fuel ASTON MARTIN DB7 1997 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 3 of 421

^?

Introduction

#

••t

*<;'..

Introduction '-^;^'^<-~'

^--"^^zfjj^^T^""

Workshop Manual Sections

The

DB7

Workshop Manual

is

divided .jnto,9seGtipnsE.a&foli

1 Engine

2.

Fuel,

Emission Control

and

Exhaust

3. Transmission

4.

Suspension

and

Steering

5. Brakes, Wheels

and

Tyres

6. Electrics

7. Chassis

and

Body

8.

Air

Conditioning

9. Aston Martin Diagnostic System

Procedure Numbering

The workshop manual procedures

are

numbered using

the

parts list numbers

as a key. The

first

two

digits

oi a

workshop manual procedure number

are

also

the

parts list number

(e.g.

1.5.01

Sump Removal relates

to PL 1.5 Oil

Pump

and

Sump). Thus when carrying

out a

procedure,

you can

quickly locate

the

relevant parts illustration

and

spare parts list.

To avoid excessive repetition, each procedure will

be

fully detailed once

in its

appropriate place

in the

manual.

In

any other location where this procedure

is

required,

it

will

be

referenced only

by its

title

and its

procedure number.

Special Tools

Where special service tools

are

required

to

perform

an

operation,

the

tool number

is

recorded

at the

point

of use

within

the

procedure.

An

index

and

illustrated list

is

provided

in

this section

for the

purpose

of

identifying special

tools.

References

References

to the

left, right, front

or

rear

of

the vehicle

or of

a component

are

always made as

if

sitting

in the

drivers

seat facing forward.

Any

such references

to

assemblies removed from

the

vehicle

are to the

normal orientation

of

the assembly when fitted

in the

vehicle.

Repairs

and

Replacements

Where replacement parts

are

required,

it is

essential that only genuine Aston Martin parts

are

used. Your attention

is drawn

to the

following points concerning repairs

and the

fitting

of

genuine Aston Martin parts

and

accessories:

• Safety features embodied

in the

vehicle

may be

impaired

if

other than genuine Aston Martin parts

are

fitted.

In certain territories, legislation prohibits

the

fitting

of

parts which

are not

produced

to the

manufacturers

specification.

• Adhere

to

torque wrench settings given

in

this manual.

• Locking devices, where specified, must

be

fitted.

If the

efficiency

of a

locking device

is

impaired during

removal,

it

must

be

renewed.

•

The

vehicle warranty

may be

invalidated

by the

fitting

of

other than genuine Aston Martin parts.

April

1997 Hi

Page 4 of 421

Introduction

/^r"^^^^^3^

'"'P ?

Safety Precautions L —^ ^^—^

Safety Precautions "

All service workshops are a source of potential danger and repair work should only be performed by technically

trained staff following the procedures in this manual. A safety conscious approach to the performance of all service

procedures must be observed at all times. Statutory requirements governing all aspects of health and safety at work

including directives for the proper use of materials and equipment must be implemented.

The following contains a list of particular safety precautions which should be observed; it is not intended to be

exhaustive.

Air Conditioning System

Do not disconnect any air conditioning refrigerant system pipes unless trained and instructed to do

so.

The refrigerant

used can cause blindness if allowed to contact your eyes.

Chemical Handling and Storage

Chemicalsusedintheservicingofmotorvehiclesincludeacids,adhesives, antifreeze, brake fluids, coolants, grease,

oil,

paint, resin and solvents. Exposure to certain chemicals through direct contact or inhalation can be

fatal.

Potential hazards may also be present through the incorrect use, storage and handling of chemicals causing a fire

risk. The following precautions should be observed.

1.

Strictly adhere to handling and safety information found on containers and labels.

2.

Do not store chemicals in unlabelled or incorrectly labelled containers.

3. Containers used for storing chemicals should not be left

open;

there is a risk of

spilling,

or evaporation of fumes

which may be inflammable or toxic.

4.

Do not mix chemicals unless instructed to do so following manufacturers guidelines.

5. Do not inhale chemical materials to determine identity, they may be toxic.

6. Do not use petrol, kerosene, diesel

fuel,

gas oil, thinners or solvents for washing

skin.

7. Containers whose capacity is over 25 litres (5 gallons) require a bund wall in order to contain spillages.

8. Chemicals based on solvents such as paint should not be sprayed in a confined space; work areas used for

such operations should be well ventilated and fume extraction equipment should be utilised.

9. Ensure that adequate ventilation is provided when volatile de-greasing agents are being used.

WARNING: Fume extraction equipment must be in operation when

solvents

are

used

e.g.

trichloroethane, white

spirit, SBP3, methylene chloride, perchlorethylene.

WARNING: Do not smoke in the vicinity of volatile de-greasing agents.

10.

Avoid splashing the

skin,

eyes and clothing.

11.

Clean chemicals from the skin and clothing as soon as possible after soiling.

12.

Wear protective clothing such as goggles, non porous gloves and apron when hand

I

ing battery acid and other

corrosive and toxic substances.

iv April 1997

Page 5 of 421

//—-^

^^^^5~^

' -^ ^ Introduction

Safety Precautions

Safety Precautions (continued)

Electrical Equipment

1.

Ensure that electrical equipment is in safe working order before use.

2.

Inspect power leads of all mains electrical equipment for damage and security, and check that it is properly

earthed.

3. Ensure that electrical equipment is protected by a fuse of the correct current rating.

4.

Disconnect the battery before commencing repair operations to the electrical system, fuel system and engine

or when working beneath the vehicle.

Exhaust Fumes

Engines should not be run in confined spaces, exhaust fumes contain harmful and toxic substances including carbon

monoxide which can prove fatal if inhaled. Engines must only be run where there is fume extraction equipment in

operation or where there is adequate ventilation.

Fire Precautions

1.

Ensure that a suitable form of fire extinguisher is conveniently located near the work area.

2.

Keep oils, solvents and combustible materials away from naked flames and other sources of ignition.

3. Ensure that NO SMOKING signs are posted around areas where combustible materials and vapour may be

present and ensure that the warnings are strictly observed.

4.

