technical specifications Alfa Romeo GT 2005 Owner handbook (in English)

[x] Cancel search | Manufacturer: ALFA ROMEO, Model Year: 2005, Model line: GT, Model: Alfa Romeo GT 2005Pages: 307, PDF Size: 6.05 MB

Page 7 of 307

5

THE SYMBOLS USED IN THIS BOOKLET

The symbols illustrated in these pages show the subjects

which should, in particular, be closely studied.

This indicates the correct procedures

to be followed to prevent the vehicle

from damaging the environment. Warning. Partially or fully ignoring

these rules may lead to serious injury.Warning. Partially or fully ignoring these

rules may lead to serious damage being

caused to the vehicle which, in some cir-

cumstances, may cause forfeiture of the

warranty cover.

PERSONAL

SAFETYPROTECTING THE

ENVIRONMENTVEHICLE

SAFETY

The texts, illustrations and specifications given in this booklet refer to the vehicle at the time of going to press.

As part of our ongoing striving to improve our products, Alfa Romeo may introduce technical changes during production,

therefore the specifications and fittings may be altered without prior notice.

For details on this subject, please apply to the manufacturer’s sales network.

Page 210 of 307

CORRECT USE OF THE CAR

208

It is necessary therefore to limit their use

to the purposes for which they are certified.

IMPORTANTWhen winter tyres are

used with a maximum speed index below

the one that can be reached by the vehicle

(increased by 5%), place a notice in the

passenger’s compartment, plainly in the dri-

ver’s view, which states the maximum per-

missible speed of the winter tyres (as per

CE Directive).

Fit the same type of tyre on all four

wheels (brand and profile) to ensure high-

er driving safety when braking and good

handling.

Remember that it is inappropriate to

change the direction of rotation of tyres. WINTER TYRES

These tyres are specially designed for dri-

ving on snow and ice, to be fitted in

replacement of those fitted on the car.

Use winter tyres of the same size as nor-

mal tyres provided on the car.

Alfa Romeo Authorised Services will be

pleased to advise you on the choice of the

tyre most suited to the use the Customer

intends to make of it.

For the type of tyre to be used, inflation

pressures and specifications of winter

tyres, follow the instructions given in the

“Technical Specifications” chapter.

The winter features of these tyres are

reduced considerably when the tread

depth is below 4 mm. In this case, they

should be replaced.

Due to the winter features, under normal

conditions of use or long motorway jour-

neys, the performance of these tyres is

lower than that of normal tyres.

SNOW CHAINS

Use of snow chains should be in compli-

ance with local regulations.

For versions 1.8 T. SPARK, 2.0

JTS and 1.9 JTD, tyre 195/60 R15 can

be fitted with snow chains (use snow chains

with reduced size with max. protrusion be-

yond the tyre profile of 12 mm), whereas

tyres 205/60 R15 - 205/55 R16 -

205/55 ZR16 - 215/45 R17 - 215/45

ZR17 - 225/40 ZR18 cannot be fitted with

snow chains.

On version 3.2

V6, tyres 215/45

R17” and 215/45 ZR 17” can only be fit-

ted with chains of the spiker spider type

whereas tyres 225/45 ZR17 - 225/40

ZR18 cannot be fitted with snow chains.

Snow chains SPIKES SPIDER COMPACT

(model 17003 compact) with 9 spikes with

16 mm adjustable length and 17 inch wheel

cap adapter are available at Lineaccessori

Alfa Romeo.

Snow chains should only be applied to

the drive wheels (front).

Before purchasing or using snow chains,

you are recommended to contact Alfa

Romeo Authorised Services.

Check the tensions of the chain after the

first few metres have been driven.

Page 215 of 307

IN AN EMERGENCY

213

The spare wheel has a

sticker that summarises

the main cautions for use

and limitations. The sticker

should never be removed or cov-

ered. The sticker contains the fol-

lowing in four languages:

CAUTION! FOR TEMPORARY

USE ONLY! MAX 80 km/h!

REPLACE BY NORMAL WHEEL AS

SOON AS POSSIBLE. DO NOT

COVER THIS LABEL IN USE.

Never fit a wheel cap on a com-

pact spare wheel.

The vehicle will handle differ-

ently with the spare wheel fitted:

avoid heavy braking and acceler-

ating, sharp corners and fast

bends.The life of the spare

wheel is approx. 3000

km, after this distance it

should be replaced with another

of the same type.

Never attempt to fit a conven-

tional tyre on a rim designed for

use as a compact spare wheel.

