Alfa Romeo GT 2005 Owner handbook (in English)

Manufacturer: ALFA ROMEO, Model Year: 2005, Model line: GT, Model: Alfa Romeo GT 2005Pages: 307, PDF Size: 6.05 MB

Page 211 of 307

CORRECT USE OF THE CAR

209

Keep your speed

down when snow

chains are fitted.

Do not exceed 50 km/h. Avoid

potholes, steps and pavements to

prevent damaging the tyres, sus-

pension and steering. Remember

that with snow chains fitted the

brake distance will increase.

VEHICLE INACTIVITY

If the vehicle is to be left inactive for

long periods, the following precautions

should be noted:

– House the vehicle under cover in a dry

and possibly ventilated place.

– Engage a gear.

– Check that the handbrake is not

engaged.

– Clean and protect the paintwork by

protective wax.

– Cover the rubber windscreen and

rearscreen wiper blades with talcum pow-

der and raise them off the glass.

– Open the windows slightly.

– Inflate the tyres to a pressure of 0.5

bars above normal. If possible rest the

tyres on wooden planks and periodically

check the pressure.

– Do not turn on the electronic alarm

system.– Disconnect the battery negative termi-

nal (–) from the battery and check the

battery charge. This check should be

repeated once a month during stowage.

Charge the battery if the loadless voltage

is below 12,5V.

– Do not empty the engine cooling sys-

tem.

– Cover the vehicle with a fabric or per-

forated plastic cover. Do not use compact

plastic covers which prevent the humidity

on the surface of the vehicle from evapo-

rating. Snow chains cannot be

fitted to the compact

spare wheel. So, if a front

(drive) wheel is punctured and

chains are needed, a rear wheel

should be fitted to the front of

the vehicle (inflate the tyres to

the specified pressure as soon as

possible) and the spare wheel

should be fitted to the rear. This

way, with two normal drive

wheels, snow chains can be fitted

to them to solve an emergency.

With snow chains fitted

it is advisable to turn off

the ASR system. Press

the ASR-OFF button, led on but-

ton on.

Page 212 of 307

IN AN EMERGENCY

210

3) Fully depress the accelerator pedal

and keep it pressed. The

Uwarning light

will come on for eight seconds and then

go off, now release the accelerator pedal.

4) The

Uwarning light begins to flash:

after it has flashed the same number of

times as the first digit on the CODE card,

press the accelerator pedal and keep it

pressed until the

Uwarning light turns

on (for four seconds) and then goes off;

now release the accelerator pedal.

5) The

Uwarning light starts to flash:

after the number of flashes corresponding

to the second digit on the CODE card,

press the accelerator pedal and keep it

pressed.

6) Repeat this procedure for the remain-

ing digits on the CODE card.

7) After entering the last figure, keep

the accelerator pedal pressed. The

U

warning light turns on (for four seconds)

and then goes off; now release the accel-

erator pedal.8) A quick flash of the

Uwarning light

(for about four seconds) confirms that the

operation has been carried out correctly.

9) Start the engine turning the ignition

key from MARtoAV Vwithout return-

ing the key to the STOPposition.

Conversely, if the

Uwarning light stays

on, turn the key to STOPand repeat the

procedure starting from point 1).

IMPORTANTAfter emergency starting

it is advisable to contact Alfa Romeo

Authorised Services, because the emer-

gency procedure must be repeated each

time the engine is started.

EMERGENCY

STARTING

If it is not possible to deactivate the

engine inhibitor with the Alfa Romeo

CODE system, the

YandUwarning

lights stay on and the engine will not

start. Emergency starting is needed to

start the engine.

IMPORTANTYou are advised to care-

fully read the entire procedure before car-

rying it out.

If a mistake is made during the emer-

gency procedure, the ignition key should

be turned to STOPand the operations

must be repeated from the start (point 1).

1) Read the 5-figure electronic code on

the CODE card.

2) Turn the ignition key to MAR.

