service Alfa Romeo GT 2006 Owner handbook (in English)

[x] Cancel search | Manufacturer: ALFA ROMEO, Model Year: 2006, Model line: GT, Model: Alfa Romeo GT 2006Pages: 307, PDF Size: 6.05 MB

Page 267 of 307

VEHICLE MAINTENANCE

265

Alloy rim painting

involving temperatures

exceeding 150 °C should

be avoided since wheel mechani-

cal characteristics could be

impaired.Do not cross switch the

tyres, moving them from

the right of the car to the

left and vice versa.Excessive low pressure

causes overheating of the

tyre with the possibility

of serious damage to it.Remember that vehicle

road holding also depends

on correct tyre inflation

pressure.

RUBBER HOSES

As far as the brake system and fuel sup-

ply rubber hoses are concerned, carefully

follow the Scheduled Maintenance

Programme. Indeed, ozone, high temper-

atures and the prolonged lack of fluid in

the system may cause hardening and

cracking of the hoses, with possible leaks.

Careful control is therefore necessary. IMPORTANTS

– Where possible, avoid sudden brak-

ing, tyre squealing starts, violent bumps

against kerbs, potholes or obstacles of var-

ious kinds. Prolonged driving on rough

roads may damage the tyres;

– Routinely check the tyres for cuts on

the sides, swellings or uneven tread wear.

If necessary contact Alfa Romeo

Authorised Services;

– Avoid overloading the vehicle when

travelling: this may cause serious damage

to the wheels and tyres;

– If a tyre is punctured, stop immedi-

ately and change it to avoid damage to

the tyre itself, the rim, suspensions and

steering system;

– Tyres age even if they are not used

much. Cracks in the tread rubber are a

sign of aging. In any case, if the tyres

have been on the vehicle for over 6 years,

they should be checked by specialised per-

sonnel, to see if they can still be used.

Also remember to check the compact

spare wheel;

– In case of replacement, always fit new

tyres, avoiding those of dubious origin;

Page 269 of 307

VEHICLE MAINTENANCE

267

HEADLIGHT WASHERS

(fig.17)

Regularly check that the spray jets are

intact and clean.

If it is necessary to direct the jet, contact

an Alfa Romeo Authorised Service

BODYWORK

PROTECTION FROM

ATMOSPHERIC AGENTS

The main causes of corrosion are:

– atmospheric pollution

– salty air and humidity (coastal areas,

or hot humid climates)

– seasonal environment conditions.

Not to be underestimated is also the

abrasive action of wind-borne atmospheric

dust and sand and mud and gravel raised

by other vehicles.

On your car Alfa Romeo has implement-

ed the best manufacturing technologies to

effectively protect the bodywork against

corrosion.

fig. 17

A0A0704b

These include:

– Painting products and systems which

give the vehicle particular resistance to

corrosion and abrasion.

– Use of galvanised (or pretreated)

steel sheets, with high resistance to corro-

sion.

– Spraying of the underbody, engine

compartment, wheel arches and other

parts with highly protective wax products.

– Spraying of plastic parts, with a pro-

tective function, in the more exposed

points: underdoor, inner wheel arch lin-

ings, etc.

– Use of “open” boxed sections to pre-

vent condensation and pockets of mois-

ture from triggering rust inside.

VEHICLE EXTERIOR AND

UNDERBODY WARRANTY

Alfa GTis guaranteed against perfo-

ration due to rust of any original element

of the structure or body. For the general

terms of this warranty, refer to the

Warrantly Booklet.