Have the punctured wheel

repaired and refitted as soon as

possible.

Two or more compact spare

wheels should never be used

together.

Do not grease the threads of

bolts before installing them; they

might slip out.

The jack only serves for chang-

ing wheels on the car with which

it is provided or on cars of the

same model. It must not be used

for other purposes such as for

instance raising cars of other

models. In no case should it be

used for repairs under the vehi-

cle.

Incorrect positioning of the jack

may cause the jacked vehicle to

fall.

Do not use the jack for higher

capacities than stated on its

label.Snow chains cannot be

fitted on the compact

spare wheel, so, if a front

wheel is punctured and chains

need to be used, the front axle

should be fitted with normal

wheels and the compact spare

wheel fitted to the rear. This

way, with two normal wheels at

the front, snow chains can be fit-

ted thereby solving the emer-

gency situation.

Never tamper with the inflation

valve.

Do not insert tools of any kind

between the rim and the tyre.

Check, and if necessary, restore

the pressure of the tyres and of

the compact spare wheel to the

values given in the “Technical

Specifications” chapter.

Page 252 of 307

VEHICLE MAINTENANCE

250

ADDITIONAL

OPERATIONS

Every 1000 kmor before long jour-

neys, check and if necessary top up:

– engine coolant fluid level

– brake/hydraulic clutch control fluid

level

– power steering fluid level

– windscreen and headlamp washer

fluid level

– tyre pressure and conditions.

Every 3000 kmcheck and if necessary

top up the engine oil level.

The use of FL Seleniaproducts is rec-

ommended which have been designed

and made expressly for Alfa Romeo cars

(see “Refuelling” in the “Technical

Specifications” chapter).

ANNUAL INSPECTION

PROGRAMME

For cars with an annual mileage

of below 20,000 km (for exam-

ple about 10,000 km) the follow-

ing yearly inspection programme

is advised:

– Check tyre conditions/wear and if

necessary adjust the pressure (including

spare wheel)

– Check operation of lighting system

(headlights, direction indicators, hazard

warning lights, boot, passenger compart-

ment, glovebox lights, warning lights,

etc.)

– Check operation of windscreen wiper

system, spray jet adjustment

– Check position/wear of windscreen

– Check front disk brake pad conditions

and wear– Sight check for conditions of: engine,

gearbox, transmission, pipes (exhaust -

fuel supply - brakes), rubber parts (boots

- sleeves - bushes etc..), brake and fuel

supply system hoses

– Check for bonnet and boot lock clean-

ness, lever cleanness and lubrication

– Check battery charge

– Sight check for conditions of various

drive belts

– Check and if necessary top up fluid

levels (engine coolant, brakes, wind-

screen washer, battery etc. )

– Change engine oil and engine oil filter

– Change pollen filter.

Page 260 of 307

Oil consumption is very

low; if topping up again is

needed shortly after-

wards, have the system checked

for possible leaks by Alfa Romeo

Authorised Services.

VEHICLE MAINTENANCE

258

When loosening the

reservoir cap do not

allow the fluid to come

into contact with painted parts. If

it does, wash it off immediately

with water. Do not allow the power

steering fluid to touch hot

parts of the engine: it is

inflammable.

