tyre pressure ASTON MARTIN DB AR1 Q 2003 Owners Guide

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2003, Model line: DB AR1 Q, Model: ASTON MARTIN DB AR1 Q 2003Pages: 279, PDF Size: 3.77 MB

Page 11 of 279

xi

Regular Checks

In the interests of safety and reliability, it is advisable to carry out the

following checks at the intervals suggested (more frequently if the vehicle is

heavily used or operating in adverse conditions), and always before starting

on a long journey. Refer to the Owner Maintenance section of this guide.

Each Day

Check that there is sufficient fuel for the intended journey, particularly at

night and before entering highways.

Weekly - (Daily if covering high mileage or touring)

Tyres - Check the tyres, including the spare (if fitted) for condition and

pressure. See the 'Specifications' section for the recommended tyre pressures.

Lights - Check that all exterior lights and direction indicators function

correctly and that the lenses are clean.

Engine Oil - With the vehicle standing on level ground, check the oil level

and top up if necessary with oil of the correct grade.

Engine Cooling System - With the engine cold, check the level of the engine

coolant. Top-up if necessary with coolant containing the required percentage

of anti-freeze. Any significant coolant loss should be investigated by your

Aston Martin Dealer.

Brake Fluid - Check the level of the fluid in the brake reservoir. Top-up if

necessary with the specified brake fluid from a new unopened container.

Power Steering Fluid - Check and top-up the level of fluid in the power

steering reservoir with fluid of the correct specification.

DB AR1 Owners Guide

Page 123 of 279

F - Owner Maintenance

1-F-14

Tyre Pressures

In the interest of safety and tyre life it is important that correct tyre pressures

are carefully maintained (See 'Specifications').

Road holding, steering and braking are especially vulnerable to incorrect

tyre pressures.

Pressures increase slightly when tyres are hot and, for an accurate reading,

pressures should be checked when the tyres are cold.

After checking the pressures ensure that the valve caps are securely replaced

to provide an additional air seal and to prevent the ingress of dirt.

Running-In New Tyres

When new tyres have been fitted, speed should be limited, particularly

during the first 80 km (50 miles) or so of driving. Fast cornering, hard braking,

and harsh acceleration should also be avoided during this period.

Tyre Service

Tyres should be examined at regular intervals for wear and damage. Stones

or other objects which have become lodged in the tyre treads should be

carefully removed.

When new tyres are required, it is advisable to consult an Aston Martin

dealer who will be able to supply tyres to the correct specification.

Page 127 of 279

F - Owner Maintenance

1-F-18

The Vehicle Toolkit

On vehicles fitted with a space-saver spare wheel , the tool kit is stored in

the spare wheel insert.

On vehicles without the spare wheel option the vehicle toolkit is stored in

a well within the boot floor and covered by a boot floor liner panel. The

standard toolkit consists of the following items:

• 2 Tyre Inflation Aerosols and Warning Labels

• 1 Tyre Pressure Gauge

• 1 Towing Eye

• 1 Pair of Pliers

• 1 Screwdriver

• 1 Pair of Gloves

• 1 Locking Wheelnut Socket (UK only)

• 1 Bulb and Fuse Kit

• 1 Allen Key

Lift up the boot floor to access the toolkit.

Page 130 of 279

F - Owner Maintenance

1-F-21 3. Firmly screw the aerosol to the valve of the punctured tyre. Remove the

cap from the canister. Holding the canister upright, press the button until

the contents of the can are completely emptied into the punctured tyre.

This may take up to 5 minutes per canister.

4. Repeat step 3 with the second canister.

WARNING: Because of the large air volume contained in tyres fitted to the

vehicle, two canisters are required to provide reinflation of a deflated tyre to

a safe working pressure.

5. Fit the 30 mph maximum speed WARNING labels to the repaired wheel

and to the steering wheel. Remove the steering wheel label only when

a new replacement tyre has been fitted.

