tow Alfa Romeo GT 2010 Owner handbook (in English)

[x] Cancel search | Manufacturer: ALFA ROMEO, Model Year: 2010, Model line: GT, Model: Alfa Romeo GT 2010Pages: 271, PDF Size: 5.34 MB

Page 183 of 271

IN AN EMERGENCY

181

STARTING BY INERTIA

If the car is equipped with “Kit for tyre re-

pair Fix&Go“, see the instructions contained

in the following chapter.

GENERAL INSTRUCTIONS

As an alternative to the FIX & GO, the car

can be provided (upon request) with space-

saver spare wheel or standard wheel; wheel

changing and correct use of the jack call for

some precautions as listed below.

IN THE EVENT OF A PUNCTURE

Never push, tow or coast

start the car. This could

cause fuel to flow into the

catalyst damaging it irreversibly.

Remember that the en-

gine brake and power

steering are not opera-

tional until the engine is started,

therefore, much greater effort than

usual is needed on the brake ped-

al and steering wheel.

Signal the presence of the

stationary car according to

current regulations: hazard

warning lights, reflecting triangle

etc.. Any passengers should leave

the car and wait for the wheel to be

changed out of harm of the traffic.

If parked on a slope or rough sur-

face, chock the wheels with

wedges or other suitable devices

to prevent the car from rolling.

Never start the engine

with the car jacked.

When driving with a trail-

er, disconnect the trailer before

raising the car. The compact spare

wheel is specific to your car, do not

use it on other models, or use the

spare wheel of other models on

your car.

Should the type of wheels used

be changed (alloy rims instead of

steel), it is also necessary to

change the whole set of fastening

bolts with others of suitable size.

The compact spare wheel is nar-

rower than normal wheels, it

should be used only for the dis-

tance necessary to reach a service

point to have the punctured tyre

repaired and, during its use, the car

speed must not exceed 80 km/h.

Page 187 of 271

IN AN EMERGENCY

185

– Using the wrench provided, tighten the

fastening bolts.

– Lower the car and remove the jack.

– Using the wrench provided, fully tight-

en the bolts in the sequence shown previ-

ously for the compact spare wheel fig. 8.

– Place the cap near the wheel so that the

inflation valve can come through the slot

provided on the cap.

– Press the circumference of the cap, start-

ing from the parts nearest to the inflation

valve until it is inserted completely.

IMPORTANTIncorrect fitting may cause

the wheel cap to come off when the car is

travelling.For versions with alloy rims:

– Tighten the pin (A-fig. 9) in one of

the fastening bolt holes on the wheel hub.

– Insert the wheel on the pin and, using

the wrench provided, tighten the four bolts

available. This is facilitated by the extension

provided (B).

– Remove the pin (A-fig. 9) and tight-

en the last fastening bolt.

– Lower the car and remove the jack.

– Using the wrench provided, tighten the

bolts in the sequence shown previously for

the compact spare wheel fig. 8.After refitting a wheel:

– stow the spare wheel in the space pro-

vided in the boot

– insert the jack in its container forcing it

lightly to prevent it from vibrating when trav-

elling

– place the tools used in the housings in

the container

– stow the container complete with tools

on the spare wheel and secure everything

with the clamping device (A-fig. 3)

– correctly re-position the stiff cover.

fig. 7

A0A0155b

fig. 8

A0A0156b

fig. 9

A0A0693b

Page 188 of 271

IN AN EMERGENCY

186

QUICK TYRE

REPAIR KIT

FIX&GO automatic

The car is equipped with a tyre quick re-

pairing kit called “FIX&GO automatic”, re-

placing the tools and the compact spare

wheel usually provided with the car.

