light ALFA ROMEO STELVIO 2022 Owners Manual

[x] Cancel search | Manufacturer: ALFA ROMEO, Model Year: 2022, Model line: STELVIO, Model: ALFA ROMEO STELVIO 2022Pages: 256, PDF Size: 10.17 MB

Page 216 of 256

SERVICING AND MAINTENANCE

214

3. Turn the bulb/connector assembly counter-

clockwise, and then slide it off the headlight

body.

Bulb/Connector

4. Remove the bulb by sliding it off the bulb holder.

5. Install the new bulb, making sure it is correctly inserted in the bulb holder.

6. Insert the bulb/connector assembly in the housing on the headlight body and turn it

clockwise, making sure that it is locked

correctly.

7. Install the protective cover.

Front Light Cluster With Main Beam Xenon Gas

Discharge Headlights

To replace the bulbs of the main beam

headlights, contact an authorized dealer.

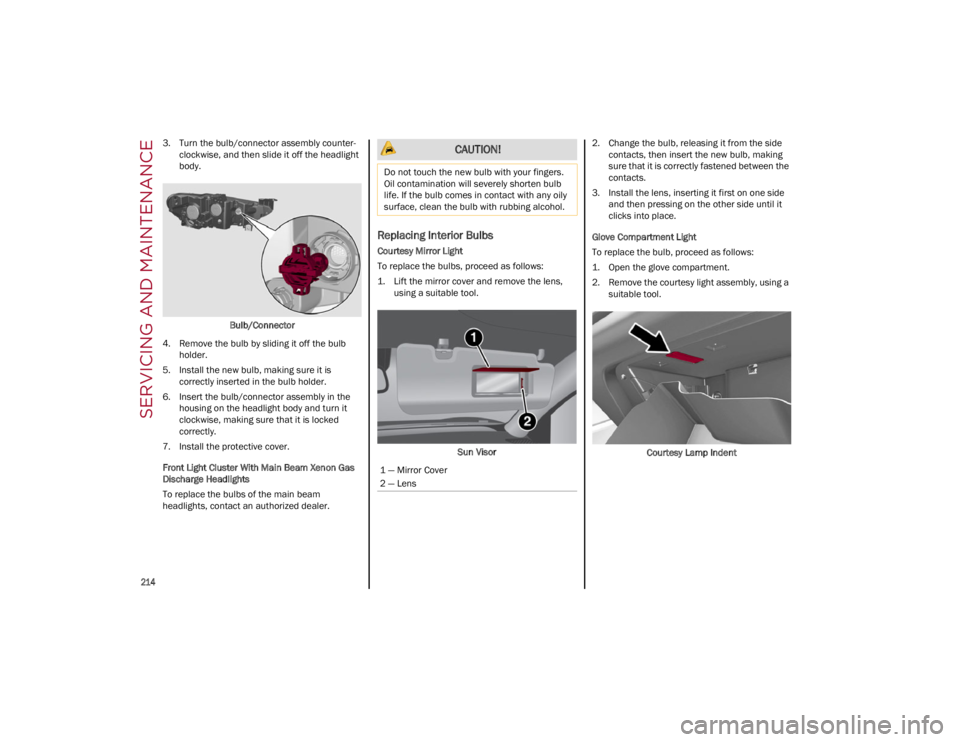

Replacing Interior Bulbs

Courtesy Mirror Light

To replace the bulbs, proceed as follows:

1. Lift the mirror cover and remove the lens, using a suitable tool.

Sun Visor 2. Change the bulb, releasing it from the side

contacts, then insert the new bulb, making

sure that it is correctly fastened between the

contacts.

3. Install the lens, inserting it first on one side and then pressing on the other side until it

clicks into place.

Glove Compartment Light

To replace the bulb, proceed as follows:

1. Open the glove compartment.

2. Remove the courtesy light assembly, using a suitable tool.

Courtesy Lamp Indent

CAUTION!

Do not touch the new bulb with your fingers.

Oil contamination will severely shorten bulb

life. If the bulb comes in contact with any oily

surface, clean the bulb with rubbing alcohol.

1 — Mirror Cover

2 — Lens

22_GU_OM_EN_USC_t.book Page 214

Page 217 of 256

215

3. Open protective cover and remove the bulbpulling out of the connector.

Cover And Bulb Removal Direction

4. Install bulb, making sure that it is correctly inserted fully.

5. Close the protective cover on the lens.

6. Install courtesy light, inserting it first on one side and then pressing on the other side until

it clicks into place.