Ensure that dry sand is available to soak up any spillage of fuel or other flammable solutions.

5. Fume extraction equipment must be available and in full working order to remove combustible and toxic

vapours.

6. All personnel should be aware of the fire drill procedures and precautions.

Jacking and Lifting

1.

The recommended procedures for lifting, jacking and towing are included latefin this seetion-and must be

strictly observed to ensure personal safety.

2.

Always use a vehicle hoist, ramp or pit for working beneath the car in preferencetd^&^cking

3. Never rely on a jack to support a car independently, use axle stands or blocks carefully pJaQed at the jacking

points to provide rigid support.

4.

When working beneath a vehicle, chock the wheels as well as applying the handbrake.

5. Ensure that the vehicle is standing on firm level ground before jacking or lifting.

5. Check any lifting equipment used has adequate capacity for the load being lifted and is ih"fdll working order.

Tools and Equipment

1.

Do not leave tools, equipment, spilt oil, etc. around or on the work area.

2.

Ensure that tools and equipment used are in good condition; do not use damaged or defective tools or

equipment.

3. Do not apply heat in an attempt to free stiff nuts or fittings; as well as causing damage to protective coatings,

there is a risk of damage to electronic equipment and brake lines from stray heat.

4.

Use the recommended service tool where instructed to do so.

April 1997 v

Page 6 of 421

Introduction //—">) ^nir>^ ' ^ 1

Safety Precautions L 1 .^—y^

Safety Precautions (continued)

Used Engine Oil

Prolonged and repeated contart with mineral oil will result in the removal of natural fats from the

skin,

leading to

dryness, irritation and dermatitis. In addition, used engineoii contains potentially harmful contaminants which may

cause skin cancer. Adequate means of skin protection and washing facilities should be provided.

Health protection precautions:

1.

Avoid prolonged and repeated contact with oils, particularly used engine oil.

2.

Wear protective clothing, including impervious gloves where practicable.

3. Do not put oily rags in pockets.

4.

Avoid contaminating clothes with oil.

5. Overalls must be cleaned regularly. Discard unwashable clothes and oil impregnated footwear.

6. First aid treatment should be obtained immediately for open cuts or wounds.

7. Use barrier creams, apply before each work period to help the removal of oil from the

skin.

8. Wash with soap and water to ensure all oil is removed. Preparations containing lanolin replace the natural

skin oils which have been removed.

9. Do not use petrol, kerosene, diesel

fuel,

gas oil, thinners or solvents for washing

skin.

10.

If skin disorders develop, obtain medical advice.

11.

Where practicable, degrease components prior to handling.

12.

Where there is a risk of eye contact, eye protection should be worn, in addition, an eyewash facility should

be provided.

Environmental Protection

It is illegal to pour used oil on the ground, down sewers or drains, or into water courses. The burning of used engine

oil in small space heaters or boilers is not recommended unless emission control equipment is

fitted;

in case of doubt,

contact the Local Authority for advice on disposal facilities.

vi April 1997

Page 21 of 421

3^?

Electrics

Rear Lamp Cluster / Central Locking System / Door Lock Motors

6.7.02 Rear Lamp Cluster Door Mounted Components

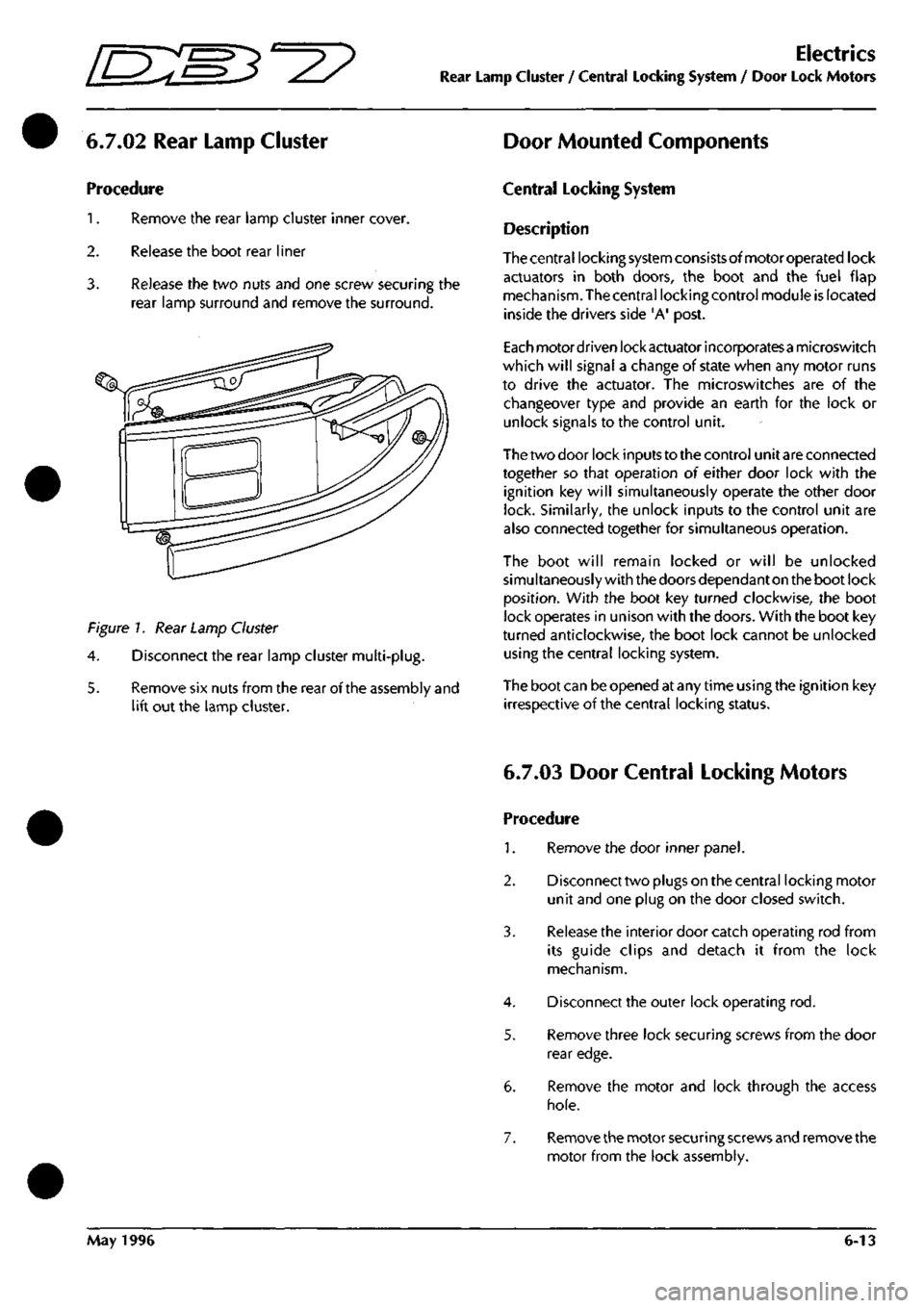

Procedure

1.

