ignition ALFA ROMEO STELVIO 2022 Repair Manual

[x] Cancel search | Manufacturer: ALFA ROMEO, Model Year: 2022, Model line: STELVIO, Model: ALFA ROMEO STELVIO 2022Pages: 256, PDF Size: 10.17 MB

Page 179 of 256

177

To Use SOS - Emergency Call

Push and hold the SOS - Emergency Call button

for a few seconds. The LED, located next to the

SOS button, will blink once and then stay on

indicating a call has been placed.

NOTE:

If the SOS - Emergency Call button is accidentally

pushed, there is a 10 second delay before the call

is placed. The system will issue a verbal alert that

a call is about to be made. To cancel the call

connection, push the SOS - Emergency Call

button again.

Once a connection between the vehicle and an

emergency service operator is made, the SOS -

Emergency Call system will transmit the following

important vehicle information to the operator:

Indication that the occupant placed an SOS -

Emergency Call.

The Vehicle Identification Number (VIN).

The last known GPS coordinates of the vehicle.

You will then be able to speak with the emergency

service operator to determine if additional help is

needed.

The SOS - Emergency Call has priority over other

audio sources, which will be muted. If you have a

phone connected via Bluetooth®, it is discon -

nected and reconnected at the end of the SOS -

Emergency Call. Voice prompts will guide you

during the SOS - Emergency Call. If a connection

is made between an emergency service operator

and your vehicle, emergency service operators

may record conversations and sounds within your

vehicle once a connection is made, and by using

the service you consent to having this information

shared.

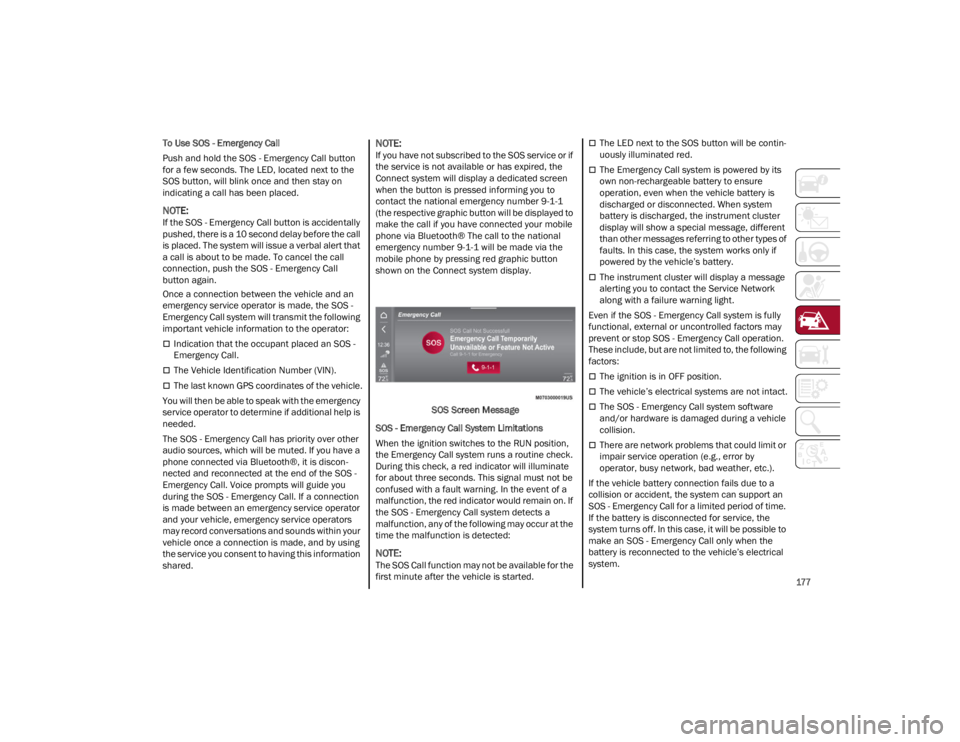

NOTE:

If you have not subscribed to the SOS service or if

the service is not available or has expired, the

Connect system will display a dedicated screen

when the button is pressed informing you to

contact the national emergency number 9-1-1

(the respective graphic button will be displayed to

make the call if you have connected your mobile

phone via Bluetooth® The call to the national

emergency number 9-1-1 will be made via the

mobile phone by pressing red graphic button

shown on the Connect system display.

SOS Screen Message

SOS - Emergency Call System Limitations

When the ignition switches to the RUN position,

the Emergency Call system runs a routine check.

During this check, a red indicator will illuminate

for about three seconds. This signal must not be

confused with a fault warning. In the event of a

malfunction, the red indicator would remain on. If

the SOS - Emergency Call system detects a

malfunction, any of the following may occur at the

time the malfunction is detected:

NOTE:

The SOS Call function may not be available for the

first minute after the vehicle is started.

The LED next to the SOS button will be contin -

uously illuminated red.

The Emergency Call system is powered by its

own non-rechargeable battery to ensure

operation, even when the vehicle battery is

discharged or disconnected. When system

battery is discharged, the instrument cluster

display will show a special message, different

than other messages referring to other types of

faults. In this case, the system works only if

powered by the vehicle’s battery.

The instrument cluster will display a message

alerting you to contact the Service Network

along with a failure warning light.

Even if the SOS - Emergency Call system is fully

functional, external or uncontrolled factors may

prevent or stop SOS - Emergency Call operation.