Luggage Compartment Courtesy Lights

To replace the bulbs, proceed as follows:

1. Open the liftgate, and remove the liftgate lamp assembly using a suitable tool. Ceiling Light Indent

2. Open protective cover and remove the bulb pulling out of the connector.

Cover And Bulb Removal Direction

3. Install bulb, making sure that it is correctly inserted fully.

4. Close the protective cover on the lens.

5. Install liftgate lamp in the correct position, inserting it first on one side, and then

pressing on the other side until it clicks into

place. Puddle Lights On Door Panel

To replace the bulb, proceed as follows:

1. Open the door and remove the puddle light

assembly, using a suitable tool.

Puddle Light Indent

2. Open protective cover and remove the bulb pulling out of the connector.

Cover And Bulb Removal Direction

22_GU_OM_EN_USC_t.book Page 215

Page 218 of 256

SERVICING AND MAINTENANCE

216

3. Install bulb, making sure that it is correctlyinserted fully.

4. Close the protective cover on the lens.

5. Install puddle light in the correct position, inserting it first on one side and then pressing

on the other side until it clicks into place.

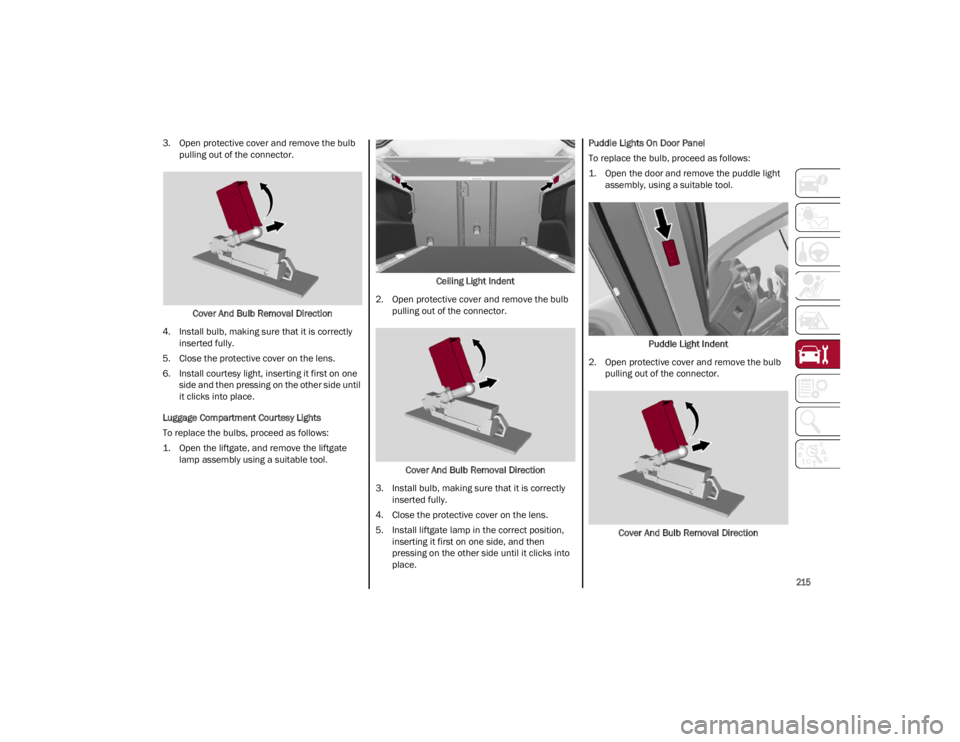

TIRES

TIRE SAFETY INFORMATION

Tire safety information will cover aspects of the

following information: Tire Markings, Tire Identifi -

cation Numbers, Tire Terminology and

Definitions, Tire Pressures, and Tire Loading.

