power steering ASTON MARTIN DB7 1997 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 14 of 421

Electrics

Starter Motor / Steering Wheel - Removal Procedures ^n:M3^^2?

6.3.02 Starter Motor

Procedure

1.

Disconnect the battery.

2.

Remove the inlet air trunkins

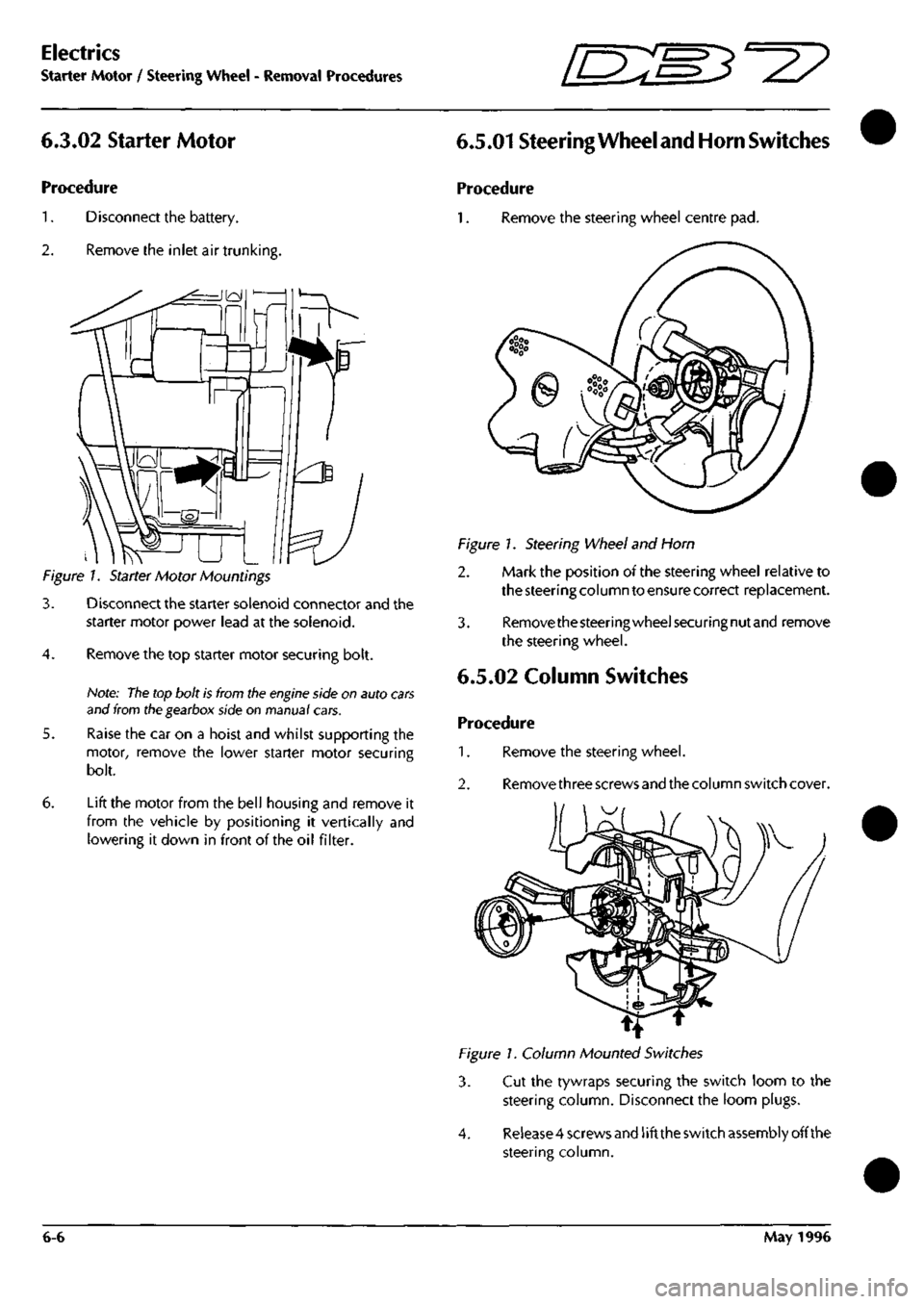

Figure 1. Starter Motor Mountings

3. Disconnect the starter solenoid connector and the

starter motor power lead at the solenoid.

4.

Remove the top starter motor securing bolt.

Note:

The

top bolt is from tlie

engine

side on auto

cars

and from ttie gearbox side on manual cars.

5. Raise the car on a hoist and whilst supporting the

motor, remove the lower starter motor securing

bolt.