These include, but are not limited to, the following

factors:

The ignition is in OFF position.

The vehicle’s electrical systems are not intact.

The SOS - Emergency Call system software

and/or hardware is damaged during a vehicle

collision.

There are network problems that could limit or

impair service operation (e.g., error by

operator, busy network, bad weather, etc.).

If the vehicle battery connection fails due to a

collision or accident, the system can support an

SOS - Emergency Call for a limited period of time.

If the battery is disconnected for service, the

system turns off. In this case, it will be possible to

make an SOS - Emergency Call only when the

battery is reconnected to the vehicle’s electrical

system.

22_GU_OM_EN_USC_t.book Page 177

Page 180 of 256

IN CASE OF EMERGENCY

178

(Continued)

(Continued)

System Requirements

Vehicle must have an operable 3G network

connection.

Vehicle must be powered with a properly

functioning electrical system.

The ignition must be in the RUN or ACC

position.

Frequently Asked Questions:

What happens if I accidentally push the SOS -

Emergency Call Button?

You have 10 seconds

after pushing the emergency button to cancel the

call. To cancel the call, push the button again.

What type of information is sent when I make an

SOS - Emergency Call from my vehicle? Certain

vehicle information, such as the VIN, is

transmitted along with last known GPS location.

Also note that emergency service operators may

record conversations and sounds within your

vehicle once a connection is made, and by using

the service you consent to having this information

shared.

When can I use the SOS - Emergency

Call button? You can ONLY use the

SOS - Emergency Call button to make a

call if you or someone else needs

emergency assistance.

JACKING AND TIRE

CHANGING

WARNING!

Never place anything on or near the vehicle’s

3G and GPS aerials. You could prevent 3G

and GPS signal reception, which can prevent

your vehicle from placing an emergency call.

An operable 3G network connection and a

GPS signal is required for the SOS-

Emergency Call system to function properly.

Do not add any aftermarket electrical

equipment to the vehicle’s electrical system.

This may prevent your vehicle from sending a

signal to initiate an emergency call. To avoid

interference that can cause the

SOS-Emergency Call system to fail, never

add aftermarket equipment (e.g., two-way

mobile radio, CB radio, data recorder, etc.) to

your vehicle’s electrical system or modify the

antennas on your vehicle. IF YOUR VEHICLE

AND SYSTEM LOSES BATTERY POWER FOR

ANY REASON (INCLUDING DURING OR AFTER

AN ACCIDENT) THE SOS FEATURES, APPS

AND SERVICES AMONG OTHERS WILL NOT

OPERATE.

The Occupant Restraint Controller (ORC)

turns on the air bag warning light in the

instrument cluster if a malfunction in any

part of the air bag system is detected. If the

air bag warning light is illuminated, the air

bag system may not be working properly and

the SOS-Emergency Call system may not be

able to send a signal to an emergency

service operator. If the air bag warning light

is illuminated, contact the Service Network

to have the air bag system checked

immediately.

Ignoring the LED on the SOS-Emergency Call

button could mean you will not have

emergency call services if needed. If the LED

on SOS-Emergency Call button is illuminated

red, contact the Service Network to have the

emergency call system checked

immediately.

If anyone in the vehicle could be in danger

(e.g., fire or smoke is visible, dangerous road

conditions or location), do not wait for voice

contact from an emergency service operator.

All occupants should exit the vehicle

immediately and move to a safe location.

Failure to perform scheduled maintenance

and regularly inspect your vehicle may result

in vehicle damage, accident or injury.

WARNING!

WARNING!

Do not attempt to change a tire on the side of

the vehicle close to moving traffic. Pull far

enough off the road to avoid the danger of

being hit when operating the jack or

changing the wheel.

22_GU_OM_EN_USC_t.book Page 178

Page 181 of 256

179

GENERAL INSTRUCTIONS

This vehicle can be equipped with a Tire Service

Kit

Ú

page 181.

As an alternative to the Tire Service Kit, the

vehicle may be purchased with a compact spare

tire

Ú

page 179.

JACK INFORMATION AND USAGE

P

RECAUTIONS

Jack Information

The jack weighs 4.4 lb (2 kg).

The jack requires no adjustment.

The jack cannot be repaired, and in the event

of a fault it must be replaced by another factory

replacement.

No tool other than its extension lever may be

fitted on the jack. Jack Maintenance

Prevent any dirt from depositing on the "worm

screw".

Keep the "worm screw" lubricated.

Never modify the jack.

Conditions Of Non-Use Of The Jack

Temperatures below −40°F (−40°C).

On sandy or muddy ground.

On uneven ground.

On steep slopes in extreme weather

conditions.

In direct contact with the engine or for repairs

under the vehicle.

On boats.

