wheel ASTON MARTIN DB AR1 Q 2003 Owners Guide

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2003, Model line: DB AR1 Q, Model: ASTON MARTIN DB AR1 Q 2003Pages: 279, PDF Size: 3.77 MB

Page 117 of 279

F - Owner Maintenance

1-F-8

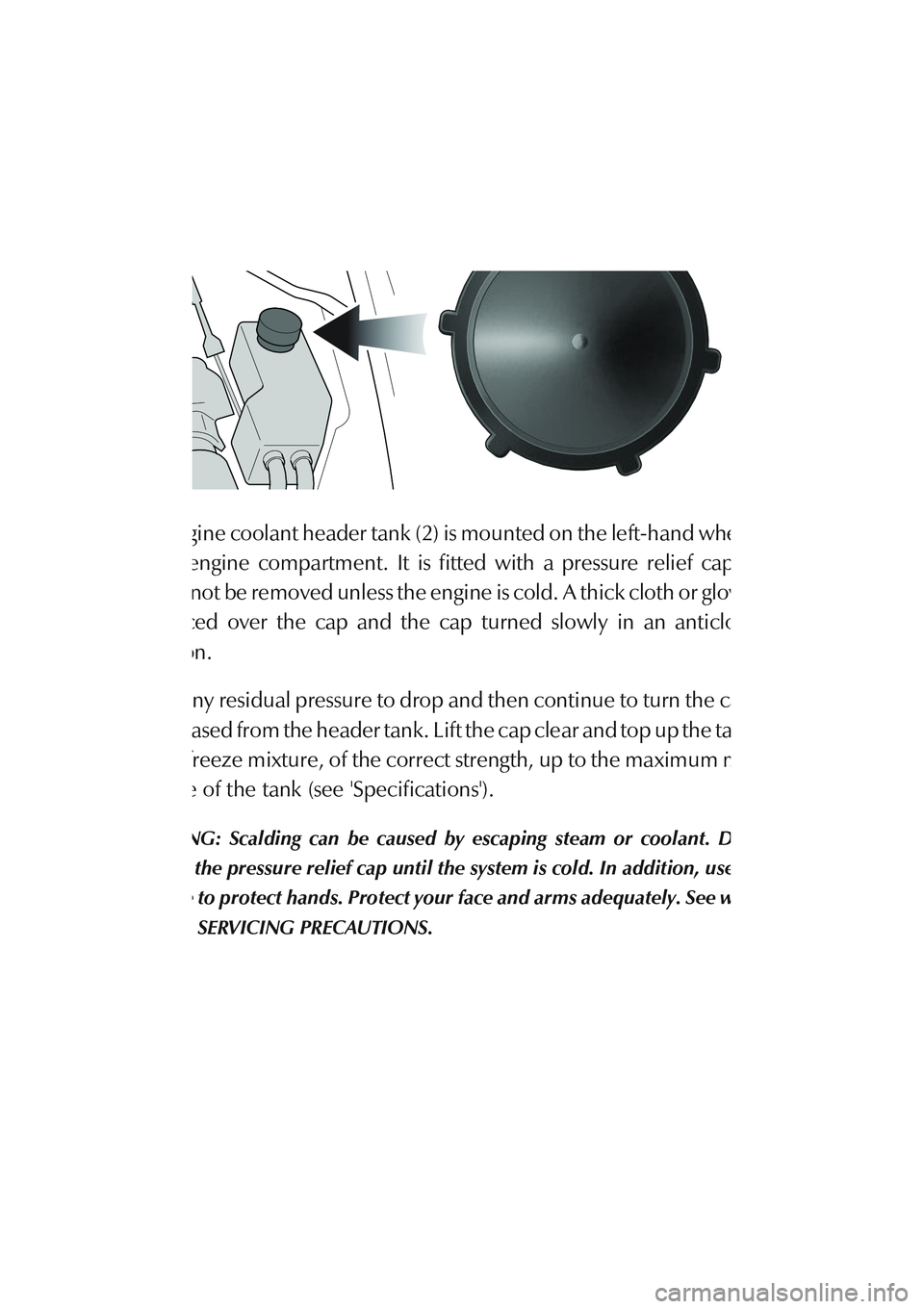

Engine Coolant Level Check

The engine coolant header tank (2) is mounted on the left-hand wheel arch

in the engine compartment. It is fitted with a pressure relief cap which

should not be removed unless the engine is cold. A thick cloth or glove must

be placed over the cap and the cap turned slowly in an anticlockwise

direction.

Allow any residual pressure to drop and then continue to turn the cap until

it is released from the header tank. Lift the cap clear and top up the tank with

an antifreeze mixture, of the correct strength, up to the maximum mark on

the side of the tank (see 'Specifications').