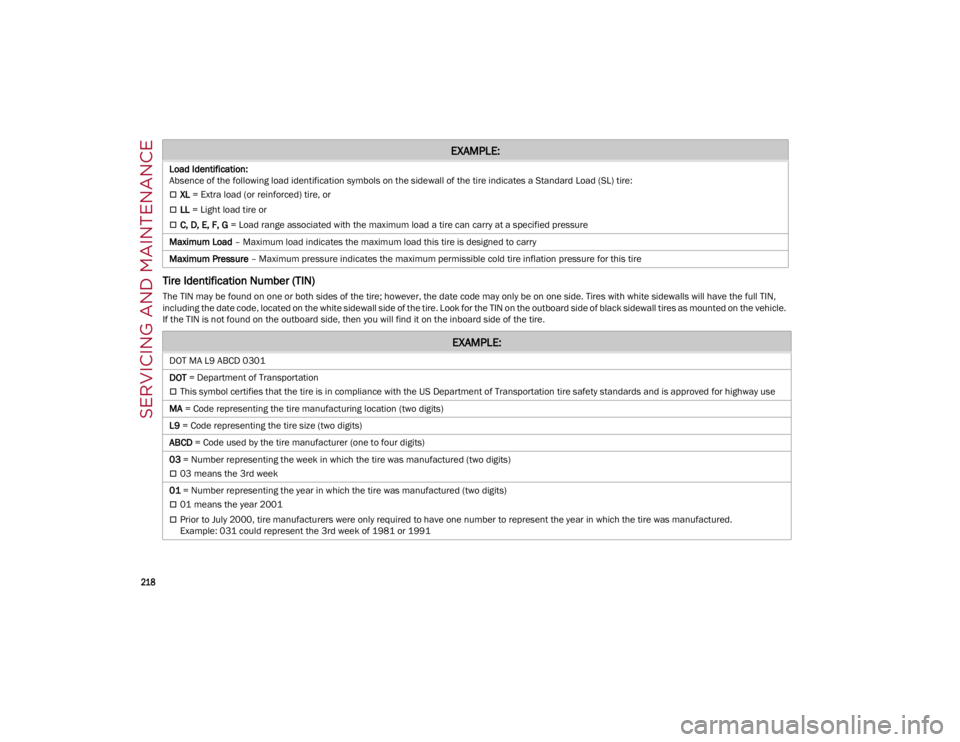

Tire Markings

Tire Markings

NOTE:

P (Passenger) — Metric tire sizing is based on

US design standards. P-Metric tires have the

letter “P” molded into the sidewall preceding

the size designation.

Example: P215/65R15 95H.

European — Metric tire sizing is based on

European design standards. Tires designed to

this standard have the tire size molded into the

sidewall beginning with the section width. The

letter "P" is absent from this tire size

designation.

Example: 215/65R15 96H.

LT (Light Truck) — Metric tire sizing is based on

US design standards. The size designation for

LT-Metric tires is the same as for P-Metric tires

except for the letters “LT” that are molded into

the sidewall preceding the size designation.

Example: LT235/85R16.

Temporary spare tires are designed for

temporary emergency use only. Temporary

high pressure compact spare tires have the

letter “T” or “S” molded into the sidewall

preceding the size designation.

Example: T145/80D18 103M.

High flotation tire sizing is based on US design

standards and it begins with the tire diameter

molded into the sidewall.

Example: 31x10.5 R15 LT.

1 — US DOT Safety Standards Code (TIN)