Remove the rear lamp cluster inner cover.

2.

Release the boot rear liner

3. Release the two nuts and one screw securing the

rear lamp surround and remove the surround.

Figure 7. Rear Lamp Cluster

4.

Disconnect the rear lamp cluster multi-plug.

5. Remove six nuts from the rear of the assembly and

lift out the lamp cluster.

Central Locking System

Description

Thecentral locking system consistsofmotoroperated lock

actuators in both doors, the boot and the fuel flap

mechanism. The central locking control module is located

inside the drivers side 'A' post.

Each motordriven lock actuator incorporatesa microswitch

which will signal a change of state when any motor runs

to drive the actuator. The microswitches are of the

changeover type and provide an earth for the lock or

unlock signals to the control unit.

The two door lock inputs to the control unit are connected

together so that operation of either door lock with the

ignition key will simultaneously operate the other door

lock. Similarly, the unlock inputs to the control unit are

also connected together for simultaneous operation.

The boot will remain locked or will be unlocked

simultaneously with the doors dependant on the boot lock

position.

With the boot key turned clockwise, the boot

lock operates in unison with the doors. With the boot key

turned anticlockwise, the boot lock cannot be unlocked

using the central locking system.

The boot can be opened at any time using the ignition key

irrespective of the central locking status.

6.7.03 Door Central Locking Motors

Procedure

1.

Remove the door inner panel.

2.

Disconnect two plugs on the central locking motor

unit and one plug on the door closed switch.

3. Release the interior door catch operating rod from

its guide clips and detach it from the lock

mechanism.

4.

Disconnect the outer lock operating rod.

5. Remove three lock securing screws from the door

rear edge.

6. Remove the motor and lock through the access

hole.

7. Remove the motor securing screws and remove the

motor from the lock assembly.

May 1996 6-13

Page 28 of 421

Electrics

Electrical Component Location Index •

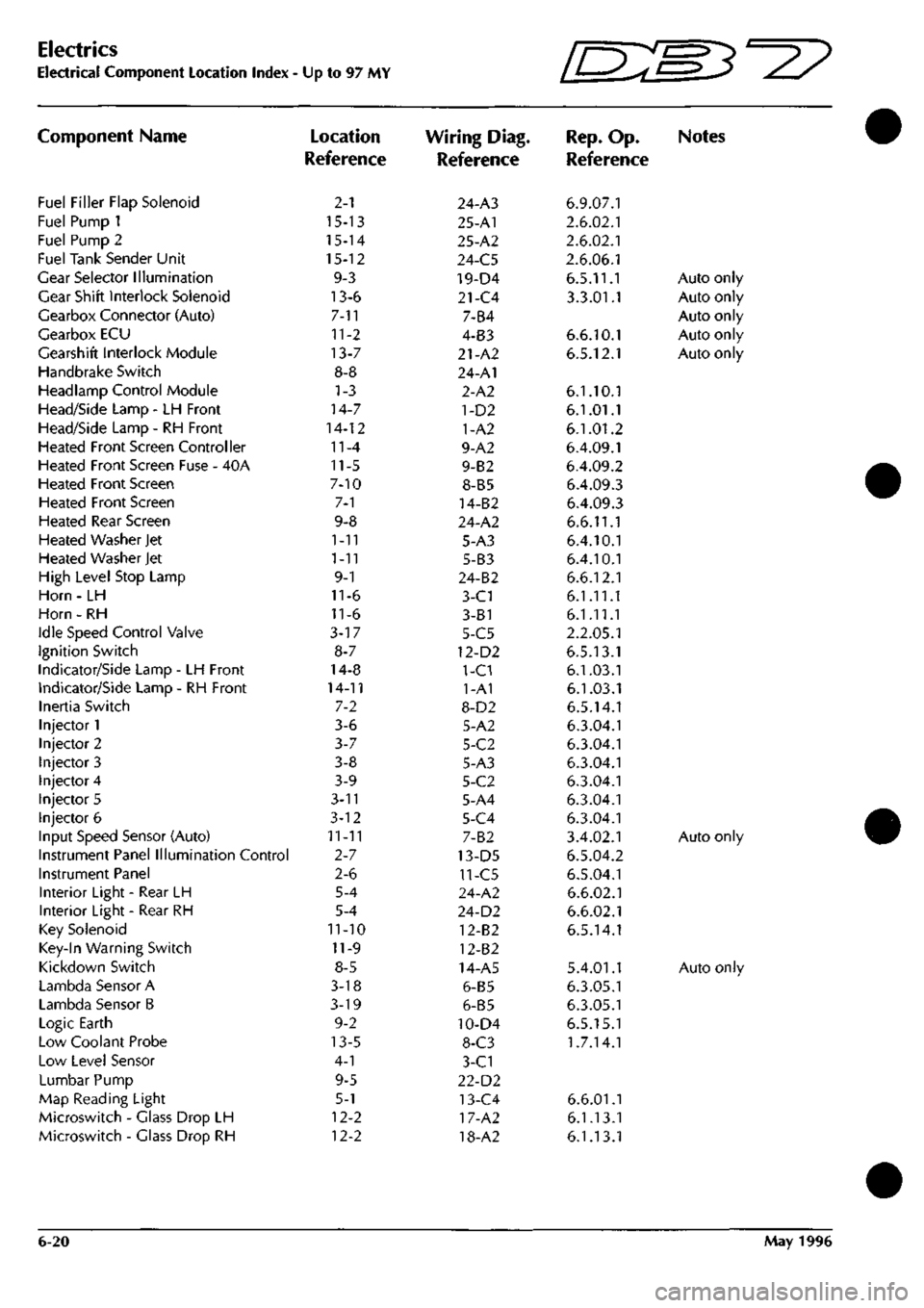

Component Name

Fuel Filler Flap Solenoid

Fuel Pump 1

Fuel Pump 2

Fuel Tank Sender Unit

Gear Selector Illumination

Gear Shift Interlock Solenoid

Gearbox Connector (Auto)