6. Lift the motor from the bell housing and remove it

from the vehicle by positioning it vertically and

lowering it down in front of the oil filter.

6.5.01 Steering

Wheel and Horn

Switches

Procedure

1.

Remove the steering wheel centre pad.

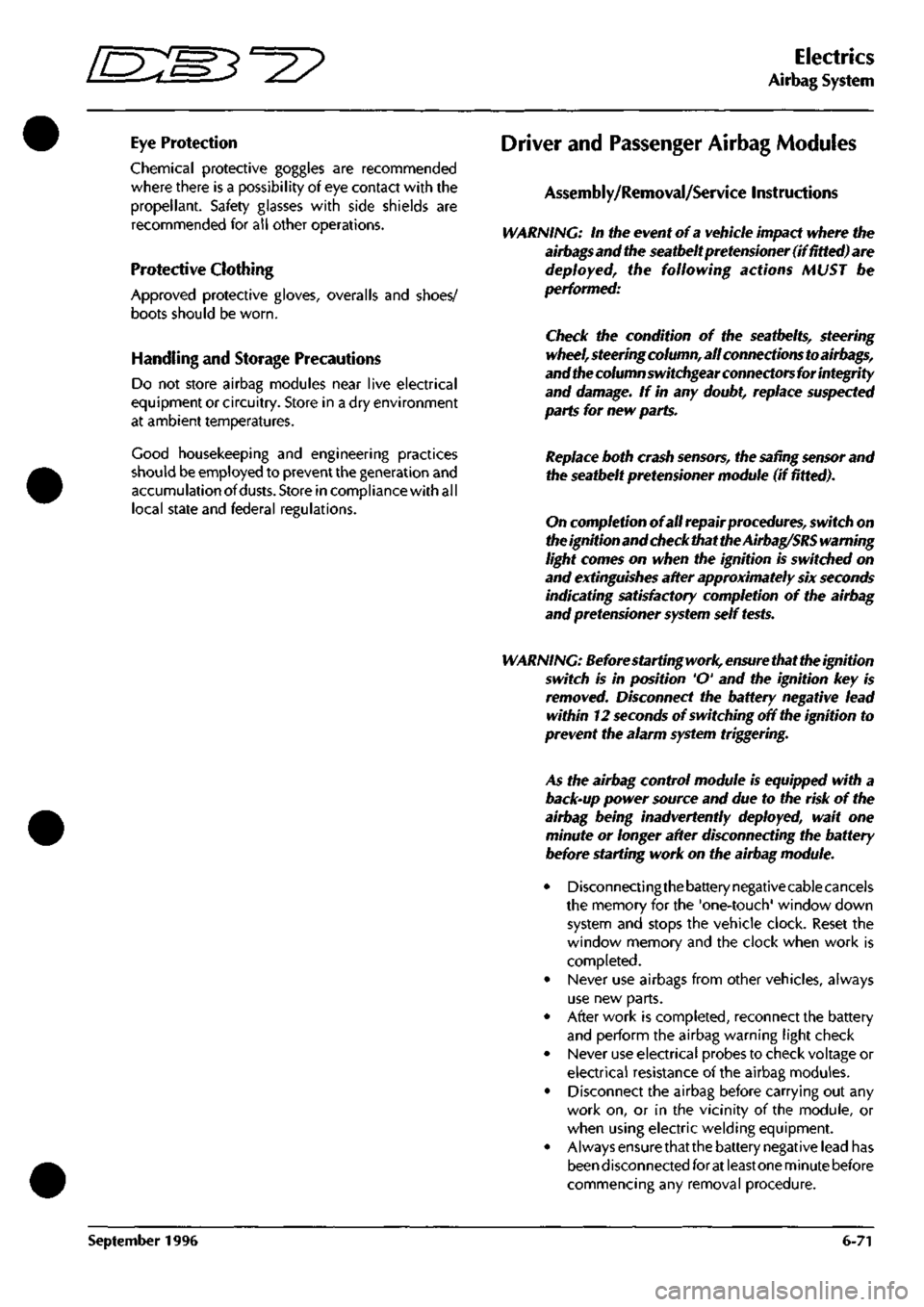

Figure 1. Steering Wheel and Horn

2. Mark the position of the steering wheel relative to

the steering column to ensure correct replacement.

3. Removethesteeringwheelsecuringnutand remove

the steering wheel.

6.5.02 Column Switches

Procedure

1.

Remove the steering wheel.

2.

Remove three screws and the column switch cover.

