length ASTON MARTIN DB7 1997 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 188 of 421

Electrics

Airbag System =7?

Spillage and Leakage

If material is spilled or released, contact Aston

Martin Technical Support for advice on clean-up

procedures. All personnel must be kept away from

the contaminated area.

Do not dispose of contaminated propellant or

water into storm or sanitary sewers, ground water

or

soil.

Spills may be reportable to state and/or federal

authorities.

Materials must be disposed of by incineration or

chemical oxidation under carefully controlled

conditions by specially trained individuals and in

accordancewith local stateandfederal regulations.

Scrapping Vehicles with Live Airbags

when scrapping a vehicle with live airbags, first

deploy the airbags in accordance with the following

procedure. This procedure assumes that the airbag

wiring is undamaged

See Handling/Safety Information.

If the airbags are to be removed, see the airbag

module assembly/removal/servicing instructions.

Equipment required:

Four insulation displacement connectors

(scotch locks).

Charged 'slave' battery.

Two 10 metre lengths of

1

mm^ wire fitted with

crocodile clips on one end.

Procedure

WARNING: The deployment procedure must be

carried out outdoors away from other personnel.

1.

Remove any loose debris from around the airbag

modules and ensure that no flammable liquids are

present.

2.

Disconnect the vehicle battery.

WARNING: Always connect to the airbag

first,

as

the bag will deploy immediately on connection to

the battery.

3. Remove the passenger side airbag deployment

door and underscuttle panel.

4.

Remove the drivers side underscuttle panel.

5. Disconnect the airbag connector for the spiral

cassette under the fascia and at the wire (drivers

side).

6. Locate the harness connectors and cut the wires

leading from the airbag just above the mating plug

(passengers side).

Note: The harness connected between the driver's

airbag

and the connector

has

one red

feed

wire and

one

grey/orange return

wire.

The

harness

connected between

the

passenger's

airbag and the connector

has

one blue/

orange

feed wire and one

pinl

return wire.

6-72 September1996

Page 230 of 421

Body and Trim //-->> ^izz^^ ' ^ ^

Body Repair ' —^^ '-^ >^-/

Body Repair

Introduction

This section contains information for the body repair and rectification of the vehicle. Wherever possible the vehicle

must be returned to its original manufactured condition. Following repair the vehicle must be fully checked and, if

necessary, the braking system and steering must be fully reset.

Health and Safety

Ensure that the correct working practices are established before beginning work.

Observe that the correct working practices are followed whether they be legislative or common sense.

Be aware of the potential risks of using materials used in the manufacture and repair of vehicles and take the

appropriate precautions.

Warning: Make sure that the working practices for the air conditioning

system

are followed: do not vent the refrigerant

directly into the atmosphere and always use the approved recovery/recycle /recharge equipment, always wear

suitable protective garments to prevent injury to the eyes and the skin.

Potential Risks

Paint

If the organic solvents, contained in paints, are inhaled for any length of time damage can be caused to the liver,

kidneys, respiratory tract and the digestive system.

Prolonged exposure to isocyanates can cause lung sensitisation and asthma-like symtoms can develop with

subsequent re-exposure to even low concentrations.

Solvent inhilation can cause dizziness or loss of consciousness.

Inhilation of spray dust and sanding debris can cause lung damage.

Paint activatorsand additives will damage the eyesor can cause dermatitis if allowed to splash and come into contact

with these areas. Peroxide and acid catalysts can cause burns.

Applied heat

There is considerable risk of damage to the eyes and skin when welding or flame cutting.

Fire is a serious danger as many materials and fluids in the vehicle are inflammable.

Toxic and dangerous fumes can be liberated when the following are subjected to heat; expanded foam, corrosion

protection,

adhesive and sealing compounds,

trim,

seat material and paints that contain isocyanates.

When heated to

a

temperature of 300°C, polyu rethane based compounds can

1

iberate small quantities of isocyanate.

Many types of nitrogen containing chemicals may be liberated as breakdown products, these chemicals can

contain isocyanates, oxides of nitrogen and hydrogen cyanide.