I I

N N

A A

N N

E E

M M

E E

R R

G G

E E

N N

C C

Y Y

Page 213 of 307

IN AN EMERGENCY

211

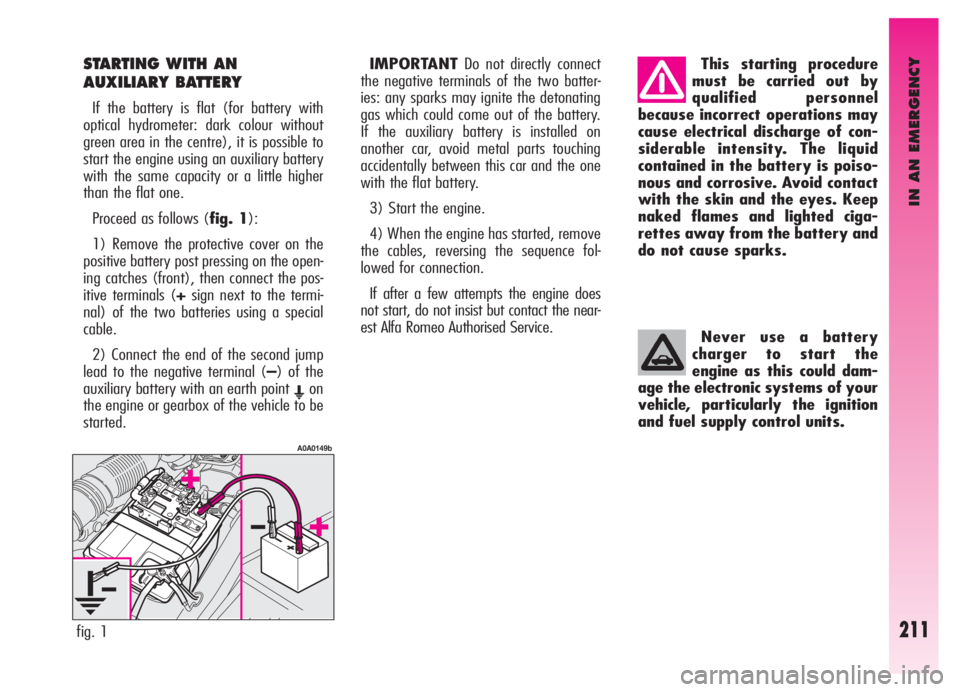

STARTING WITH AN

AUXILIARY BATTERY

If the battery is flat (for battery with

optical hydrometer: dark colour without

green area in the centre), it is possible to

start the engine using an auxiliary battery

with the same capacity or a little higher

than the flat one.

Proceed as follows (fig. 1):

1) Remove the protective cover on the

positive battery post pressing on the open-

ing catches (front), then connect the pos-

itive terminals (+sign next to the termi-

nal) of the two batteries using a special

cable.

2) Connect the end of the second jump

lead to the negative terminal (–) of the

auxiliary battery with an earth point

Eon

the engine or gearbox of the vehicle to be

started.IMPORTANTDo not directly connect

the negative terminals of the two batter-

ies: any sparks may ignite the detonating

gas which could come out of the battery.

If the auxiliary battery is installed on

another car, avoid metal parts touching

accidentally between this car and the one

with the flat battery.

3) Start the engine.

4) When the engine has started, remove

the cables, reversing the sequence fol-

lowed for connection.

If after a few attempts the engine does

not start, do not insist but contact the near-

est Alfa Romeo Authorised Service.

fig. 1

A0A0149b

This starting procedure

must be carried out by

qualified personnel

because incorrect operations may

cause electrical discharge of con-

siderable intensity. The liquid

contained in the battery is poiso-

nous and corrosive. Avoid contact

with the skin and the eyes. Keep

naked flames and lighted ciga-

rettes away from the battery and

do not cause sparks.

Never use a battery

charger to start the

engine as this could dam-

age the electronic systems of your

vehicle, particularly the ignition

and fuel supply control units.

Page 214 of 307

IN AN EMERGENCY

212

STARTING BY INERTIA

If the car is equipped with “Kit for tyre

repair Fix&Go“, see the instructions con-

tained in the following chapter.

GENERAL INSTRUCTIONS

As an alternative to FIX & GO, the com-

pact spare wheel or a wheel with the nor-

mal size can be supplied upon request;

wheel changing and correct use of the

jack and compact spare wheel call for

some precautions as listed below.

IN THE EVENT OF A PUNCTURE

Never push, tow or

coast start the vehicle.

This could cause fuel to

flow into the catalyst damaging

it irreversibly.

Remember that the

engine brake and power

steering are not opera-

tional until the engine is started,

therefore, much greater effort

than usual is needed on the brake

pedal and steering wheel.

Signal the presence of

the stationary vehicle

according to current regu-

lations: hazard warning lights,

reflecting triangle etc..

Any passengers should leave

the car and wait for the wheel to

be changed out of harm of the

traffic.