fig. 10

A0A0217b

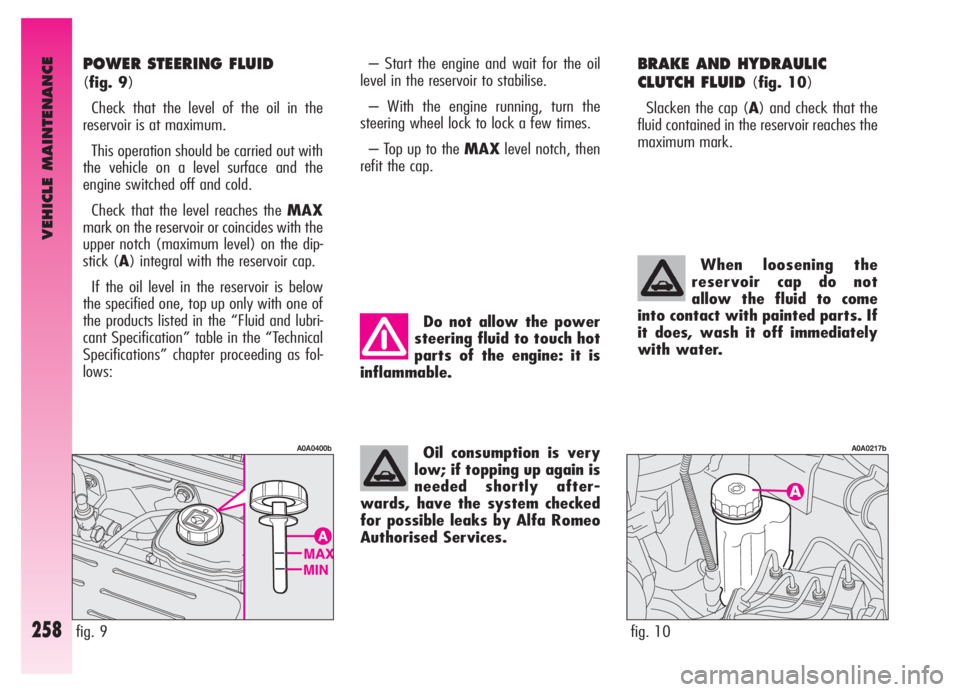

fig. 9

A0A0400b

BRAKE AND HYDRAULIC

CLUTCH FLUID

(fig. 10)

Slacken the cap (A) and check that the

fluid contained in the reservoir reaches the

maximum mark.

POWER STEERING FLUID

(fig. 9)

Check that the level of the oil in the

reservoir is at maximum.

This operation should be carried out with

the vehicle on a level surface and the

engine switched off and cold.

Check that the level reaches the MAX

mark on the reservoir or coincides with the

upper notch (maximum level) on the dip-

stick (A) integral with the reservoir cap.

If the oil level in the reservoir is below

the specified one, top up only with one of

the products listed in the “Fluid and lubri-

cant Specification” table in the “Technical

Specifications” chapter proceeding as fol-

lows:– Start the engine and wait for the oil

level in the reservoir to stabilise.

– With the engine running, turn the

steering wheel lock to lock a few times.

– Top up to the MAXlevel notch, then

refit the cap.

Page 266 of 307

VEHICLE MAINTENANCE

264

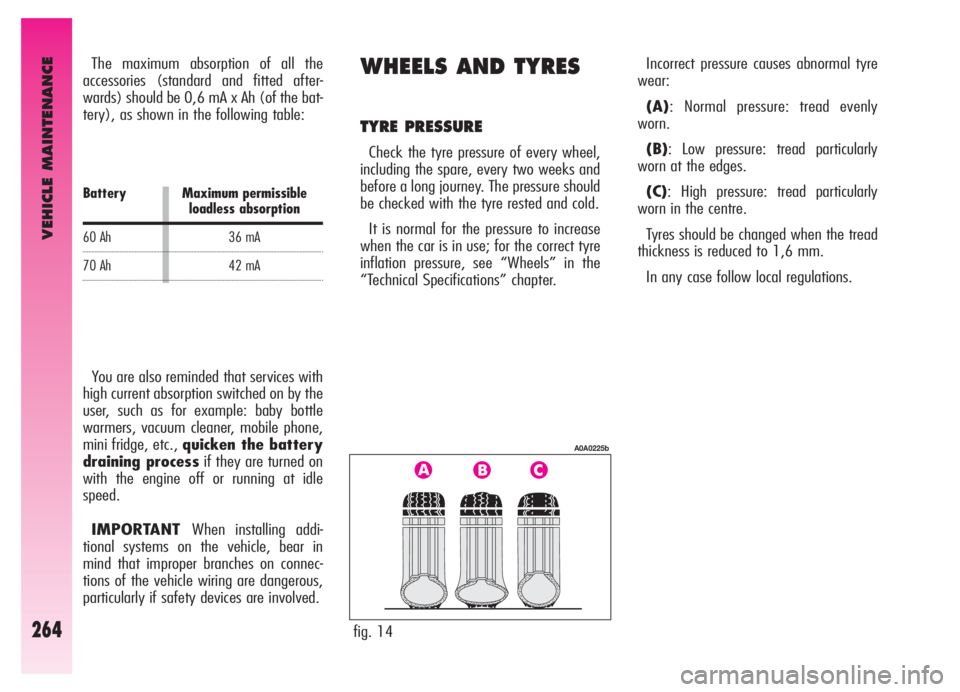

Incorrect pressure causes abnormal tyre

wear:

(A): Normal pressure: tread evenly

worn.

(B): Low pressure: tread particularly

worn at the edges.

(C): High pressure: tread particularly

worn in the centre.

