steer-

ing power supply)

WARN2

(Warning 2)

SH-MOT

(Shield motor)

MOT +

(Motor +)

MOT-

(Motor -)

Description

Detects ignition switch

IG1 signal

Detects parking brake

switch signal

Detects service check

connector signal

(Diagnostic trouble

code indication)

Ground for the steering

angle sensor

Detects A/T shift posi-

tion signal

Drives fail-safe relay

Power ground for the

TCS control valve

actuator motor

Power source for the

TCS control valve

actuator motor

Detects brake pedal

position switch signal

Detects engine speed

signal

Detects barometric

sensor signal

TCS Fl, Fuel cut

(torque down) signal

Ground for the logic

circuit

Power source for the

steering angle sensor

Drives TCS indicator light

(The indicator light comes

on by the self-bias)

Shield for the TCS con-

trol valve actuator motor

Drives TCS control

valve actuator motor

Drives TCS control

valve actuator motor

Measurement

terminals

1-GND

2

3-GND

4-GND

5-GND

6-GND

9-GND

10-GND

11-GND

12-GND

13-GND

14-GND

15-GND

16-GND

17-GND

19-20

20-19

Voltage

Conditions

(Ignition Switch ON (II))

Depress the parking

brake pedal.

Release the parking

brake pedal.

SCS service connector

connected.

SCS service connector

disconnected.

Shift the transmission

to position, then

start the engine.

Start the engine.

Start the engine.

Brake pedal depressed.

Brake pedal released.

Engine idling

TCS is functioning,

(maximum fuel cut)

TCS is not functioning.

Indicator light ON

Indicator light OFF

TCS is functioning.

TCS is not functioning.

TCS is functioning.

TCS is not functioning.

Output

voltage

VB

Below 0.6 V

VB

0V

5V

Below 0.3V

About 4V

(5V 0V)

VB

1.5V

Below 0.3 V

0V

VB

VB

0V

About 6V

(12V

0V)

About 3 V

About 1.5V

About 4.5 V

(5 V,

PWM)

Below 0.3V

About 5 V

About 2 V

VB

VB

0V

VB

0VProCarManuals.com

Page 1197 of 1954

Troubleshooting Precautions

1. In any of these cases, the TCS indicator light may come on or stay on even the TCS system is normal.

The coolant temperature is 32°F (0°C) or below.

The parking brake is applied for more than 30 seconds while the vehicle is being driven.

The tires are not inflated to the specified pressure.

The wheel sensor signal is interrupted during driving at speeds of 6 mph (10 km/h) or above due to, for example, a

vehicle spinning.

The MAP sensor, the coolant temperature sensor, the ICM or the atmospheric pressure sensor system of the PGM-FI

system is faulty.

2. TCS does not function when the TCS indicator light is ON.

3. When both the TCS indicator light and the MIL are ON, troubleshoot the PGM-FI system first.

4. When both the TCS indicator light and the ABS indicator light are ON, troubleshoot the ABS first.

5. The DTC 4-9 (ABS down) is memorized when the ABS control unit cannot output the wheel speed signal due to, for

example, a missing or blown ABS B2 (15 A) fuse. If you fail to erase the DTC of the TCS after troubleshooting the ABS,

the DTC remains in the TCS control unit memory. Therefore, be sure to test-drive the vehicle, and check the TCS indica-

tor light before starting to troubleshoot the TCS.ProCarManuals.com

Page 1234 of 1954

Component Locations

SERVICE CHECK CONNECTOR (2P)