Potentially toxic or asphyxiant fumes and gases are produced by welding, for example; zinc oxide with zinc coated

panels and ozone gas from the MIC process.

Metal repair

There is considerable risk of damage to the eyes, ears and skin when metal cutting, forming and dressing is being

carried out.

Soldering may be hazardous because of heat generated fumes and skin contact with the materials.

7-2 May 1996

Page 232 of 421

Body and Trim

Body Repair ^^

Steel Body Parts - Repair^ Remove and

Replace

Removal

1.

Expose the resistance spot

weld.

For those spot

welds that are not obviously visible use a rotary

wire brush fitted to an air drill or a hand held wire

brush.

9.

Prepare the new panel joint edges for welding by

cleaning to bright metal, both interior and exterior

edges.

Apply weld through primer or inter-weld sealer to

all surfaces to be resistance spot welded.

Where appropriate, apply metal-to-metal adhesive

or sealer in accordance with the manufacturer's

instructions.

Caution: Do not

burn

off undersea I,

use a

'hot knife' or

a

suitable solvent.

2. Cut out the spot welds using aZipcutter or roto-Bor.

At this point it may be necessary to cut out the bulk

of a panel using a pneumatic saw.

Note: On

some

panels,

before removing the bulk of the

panel, brazed

areas

and MIC welded

seams

should be

removed.

3. Separate the spot welded joints and remove the

panel remnants.

Preparing Old Surfaces

1.

Remove the weld nuggets with a sander and 36 grit

disc.

2.

Clean all flanges to a bright smooth finish.

3. Straighten existing panel joint edges as required.

Preparing New Surfaces

1.

Mark off the area of the new panel and cut to size

leaving approximately two inches overlap on the

existing panel

2.

Offer up the new panel or section and align it with

the associated parts.

3. Clamp the panel into position.

4.

Where necessary, cut the new and original panels

to form a but joint.

5. Remove all clamps and the new panel.

6. If required, apply the inner panel protection and or

sound insulation.

Panel Alignment

1.

Align the replacement panel with the associated

panel and clamp it in position.

2.

With certain panels it may be necessary to tack

weld or use PK screws.

Welding

1.

MIC tack the butt joints.

2.

Re-check the alignment and the panel contours as

necessary.

3. Select the correct arms for resistance spot welding

and ensure that the tips are correctly trimmed.

Note: It

is

recommended that

the arms are

not more than

12 in (300 mm) in length.

4.

Test the equipment for satisfactory operation using

test coupons.

In the absence of test equ ipment

a

satisfactory weld

can be verified by pulling the test coupons apart

and viewing the welded condition.

5. Resistance spot weld where required. Note the

presence of zinc coated panels and treat as

previously described.

6. Dress back all MIC tack welds.

7. MIG seam weld the butt joints.

8. Dress all welds as required.

9. Final brazeand lead load as necessary priorto paint

preparation.