Tyres should be changed when the tread

thickness is reduced to 1,6 mm.

In any case follow local regulations.

You are also reminded that services with

high current absorption switched on by the

user, such as for example: baby bottle

warmers, vacuum cleaner, mobile phone,

mini fridge, etc., quicken the battery

draining processif they are turned on

with the engine off or running at idle

speed.

IMPORTANT When installing addi-

tional systems on the vehicle, bear in

mind that improper branches on connec-

tions of the vehicle wiring are dangerous,

particularly if safety devices are involved.

WHEELS AND TYRES

TYRE PRESSURE

Check the tyre pressure of every wheel,

including the spare, every two weeks and

before a long journey. The pressure should

be checked with the tyre rested and cold.

It is normal for the pressure to increase

when the car is in use; for the correct tyre

inflation pressure, see “Wheels” in the

“Technical Specifications” chapter.

Battery

60 Ah

70 AhMaximum permissible

loadless absorption

36 mA

42 mA

The maximum absorption of all the

accessories (standard and fitted after-

wards) should be 0,6 mA x Ah (of the bat-

tery), as shown in the following table:

fig. 14

A0A0225b

Page 270 of 307

VEHICLE MAINTENANCE

268

Detergents cause water

pollution. Therefore the

vehicle should be washed

in areas equipped for collecting

and purifying the liquid used in

the washing process.Where possible, do not park under trees;

the resinous substances many species

release give the paint a dull appearance

and increase the possibility of triggering

the rust processes.

IMPORTANTBird droppings must be

washed off immediately and thoroughly

as the acid they contain is particularly

aggressive.

To correctly wash the car:

1) Remove the aerial from the roof to pre-

vent damage to it if the car is washed in

an automatic system.

2) Spray the vehicle with a low pressure

jet of water.

3) Pass a sponge moistened with a light

detergent solution, rinsing the sponge fre-

quently.

4) Rinse well with water and dry with a

jet of air or chamois leather.

When drying, take particular care with

the less visible parts like door surrounds,

bonnet and around the headlights where

water may stagnate. The vehicle should

not be taken to a closed area immediate-

ly, but left in the open so that residual

water can evaporate.

Do not wash the vehicle after it has been

left in the sun or with the bonnet hot: this

may alter the shine of the paintwork.

Exterior plastic parts must be cleaned in

the same way as the rest of the vehicle. ADVICE FOR PRESERVING

THE BODYWORK

Paint

The paintwork does not only serve an

aestethic purpose but also protects the

underlying sheet metal.

In the case of deep scrapes or scores,

you are advised to have the necessary

touching up carried out immediately to

avoid the formation fo rust.

Only original products should be used for

touching up paint (see “Body paint identi-

fication plate” in the “Technical

Specifications” chapter).

Normal paint maintenance consists in

washing at intervals depending on the

conditions and environment of use. For

example, in highly polluted areas, or if the

roads are sprayed with salt, it is wise to

wash the car more frequently.