The kit fig. 10is placed in the boot. In

the kit container you will also find the screw-

driver and the tow ring.The quick tyre repair kit includes:

– bottle A-fig. 10containing sealer and

fitted with:

– filler hose B

– sticker Cwith caution “max. 80

km/h”, to be affixed in a visible position

for the driver (instrument panel) after re-

pairing the tyre;

– compressor Dincluding gauge and con-

nections;– instruction brochure fig. 11, to be used

for prompt and proper use of the quick re-

pair kit and to be then handed to the per-

sonnel charged with handling the treated

tyre;

– a pair of protection gloves located in the

side space of the compressor;

– adapters for inflating different elements.

fig. 10

A0A1095b

fig. 11

A0A1096b

Page 200 of 271

IN AN EMERGENCY

198

– Replace the bulb;

– Refit the bulb holder turning counter-

clockwise and check that it is secured cor-

rectly;

– Refit the transparent.SIDE DIRECTION INDICATORS

(fig. 30)

– Push the transparent cover towards the

rear of the car to compress the catch (A).

Release the front part and remove this unit.

– Turn the bulb holder (B) counter-clock-

wise and remove it from the cover.

– Remove the snap-fitted bulb and replace it.

– Insert the bulb holder (B) in the trans-

parent cover, then position the unit mak-

ing sure the catch clicks into place (A).

fig. 29

A0A0626b

fig. 30

A0A0166b

FRONT DIRECTION

INDICATORS

(fig. 28-29)

To change the bulb, proceed as follows:

– Using the screwdriver provided, remove

the transparent unit operating on the two

metal clips as shown in the figure;

– Turn the bulb holder clockwise (A) and

remove it;

– Remove the bulb (B) pushing gently

and turning counter-clockwise;

fig. 28

A0A0625b

Page 215 of 271

IN AN EMERGENCY

213

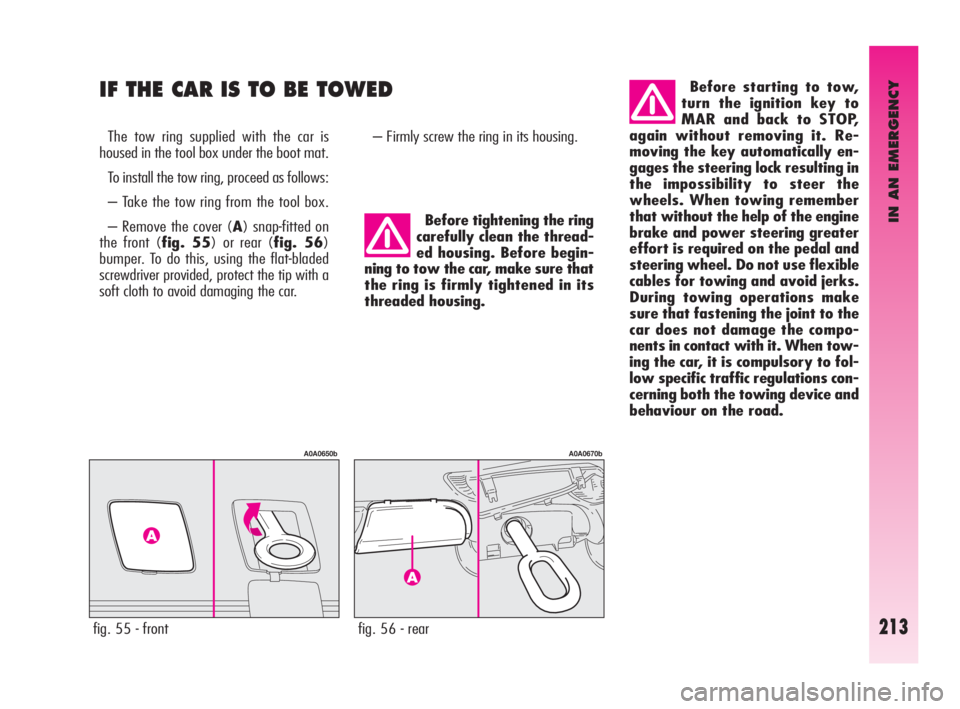

IF THE CAR IS TO BE TOWED

The tow ring supplied with the car is

housed in the tool box under the boot mat.