7-4 May 1996

Page 273 of 421

Body and Trim

Roof Seals - Adjustment

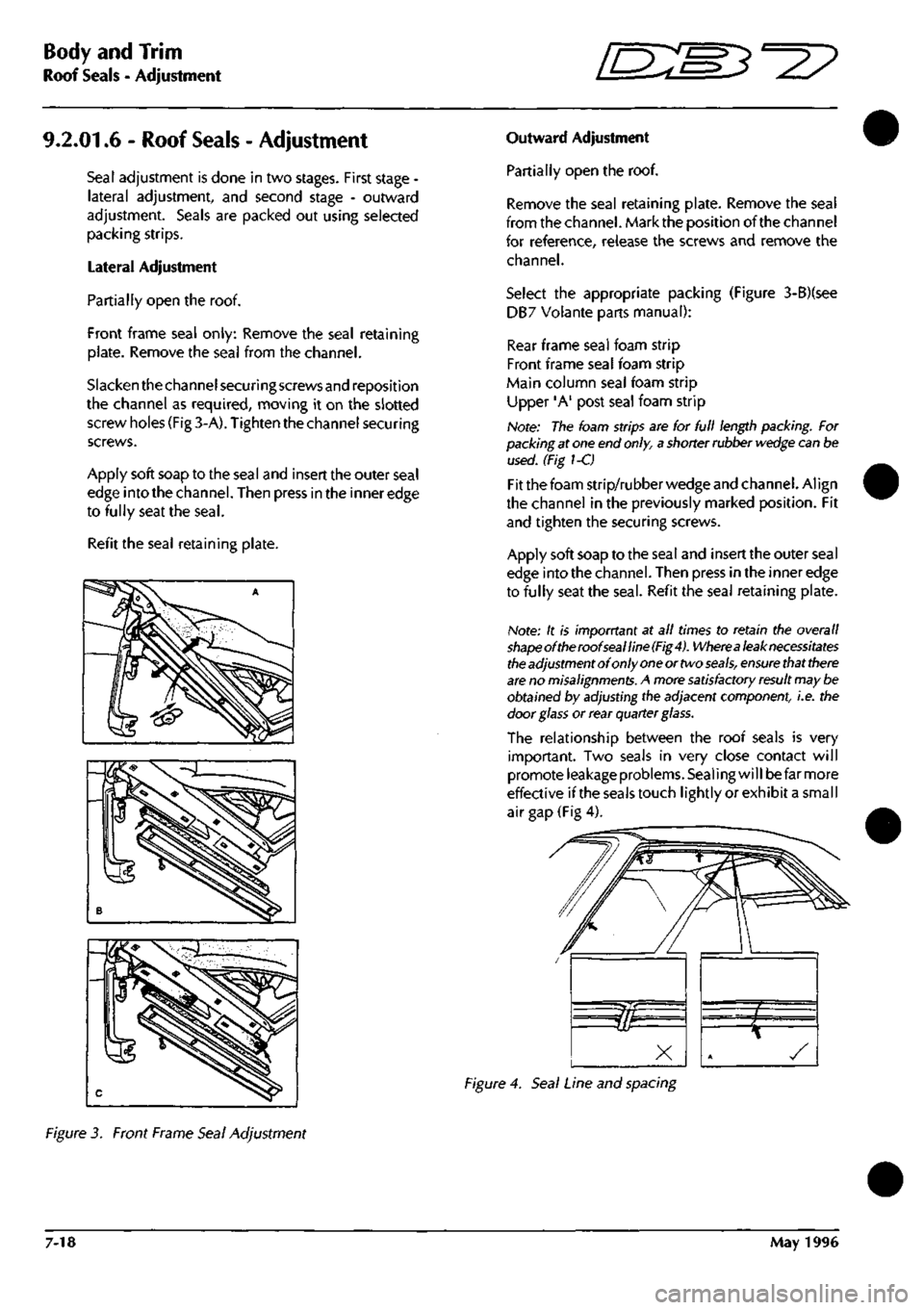

9.2.01.6 - Roof

Seals

- Adjustment

Seal adjustment is done in two stages. First stage -

lateral adjustment, and second stage - outward

adjustment. Seals are packed out using selected

packing strips.

Lateral Adjustment

Partially open the roof.

Front frame seal only: Remove the seal retaining

plate.

Remove the seal from the channel.

Slacken the channel securing screws and reposition

the channel as required, moving it on the slotted

screw holes (Fig 3-A). Tighten the channel securing

screws.

Apply soft soap to the seal and insert the outer seal

edge into the channel. Then press in the inner edge

to fully seat the

seal.

Refit the seal retaining plate.

Outward Adjustment

Partially open the roof.

Remove the seal retaining plate. Remove the seal

from the channel. Mark the position of the channel

for reference, release the screws and remove the

channel.

Select the appropriate packing (Figure 3-B)(see

DB7 Volante parts manual):

Rear frame seal foam strip

Front frame seal foam strip

Main column seal foam strip

Upper 'A' post seal foam strip

Note: The foam strips are for full length packing. For

packing at one end

only,

a shorter rubber

wedge

can be

used. (Fig 1-C)

Fit the foam strip/rubber wedge and channel. Align

the channel in the previously marked position. Fit

and tighten the securing screws.