Gearbox ECU

Gearshift Interlock Module

Handbrake Switch

Headlamp Control Module

Head/Side Lamp - LH Front

Head/Side Lamp - RH Front

Heated Front Screen Controller

Heated Front Screen Fuse - 40A

Heated Front Screen

Heated Front Screen

Heated Rear Screen

Heated Washer Jet

Heated Washer Jet

High Level Stop Lamp

Horn - LH

Horn - RH

Idle Speed Control Valve

Ignition Switch

Indicator/Side Lamp - LH Front

Indicator/Side Lamp - RH Front

Inertia Switch

Injector 1

Injector 2

Injector 3

Injector 4

Injector 5

Injector 6

Input Speed Sensor (Auto)

Instrument Panel Illumination Control

Instrument Panel

Interior Light - Rear LH

Interior Light - Rear RH

Key Solenoid

Key-In Warning Switch

Kickdown Switch

Lambda Sensor A

Lambda Sensor B

Logic Earth

Low Coolant Probe

Low Level Sensor

Lumbar Pump

Map Reading Light

Microswitch - Glass Drop LH

Microswitch - Glass Drop RH

Up to 97 MY

Location

Reference

2-1

15-13

15-14

15-12

9-3

13-6

7-11

11-2

13-7

8-8

1-3

14-7

14-12

11-4

11-5

7-10

7-1

9-8

1-11

1-11

9-1

11-6

11-6

3-17

8-7

14-8

14-11

7-2

3-6

3-7

3-8

3-9

3-n

3-12

11-11

2-7

2-6

5-4

5-4

11-10

11-9

8-5

3-18

3-19

9-2

13-5

4-1

9-5

5-1

12-2

12-2

Wiring Diag.

Reference

24-A3

25-A1

25-A2

24-C5

19-D4

21-C4

7-B4

4-B3

21-A2

24-A1

2-A2

1-D2

1-A2

9-A2

9-B2

8-B5

14-B2

24-A2

5-A3

5-B3

24-B2

3-C1

3-81

5-C5

12-D2

1-C1

1-A1

8-D2

5-A2

5-C2

5-A3

5-C2

5-A4

5-C4

7-B2

13-D5

11-C5

24-A2

24-D2

12-B2

12-B2

14-A5

6-B5

6-B5

10-D4

8-C3

3-C1

22-D2

13-C4

17-A2

18-A2

Ini^'

IL-^^'^

Rep.

Op.