Page 277 of 307

TECHNICAL SPECIFICATIONS

275

Service brakes:– front

– rear

Parking brake

BRAKES

Front

Rear

Type

Turning radius

(between pavements) m1.8 T. SPARK - 2.0 JTS - 3.2

V6 - JTD16V

rack and pinion with hydraulic power steering

11.5

SUSPENSIONS

STEERING SYSTEM

1.8 T. SPARK - 2.0 JTS - 3.2 V6- JTD16V

Disk

Disk

Controlled by hand lever, acting on the rear brakes

1.8 T. SPARK - 2.0 JTS - 3.2

V6 - JTD16V

quadrilateral system with stabiliser bar

Mc Pherson type

Page 286 of 307

TECHNICAL SPECIFICATIONS

284

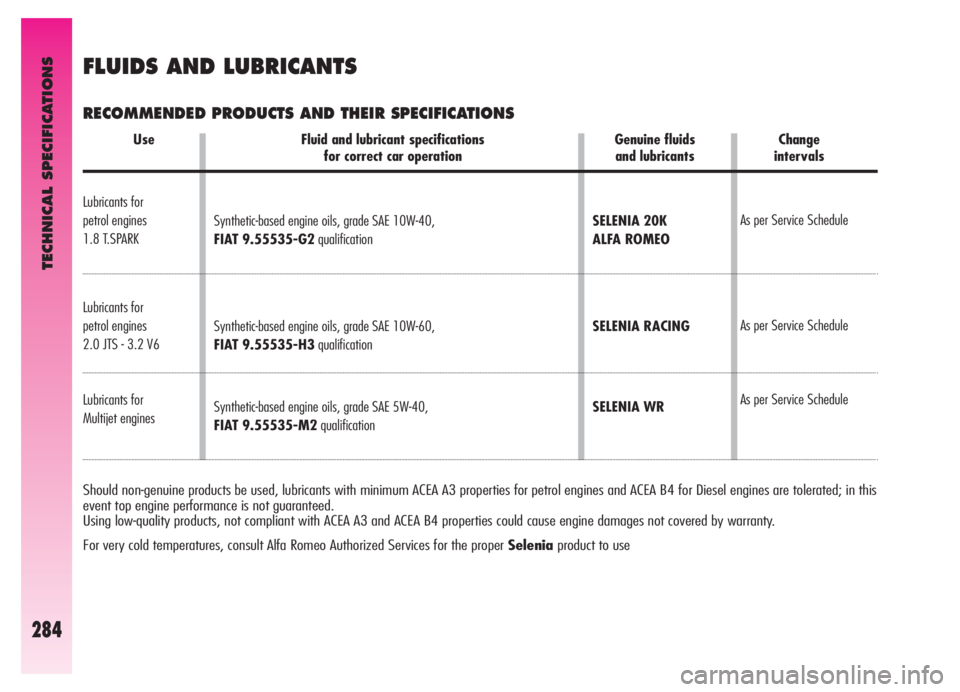

Use Fluid and lubricant specifications Genuine fluids Change

for correct car operation and lubricants intervals

Lubricants for

petrol engines

1.8 T.SPARK

Lubricants for

petrol engines

2.0 JTS - 3.2 V6

Lubricants for

Multijet engines

FLUIDS AND LUBRICANTS

RECOMMENDED PRODUCTS AND THEIR SPECIFICATIONS

Synthetic-based engine oils, grade SAE 10W-40,

FIAT 9.55535-G2qualification

Synthetic-based engine oils, grade SAE 10W-60,

FIAT 9.55535-H3qualification

Synthetic-based engine oils, grade SAE 5W-40,

FIAT 9.55535-M2qualification

Should non-genuine products be used, lubricants with minimum ACEA A3 properties for petrol engines and ACEA B4 for Diesel engines are tolerated; in this

event top engine performance is not guaranteed.

Using low-quality products, not compliant with ACEA A3 and ACEA B4 properties could cause engine damages not covered by warranty.