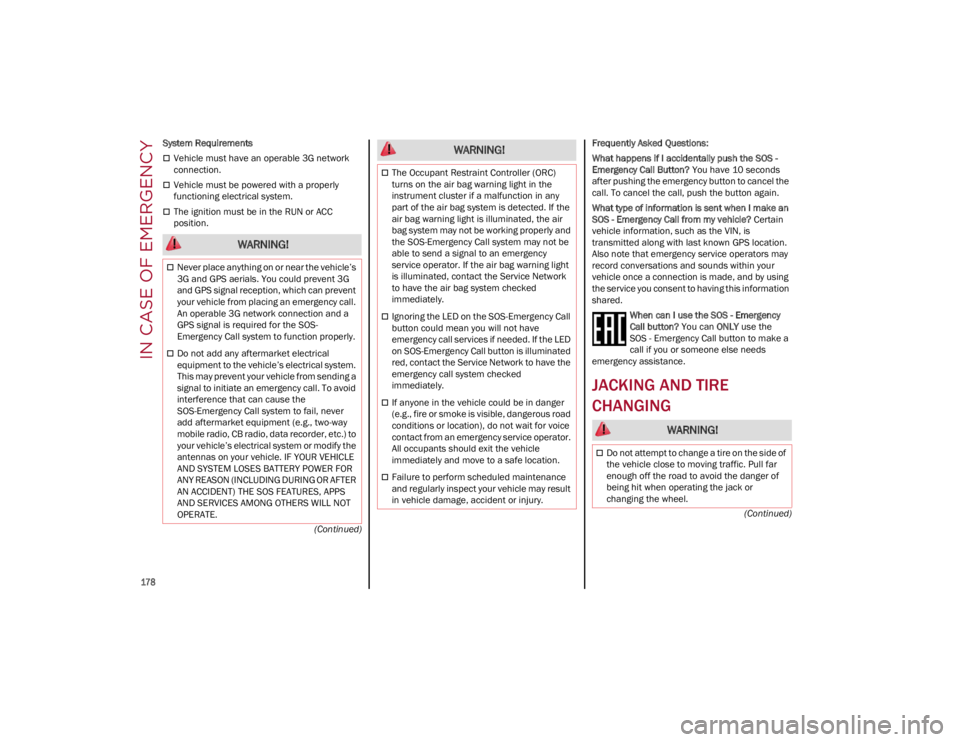

CHANGING PROCEDURE

1. Park the vehicle on a firm, level surface. Avoid ice or slippery areas.

2. Turn on the Hazard Warning Flashers.

3. Apply the Electric Park Brake.

4. Place the gear selector into PARK (P).

5. Place the ignition in the OFF mode.

6. Block both the front and rear of the wheel diagonally opposite of the jacking position.

For example, if changing the left rear tire,

block the right front wheel. Wheel Blocking Example

7. Open the liftgate and lift up the load floor using the handle.

8. Take the warning triangle and position it at a suitable distance from the vehicle to warn

oncoming vehicles.

9. Unscrew the locking plate and take out the compact spare tire and the air compressor.

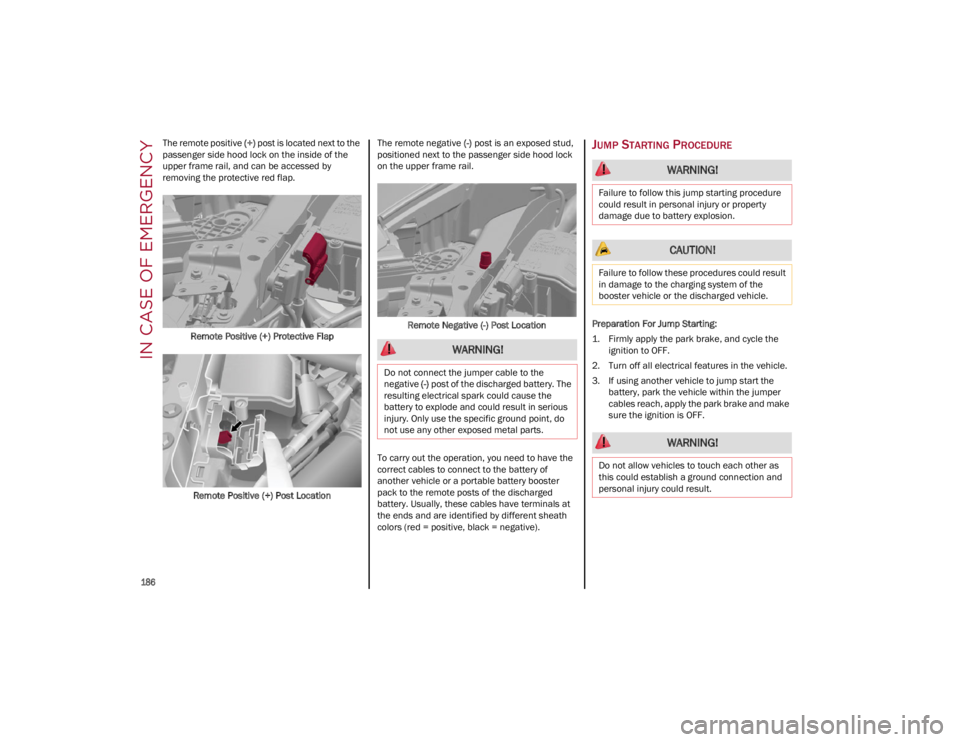

Compact Spare Tire — If Equipped

10. Remove the damaged wheel by using the wheel wrench to loosen the bolts by one turn.

Being under a jacked-up vehicle is

dangerous. The vehicle could slip off the jack

and fall on you. You could be crushed. Never

put any part of your body under a vehicle that

is on a jack. If you need to get under a raised

vehicle, take it to a service center where it

can be raised on a lift.

Never start or run the engine while the

vehicle is on a jack.

The jack is designed to be used as a tool for

changing tires only. The jack should not be

used to lift the vehicle for service purposes.

The vehicle should be jacked on a firm level

surface only. Avoid ice or slippery areas.