To install the tow ring, proceed as follows:

– Take the tow ring from the tool box.

– Remove the cover (A) snap-fitted on

the front (fig. 55) or rear (fig. 56)

bumper. To do this, using the flat-bladed

screwdriver provided, protect the tip with a

soft cloth to avoid damaging the car.– Firmly screw the ring in its housing.

fig. 55 - front

A0A0650b

fig. 56 - rear

A0A0670b

Before tightening the ring

carefully clean the thread-

ed housing. Before begin-

ning to tow the car, make sure that

the ring is firmly tightened in its

threaded housing.

Before starting to tow,

turn the ignition key to

MAR and back to STOP,

again without removing it. Re-

moving the key automatically en-

gages the steering lock resulting in

the impossibility to steer the

wheels. When towing remember

that without the help of the engine

brake and power steering greater

effort is required on the pedal and

steering wheel. Do not use flexible

cables for towing and avoid jerks.

During towing operations make

sure that fastening the joint to the

car does not damage the compo-

nents in contact with it. When tow-

ing the car, it is compulsory to fol-

low specific traffic regulations con-

cerning both the towing device and

behaviour on the road.

Page 216 of 271

IN AN EMERGENCY

214

Take care when position-

ing the arms of the lift or

workshop lift to avoid dam-

aging the side strips.

USING AN ARM LIFT OR

WORKSHOP LIFT

The car must only be lifted laterally posi-

tioning the ends of the arms or the workshop

lift in the areas illustrated, approx. 40 cm from

the profile of the wheelhouse (fig. 57).These points are identified by symbol

▼

on the bottom of the sidemember.

The car may fall if the jack

is not positioned correctly.

Never use the jack for

higher capacities than the one stat-

ed on the label.

IMPORTANTFor versions with Sele-

speed transmission, make sure that the

gears are in neutral (N) (checking that the

car moves if pushed) and then proceed as

for towing a normal car with mechanical

transmission, following the instructions giv-

en previously.

Should it be impossible to set the gears to

neutral, do not tow the car and contact Al-

fa Romeo Authorised Services.Do not start the engine

when towing the car.

IF THE CAR IS TO BE LIFTED

fig. 57

A0A0672b

Page 222 of 271

CAR MAINTENANCE

220

IMPORTANT

Engine oil

Should prevailing use of the car be under

one of the following specially heavy condi-

tions:

– trailer or caravan towing

– dusty roads

– short distances (less than 7-8 km) re-

peated and with external temperatures be-

low zero

– frequently idling engines or long distance

low speed driving or in case of a long term

inactivity

replace engine oil more frequently than re-

quired on the Scheduled Maintenance Pro-

gramme.IMPORTANT

Diesel filter

The variety of the degree of purity of the

fuel oil in commerce may make it necessary

to change the fuel oil filter more frequently

than stated in the Scheduled Maintenance

Programme. If the engine is “sobbing” it

is a sign that the filter needs changing.IMPORTANT

Air cleaner

Using the car on dusty roads change the

air cleaner more frequently than specified in

the Schedule Maintenance Programme.

For any doubts concerning the intervals be-

tween the engine oil and air cleaner re-

placement in relation to how the car is used,

contact Alfa Romeo Authorised Services.