Apply soft soap to the seal and insert the outer seal

edge into the channel. Then press in the inner edge

to fully seat the

seal.

Refit the seal retaining plate.

Note: It is imporrtant at all times to retain the overall

shapeoftheroofsealline(Fig4).

Wherea

leak necessitates

the

adjustment of only

one

or two

seals,

ensure

that

there

are

no

misalignments.

A more

satisfactory result

may be

obtained by adjusting the adjacent component, i.e. the

door

glass

or rear quarter glass.

The relationship between the roof seals is very

important. Two seals in very close contact will

promote leakage problems. Sealing will be far more

effective ifthe seals touch lightly or exhibit a small

air gap (Fig 4).

Figure 4. Seal Line and spacing

Figure 3. Front Frame Seal Adjustment

7-18 May 1996

Page 293 of 421

Air Conditioning //—^ ^ci^^ • ^ ^

Fnnrtlnn;il fhprk I *-/ -^ r <

Procedure Normal System Reaction

16.

Select ECO Blower flaps revert to fresh air position

17.

Select AC Engine revs change then stabilise

18.

Select fan speed 3 Small increase in fan speed

19.

Select fan speed 2 Fan speed lower

Centre vent and dash end cold

footwell cool

20.

Select MAX temperature

allow in-car temperature to stabilise Hot air from footwell,

(Passenger side underscuttle panel must be in place) warm from dash end

21.

Select MIN temperature and mid face level System goes to full cooling automatically

Cold air from all vent except from screen vent

Centre vent open

Blower at re-circulation

22.

Select DEMIST and full heat Demist vents open, centre vent closes and

blower flaps revert to fresh air position

System check now complete System good.

Note: A small amount of air will bleed from the

ends

of the

demist-defrost vents

in all

cases,

but there should be no leak along

the length of the vents.

8-16 May 1996

Page 411 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide ^?