WARNING!

WARNING!

Do not attempt to change a tire on the side of

the vehicle close to moving traffic. Pull far

enough off the road to avoid being hit when

operating the jack or changing the wheel.

1 — Locking Plate

22_GU_OM_EN_USC_t.book Page 179

Page 188 of 256

IN CASE OF EMERGENCY

186

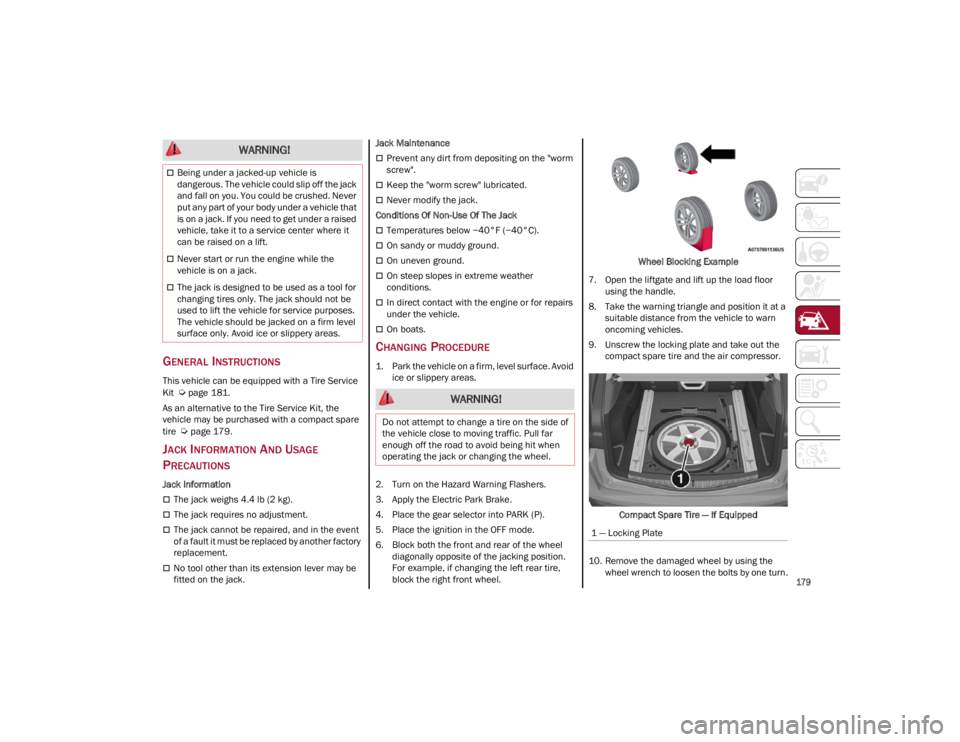

The remote positive (+) post is located next to the

passenger side hood lock on the inside of the

upper frame rail, and can be accessed by

removing the protective red flap.

Remote Positive (+) Protective Flap

Remote Positive (+) Post Location The remote negative

(-) post is an exposed stud,

positioned next to the passenger side hood lock

on the upper frame rail.

Remote Negative (-) Post Location

To carry out the operation, you need to have the

correct cables to connect to the battery of

another vehicle or a portable battery booster

pack to the remote posts of the discharged

battery. Usually, these cables have terminals at

the ends and are identified by different sheath

colors (red = positive, black = negative).JUMP STARTING PROCEDURE

Preparation For Jump Starting:

1. Firmly apply the park brake, and cycle the ignition to OFF.

2. Turn off all electrical features in the vehicle.

3. If using another vehicle to jump start the battery, park the vehicle within the jumper

cables reach, apply the park brake and make

sure the ignition is OFF.

WARNING!

Do not connect the jumper cable to the

negative (-) post of the discharged battery. The

resulting electrical spark could cause the

battery to explode and could result in serious

injury. Only use the specific ground point, do

not use any other exposed metal parts.

WARNING!

Failure to follow this jump starting procedure

could result in personal injury or property

damage due to battery explosion.

CAUTION!

Failure to follow these procedures could result

in damage to the charging system of the

booster vehicle or the discharged vehicle.

WARNING!

Do not allow vehicles to touch each other as

this could establish a ground connection and

personal injury could result.

22_GU_OM_EN_USC_t.book Page 186

Page 200 of 256

SERVICING AND MAINTENANCE

198

NOTE:

Always reinstall the oil cap and tighten to proper

torque whenever it is removed to add oil to

engine. Never run the engine with cap removed

as this could cause oil to leak from engine.

Manual Oil Level Checking Procedure —

2.9L Quadrifoglio

Check that the oil level is between the MIN and

MAX marks on dipstick, clean it with a lint-free

cloth and reinsert it. Extract the dipstick again

and check that the level is between the MIN and

MAX marks.

Top-Up And Oil Level Indication Update On

Display — 2.9L Quadrifoglio

If an engine oil top-off is needed, in order to

ensure the correct indication of the oil level on

the display, proceed with the following process:

Leave the car on flat ground with the engine

running for approximately five minutes

(temperature higher than 198°F (90°C) and

shut the engine off.

Wait for five minutes, turn the ignition to the

ACC mode without starting the engine and wait

for a few seconds.

NOTE:

If the level indication is not updated after the

previously described procedure, repeat the

engine adjustment, shut the engine off and wait

another five minutes before starting it again. If

the indication is not updated after the second

start, contact an authorized dealer.