6. Drive off immediately for 10 - 20 km (6 - 12 miles) at a maximum speed

of 50 km/h (30 mph) to allow the tyre weld product to spread within the

tyre.

7. Stop off the road in a safe place and visually inspect the tyre to confirm

that the leak has been completely sealed. Measure the tyre pressure

(pressure gauge in the tool kit) and if necessary drive to the nearest

service station and adjust to the correct pressure using an air line.

8. Limit your speed to 50 km/h (30 mph) and have the defective tyre and

valve replaced as soon as possible.

9. Purchase approved replacement aerosols and labels from your nearest

Aston Martin dealer as soon as possible.

Page 131 of 279

F - Owner Maintenance

1-F-22

Jacking and Wheel Changing

WARNINGS:

The front road wheels must be in the straight ahead position before removal. The

front tyre will catch on the wheel arch during removal if not in the "straight

ahead" position.

Check that the temporarily repaired tyre is inflated to the specified pressure.

Never exceed 50 km/h (30 mph) when a temporarily repaired wheel is fitted.

Ensure that no persons are in the vehicle before jacking commences.

Ensure that the handbrake (parking brake) is set and that the car is in 'Park' (Auto)

or 1st Gear (Manual).

Ensure that the vehicle is parked on firm and level ground to ensure a secure base

for the jack.

Do not run the engine while the car is on the jack and never let anyone work

under the car whilst it is on the jack.

Spare Wheel Access (where fitted)

On vehicles with the space saver spare

wheel, the spare wheel is stored in a

well in the boot floor.

Lift out the boot floor and toolkit.

Remove the spare wheel retaining screw

and lift out the spare wheel.

Page 133 of 279

F - Owner Maintenance

1-F-24

5. Using the handwheel (A) on the jack screwshaft, raise the jack until the

jack top plate (B) fits to the jacking point stud under the sill at the affected

wheel. Ensure that the jack baseplate is squarely seated on solid ground.

Note: In the following step, the jack handle extension (D) must be used to prevent

damage to the vehicle paintwork as the jack handle (C) is rotated.

6. Ensure the safety of any persons in the vicinity and the security of the

wheel chock. Raise the vehicle as necessary using the jack ratchet handle

(C) and extension (D) to lift the deflated wheel clear of the ground.

Remove the wheel nuts and remove the deflated wheel.

7. Mount the spare wheel on the hub. Reverse the jack ratchet handle on

the extension and partially tighten the wheel nuts.

8. Lower the vehicle to the ground. Tighten the wheel nuts alternately.

Remove the wheel chock.

9. Repack the tools into their location in the boot. Place the defective wheel

into the bag provided and place on the rear seats.

10. When the spare wheel is correctly fitted and secured, drive conservatively

(80 km/h (50 mph) maximum) and have the wheel nuts torque tightened

to 88-102 Nm (65-75 lbs/ft) at the earliest opportunity.

WARNINGS:

Follow the wheel label warnings. Failure to comply can be dangerous. Drive

cautiously and refit a serviceable standard wheel and tyre as soon as possible.

Never fit more than one temporary spare wheel at a time.

Check that the temporary spare tyre is inflated to the specified pressure.

Never exceed 80 km/h (50 mph) when the spare wheel is fitted.

Page 154 of 279

F - Owner Maintenance

1-F-45

On Board Headlight Aiming (where fitted)

The headlight assemblies (main and dipped beam lights) are factory set to

give correct forward illumination under average load conditions. Should

your headlight aiming require adjustment, it may be corrected as follows:

1. Ensure that the tyres are inflated to the specified pressures.

2. Fill the car with fuel.

3. Park the car on level ground.

NOTE: Any error in ground level will adversely influence the accuracy of the

vertical beam alignment check

4. Have an adult person sit in the drivers seat.

5. Load the boot with the normal items you carry.

6. Open the bonnet.

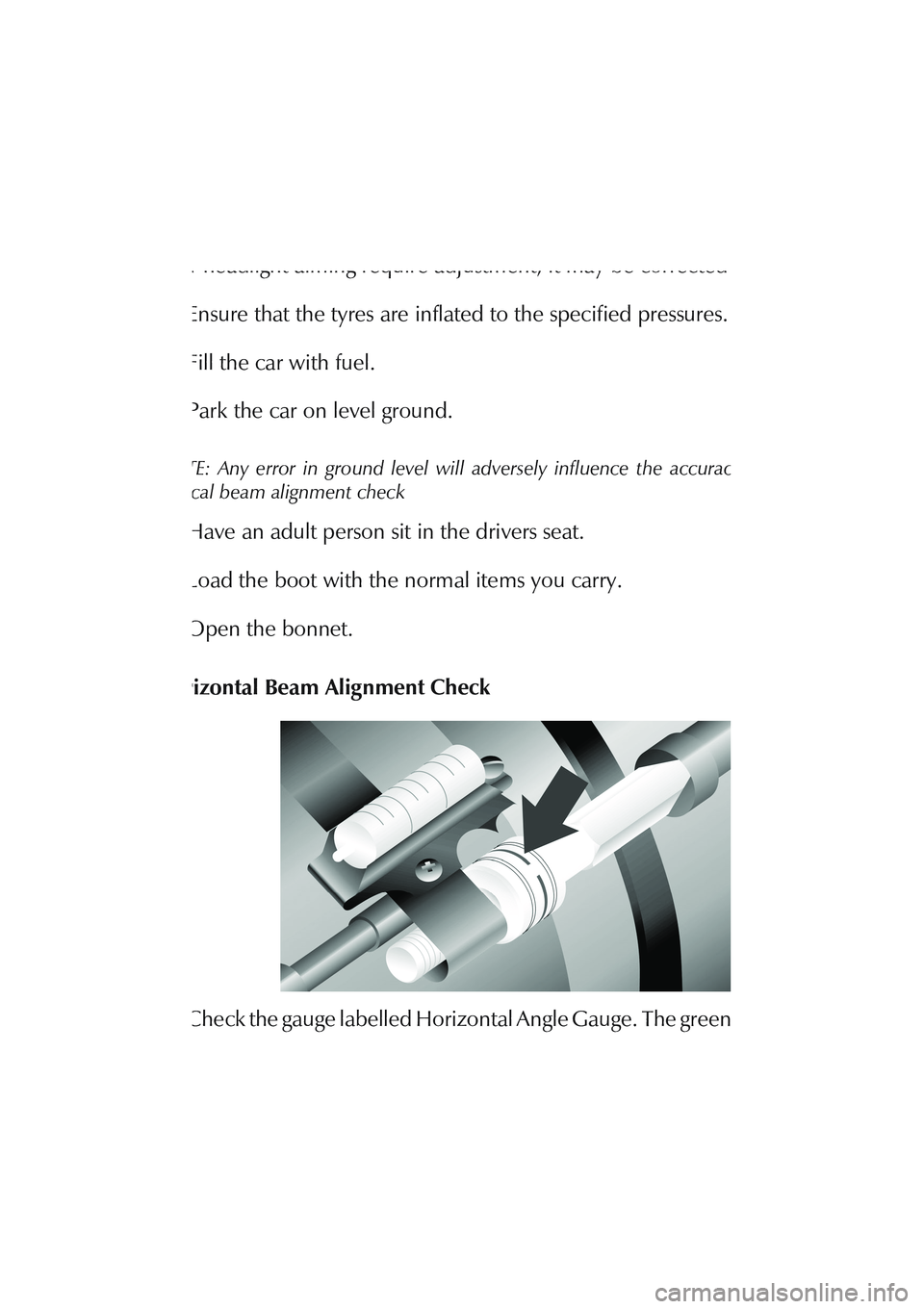

Horizontal Beam Alignment Check

1. Check the gauge labelled Horizontal Angle Gauge. The green line on the

collar must be aligned with the pointer at the side of the spirit level. If

adjustment is required, rotate the screw and collar until the green line

is aligned with the pointer.