2 — Size Designation

3 — Service Description

4 — Maximum Load

5 — Maximum Pressure

6 — Treadwear, Traction and

Temperature Grades

22_GU_OM_EN_USC_t.book Page 216

Page 219 of 256

217

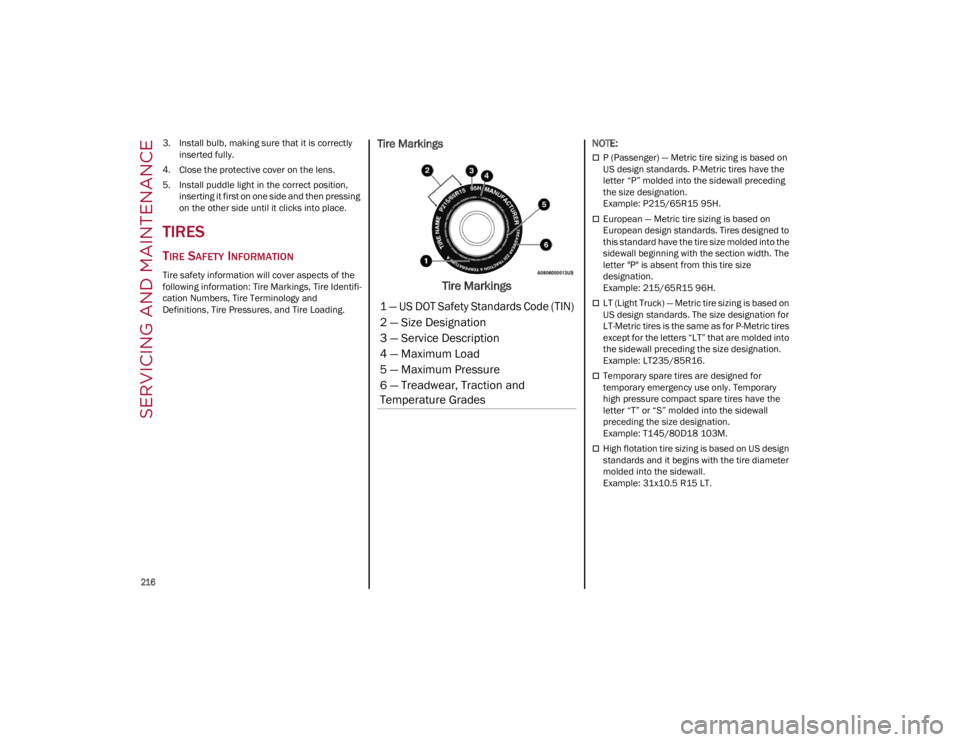

Tire Sizing Chart

EXAMPLE:

Example Size Designation: P215/65R15XL 95H, 215/65R15 96H, LT235/85R16C, T145/80D18 103M, 31x10.5 R15 LT

P

= Passenger car tire size based on US design standards, or

"....blank...." = Passenger car tire based on European design standards, or

LT = Light truck tire based on US design standards, or

T or S = Temporary spare tire or

31 = Overall diameter in inches (in)

215, 235, 145 = Section width in millimeters (mm)

65, 85, 80 = Aspect ratio in percent (%)

Ratio of section height to section width of tire, or

10.5 = Section width in inches (in)

R = Construction code

"R" means radial construction, or

"D" means diagonal or bias construction

15, 16, 18 = Rim diameter in inches (in)

Service Description:

95 = Load Index

A numerical code associated with the maximum load a tire can carry

H = Speed Symbol

A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain operating conditions

The maximum speed corresponding to the speed symbol should only be achieved under specified operating conditions (i.e., tire pressure, vehicle

loading, road conditions, and posted speed limits)

22_GU_OM_EN_USC_t.book Page 217

Page 220 of 256

SERVICING AND MAINTENANCE

218

Tire Identification Number (TIN)

The TIN may be found on one or both sides of the tire; however, the date code may only be on one side. Tires with white sidewalls will have the full TIN,

including the date code, located on the white sidewall side of the tire. Look for the TIN on the outboard side of black sidewall tires as mounted on the vehicle.

If the TIN is not found on the outboard side, then you will find it on the inboard side of the tire.Load Identification:

Absence of the following load identification symbols on the sidewall of the tire indicates a Standard Load (SL) tire:

XL

= Extra load (or reinforced) tire, or

LL = Light load tire or

C, D, E, F, G = Load range associated with the maximum load a tire can carry at a specified pressure

Maximum Load – Maximum load indicates the maximum load this tire is designed to carry

Maximum Pressure – Maximum pressure indicates the maximum permissible cold tire inflation pressure for this tire

EXAMPLE:

EXAMPLE:

DOT MA L9 ABCD 0301

DOT = Department of Transportation

This symbol certifies that the tire is in compliance with the US Department of Transportation tire safety standards and is approved for highway use

MA = Code representing the tire manufacturing location (two digits)

L9 = Code representing the tire size (two digits)

ABCD = Code used by the tire manufacturer (one to four digits)

03 = Number representing the week in which the tire was manufactured (two digits)

03 means the 3rd week

01 = Number representing the year in which the tire was manufactured (two digits)

01 means the year 2001

Prior to July 2000, tire manufacturers were only required to have one number to represent the year in which the tire was manufactured.

Example: 031 could represent the 3rd week of 1981 or 1991

22_GU_OM_EN_USC_t.book Page 218

Page 227 of 256

225

Tire Spinning

When stuck in mud, sand, snow, or ice conditions,

do not spin your vehicle's wheels above 30 mph

(48 km/h) or for longer than 30 seconds contin-

uously without stopping.