Top-Up And Oil Level Indication Update On

Display — 2.0L

If an engine oil top-off is needed, in order to

ensure the correct indication of the oil level on

the display, proceed with the following process:

Leave the car on flat ground with the engine

running for approximately five minutes

(temperature higher than 176°F (80°C) and

shut the engine off.

Start the engine again and idle it for about two

minutes.

NOTE:

If you have added the specified amount of oil and

the indicator is not reading “Full”, please contact

an authorized dealer.

ENGINE COOLANT FLUID

If the level is too low, unscrew the cap of the

reservoir and add the fluid described

Ú

page 242.

WASHER FLUID FOR WINDSHIELD/

H

EADLIGHTS

The windshield and headlight (if equipped)

washer fluid reservoir is equipped with a

telescopic filler neck.

If the level is too low, remove reservoir cap and lift

the filler neck. Then, add the fluid described

Ú

page 242. After filling the reservoir, lower the

filler neck and install the reservoir cap until you

hear it click.

CAUTION!

The oil level is not refreshed immediately on

the display after topping off. Consequently,

wait for the oil level to be refreshed on the

display and follow the procedure below.

WARNING!

If the engine oil is being topped up, wait for the

engine to cool down before loosening the filler

cap, particularly for vehicles with aluminum

cap (if equipped). WARNING: risk of burns!

CAUTION!

The oil level must never exceed the MAX mark.

If the MAX mark is exceeded (last notch on the

right turns red) after the fill-up, go to an

authorized dealer as soon as possible to have

the oil in excess removed.

Do not add oil with specifications different

from those of the oil already in the engine.

Used engine oil and oil filters contain

substances which are harmful to the

environment. To change the oil and filters, we

advise you to contact an authorized dealer.

22_GU_OM_EN_USC_t.book Page 198

Page 205 of 256

203

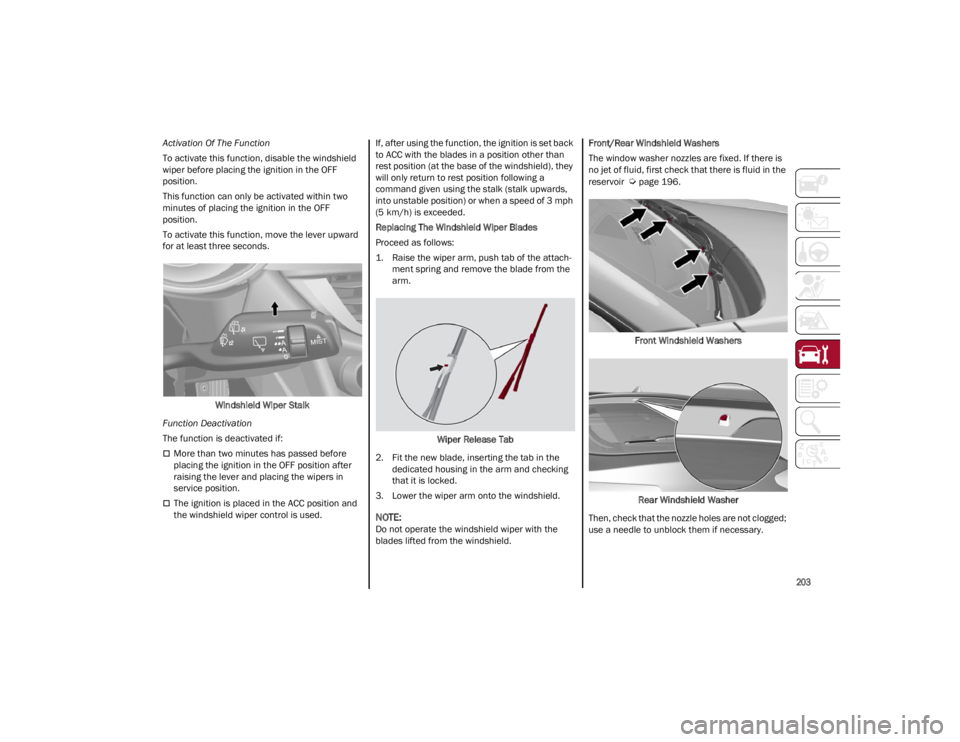

Activation Of The Function

To activate this function, disable the windshield

wiper before placing the ignition in the OFF

position.

This function can only be activated within two

minutes of placing the ignition in the OFF

position.

To activate this function, move the lever upward

for at least three seconds.Windshield Wiper Stalk

Function Deactivation

The function is deactivated if:

More than two minutes has passed before

placing the ignition in the OFF position after

raising the lever and placing the wipers in

service position.

The ignition is placed in the ACC position and

the windshield wiper control is used. If, after using the function, the ignition is set back

to ACC with the blades in a position other than

rest position (at the base of the windshield), they

will only return to rest position following a

command given using the stalk (stalk upwards,

into unstable position) or when a speed of 3 mph

(5 km/h) is exceeded.

Replacing The Windshield Wiper Blades

Proceed as follows:

1. Raise the wiper arm, push tab of the attach- ment spring and remove the blade from the

arm.

Wiper Release Tab

2. Fit the new blade, inserting the tab in the dedicated housing in the arm and checking

that it is locked.