For very cold temperatures, consult Alfa Romeo Authorized Services for the proper Seleniaproduct to use

SELENIA 20K

ALFA ROMEO

SELENIA RACING

SELENIA WRAs per Service Schedule

As per Service Schedule

As per Service Schedule

Page 306 of 307

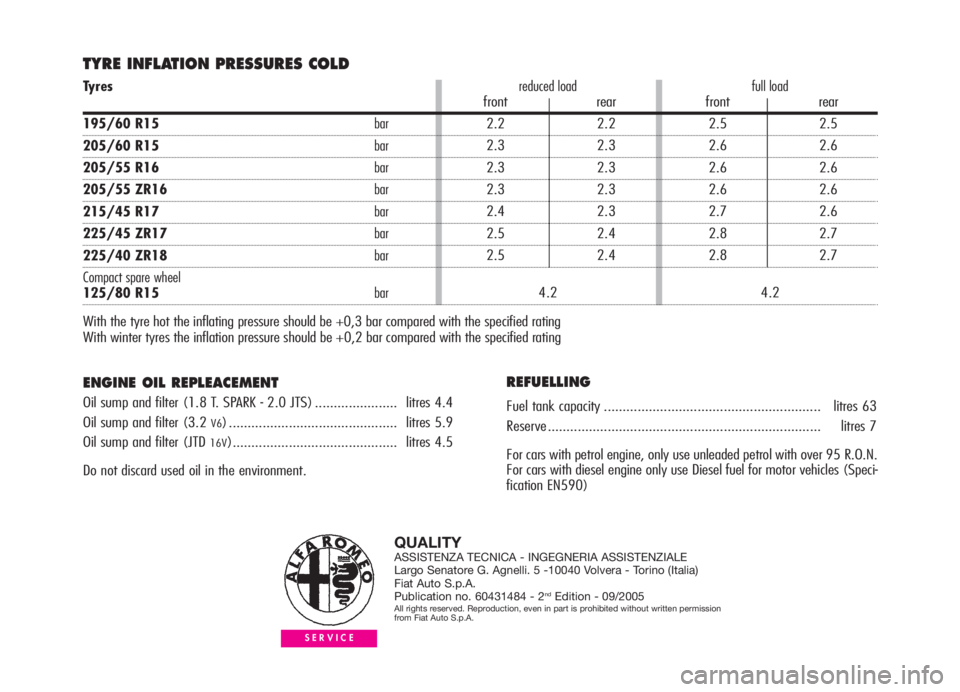

TYRE INFLATION PRESSURES COLD

ENGINE OIL REPLEACEMENT

Oil sump and filter (1.8 T. SPARK - 2.0 JTS) ...................... litres 4.4

Oil sump and filter (3.2

V6) ............................................. litres 5.9

Oil sump and filter (JTD

16V)............................................ litres 4.5

Do not discard used oil in the environment.

REFUELLING

Fuel tank capacity .......................................................... litres 63

Reserve ......................................................................... litres 7

For cars with petrol engine, only use unleaded petrol with over 95 R.O.N.

For cars with diesel engine only use Diesel fuel for motor vehicles (Speci-

fication EN590)

QUALITYASSISTENZA TECNICA - INGEGNERIA ASSISTENZIALE

Largo Senatore G. Agnelli. 5 -10040 Volvera - Torino (Italia)

Fiat Auto S.p.A.

Publication no. 60431484 - 2

ndEdition - 09/2005All rights reserved. Reproduction, even in part is prohibited without written permission

from Fiat Auto S.p.A.

SERVICE

With the tyre hot the inflating pressure should be +0,3 bar compared with the specified rating

With winter tyres the inflation pressure should be +0,2 bar compared with the specified rating

Tyres

195/60 R15bar

205/60 R15bar

205/55 R16bar

205/55 ZR16bar

215/45 R17bar

225/45 ZR17bar

225/40 ZR18bar

Compact spare wheel

125/80 R15barreduced load

front rear

2.2 2.2

2.3 2.3

2.3 2.3

2.3 2.3

2.4 2.3

2.5 2.4

2.5 2.4

4.2full loadfront rear

2.5 2.5

2.6 2.6

2.6 2.6

2.6 2.6

2.7 2.6

2.8 2.7

2.8 2.7

4.2