Page 253 of 271

TECHNICAL SPECIFICATIONS

251

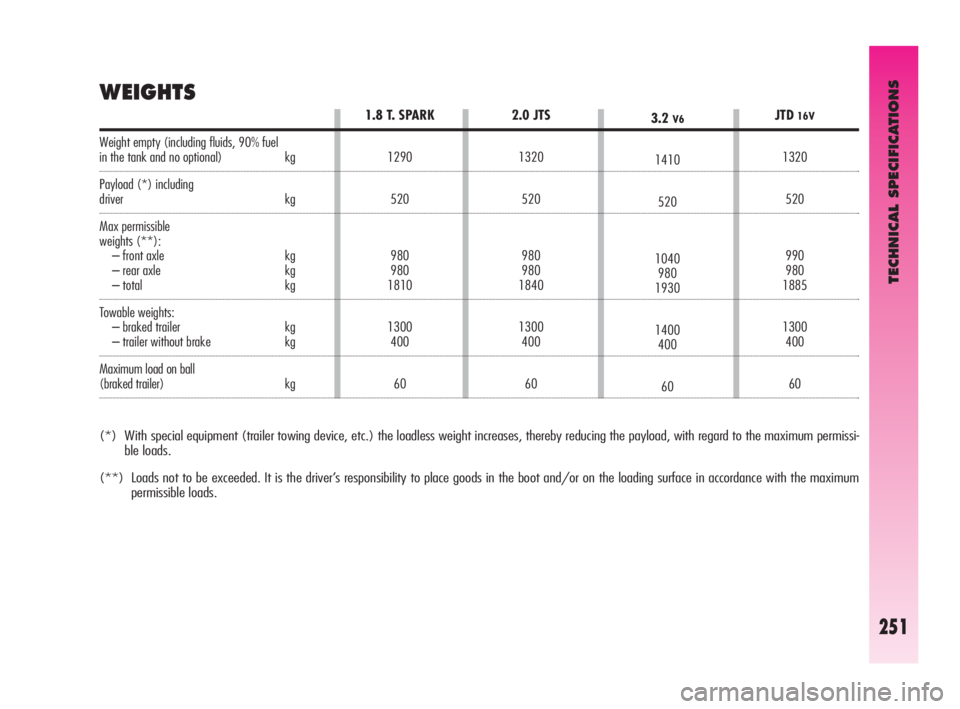

Weight empty (including fluids, 90% fuel

in the tank and no optional) kg

Payload (*) including

driver kg

Max permissible

weights (**):

– front axle kg

– rear axle kg

– total kg

Towable weights:

– braked trailer kg

– trailer without brake kg

Maximum load on ball

(braked trailer) kg

WEIGHTS

(*) With special equipment (trailer towing device, etc.) the loadless weight increases, thereby reducing the payload, with regard to the maximum permissi-

ble loads.

(**) Loads not to be exceeded. It is the driver’s responsibility to place goods in the boot and/or on the loading surface in accordance with the maximum

permissible loads.