If parked on a slope or rough

surface, chock the wheels with

wedges or other suitable devices

to prevent the car from rolling.

Never start the engine

with the car jacked.

When driving with a

trailer, disconnect the trailer

before raising the car.

The compact spare wheel is spe-

cific to your car, do not use it on

other models, or use the spare

wheel of other models on your

vehicle.

Should the type of wheels used

be changed (alloy rims instead of

steel), it is also necessary to

change the whole set of fastening

bolts with others of suitable size.

The compact spare wheel is nar-

rower than normal wheels, it

should be used only for the dis-

tance necessary to reach a service

point to have the punctured tyre

repaired and, during its use, the

car speed must not exceed 80

km/h.

Page 215 of 307

IN AN EMERGENCY

213

The spare wheel has a

sticker that summarises

the main cautions for use

and limitations. The sticker

should never be removed or cov-

ered. The sticker contains the fol-

lowing in four languages:

CAUTION! FOR TEMPORARY

USE ONLY! MAX 80 km/h!

REPLACE BY NORMAL WHEEL AS

SOON AS POSSIBLE. DO NOT

COVER THIS LABEL IN USE.

Never fit a wheel cap on a com-

pact spare wheel.

The vehicle will handle differ-

ently with the spare wheel fitted:

avoid heavy braking and acceler-

ating, sharp corners and fast

bends.The life of the spare

wheel is approx. 3000

km, after this distance it

should be replaced with another

of the same type.

Never attempt to fit a conven-

tional tyre on a rim designed for

use as a compact spare wheel.

Have the punctured wheel

repaired and refitted as soon as

possible.

Two or more compact spare

wheels should never be used

together.

Do not grease the threads of

bolts before installing them; they

might slip out.

The jack only serves for chang-

ing wheels on the car with which

it is provided or on cars of the

same model. It must not be used

for other purposes such as for

instance raising cars of other

models. In no case should it be

used for repairs under the vehi-

cle.

Incorrect positioning of the jack

may cause the jacked vehicle to

fall.

Do not use the jack for higher

capacities than stated on its

label.Snow chains cannot be

fitted on the compact

spare wheel, so, if a front

wheel is punctured and chains

need to be used, the front axle

should be fitted with normal

wheels and the compact spare

wheel fitted to the rear. This

way, with two normal wheels at

the front, snow chains can be fit-

ted thereby solving the emer-

gency situation.

Never tamper with the inflation

valve.

Do not insert tools of any kind

between the rim and the tyre.

Check, and if necessary, restore

the pressure of the tyres and of

the compact spare wheel to the

values given in the “Technical

Specifications” chapter.

Page 216 of 307

IN AN EMERGENCY

214

CHANGING A WHEEL

Please be informed that:

– the jack mass is 2,100 kg.

– the jack requires no adjustment.

– the jack cannot be repaired. In the

event of breakage, it must be replaced by

another original one.

– no tools other than its operating crank

can be fitted to the jack.

To change a wheel, proceed as follows:– Stop the car in such a position that it

is not dangerous for the traffic, where it is

possible to change the wheel safely.

Where possible, park on a level, compact

surface.

– Switch off the engine and engage the

handbrake.

– Engage first gear or reverse.– Use handle(A-fig.2) to remove the

stiff covering (B).

– Loosen the clamping device (A-

fig. 3).

– Take out the tool container (B) and

take it near the wheel to be changed.

– Take the spare wheel (C).

– Remove the wheel cap (A-fig. 4)

(only versions with steel rims)

fig. 2

A0A0645b

fig. 3

A0A0151b

fig. 4

A0A0154b

Page 217 of 307

IN AN EMERGENCY

215

– Using the wrench provided (A-

fig. 5), loosen the fastening bolts by

about one turn.

– Set the jack under the car, near the

wheel to be changed taking care not to

damage the plastic streamlined guard.

– Work the jack crank (A-fig. 6), to

extend it until the groove (B) on the

upper part of jack is correctly inserted on

the lower profile of the body (C) approx.

40 cm from the profile of the wheelhouse.

– Work the jack and raise the car until

the wheel is a few centimetres from the

ground.

– Completely unscrew the fastening

bolts and remove the wheel.– Make sure that the contact surfaces of

the spare wheel with the hub are clean

and free of impurities which may later

cause the fastening bolts to slacken.

– Install the spare wheel matching the

hole (A-fig. 7) with the corresponding

pin (B).

– Using the wrench provided, fasten the

five bolts.

– Lower the car and remove the jack.