Page 273 of 307

TECHNICAL SPECIFICATIONS

271

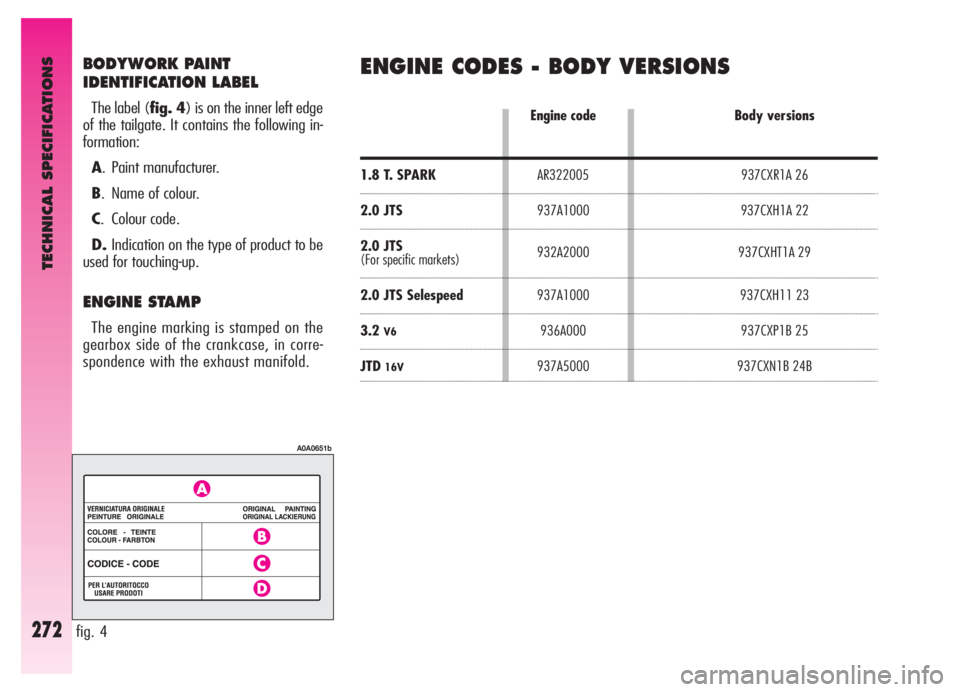

IDENTIFICATION LABEL

This (fig. 2) is to be found on the front

crossmember of the engine compartment.

It contains the following information:

(A)Space for details of national ho-

mologation

(B)Space for punching the consecutive

chassis number

(C)Space available for maximum

weights authorised by various na-

tional regulations

(D)Space for version and any supple-

mentary indications to those specified(E)Space for smoke coefficient (JTD ver-

sions)

(F)Space for punching manufacturer’s

name.

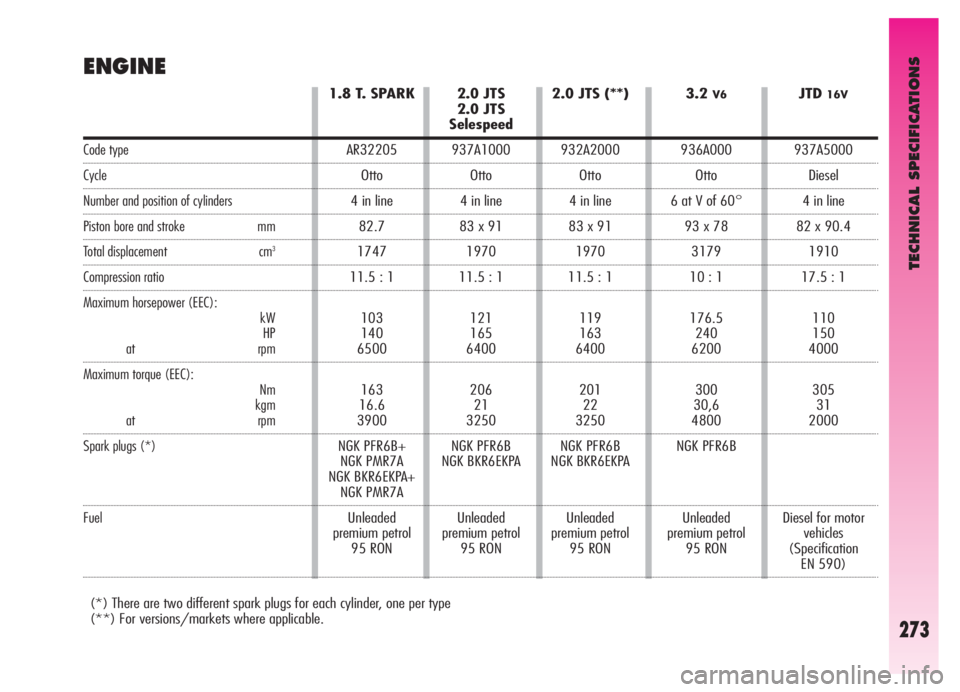

BODYWORK LABEL

This is located in the engine bay, to one side

of the upper right shock absorber (fig. 3)

and contains:

– Type of vehicle: ZAR 937.000

– Manufacturer’s serial number (chassis

number).