WARNING: Scalding can be caused by escaping steam or coolant. DO NOT

remove the pressure relief cap until the system is cold. In addition, use a cloth

or glove to protect hands. Protect your face and arms adequately. See warnings

given in SERVICING PRECAUTIONS.

Page 122 of 279

F - Owner Maintenance

1-F-13

Windscreen Washer Jets

A washer jet housing is located on each of the

two windscreen wiper arms. Each housing

contains six washer jets.

Adjust the angle of the jets if necessary using

a fine needle so that fluid covers the full length

of both sides of the wiper blades and all spray

stays on the windscreen.

Wheels and Tyres

The tyres detailed in the specification section of this Owner's Guide are the

only tyres approved for use on this vehicle.

To maintain the high performance capability of the car, specified tyres

should be fitted when replacement becomes necessary. The recommended

tyres for DB AR1 are not unidirectional. Tyre sizes are different on the front

and rear axles. Therefore, complete wheels cannot be swapped between

axles, but may be swapped from one side of the vehicle to the other.

It is a characteristic of high performance tyres that temporary 'flat spots' may

develop if the vehicle is left standing in high or low ambient temperatures

for any length of time. These 'flat spots will manifest themselves as minor

vibrations when the car is first driven from cold. As the tyres warm up to

operating temperature, the normal tyre shape should be restored and the

vibrations cease. If vibrations persist, consult your Aston Martin dealer.

Page 124 of 279

F - Owner Maintenance

1-F-15 Only fit the specified tyres. These are designed for the potential speed,

acceleration, handling and braking performance of the car

New tyres should not be fitted to the front wheels in combination with worn

rear tyres as rear end stability will be affected. Consult your Aston Martin

dealer for advice if the rear tyres are also worn.

Each wheel and tyre unit must be balanced dynamically to ensure efficient

steering, optimum tyre wear and maximum ride comfort. Because of the

potentially high speeds, it is essential that wheel balancing is carried out

when new tyres are fitted.

WARNING: Because of the high performance potential of your DB AR1, Aston

Martin strongly recommend replacement of any damaged or worn tyre.

Tread Wear Indicators

Tread wear indicators are incorporated

into the construction of all tyres. These

indicators are integral moulded ribs

spaced at regular intervals around the

circumference of the tyre and extend

across the full width of the tread, in all

primary grooves.

When a tyre has worn causing one or more of the indicators to be flush with

the outer face of the tread, only 1.6mm (0.062in) or less tread depth remains

and the tyre has reached its wear limit. It then becomes illegal in certain

countries and must be replaced.

Page 125 of 279

F - Owner Maintenance

1-F-16

Winter Tyres

Two options are available to equip your DB AR1 for winter motoring.

Snow Tyres - The recommended snow tyres fit to the normal 8 inch front

wheel rims. Four 8 inch front wheel rims and winter tyres are required to

fully equip the car for severe weather driving. (See the Specifications section

of this Owner's Guide).

Snow Chains - These are available from your Aston Martin dealer and will

fit only the 8 inch road wheels fitted with snow tyres.

United States Department of Transportation

Uniform Tyre Quality Grades

The following information relates to the tyre grading system developed by

the National Highway Traffic Safety Administration which will grade tyres by

tread wear, traction and temperature performance.

All passenger car tyres must conform to federal safety requirements in

addition to these grades.

Treadwear

The treadwear grade is a comparative rating based on the wear rate of the

tyre when tested under controlled conditions on a specified government test

course. For example, a tyre graded 150 would wear one and a half times as

well on the government course as a tyre graded 100. The relative performance

of tyres depends upon the actual conditions of their use, however, and may

depart significantly from the norm due to variations in driving habits, service

practices and differences in road characteristics and climate.

Page 126 of 279

F - Owner Maintenance

1-F-17 Traction - A, B, C

The traction grades, from the highest to the lowest are A, B and C, and they

represent the tyre's ability to stop on wet pavement as measured under

controlled conditions on specified government test surfaces of asphalt and

concrete. A tyre marked 'C' may have poor traction performance.

WARNING:

The traction grade assigned to this tyre is based on braking (straight ahead)

traction tests and does not include cornering (turning) traction.

Temperature - A, B, C

The temperature grades are 'A' (the highest), 'B' and 'C' representing the tyres

resistance to the generation of heat and its ability to dissipate heat when

tested under controlled conditions on a specified indoor laboratory test

wheel. Sustained high temperature can cause the material of the tyre to

degenerate and reduce tyre life, and excessive temperature can lead to

sudden tyre failure.

The grade 'C' corresponds to a level of performance which all passenger car

tyres must meet under the Federal Motor Vehicle Safety Standard No. 109.

Grades 'B' and 'A' represent higher levels of performance on the laboratory

test wheel than the minimum required by law.