Page 167 of 279

F - Owner Maintenance

1-F-58

Storing the Car - Recommendations

Note: These recommendations apply to new and pre-owned cars either in

Dealer or customer ownership.

When ever the car is not in use always cover the car with it's fabric cover.

If the vehicle is not to be used for periods up to six months it should be stored

in a dry, well ventilated building.

Drive the car for a sufficient distance to warm the oil in the engine, torque

convertor, transmission and final drive unit; this ensures complete lubrication

of the internal components.

Check the engine coolant level. Top up if necessary with the correct

antifreeze/water solution.

In order to take the weight off the tyres, raise the car with a jack and place

supports under the front and rear suspension.

If the vehicle is not raised from the ground, increase the tyre pressures to 3.4

bar 340 kpa 50 psi. Cover the tyres to exclude any light. Rotate the wheels

1/4 turn every month to avoid tyre flat spots.

The battery should be removed and cleaned. Fully charge the battery on a

trickle charger and recharge once a month.

Once a month

Reconnect the battery and ventilate the storage area. Start and run the

engine until fully warmed up. Check that there are no fluid leaks. Check

and correct the tyre pressures if necessary.

Run the Air Conditioning system to keep the internal parts of the Air

Conditioning system lubricated.

Page 168 of 279

F - Owner Maintenance

1-F-59 When returning the car to normal service, set the tyre pressures to normal

specification before driving on the road.

Extended Storage

For storage periods exceeding six months the following additional measures

are recommended;

Run the car until there is as small a quantity of fuel in the tank as is practical

for storage purposes.

Caution: Do Not Drain The Fuel System

Add Engine Oil to the remaining fuel in the tank to ensure a concentration

of 2% (i.e. 20ml per 1 litre of fuel) and then run the engine for not less than

ten minutes to circulate the mixture thoroughly through the entire fuel

system.

Inspect the rubber connections of the cooling system and have them

renewed if necessary.

Wash the bodywork of the car thoroughly and repair any paint

blisters or patches of rust in order to prevent any further deterioration.

Apply a suitable polish.

Clean the carpets and upholstery thoroughly. Dust them with an

anti-moth powder and store in a dry place. Treat all leather upholstery

with an appropriate leather conditioner.

If the storage building is dry leave the car windows slightly open. If

there is any tendency towards dampness close the car doors and

windows and place an anti-moisture compound such as Silica desiccant

bags in an open metal container inside the car.

Cover the car with it's fabric cover.

Page 169 of 279

F - Owner Maintenance

1-F-60

Recommissioning After Storage

Provided that the car has been stored in accordance with the recommended

procedure, the following points only should require attention before using

the car on the road.

Check the tyre pressures, inflate if necessary and lower the car to the ground.

Fully charge and refit the battery. Reset the clock and electric windows.

Drain the engine sump and final drive unit, fit a new engine oil filter element,

then refill with the approved oils. Check the coolant level and if necessary

top up with the correct antifreeze/water solution.

Check all fluid levels and top-up as necessary. Fill the fuel tank

Caution: Starting the engine without sufficient lubrication can cause serious engine

damage. Take care to establish engine oil pressure as directed in the following steps

before allowing the engine to start.

Press and hold the accelerator hard to the floor (kickdown switch actuated).

This will temporarily inhibit the fuel injectors during cranking. Turn on the

ignition. Press and hold the starter button to crank the engine until normal

oil pressure is indicated on the oil pressure gauge. Release the starter button

and the accelerator pedal.

Start the engine normally and check that the oil pressure and ignition

warning lights go out as the engine starts indicating correct oil pressure and

battery charging. Raise the bonnet and check for leaks of fuel, oil and

coolant.

Finally, check the operation of all instruments, lights and accessories.