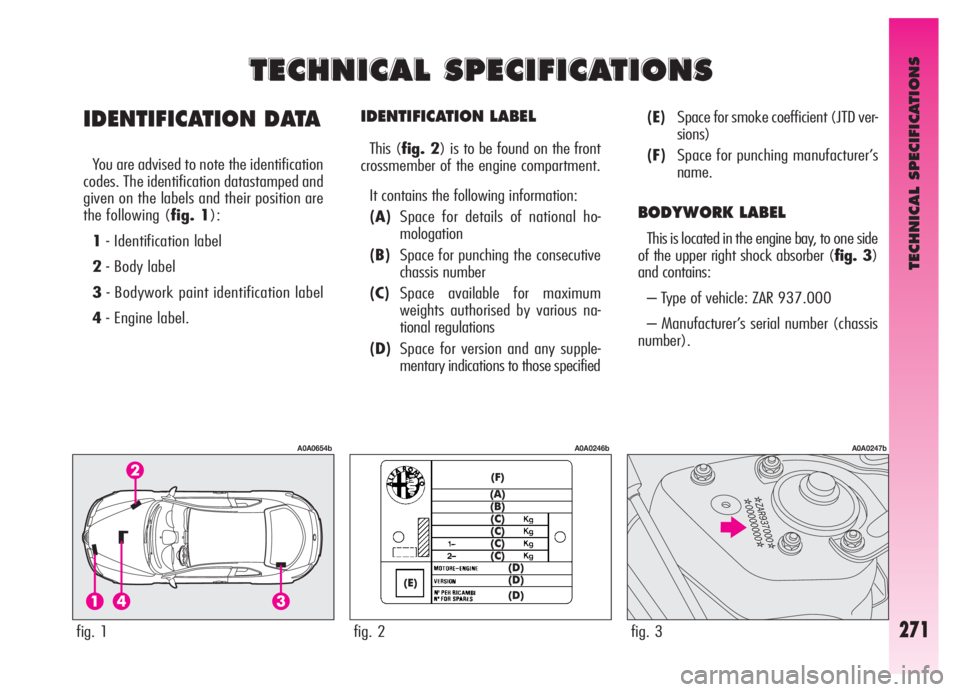

IDENTIFICATION DATA

You are advised to note the identification

codes. The identification datastamped and

given on the labels and their position are

the following (fig. 1):

1- Identification label

2- Body label

3- Bodywork paint identification label

4- Engine label.

T T

E E

C C

H H

N N

I I

C C

A A

L L

S S

P P

E E

C C

I I

F F

I I

C C

A A

T T

I I

O O

N N

S S

fig. 1

A0A0654b

fig. 2

A0A0246b

fig. 3

A0A0247b

Page 274 of 307

TECHNICAL SPECIFICATIONS

272

BODYWORK PAINT

IDENTIFICATION LABEL

The label (fig. 4) is on the inner left edge

of the tailgate. It contains the following in-

formation:

A. Paint manufacturer.

B. Name of colour.

C. Colour code.

D.Indication on the type of product to be

used for touching-up.

ENGINE STAMP

The engine marking is stamped on the

gearbox side of the crankcase, in corre-

spondence with the exhaust manifold.

ENGINE CODES - BODY VERSIONS

fig. 4

A0A0651b

Engine code Body versions

1.8 T. SPARKAR322005 937CXR1A 26

2.0 JTS937A1000 937CXH1A 22

2.0 JTS

932A2000 937CXHT1A 29

(For specific markets)

2.0 JTS Selespeed937A1000 937CXH11 23

3.2V6936A000 937CXP1B 25

JTD16V937A5000 937CXN1B 24B

Page 275 of 307

TECHNICAL SPECIFICATIONS

273

ENGINE

2.0 JTS

2.0 JTS

Selespeed

937A1000

Otto

4 in line

83 x 91

1970

11.5 : 1

121

165

6400

206

21

3250

NGK PFR6B

NGK BKR6EKPA

Unleaded

premium petrol

95 RON2.0 JTS (**)

932A2000

Otto

4 in line

83 x 91

1970

11.5 : 1

119

163

6400

201

22

3250

NGK PFR6B

NGK BKR6EKPA

Unleaded

premium petrol

95 RONJTD16V

937A5000

Diesel

4 in line

82 x 90.4

1910

17.5 : 1

110

150

4000

305

31

2000

Diesel for motor

vehicles

(Specification

EN 590) 3.2

V6

936A000

Otto

6 at V of 60°

93 x 78

3179

10 : 1

176.5

240

6200

300

30,6

4800

NGK PFR6B

Unleaded

premium petrol

95 RON

(*) There are two different spark plugs for each cylinder, one per type

(**) For versions/markets where applicable.1.8 T. SPARK

AR32205

Otto

4 in line

82.7

1747

11.5 : 1

103

140

6500

163

16.6

3900

NGK PFR6B+

NGK PMR7A

NGK BKR6EKPA+

NGK PMR7A

Unleaded

premium petrol

95 RONCode type

Cycle

Number and position of cylinders

Piston bore and stroke mm

Total displacement cm3

Compression ratio

Maximum horsepower (EEC):

kW

HP

at rpm

Maximum torque (EEC):

Nm

kgm

at rpm

Spark plugs (*)

Fuel