WARNING:

The temperature grade for this tyre is established for a tyre that is properly

inflated and not overloaded. Excessive speed, under-inflation or excessive

loading, either separately or in combination, can cause heat build-up and

possible tyre failure.

Page 127 of 279

F - Owner Maintenance

1-F-18

The Vehicle Toolkit

On vehicles fitted with a space-saver spare wheel , the tool kit is stored in

the spare wheel insert.

On vehicles without the spare wheel option the vehicle toolkit is stored in

a well within the boot floor and covered by a boot floor liner panel. The

standard toolkit consists of the following items:

• 2 Tyre Inflation Aerosols and Warning Labels

• 1 Tyre Pressure Gauge

• 1 Towing Eye

• 1 Pair of Pliers

• 1 Screwdriver

• 1 Pair of Gloves

• 1 Locking Wheelnut Socket (UK only)

• 1 Bulb and Fuse Kit

• 1 Allen Key

Lift up the boot floor to access the toolkit.

Page 128 of 279

F - Owner Maintenance

1-F-19

No Spare Wheel Option

Spare Wheel Option

Page 129 of 279

F - Owner Maintenance

1-F-20

Tyre Inflation Aerosols

Your DB AR1 is equipped with two tyre inflation aerosols instead of a spare

wheel. The aerosols are located with the tool kit. In the event of a simple

puncture, the following procedure must be used to perform a safe temporary

reinflation of the tyre. Tyres with major damage cannot be repaired using

inflation aerosols.

WARNING: A replacement tyre must be fitted at the earliest possible opportunity

This is particularly important because of the high performance potential of the

DB AR1.

Warning labels must be placed on the steering wheel and on the repaired wheel

to remind the driver and operator that tyre sealant is in use.

This type of tyreweld is not a permanent repair, but is designed to get you to a

place of repair. The tyre should be replaced as soon as possible.

After affecting a temporary repair, travel at a maximum speed of 50 Km/h (30

mph) until the defective tyre is replaced.

Warning: Inflation aerosols are not suitable for large holes or for repairs to tyre

walls. Do not attempt a repair if the tyre has been displaced from the rim.

Reinflation Procedure

1. Move the vehicle to a safe location and if possible, remove the object

causing the puncture. Reposition the vehicle so that the puncture is at

the bottom of the tyre. Remove the valve cap, deflate the tyre completely

and clean the valve if necessary.

2. Shake both cans of tyre sealant. Warm the cans (e.g. by placing in the

warm air from the heater) if the temperature is below freezing.

Page 130 of 279

F - Owner Maintenance

1-F-21 3. Firmly screw the aerosol to the valve of the punctured tyre. Remove the

cap from the canister. Holding the canister upright, press the button until

the contents of the can are completely emptied into the punctured tyre.

This may take up to 5 minutes per canister.

4. Repeat step 3 with the second canister.

WARNING: Because of the large air volume contained in tyres fitted to the

vehicle, two canisters are required to provide reinflation of a deflated tyre to

a safe working pressure.

5. Fit the 30 mph maximum speed WARNING labels to the repaired wheel

and to the steering wheel. Remove the steering wheel label only when

a new replacement tyre has been fitted.

6. Drive off immediately for 10 - 20 km (6 - 12 miles) at a maximum speed

of 50 km/h (30 mph) to allow the tyre weld product to spread within the

tyre.

7. Stop off the road in a safe place and visually inspect the tyre to confirm

that the leak has been completely sealed. Measure the tyre pressure

(pressure gauge in the tool kit) and if necessary drive to the nearest

service station and adjust to the correct pressure using an air line.

8. Limit your speed to 50 km/h (30 mph) and have the defective tyre and

valve replaced as soon as possible.

9. Purchase approved replacement aerosols and labels from your nearest

Aston Martin dealer as soon as possible.

Page 131 of 279

F - Owner Maintenance

1-F-22

Jacking and Wheel Changing

WARNINGS:

The front road wheels must be in the straight ahead position before removal. The

front tyre will catch on the wheel arch during removal if not in the "straight

ahead" position.

Check that the temporarily repaired tyre is inflated to the specified pressure.

Never exceed 50 km/h (30 mph) when a temporarily repaired wheel is fitted.

Ensure that no persons are in the vehicle before jacking commences.

Ensure that the handbrake (parking brake) is set and that the car is in 'Park' (Auto)

or 1st Gear (Manual).

Ensure that the vehicle is parked on firm and level ground to ensure a secure base

for the jack.

Do not run the engine while the car is on the jack and never let anyone work

under the car whilst it is on the jack.

Spare Wheel Access (where fitted)

On vehicles with the space saver spare

wheel, the spare wheel is stored in a

well in the boot floor.

Lift out the boot floor and toolkit.

Remove the spare wheel retaining screw

and lift out the spare wheel.