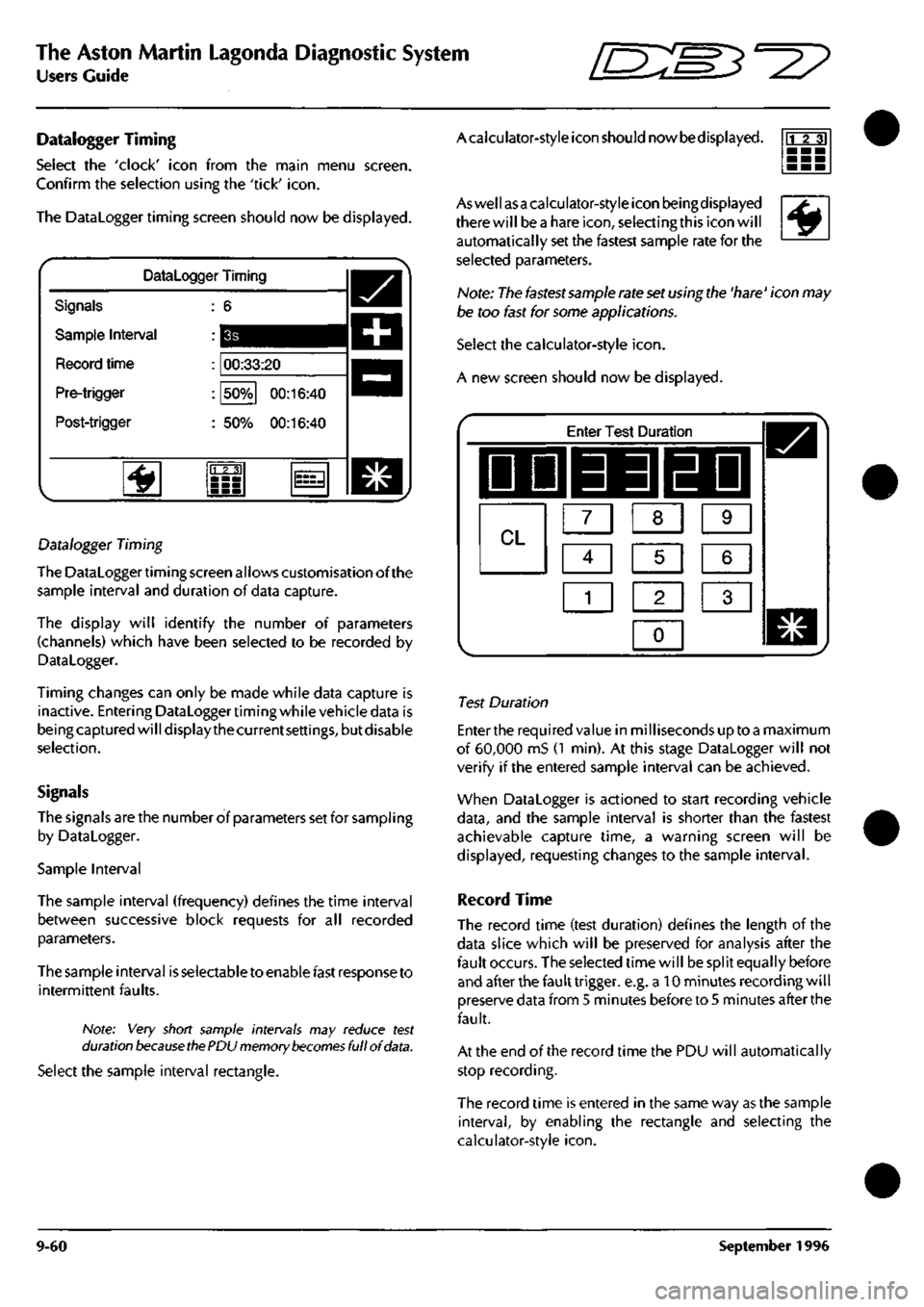

Datalogger Timing

Select the 'clock' icon from the main menu screen.

Confirm the selection using the 'tick'

icon.

The Datalogger timing screen should now be displayed.

Datalogger Timing

Signals

Sample Interval

Record time

Pre-trigger

Post-trigger

00:33:20

50%

00:16:40

50%

00:16:40

'^

23]

Datalogger Timing

The Datalogger timing screen allows customisation of the

sample interval and duration of data capture.

The display will identify the number of parameters

(channels) which have been selected to be recorded by

Datalogger.

Timing changes can only be made while data capture is

inactive. Entering Dataloggertiming while vehicle data is

being captured will display the current

settings,

but disable

selection.

Signals

The signals are the number of parameters set for sampIing

by Datalogger.

Sample Interval

The sample interval (frequency) defines the time interval

between successive block requests for all recorded

parameters.

The sample interval is selectable to enable fast response to

intermittent faults.

Note: Very short sample intervals may reduce test

duration

because ttie

PDU memory

becomes

full of

data.

Select the sample interval rectangle.

Acaiculator-style icon should nowbedisplayed. rrr?]

^

Aswellasa calculator-style icon beingdisplayed

there will bea hare

icon,

selecting this icon will

automatically set the fastest sample rate for the

selected parameters.

Note: The fastest sannple rate set using the 'hare' icon may

be too fast for some applications.

Select the calculator-style

icon.

A new screen should now be displayed.

Enter Test Duration

IDD 33 EDI

CL m m [Z]

Ci] ra [I]

1

1 2 1 3 1

0

1

Test Duration

Enter the required value in milliseconds up toa maximum

of 60,000 mS (1 min). At this stage Datalogger will not

verify if the entered sample interval can be achieved.

When Datalogger is actioned to start recording vehicle

data,

and the sample interval is shorter than the fastest

achievable capture time, a warning screen will be

displayed,

requesting changes to the sample interval.

Record Time

The record time (test duration) defines the length of the

data slice which will be preserved for analysis after the

fault occurs. The selected time will be split equally before

and after the fault trigger, e.g. a 10 minutes recording will

preserve data from 5 minutes before to 5 minutes after the

fault.

At the end of the record time the PDU will automatically

stop recording.

The record time is entered in the same way as the sample

interval,

by enabling the rectangle and selecting the

calculator-style

icon.

9-60 September 1996