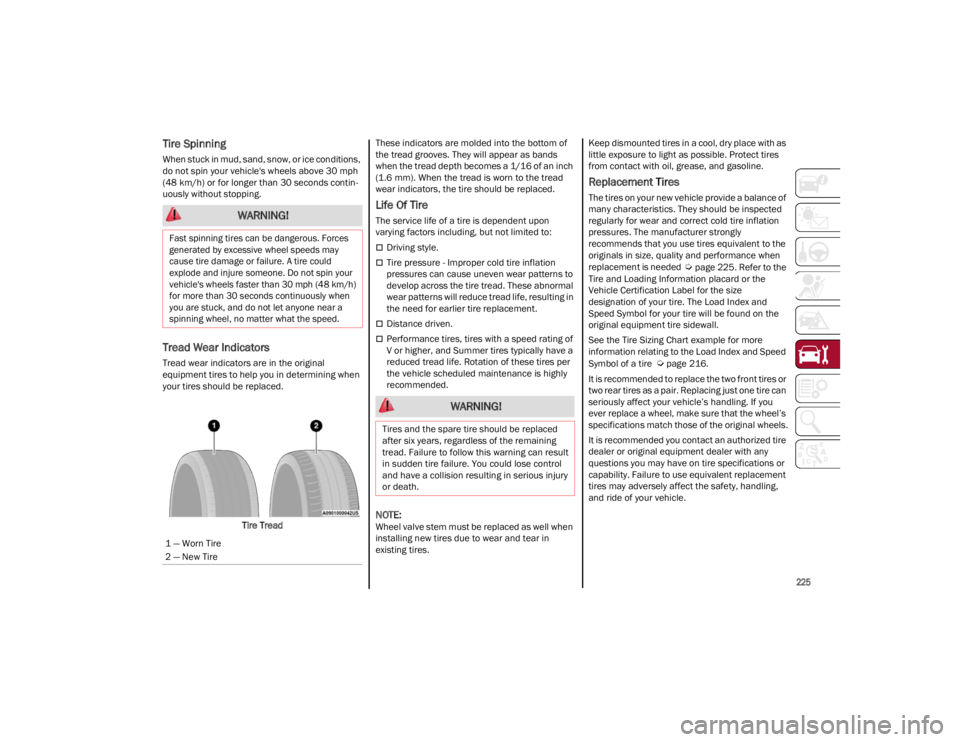

Tread Wear Indicators

Tread wear indicators are in the original

equipment tires to help you in determining when

your tires should be replaced.

Tire Tread These indicators are molded into the bottom of

the tread grooves. They will appear as bands

when the tread depth becomes a 1/16 of an inch

(1.6 mm). When the tread is worn to the tread

wear indicators, the tire should be replaced.

Life Of Tire

The service life of a tire is dependent upon

varying factors including, but not limited to:

Driving style.

Tire pressure - Improper cold tire inflation

pressures can cause uneven wear patterns to

develop across the tire tread. These abnormal

wear patterns will reduce tread life, resulting in

the need for earlier tire replacement.

Distance driven.

Performance tires, tires with a speed rating of

V or higher, and Summer tires typically have a

reduced tread life. Rotation of these tires per

the vehicle scheduled maintenance is highly

recommended.

NOTE:

Wheel valve stem must be replaced as well when

installing new tires due to wear and tear in

existing tires. Keep dismounted tires in a cool, dry place with as

little exposure to light as possible. Protect tires

from contact with oil, grease, and gasoline.

Replacement Tires

The tires on your new vehicle provide a balance of

many characteristics. They should be inspected

regularly for wear and correct cold tire inflation

pressures. The manufacturer strongly

recommends that you use tires equivalent to the

originals in size, quality and performance when

replacement is needed

Ú

page 225. Refer to the

Tire and Loading Information placard or the

Vehicle Certification Label for the size

designation of your tire. The Load Index and

Speed Symbol for your tire will be found on the

original equipment tire sidewall.

See the Tire Sizing Chart example for more

information relating to the Load Index and Speed

Symbol of a tire

Ú

page 216.