3. Lower the wiper arm onto the windshield.

NOTE:

Do not operate the windshield wiper with the

blades lifted from the windshield. Front/Rear Windshield Washers

The window washer nozzles are fixed. If there is

no jet of fluid, first check that there is fluid in the

reservoir

Ú

page 196.

Front Windshield Washers

Rear Windshield Washer

Then, check that the nozzle holes are not clogged;

use a needle to unblock them if necessary.

22_GU_OM_EN_USC_t.book Page 203

Page 206 of 256

SERVICING AND MAINTENANCE

204

(Continued)

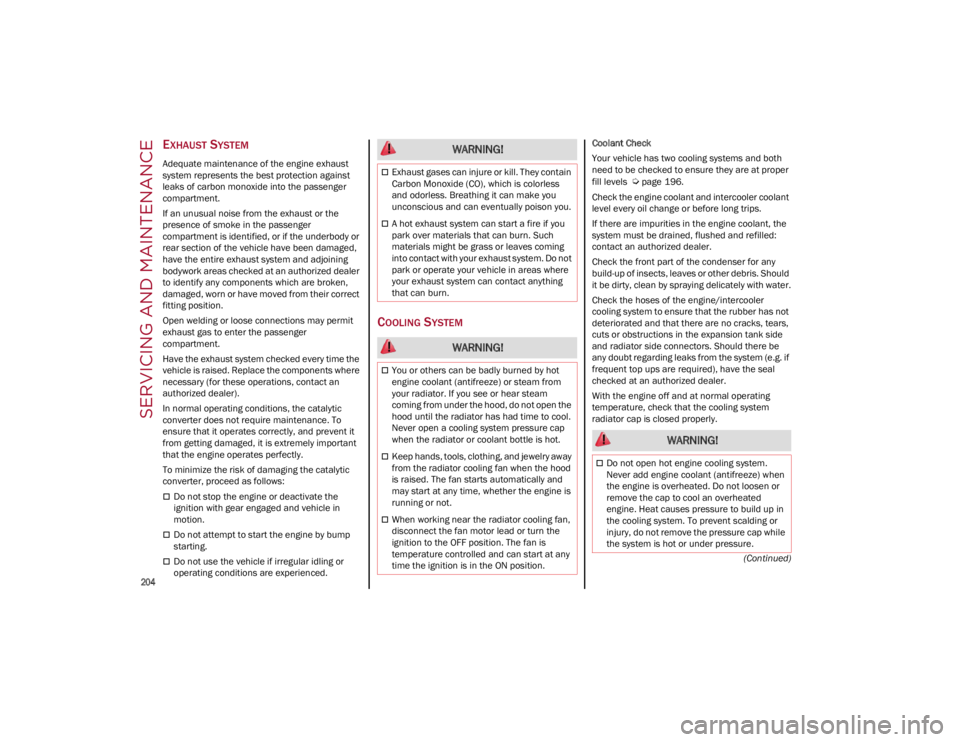

EXHAUST SYSTEM

Adequate maintenance of the engine exhaust

system represents the best protection against

leaks of carbon monoxide into the passenger

compartment.

If an unusual noise from the exhaust or the

presence of smoke in the passenger

compartment is identified, or if the underbody or

rear section of the vehicle have been damaged,

have the entire exhaust system and adjoining

bodywork areas checked at an authorized dealer

to identify any components which are broken,

damaged, worn or have moved from their correct

fitting position.

Open welding or loose connections may permit

exhaust gas to enter the passenger

compartment.

Have the exhaust system checked every time the

vehicle is raised. Replace the components where

necessary (for these operations, contact an

authorized dealer).

In normal operating conditions, the catalytic

converter does not require maintenance. To

ensure that it operates correctly, and prevent it

from getting damaged, it is extremely important

that the engine operates perfectly.

To minimize the risk of damaging the catalytic

converter, proceed as follows:

Do not stop the engine or deactivate the

ignition with gear engaged and vehicle in

motion.

Do not attempt to start the engine by bump

starting.

Do not use the vehicle if irregular idling or

operating conditions are experienced.

COOLING SYSTEM

Coolant Check

Your vehicle has two cooling systems and both

need to be checked to ensure they are at proper

fill levels

Ú

page 196.

Check the engine coolant and intercooler coolant

level every oil change or before long trips.

If there are impurities in the engine coolant, the

system must be drained, flushed and refilled:

contact an authorized dealer.

Check the front part of the condenser for any

build-up of insects, leaves or other debris. Should

it be dirty, clean by spraying delicately with water.

Check the hoses of the engine/intercooler

cooling system to ensure that the rubber has not

deteriorated and that there are no cracks, tears,

cuts or obstructions in the expansion tank side

and radiator side connectors. Should there be

any doubt regarding leaks from the system (e.g. if

frequent top ups are required), have the seal

checked at an authorized dealer.

With the engine off and at normal operating

temperature, check that the cooling system

radiator cap is closed properly.

WARNING!

Exhaust gases can injure or kill. They contain

Carbon Monoxide (CO), which is colorless

and odorless. Breathing it can make you

unconscious and can eventually poison you.

A hot exhaust system can start a fire if you

park over materials that can burn. Such

materials might be grass or leaves coming

into contact with your exhaust system. Do not

park or operate your vehicle in areas where

your exhaust system can contact anything

that can burn.

WARNING!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from

your radiator. If you see or hear steam

coming from under the hood, do not open the

hood until the radiator has had time to cool.

Never open a cooling system pressure cap

when the radiator or coolant bottle is hot.