JTD16V

1320

520

990

980

1885

1300

400

60

3.2V6

1410

520

1040

980

1930

1400

400

60

2.0 JTS

1320

520

980

980

1840

1300

400

60

1.8 T. SPARK

1290

520

980

980

1810

1300

400

60

Page 265 of 271

ALPHABETICAL INDEX

263

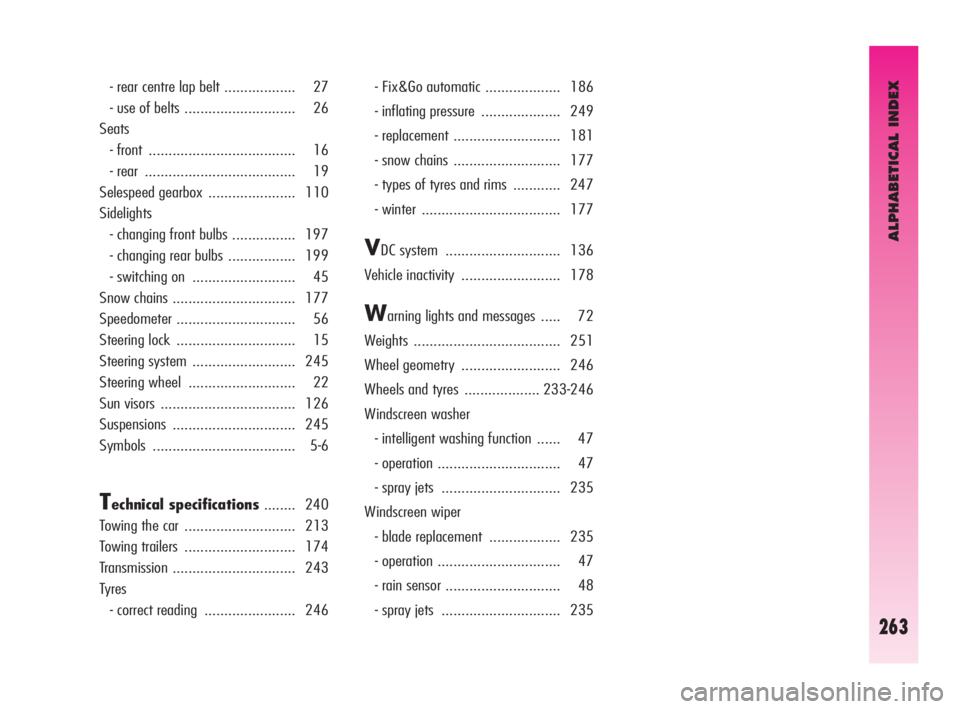

- rear centre lap belt .................. 27

- use of belts ............................ 26

Seats

- front ..................................... 16

- rear ...................................... 19

Selespeed gearbox ...................... 110

Sidelights

- changing front bulbs ................ 197

- changing rear bulbs ................. 199

- switching on .......................... 45

Snow chains ............................... 177

Speedometer .............................. 56

Steering lock .............................. 15

Steering system .......................... 245

Steering wheel ........................... 22

Sun visors .................................. 126

Suspensions ............................... 245

Symbols .................................... 5-6

Technical specifications........ 240

Towing the car ............................ 213

Towing trailers ............................ 174

Transmission ............................... 243

Tyres

- correct reading ....................... 246 - Fix&Go automatic ................... 186

- inflating pressure .................... 249

- replacement ........................... 181

- snow chains ........................... 177

- types of tyres and rims ............ 247

- winter ................................... 177

VDC system ............................. 136

Vehicle inactivity ......................... 178

Warning lights and messages ..... 72

Weights ..................................... 251

Wheel geometry ......................... 246

Wheels and tyres ................... 233-246

Windscreen washer

- intelligent washing function ...... 47

- operation ............................... 47

- spray jets .............................. 235

Windscreen wiper

- blade replacement .................. 235

- operation ............................... 47

- rain sensor ............................. 48

- spray jets .............................. 235

Page 266 of 271

PROVISIONS FOR THE PROCESSING OF A VEHICLE

AT THE END OF ITS LIFE-CYCLE

For years now Alfa Romeo has been developing its global commitment towards the safeguarding and protection of the Environment through

the continuous improvement of its production processes and the making of increasingly more “eco friendly” products. With a view to guaran-

teeing the best possible service to clients in full observance of environmental standards and in response to the obligations imposed by Euro-

pean Directive 2000/53/EC on end-of-life vehicles, Alfa Romeo offers its clients the possibility to hand in their vehicle* at the end of its life

span without additional costs.

The European Directive, in fact, provides for the take-back of the vehicle without the last holder or owner of the same incurring expenses due

to the fact that the market value of the vehicle is zero or negative. In particular, in almost all of the countries of the

European Union, up until 1st January 2007, take-back of the vehicle free of charge only applies to vehicles registered from 1 July 2002 on,

while, from 2007 on, take-back will be carried out free of charge, independently of the year of registration, provided that the vehicle still con-

tains all its essential component parts (especially engine and body) and is free from additional waste materials.

Our contracted network of authorised treatment facilities has been carefully selected in order to provide a quality service to our customers by

de-polluting and recycling “End of Life Vehicles” to approved environmental standards. To find out the location of your nearest authorised

treatment facility, offering free of charge take-back, simply contact one of our dealers or refer to the Alfa Romeo web site or call the toll free

number 00800 2532 0000.

*

Passenger transportation vehicles to seat a max. of nine persons, having a total admissible weight of 3.5 t