It is recommended to replace the two front tires or

two rear tires as a pair. Replacing just one tire can

seriously affect your vehicle’s handling. If you

ever replace a wheel, make sure that the wheel’s

specifications match those of the original wheels.

It is recommended you contact an authorized tire

dealer or original equipment dealer with any

questions you may have on tire specifications or

capability. Failure to use equivalent replacement

tires may adversely affect the safety, handling,

and ride of your vehicle.

WARNING!

Fast spinning tires can be dangerous. Forces

generated by excessive wheel speeds may

cause tire damage or failure. A tire could

explode and injure someone. Do not spin your

vehicle's wheels faster than 30 mph (48 km/h)

for more than 30 seconds continuously when

you are stuck, and do not let anyone near a

spinning wheel, no matter what the speed.

1 — Worn Tire

2 — New Tire

WARNING!

Tires and the spare tire should be replaced

after six years, regardless of the remaining

tread. Failure to follow this warning can result

in sudden tire failure. You could lose control

and have a collision resulting in serious injury

or death.

22_GU_OM_EN_USC_t.book Page 225

Page 232 of 256

SERVICING AND MAINTENANCE

230

TEMPERATURE GRADES

The temperature grades are A (the

highest), B, and C, representing the

tire's resistance to the generation of

heat and its ability to dissipate heat,

when tested under controlled conditions

on a specified indoor laboratory test

wheel. Sustained high temperature can

cause the material of the tire to

degenerate and reduce tire life, and

excessive temperature can lead to

sudden tire failure. The grade C

corresponds to a level of performance,

which all passenger vehicle tires must

meet under the Federal Motor Vehicle

Safety Standard No. 109. Grades B and

A represent higher levels of

performance on the laboratory test

wheel, than the minimum required by

law.

STORING THE VEHICLE

If the vehicle is left inactive for longer than a

month, the following precautions should be

observed:

Park the vehicle in an area that is covered and

dry, and well-ventilated if possible. Slightly

open the windows.

Check that the Electric Park Brake (EPB) is not

activated.

Carry out the “Liftgate Emergency Opening”

procedure

Ú

page 59.

Disconnect the negative battery terminal and

check the battery charge. Repeat this check

once every three months during storage.

If the battery is not disconnected from the

electrical system, check its state of charge

every 30 days.

Clean and protect the painted parts using

protective wax.

Clean and protect the shiny metal parts using

special compounds available commercially.

Sprinkle talcum powder on the windshield

wiper rubber blades, and lift them off the

glass.

Cover the vehicle with a fabric or perforated

plastic sheet, paying particular care not to

damage the painted surface by dragging any

dust that may have accumulated on it. Do not

use compact plastic sheets, as they do not

allow humidity to evaporate from the surface

of the vehicle.

Inflate tires to +7.25 psi (+0.5 bar) above the

standard prescribed pressure and check it

periodically.

Do not drain the engine cooling system.

Any time the vehicle is left inactive for two

weeks or more, operate the air conditioning

system with engine idling for at least five

minutes, setting external air and with fan set to

maximum speed. This operation will ensure

appropriate lubrication for the system, thus

minimizing the possibility of damage to the

compressor when the system is operated

again.

NOTE:

After cycling the ignition to STOP and having

closed the driver side door, wait at least one

minute before disconnecting the electrical supply

from the battery. When reconnecting the elec-

trical supply to the battery, make sure that the

ignition is in the STOP position and the driver’s

side door is closed.

WARNING!

The traction grade assigned to this tire is

based on straight-ahead braking traction

tests, and does not include acceleration, cor -

nering, hydroplaning, or peak traction charac -

teristics.

WARNING!

The temperature grade for this tire is estab -

lished for a tire that is properly inflated and not

overloaded. Excessive speed, under-inflation,

or excessive loading, either separately or in

combination, can cause heat buildup and pos-

sible tire failure.

22_GU_OM_EN_USC_t.book Page 230

Page 233 of 256

231

BODYWORK

PROTECTION AGAINST ATMOSPHERIC

A

GENTS

The vehicle is equipped with the best available

technological solutions to protect the bodywork

against corrosion.

These include:

Painting products and systems which give the

vehicle resistance to corrosion and abrasion.

Use of galvanized (or pre-treated) steel sheets,

with high resistance to corrosion.

Spraying of plastic parts, with a protective

function in the more exposed points: under

door, inner wing, edges, etc.