Reference

6.9.07.1

2.6.02.1

2.6.02.1

2.6.06.1

6.5.11.1

3.3.01.1

6.6.10.1

6.5.12.1

6.1.10.1

6.1.01.1

6.1.01.2

6.4.09.1

6.4.09.2

6.4.09.3

6.4.09.3

6.6.11.1

6.4.10.1

6.4.10.1

6.6.12.1

6.1.11.1

6.1.11.1

2.2.05.1

6.5.13.1

6.1.03.1

6.1.03.1

6.5.14.1

6.3.04.1

6.3.04.1

6.3.04.1

6.3.04.1

6.3.04.1

6.3.04.1

3.4.02.1

6.5.04.2

6.5.04.1

6.6.02.1

6.6.02.1

6.5.14.1

5.4.01.1

6.3.05.1

6.3.05.1

6.5.15.1

1.7.14.1

6.6.01.1

6.1.13.1

6.1.13.1

W3^y

Notes

Auto only

Auto only

Auto only

Auto only

Auto only

Auto only

Auto only

6-20 May 1996

Page 29 of 421

[n:m3^y

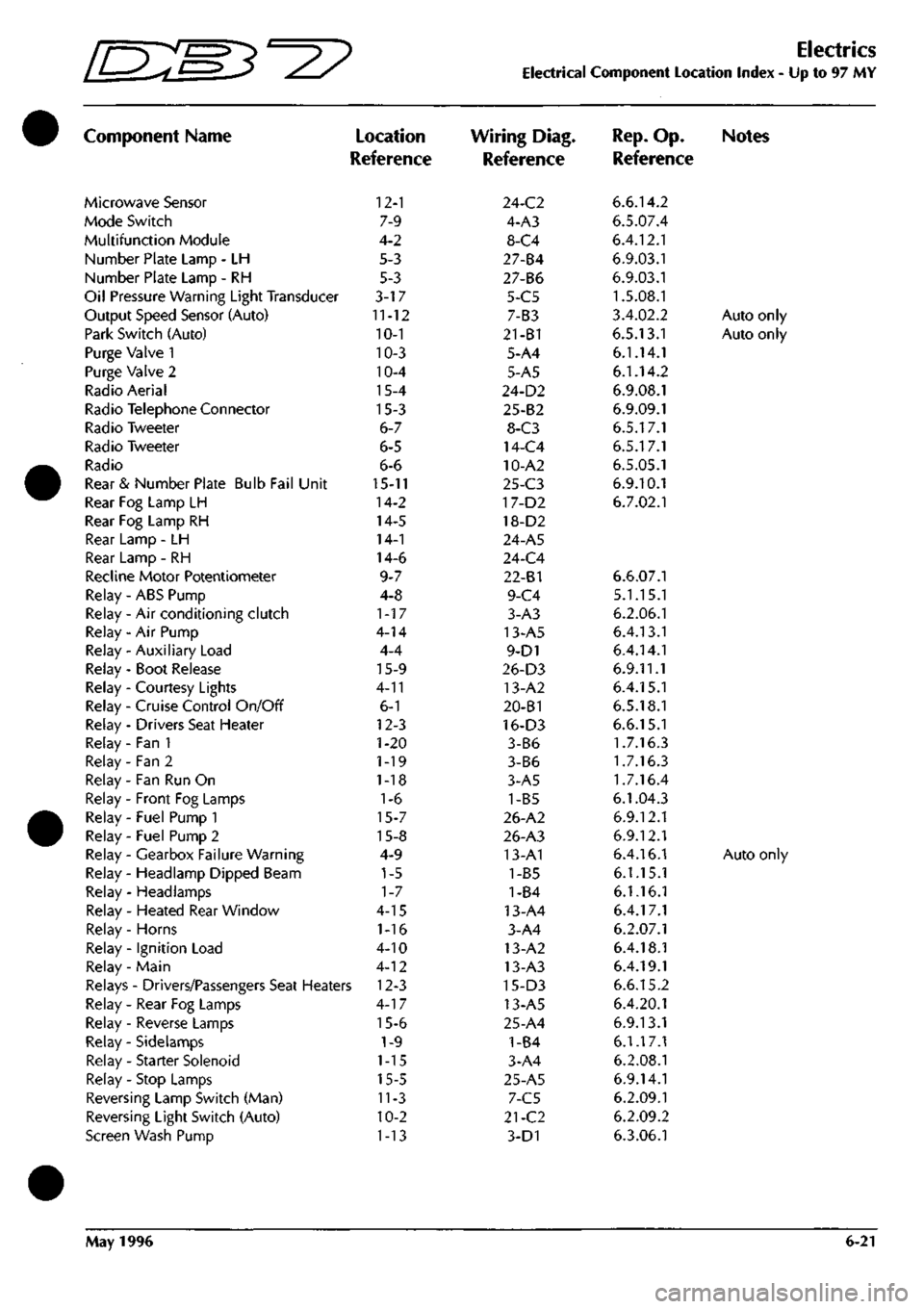

Component Name

Microwave Sensor

Mode Switch

Multifunction Module

Number Plate Lamp - LH

Number Plate Lamp - RH

Oil Pressure Warning Light Transducer

Output Speed Sensor (Auto)

Park Switch (Auto)

Purge Valve 1

Purge Valve 2

Radio Aerial

Radio Telephone Connector

Radio Tweeter

Radio Tweeter

Radio

Rear & Number Plate Bulb Fail Unit

Rear Fog Lamp LH

Rear Fog Lamp RH

Rear Lamp - LH

Rear Lamp - RH

Recline Motor Potentiometer

Relay - ABS Pump

Relay - Air conditioning clutch

Relay - Air Pump

Relay - Auxiliary Load

Relay - Boot Release

Relay - Courtesy Lights

Relay - Cruise Control On/Off

Relay - Drivers Seat Heater

Relay - Fan 1

Relay - Fan 2

Relay - Fan Run On

Relay - Front Fog Lamps

Relay - Fuel Pump 1

Relay - Fuel Pump 2

Relay - Gearbox Failure Warning

Relay - Headlamp Dipped Beam

Relay - Headlamps

Relay - Heated Rear Window

Relay - Horns

Relay - Ignition Load

Relay - Main

)

Location

Reference

12-1

7-9

4-2

5-3

5-3

3-17

11-12

10-1

10-3

10-4

15-4

15-3

6-7

6-5

6-6

15-11

14-2

14-5

14-1

14-6

9-7

4-8

1-17

4-14

4-4

15-9

4-11

6-1

12-3

1-20

1-19

1-18

1-6

15-7

15-8

4-9

1-5

1-7

4-15

1-16

4-10

4-12

Relays - Drivers/Passengers Seat Heaters 12-3

Relay - Rear Fog Lamps

Relay - Reverse Lamps

Relay - Sidelamps

Relay - Starter Solenoid

Relay - Stop Lamps

Reversing Lamp Switch (Man)

Reversing Light Switch (Auto)

Screen Wash Pump

4-17

15-6

1-9

1-15

15-5

11-3

10-2

1-13

Electrics

Electrical Component Location Index - Up to 97 MY

Wiring Diag.

Reference

24-C2

4-A3

8-C4

27-84

27-B6

5-C5

7-B3

21-B1

5-A4

5-A5

24-D2

25-B2

8-C3

14-C4

10-A2

25-C3

17-D2

18-D2

24-A5

24-C4

22-81

9-C4

3-A3

13-A5

9-D1

26-D3

13-A2

20-B1

16-D3

3-B6

3-B6

3-A5

1-B5

26-A2

26-A3

13-A1

1-B5

1-84

13-A4

3-A4

13-A2

13-A3

15-D3

13-A5

25-A4

1-B4

3-A4

25-A5

7-C5

21-C2

3-D1

Rep.

Op. Notes

Reference

6.6.14.2

6.5.07.4

6.4.12.1

6.9.03.1

6.9.03.1

1.5.08.1

3.4.02.2

Auto only

6.5.13.1

Auto only

6.1.14.1

6.1.14.2

6.9.08.1

6.9.09.1

6.5.17.1

6.5.17.1

6.5.05.1

6.9.10.1

6.7.02.1

6.6.07.1

5.1.15.1

6.2.06.1

6.4.13.1

6.4.14.1

6.9.11.1

6.4.15.1

6.5.18.1

6.6.15.1

1.7.16.3

1.7.16.3

1.7.16.4

6.1.04.3

6.9.12.1

6.9.12.1

6.4.16.1

Auto only

6.1.15.1

6.1.16.1

6.4.17.1

6.2.07.1

6.4.18.1

6.4.19.1

6.6.15.2

6.4.20.1

6.9.13.1

6.1.17.1

6.2.08.1

6.9.14.1

6.2.09.1

6.2.09.2

6.3.06.1

May 1996 6-21

Page 97 of 421

I NO COLOUR AlttA 1503 BW CI

H/BRAKE.