RIGHT-REAR WHEEL SENSOR

VSA CONVERTER UNIT

VSA MODULATOR

CONTROL UNIT

TCS CONTROL

VALVE SENSOR

RIGHT-FRONT

WHEEL SENSOR

PRECHARGE

PUMP MOTOR

STEERING

ANGLE SENSOR

YAW RATE/LATERAL

ACCELERATION SENSOR

TCS CONTROL VALVE

ACTUATOR

UNDER-HOOD

RELAY BOX C

UNDER-HOOD

FUSE/RELAY BOX

VSA OFF SWITCH

UNDER-DASH FUSE/RELAY BOX

LEFT-FRONT WHEEL SENSOR

LEFT-REAR

WHEEL SENSOR

GAUGE ASSEMBLY

ABS INDICATOR

VSA SYSTEM INDICATOR

UNDER-HOOD FUSE/RELAY BOX

STOP/HORN

(20 A) FUSE

BRAKE SYSTEM INDICATOR

VSA ACTIVATION INDICATOR

UNDER-DASH FUSE/RELAY BOX

TCS

(15 A) FUSE

VSA

(20 A) FUSE

METER

(15 A) FUSE

ECU

(20 A) FUSE

METER

(7.5 A) FUSE

BATTERY

(120 A) FUSE

VSA MOTOR (40 A) FUSE

IG SW (50 A) FUSE

UNDER-HOOD RELAY BOX C

FAIL-SAFE RELAY

GAUGE RELAY

PCM

R/C MIRROR

(7.5 A) FUSEProCarManuals.com

Page 1279 of 1954

Troubleshooting

DTC 71: Abnormal Wheel Speed Signal

Are any DTCs except 71 indicated?

Check the tires.

Are tires with specified size and

inflated to specification?

Check for brake drag.

Do the brakes drag?

Visually check for appropriate

wheel sensor and pulser installa-

tion (see table).

Are they installed correctly?

Check the four pulser gears for a

chipped tooth (see table).

Is the pulser OK?

Problem Verification:

1. Clear the DTC.

2. Test-drive the vehicle at 19

mph (30 km/h) or more.

3. Verify the DTC.

Is DTC 71 indicated?

YES

Check for loose terminals in the

VSA control unit 42P connector.

If necessary, substitute a known-

good VSA modulator-control

unit, and recheck.

Preform the appropriate trou-

bleshooting for the DTC.

Replace the tire(s) with the spec-

ified size.

Repair the brake drag.

Reinstall or replace the wheel

sensor or pulser.

Replace the driveshaft or hub

unit. (Chipped pulser gear.)

The system is OK at this time.

Verify the DTC.ProCarManuals.com

Page 1304 of 1954

VSA Modulator-Control Unit

Removal/Installation

NOTE:

Do not spill brake fluid on the vehicle; it may damage the paint; if brake fluid does contact the paint, wash it off imme-

diately with water.

Take care not to damage or deform the brake lines during removal and installation.

To prevent the brake fluid from flowing, plug and cover the hose ends and joints with a shop towel or equivalent material.

Removal

1. Disconnect the pressure sensor 3P connector.

2. Pull the locking lever of the VSA control unit 42P connec-

tor up, then disconnect the connector.

3. Disconnect the six brake lines.

4. Remove the two 8 mm nuts.

5. Remove the VSA modulator-control unit.

Installation

1. Install the VSA modulator-control unit, then tighten the

two 8 mm nuts.

2. Align the connecting surfaces of the VSA control unit 42P

connector.

3. Push the locking lever of the VSA control unit 42P connec-

tor down until you hear a click.

4. Connect the pressure sensor 3P connector.

5. Connect the six brake lines.

6. Perform the precharge brake line bleeding (see page 19-

271).

7. Bleed the brake system, starting with the front wheels.

8. Start the engine, and check that the ABS indicator goes

off.

9. Test-drive the vehicle, and check that the ABS indicator

does not come on.

To right-rear

To left-rear

PRESSURE SENSOR

3P CONNECTOR

VSA MODULATOR

CONTROL UNIT

LOCKING LEVER

VSA CONTROL UNIT

42P CONNECTOR

To right-front

To left-front

FLARE NUT

15 N-m (1.5 kgf-m, 11 Ibf-ft)

MOUNTING BOLT

VSA CONTROL UNIT 42P CONNECTOR

8 mm BOLT

22 N-m (2.2 kgf-m, 16 Ibf-ft)

8 mm NUT

9 N-m (0.9 kgf-m, 7 Ibf-ft)

RUBBER MOUNT

BRACKETProCarManuals.com