Use of “open” boxed sections to prevent

condensation and pockets of moisture which

could favor the formation of rust inside.

Use of special films to protect against abrasion

in exposed areas (e.g. rear wing, doors, etc.).

CORROSION WARRANTY

Your vehicle is covered by Corrosion Warranty

against perforation due to rust of any original

element of the structure or bodywork. For the

general terms of this warranty, refer to the

Warranty Booklet.

PRESERVING THE BODYWORK

Paint

Touch up abrasions and scratches immediately to

prevent the formation of rust.

Maintenance of paintwork consists of washing

the vehicle: the frequency depends on the conditions and environment where the vehicle is

used. For example, it is advisable to wash the

vehicle more often in areas with high levels of

atmospheric pollution or salted roads.

Some parts of the vehicle may be covered with a

matte paint which, in order to be maintained

intact, requires special care.

To correctly wash the vehicle, follow these

instructions:

If high pressure jets or cleaners are used to

wash the vehicle, keep a distance of at least

15 inches (40 cm) from the bodywork to avoid

damage or alteration. Build up of water could

cause damage to the vehicle in the long term.

To make it easier to remove any dirt deposits in

the area where the blades are normally located

it is recommended to position the windshield

wipers vertically (service position)

Ú

page 201.

Wash the bodywork using a low pressure jet of

water if possible.

Wipe a sponge with a slightly soapy solution

over the bodywork, frequently rinsing the

sponge.

Rinse well with water and dry with a leather

chamois.

Dry the less visible parts (e.g. door frames, hood,

headlight frames, etc.) with special care, as water

may stagnate more easily in these areas. Do not

wash the vehicle after it has been left in the sun

or with the hood hot: this may alter the shine of

the paintwork.

NOTE:

Avoid parking under trees; the resin dropped by

trees makes the paintwork go opaque and

increases the possibility of corrosion. Exterior plastic parts must be cleaned in the

same way as the rest of the vehicle.

If washing the vehicle in a service that moves the

vehicle, for vehicles with automatic transmissions,

proceed with the following directions:

Ensure that the vehicle is on a flat surface.

Disable the automatic engagement of the

parking brake

Ú

page 84.

With the vehicle stationary, the gear in

NEUTRAL (N) and the brake pedal pressed,

push the START button.

NOTE:

The vehicle will remain in NEUTRAL (N) for

15 minutes before PARK (P) will be engaged auto

-

matically.

Windows

Use specific detergents and clean cloths to

prevent scratching or altering the transparency.

Front Headlights

Use a soft cloth soaked in water and detergent for

washing vehicles.

NOTE:

Never use aromatic substances (e.g. gasoline)

or ketones (e.g. acetone) for cleaning the

plastic lenses of the headlights.

When cleaning with a pressure washer, keep

the pressure washer at least eight inches

(20 cm) away from the headlights.

CAUTION!

Wipe the rear window inside gently with a cloth

following the direction of the filaments to avoid

damaging the heating device.

22_GU_OM_EN_USC_t.book Page 231

Page 234 of 256

SERVICING AND MAINTENANCE

232

Engine Compartment

At the end of every Winter, wash the engine

compartment thoroughly, taking care not to aim

the jet of water directly at the electronic control

units or at the windshield wiper motors. Have this

operation performed at a specialized workshop

Ú

page 200.

NOTE:

The washing should take place with the engine

cold and the ignition device in the STOP position.

After the washing operation, make sure that the

various protections (e.g. rubber caps and guards)

have not been removed or damaged.

INTERIORS

Periodically check the cleanliness of the interior,

beneath the mats, which could cause oxidation of

the sheet metal.

SEATS AND FABRIC PARTS

Remove dust with a soft brush or a vacuum

cleaner. It is advised to use a moist brush on

velvet upholstery. Rub the seats with a sponge

moistened with a solution of water and neutral

detergent.

Cleaning heat press images on seats —

if equipped:

Due to the color, opacity and wear-resistant

protection with which the heat press images on

some seats are made, they may be subject to

temporary scratching if they are touched by finger

nails, keys, or other hard objects. In such cases,

the visible signs do not impair the profiled

images, and can easily be removed by wiping the affected area with a microfiber cloth moistened

with water (not dry) to restore the seat to its

original condition. The microfiber cloth must not

have been previously soaked in other substances

or detergents.