ISWITCH I

HO COLOUR 5 YS 175 PY 259 OR 260 0 261 NR 4T4 YO 475 B 476 BR 479 s 481 B 482 BR 483 LCK 484 RIN 486 RN 487 GR 489 UIN 491 W 492 rw

493

KB

494

BR

495

OR

495

OU

497

SLG

500

KB

501

GB

503

BW

504

GW

505

LGO

506

OW

507

GP

509

OG

829

NO

833

PS

834

NS

835

NY

836

U

841

P

842

PK

850

P

851

PK

855

HP

858

RU

872

BRO

973

HP

975

RU

89J

R

894

WS

896

R

897

WS

902

G

904

0

907

WK

930

WK

AREA

B6 B6 86 86 B6 02 B2 B2 86 C2 C2 B6 A4 Dl

B2-I8I

A4 B6 B6 B6 86 Be 66 B6 B6 B6 Al

C2-I87

C5 A3 B6 A3 B6 B6 B6 C6

C2-185

A3 A3 Dl Dl C4 D4 A4 A5 85 BG B6 86 Be B6 B6 B6 86

HO COLOUR

839 B 840 B

TBtr

B4-I8;

NO COLOUR PIN ARE!" 508 OG I CI 506 OW J a FUEL FILLER FLAP

N6

tbim AREA

873

HP CI

874

BR

C3-I9I

INTERIOR LIGHT

NO COLOUR

PIH

841

P I

842

PK 2

CI

ja

JHEATEC

|BACKLI

J

HEATED

I

BACKLIGHT

I

NO

COLOUR AREA

I

ll>13

B

Ag-I8?l

NO COLOUR

PIN

872

BRD 1

484

RIN 2

W

UIN J

AREA

CI 81 Bl

,

BOOT LAMP,

r^

NO COLOUR

PIN

I

844 B 2

845

CP 3

TBET

A2-I82 C6

LH REAR LAMP

NO COLOUR

PIN

875

RU

876

GN

877

GR

878

B

879

RS

880

GP

1 2 3 4 5 _6

AREA

a

C3-I9C B2-I8I B4-I8; B4-I8<

BG LH

SIDEMARKER

^

HO COLOUR

PIN

JRET

476

BR I Bl

47?

6 i B!

HO COLOUR

PIH

870

RS I

671

B 2_

AREA B4-I8'

SUM

NO

C6L6UD

i^iti

SEET

846 NS I Ce

847

NY 2 C6 848 \l i

C2-I85

(^

482

BR I W i 2_

TSfT

-0 H—— S NO COLOUR 849 TIN AREA JS_J

NO COLOUR AREA 854

BR

C3-I9I 855

HP CI

I BOOT LAMP,

SPL

189

SPL

192

NO COLOUR 865

BR

866

PG

867

RS

868

RG m B

PIN 1 2 3 4 5 6 7

9

.

ARtA C3-I9I 06

ce

03-189 C5-ieB

NO

t6L6ul)

5 YS 175 PY 259 OR 260 0 261 NR 483 LGK 479 S 491 W 492 YW 493 KB 494 8R 495 OR 496 OU 497 SLG 500 KB 901 GB 507 GP 629 NO 833 PS 834 NS 835 NY 845 GP 846 NS 847 NY 849 TIN 852 P 863 GP 866 PG 867 RS

-mr Bl Bl Bl Bl Bl Bl Bl ei Bl Bl Bl Bl Bl Bl CI CI CI CI CI a CI 82 B2 C2 C2 02 04 C5 C5

•w 880 «B5 889 890 891 893 894 896 897 900 902 904 907 918 927 930 932 933 936 939 941

-mem

GP B BR 8 B R WS R WS GH 6 G WK R6 BRD WK GW GR U B RS

-ARIT

86

C5-I92 C3-I9I C5-I92 D2-I68

CI a CI 01

C3-I9C

01 Dl Dl

c3-ies

C2-I86 Dl 0-187 B2-I8I C2-I65 C5-192 C4-I84

RH REAR

LAI*

(5

Dl 05 0 Q B 0

SHEET

27

AREA

C5

.» ^

NO COLOUR AREA 505

LGO CI

'_S C5H92

J

FUEL

I

SENDi

-t

1

FUEL TANK

'

SENDER UNIT

NO COLOUR

PIN

858

RU

859

CN

860

GW

861

8

862

RG

Ki

?F

1 2 3 4 5

.._6_

AREA

CI

C5-I9C C2-I87 02-188 D5-I89

«

INTERIOR! 'LIGHT

I

•HEATED BACKLIGHT'

I

NO

COLOUR i486

RN

AREA 81 HO COLOUR

PIN

AREA

850 P I CI

851

PK 2 CI

NO COLOUR

PIN

I

852

P

474

YG

^ii_

C6 Bl

lK^^2

RH SIDEMARKER NO COLOUR

PIN

AREA 856

RG I

D3-IS9 657

B 2 E2:

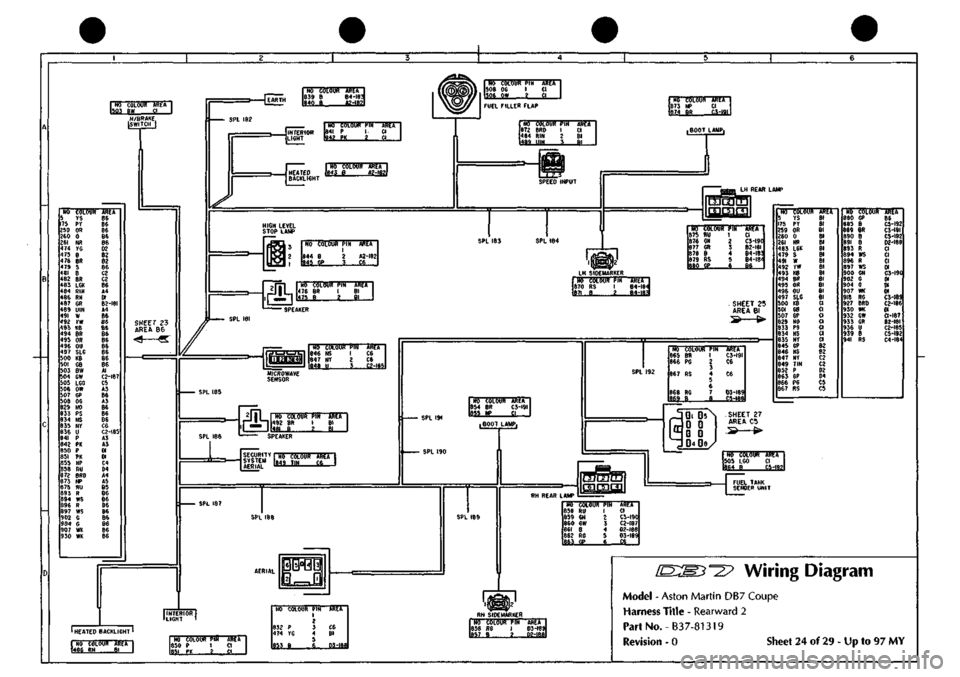

Wiring Diagram

Model - Aston Martin DB7 Coupe

Harness Title - Rearward 2

PartNo.-B37-81319

Revision - 0 Sheet 24 of 29 - Up to 97 MY

Page 101 of 421

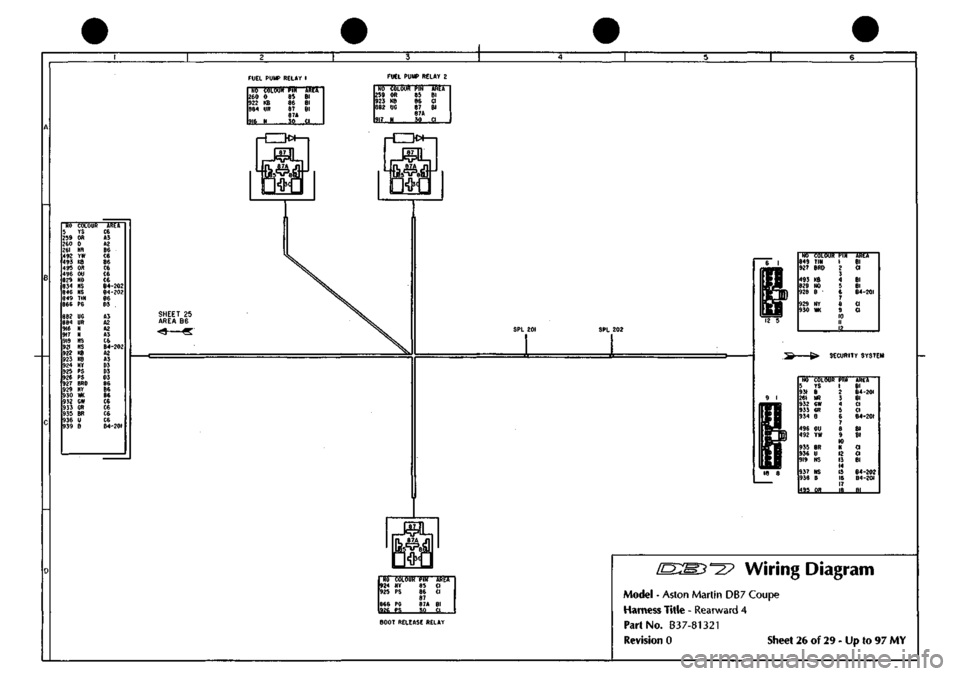

FUEL PUMP RELAY

1

NO COLOUC 260

0

922

KB

884

m

916

N

PIN

AI^CA

89

Bl

86

Bl

87

Bl

e7A SO

CI

FUEL PUMP RELAY

2

m

itLoUl!

tm

259

OR 85

923

KB 86

882

UG 87

87A 917

N SO

km Bl a Bl

.,?!

[M]

rCZK>»—1

HO COLOUR

5

rs

259

OR

260

0

261

NR

492

YW

493

KB 495 OR 496 OU 829 NO 834 N5 846 NS 849 TIN 866 PS

882

UG

884

UR

916

H

917 919 921 922

KB

923

KB

924

NY

925

PS

926

PS

927

BRD

929

NY 930 m 932 GW

933

GR 935 BR 936 U 939 B

C6

A3 A2

86 C6 B6

C6

C6 C6

B4-202

84-202

B6 03

A3 A2 A2 A3

C6

B4-202

A2 A3 03 03 03

86 86 86 C6 C6 C6 C6

B4-20I

SPL

202

M6

cbmk pld

849

TIN

927

BRD

493

KB

829

NO

928

B •

929

NY

930

WK

1 2 3 4 5 6 7 8 9 10 II 12

Uih Bl CI

Bl Bl B4-20I

CI CI

SECURITY SYSTEM

NO COLOUI 5

YS

931

B

261

NR

932

GW

953

GR

934

B

496

OU

492

YW

935

BR

936

U

919

NS

937

NS

938

B

495

OR

PIN 1 ? 3 4 5 6 7 8 9 10 II 12 13 14 15 16 17

J?...

AREA Bl B4-20I Bl CI CI B4-20I

Bl Bl

CI CI Bl

B4-202

84-201

Bl

I Is?""—I

NO COLOUR

PIN

924

NY 85

925

PS 86

87 866

PG 87A

926

PS 30

-mr Cl CI

Bl CI

BOOT RELEASE RELAY

Wiring Diagram

Model

-

Aston Martin

DB7

Coupe

Harness Title

-

Rearward

4

Part

No.