– Using the wrench provided, fully tighten

the bolts in the sequence shown in fig. 8.REFITTING A NORMAL WHEEL

– Following the procedure described

previously, raise the car and remove the

spare wheel.

For versions with steel rims:

– Fit the normal wheel matching the

hole (A-fig. 7) with the corresponding

pin (B).

– Make sure that the contact surfaces of

the wheel with the hub are clean and free

of impurities which may later cause the

fastening bolts to slacken.

fig. 5

A0A0694b

fig. 6

A0A0695b

Page 218 of 307

IN AN EMERGENCY

216

– Using the wrench provided, tighten

the fastening bolts.

– Lower the car and remove the jack.

– Using the wrench provided, fully tight-

en the bolts in the sequence shown previ-

ously for the compact spare wheel fig. 8.

– Place the cap near the wheel so that

the inflation valve can come through the

slot provided on the cap.

– Press the circumference of the cap,

starting from the parts nearest to the infla-

tion valve until it is inserted completely.

IMPORTANTIncorrect fitting may

cause the wheel cap to come off when the

car is travelling.For versions with alloy rims:

– Tighten the pin (A-fig. 9) in one of

the fastening bolt holes on the wheel hub.

– Insert the wheel on the pin and, using

the wrench provided, tighten the four bolts

available. This is facilitated by the exten-

sion provided (B).

– Remove the pin (A-fig. 9) and tight-

en the last fastening bolt.

– Lower the car and remove the jack.

– Using the wrench provided, tighten

the bolts in the sequence shown previous-

ly for the compact spare wheel fig. 8.After refitting a wheel:

– stow the spare wheel in the space pro-

vided in the boot

– insert the jack in its container forcing

it lightly to prevent it from vibrating when

travelling

– place the tools used in the housings in

the container

– stow the container complete with tools

on the spare wheel and secure everything

with the clamping device (A-fig. 3)

– correctly re-position the stiff cover.

fig. 7

A0A0155b

fig. 8

A0A0156b

fig. 9

A0A0693b

Page 219 of 307

IN AN EMERGENCY

217

QUICK TYRE REPAIR

KIT FIX&GO automatic

The car is provided with the quick tyre re-

pair kit “FIX&GO automatic”, instead of the

traditional tool kit and space-saver spare

wheel.

The kit fig. 10, is placed in the boot. In

this container are also housed the screw-

driver and the tow hitch. The quick tyre repair kit includes:

– a bottle A-fig. 10containing the seal-

er, fitted with:

– filling pipe B

– sticker Cbearing the notice “max. 80

km/h”, to be placed in a position visible

to the driver (on the instrument panel) af-

ter fixing the tyre;

– compressor Dwith pressure gauge and

fittings;– instruction brochure fig. 11, to be used

for prompt and proper use of the quick re-

pair kit and to be then handed to the per-

sonnel charged with handling the tyre treat-

ed with the tyre repair kit;

– a pair of protection gloves located in the

side space of the compressor;

– adapters for inflating different elements.

fig. 10

A0A1095b

fig. 11

A0A1096b

Page 220 of 307

IN AN EMERGENCY

218

Hand the instruction

brochure to the personnel

charged with treating the

tyre repaired with the kit.

In the event of a puncture

caused by foreign bodies,

it is possible to repair tyres

showing damages on the track or

shoulder up to max 4 mm diame-

ter. IT SHOULD BE NOTICED THAT:

The sealing fluid of the quick tyre repair kit

is effective with external temperatures be-

tween –20°C and +50°C. The sealing flu-

id has limited life.

Holes and damages on

the tyre side walls cannot

be repaired. Do not use the

quick tyre repair kit if damaging

is due to running with flat tyre.

Repairs are not possible

in case of damages on the

wheel rim (bad groove dis-

tortion causing air loss). Do not re-

move foreign bodies (screws or

nails) from the tyre.The cylinder contains eth-

ylene glycol. The cylinder

contains latex: it can cause

allergic reactions. It is harmful if in-

gested or inhaled and irritant for

the eyes and in case of contact. In

case of contact rinse immediately

with water and take off contami-

nated clothes. If swallowed, do not

induce vomit, rinse out the mouth,

drink a lot of water and call the

doctor immediately. Keep away

from children. This product must

not be used by asthmatics. Do not

inhale vapours. Call the doctor im-

mediately in case of allergic reac-

tions. Keep the cylinder in the

space provided for the purpose and

far from heat. The sealing fluid has

limited life.