Keep hands, tools, clothing, and jewelry away

from the radiator cooling fan when the hood

is raised. The fan starts automatically and

may start at any time, whether the engine is

running or not.

When working near the radiator cooling fan,

disconnect the fan motor lead or turn the

ignition to the OFF position. The fan is

temperature controlled and can start at any

time the ignition is in the ON position.

WARNING!

Do not open hot engine cooling system.

Never add engine coolant (antifreeze) when

the engine is overheated. Do not loosen or

remove the cap to cool an overheated

engine. Heat causes pressure to build up in

the cooling system. To prevent scalding or

injury, do not remove the pressure cap while

the system is hot or under pressure.

22_GU_OM_EN_USC_t.book Page 204

Page 209 of 256

207

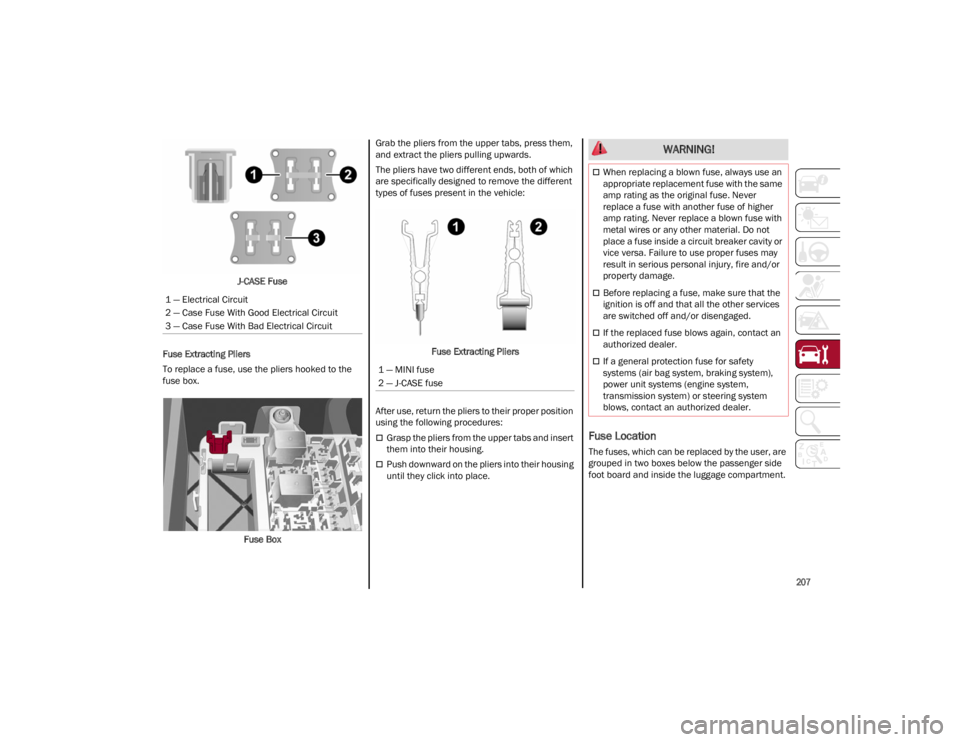

J-CASE Fuse

Fuse Extracting Pliers

To replace a fuse, use the pliers hooked to the

fuse box.

Fuse Box Grab the pliers from the upper tabs, press them,

and extract the pliers pulling upwards.

The pliers have two different ends, both of which

are specifically designed to remove the different

types of fuses present in the vehicle:

Fuse Extracting Pliers

After use, return the pliers to their proper position

using the following procedures:

Grasp the pliers from the upper tabs and insert

them into their housing.

Push downward on the pliers into their housing

until they click into place.

Fuse Location

The fuses, which can be replaced by the user, are

grouped in two boxes below the passenger side

foot board and inside the luggage compartment.

1 — Electrical Circuit

2 — Case Fuse With Good Electrical Circuit

3 — Case Fuse With Bad Electrical Circuit

1 — MINI fuse

2 — J-CASE fuse

WARNING!

When replacing a blown fuse, always use an

appropriate replacement fuse with the same

amp rating as the original fuse. Never

replace a fuse with another fuse of higher

amp rating. Never replace a blown fuse with

metal wires or any other material. Do not

place a fuse inside a circuit breaker cavity or

vice versa. Failure to use proper fuses may

result in serious personal injury, fire and/or

property damage.

Before replacing a fuse, make sure that the

ignition is off and that all the other services

are switched off and/or disengaged.

If the replaced fuse blows again, contact an

authorized dealer.

If a general protection fuse for safety

systems (air bag system, braking system),

power unit systems (engine system,

transmission system) or steering system

blows, contact an authorized dealer.

22_GU_OM_EN_USC_t.book Page 207

Page 232 of 256

SERVICING AND MAINTENANCE

230

TEMPERATURE GRADES

The temperature grades are A (the

highest), B, and C, representing the

tire's resistance to the generation of

heat and its ability to dissipate heat,

when tested under controlled conditions

on a specified indoor laboratory test

wheel. Sustained high temperature can

cause the material of the tire to

degenerate and reduce tire life, and

excessive temperature can lead to

sudden tire failure. The grade C

corresponds to a level of performance,

which all passenger vehicle tires must

meet under the Federal Motor Vehicle

Safety Standard No. 109. Grades B and

A represent higher levels of

performance on the laboratory test

wheel, than the minimum required by

law.