B37-81321

Revision

0

Sheet

26 of 29 - Up to 97 MY

Page 109 of 421

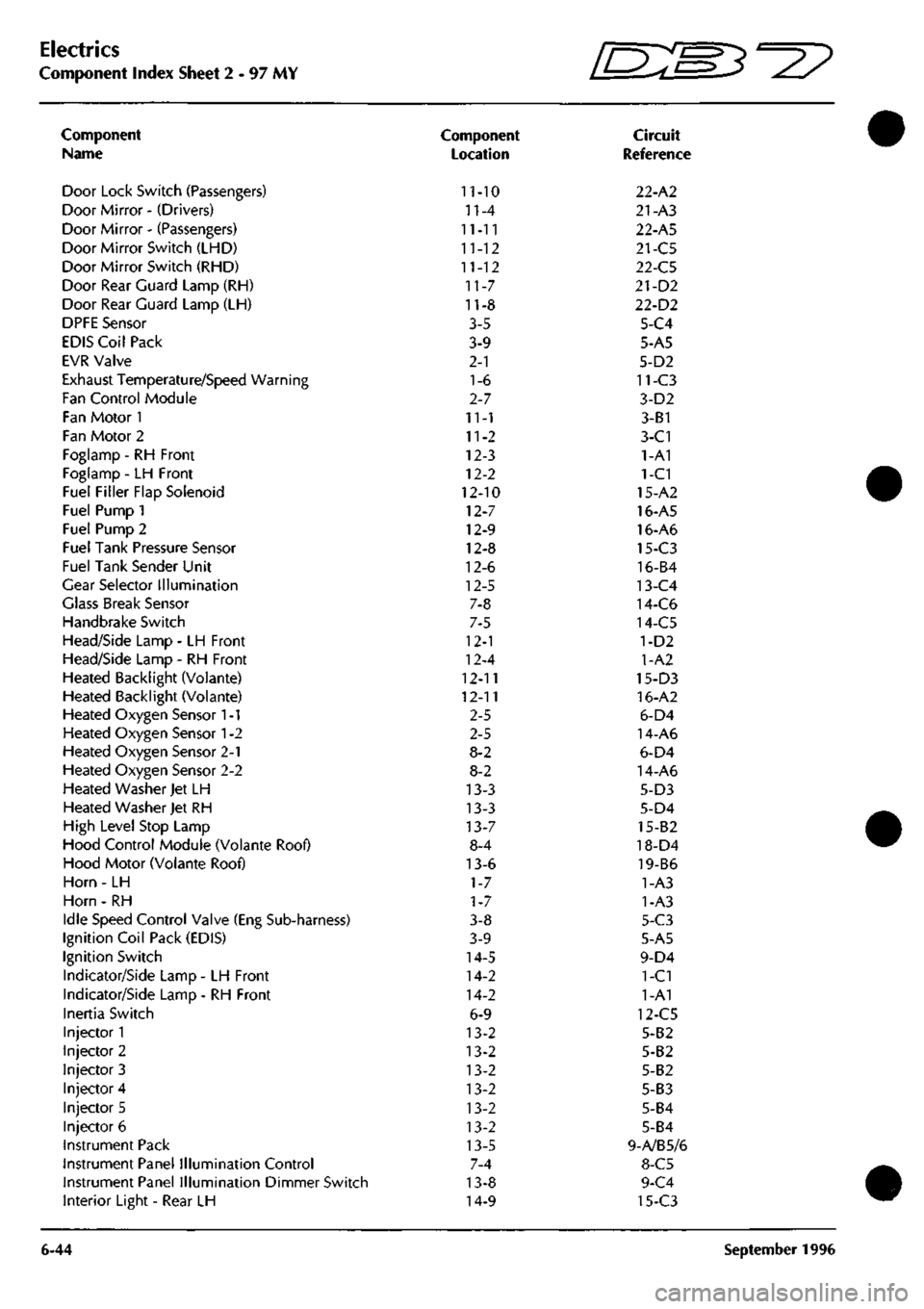

Electrics

Component Index Sheet 2 - 97 MY

Component

Name

Door Lock Switch (Passengers)

Door Mirror - (Drivers)

Door Mirror - (Passengers)

Door Mirror Switch (LHD)

Door Mirror Switch (RHD)

Door Rear Guard Lamp (RH)

Door Rear Guard Lamp (LH)

DPFE Sensor

EDIS Coil Pack

EVR Valve

Exhaust Temperature/Speed Warning

Fan Control Module

Fan Motor 1

Fan Motor 2

Foglamp - RH Front

Foglamp - LH Front

Fuel Filler Flap Solenoid

Fuel Pump 1

Fuel Pump 2

Fuel Tank Pressure Sensor

Fuel Tank Sender Unit

Gear Selector Illumination

Glass Break Sensor

Handbrake Switch

Head/Side Lamp - LH Front

Head/Side Lamp - RH Front

Heated Backlight (Volante)

Heated Backlight (Voiante)

Heated Oxygen Sensor

1

-1

Heated Oxygen Sensor

1

-2

Heated Oxygen Sensor 2-1

Heated Oxygen Sensor 2-2

Heated Washer Jet LH

Heated Washer Jet RH

High Level Stop Lamp

Hood Control Module (Volante Roof)

Hood Motor (Volante Roof)

Horn - LH

Horn - RH

Idle Speed Control Valve (Eng Sub-harness)

Ignition Coil Pack (EDIS)

Ignition Switch

Indicator/Side Lamp - LH Front

Indicator/Side Lamp - RH Front

Inertia Switch

Injector 1

Injector 2

Injector 3

Injector 4

Injector 5

Injector 6

Instrument Pack

Instrument Panel Illumination Control

Instrument Panel Illumination Dimmer Switch

Interior Light - Rear LH

6-44

Component

Location

11-10

n-4

11-11

11-12

11-12

11-7

11-8

3-5

3-9

2-1

1-6

2-7

11-1

11-2

12-3

12-2

12-10

12-7

12-9

12-8

12-6

12-5

7-8

7-5

12-1

12-4

12-11

12-11

2-5

2-5

8-2

8-2

13-3

13-3

13-7

8-4

13-6

1-7

1-7

3-8

3-9

14-5

14-2

14-2

6-9

13-2

13-2

13-2

13-2

13-2

13-2

13-5

7-4

13-8

14-9

fEB^-^?

Circuit

Reference

22-A2

21-A3

22-A5

21-C5

22-C5

21-D2

22-D2

5-C4

5-A5

5-D2

11-C3

3-D2

3-B1

3-C1

1-A1

1-C1

15-A2

16-A5

16-A6

15-C3

16-B4

13-C4

14-C6

14-C5

1-D2

1-A2

15-D3

16-A2

6-D4

14-A6

6-D4

14-A6

5-D3

5-D4

15-82

18-D4

19-B6

1-A3

1-A3

5-C3

5-A5

9-D4

1-C1

1-A1

12-C5

5-B2

5-B2

5-B2

5-B3

5-B4

5-B4

9-A/B5/6

8-C5

9-C4

15-C3

September 1996