LEATHER SEATS

Remove the dry dirt with a chamois or slightly

damp cloth, without exerting too much pressure.

Remove any liquid or grease stains using an

absorbent dry cloth, without rubbing. Then clean

with a soft cloth or buckskin cloth dampened with

water and mild soap. If the stain persists, use

specific products and observe the instructions

carefully.

NOTE:

Never use alcohol. Make sure that the cleaning

products used contain no alcohol or alcohol deriv

-

atives, even in small quantities.

PLASTIC AND COATED PARTS

Clean interior plastic parts with a damp cloth (if

possible made from microfiber), and a solution of

water and neutral, non-abrasive detergent.

To clean oily or persistent stains, use specific

products free from solvents and designed to

maintain the original appearance and color of the

components.

Remove any dust using a microfiber cloth, if

necessary moistened with water. The use of

paper tissues is not recommended as these may

leave residues.

ALCANTARA PARTS — IF EQUIPPED

Alcantara parts maintenance procedure:

Treat the surface with a microfiber cloth

moistened with mild marseille soap and water,

taking care to apply a uniform light pressure

over the entire area (do not rub vigorously).

Rinse and wring out the microfiber cloth, and

pass it over the entire area again.

Let it dry, and then brush gently with a soft

brush.

GENUINE LEATHER PARTS

Use only water and mild soap to clean these

parts. Never use alcohol or alcohol-based

products.

Before using a specific product for cleaning

interiors, make sure that it does not contain

alcohol and/or alcohol based substances.

CARBON FIBER PARTS

To eliminate small scratches and marks on the

carbon, contact an authorized dealer. An

improperly performed operation may irreparably

damage the carbon.

CAUTION!

Precautions have been taken to safeguard all

parts and connections however, the pressures

generated by these machines is such that

complete protection against water ingress

cannot be guaranteed.

22_GU_OM_EN_USC_t.book Page 232

Page 241 of 256

239

FUEL REQUIREMENTS

This engine is designed to meet all

emission regulations, and provide

satisfactory fuel economy and

performance when using high-quality

unleaded regular gasoline having a posted octane

number of 87 as specified by the (R+M)/2 method.

For optimal performance the use of 91 or higher

octane premium gasoline is recommended in these

engines.

While operating on gasoline with the required

octane number, hearing a light knocking sound

from the engine is not a cause for concern.

However, if the engine is heard making a heavy

knocking sound, see an authorized dealer

immediately. Use of gasoline with a lower than

recommended octane number can cause engine

failure and may void or not be covered by the New

Vehicle Limited Warranty. Poor quality gasoline can cause problems such as

hard starting, stalling, and hesitations. If you

experience these symptoms, try another brand of

gasoline before considering service for the

vehicle.

REFORMULATED GASOLINE

Many areas of the country require the use of

cleaner burning gasoline referred to as

“reformulated gasoline”. Reformulated gasoline

contains oxygenates and are specifically blended

to reduce vehicle emissions and improve air

quality.

The use of reformulated gasoline is

recommended. Properly blended reformulated

gasoline will provide improved performance and

durability of engine and fuel system components.

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend unleaded gasoline with

oxygenates such as ethanol.

Weights2.9L engine

Unladen weight (with all fluids, fuel tank filled to 90% and without optional

equipment) 4,308 lb

Payload including the driver

1

1. If special equipment is fitted the empty weight will increase and consequently the payload will decrease in relation to the maximum permitted loads.

992 lb

Maximum permitted loads

2

2. Loads not to be exceeded. The user is responsible for arranging goods in the luggage compartment and/or on the load platform within the maximum permitted loads.

242 lb

– Front axle 2,579 lb

– Rear axle 2,976 lb

– Total 5,423 lb

Maximum load on roof 165 lb (75 kg)

CAUTION!

DO NOT use E-85, gasoline containing

methanol, or gasoline containing more than

15% ethanol (E-15). Use of these blends may

result in starting and drivability problems,

damage critical fuel system components,

cause emissions to exceed the applicable

standard, and/or cause the Malfunction

Indicator Light to illuminate. Please observe

pump labels as they should clearly

communicate if a fuel contains greater than

15% ethanol (E-15).

22_GU_OM_EN_USC_t.book Page 239