STORING THE VEHICLE

If the vehicle is left inactive for longer than a

month, the following precautions should be

observed:

Park the vehicle in an area that is covered and

dry, and well-ventilated if possible. Slightly

open the windows.

Check that the Electric Park Brake (EPB) is not

activated.

Carry out the “Liftgate Emergency Opening”

procedure

Ú

page 59.

Disconnect the negative battery terminal and

check the battery charge. Repeat this check

once every three months during storage.

If the battery is not disconnected from the

electrical system, check its state of charge

every 30 days.

Clean and protect the painted parts using

protective wax.

Clean and protect the shiny metal parts using

special compounds available commercially.

Sprinkle talcum powder on the windshield

wiper rubber blades, and lift them off the

glass.

Cover the vehicle with a fabric or perforated

plastic sheet, paying particular care not to

damage the painted surface by dragging any

dust that may have accumulated on it. Do not

use compact plastic sheets, as they do not

allow humidity to evaporate from the surface

of the vehicle.

Inflate tires to +7.25 psi (+0.5 bar) above the

standard prescribed pressure and check it

periodically.

Do not drain the engine cooling system.

Any time the vehicle is left inactive for two

weeks or more, operate the air conditioning

system with engine idling for at least five

minutes, setting external air and with fan set to

maximum speed. This operation will ensure

appropriate lubrication for the system, thus

minimizing the possibility of damage to the

compressor when the system is operated

again.

NOTE:

After cycling the ignition to STOP and having

closed the driver side door, wait at least one

minute before disconnecting the electrical supply

from the battery. When reconnecting the elec-

trical supply to the battery, make sure that the

ignition is in the STOP position and the driver’s

side door is closed.

WARNING!

The traction grade assigned to this tire is

based on straight-ahead braking traction

tests, and does not include acceleration, cor -

nering, hydroplaning, or peak traction charac -

teristics.

WARNING!

The temperature grade for this tire is estab -

lished for a tire that is properly inflated and not

overloaded. Excessive speed, under-inflation,

or excessive loading, either separately or in

combination, can cause heat buildup and pos-

sible tire failure.

22_GU_OM_EN_USC_t.book Page 230

Page 234 of 256

SERVICING AND MAINTENANCE

232

Engine Compartment

At the end of every Winter, wash the engine

compartment thoroughly, taking care not to aim

the jet of water directly at the electronic control

units or at the windshield wiper motors. Have this

operation performed at a specialized workshop

Ú

page 200.

NOTE:

The washing should take place with the engine

cold and the ignition device in the STOP position.

After the washing operation, make sure that the

various protections (e.g. rubber caps and guards)

have not been removed or damaged.

INTERIORS

Periodically check the cleanliness of the interior,

beneath the mats, which could cause oxidation of

the sheet metal.

SEATS AND FABRIC PARTS

Remove dust with a soft brush or a vacuum

cleaner. It is advised to use a moist brush on

velvet upholstery. Rub the seats with a sponge

moistened with a solution of water and neutral

detergent.

Cleaning heat press images on seats —

if equipped:

Due to the color, opacity and wear-resistant

protection with which the heat press images on

some seats are made, they may be subject to

temporary scratching if they are touched by finger

nails, keys, or other hard objects. In such cases,

the visible signs do not impair the profiled

images, and can easily be removed by wiping the affected area with a microfiber cloth moistened

with water (not dry) to restore the seat to its

original condition. The microfiber cloth must not

have been previously soaked in other substances

or detergents.

LEATHER SEATS

Remove the dry dirt with a chamois or slightly

damp cloth, without exerting too much pressure.

Remove any liquid or grease stains using an

absorbent dry cloth, without rubbing. Then clean

with a soft cloth or buckskin cloth dampened with

water and mild soap. If the stain persists, use

specific products and observe the instructions

carefully.

NOTE:

Never use alcohol. Make sure that the cleaning

products used contain no alcohol or alcohol deriv

-

atives, even in small quantities.

PLASTIC AND COATED PARTS

Clean interior plastic parts with a damp cloth (if

possible made from microfiber), and a solution of

water and neutral, non-abrasive detergent.

To clean oily or persistent stains, use specific

products free from solvents and designed to

maintain the original appearance and color of the

components.

Remove any dust using a microfiber cloth, if

necessary moistened with water. The use of

paper tissues is not recommended as these may

leave residues.

ALCANTARA PARTS — IF EQUIPPED

Alcantara parts maintenance procedure:

Treat the surface with a microfiber cloth

moistened with mild marseille soap and water,

taking care to apply a uniform light pressure

over the entire area (do not rub vigorously).

Rinse and wring out the microfiber cloth, and

pass it over the entire area again.

Let it dry, and then brush gently with a soft

brush.

GENUINE LEATHER PARTS

Use only water and mild soap to clean these

parts. Never use alcohol or alcohol-based

products.

Before using a specific product for cleaning

interiors, make sure that it does not contain

alcohol and/or alcohol based substances.

CARBON FIBER PARTS

To eliminate small scratches and marks on the

carbon, contact an authorized dealer. An

improperly performed operation may irreparably

damage the carbon.

CAUTION!

Precautions have been taken to safeguard all

parts and connections however, the pressures

generated by these machines is such that

complete protection against water ingress

cannot be guaranteed.

22_GU_OM_EN_USC_t.book Page 232