1^

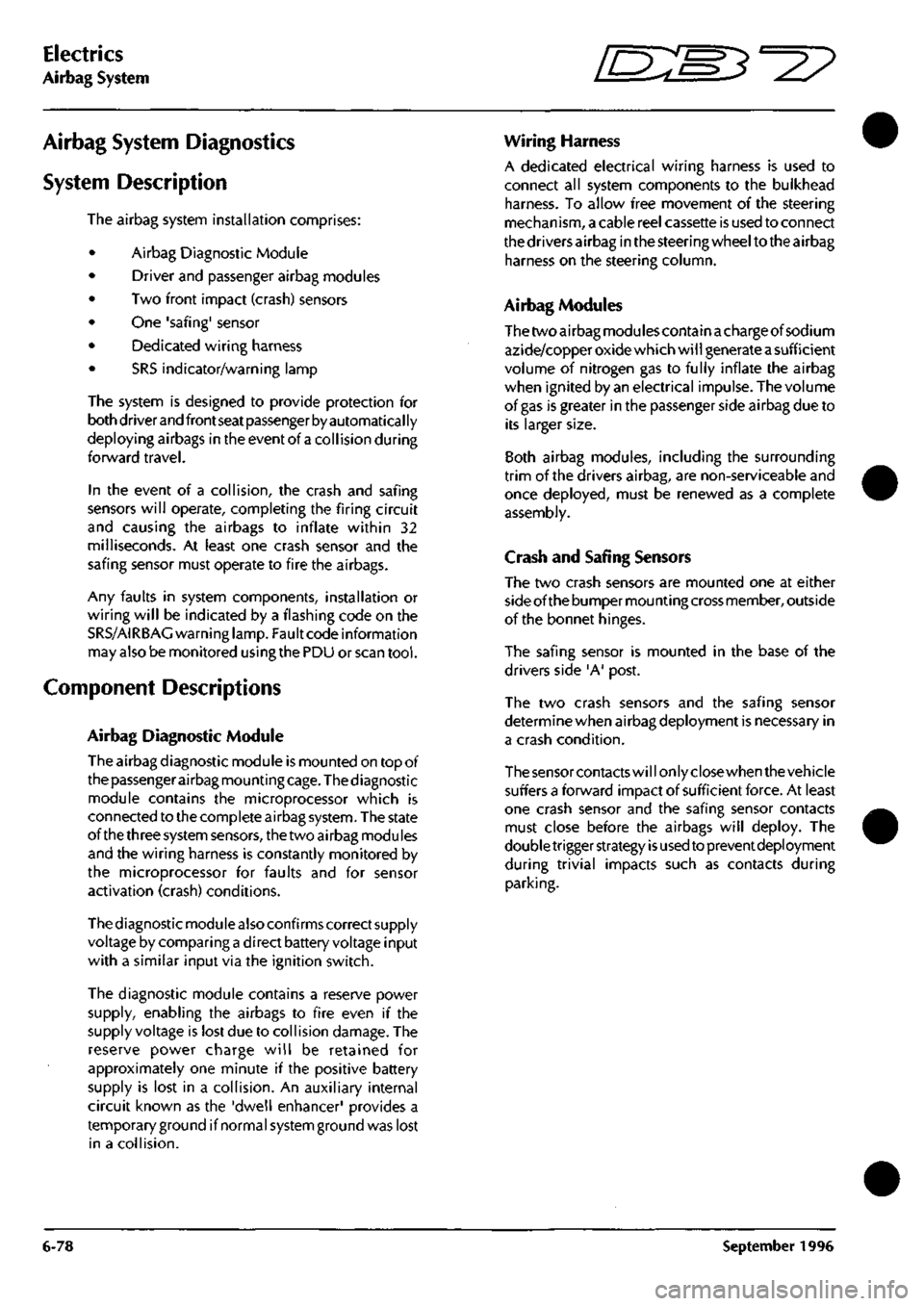

Figure 1. Column Mounted Switches

3. Cut the tywraps securing the switch loom to the

steering column. Disconnect the loom plugs.

4.

Release 4 screws and

1

ift the switch assembly off the

steering column.

6-6 May 1996

Page 187 of 421

^=2?

Electrics

Airbag System

Eye Protection

Chemical protective goggles are recommended

where there is a possibility of eye contact with the

propellant. Safety glasses with side shields are

recommended for all other operations.

Protective Clothing

Approved protective gloves, overalls and shoes/

boots should be worn.

Handling and Storage Precautions

Do not store airbag modules near live electrical

equipment or circuitry. Store in a dry environment

at ambient temperatures.

Good housekeeping and engineering practices

should be employed to prevent the generation and

accumulation of

dusts.

Store in compliance with all

local state and federal regulations.

Driver and Passenger Airbag Modules

Assembly/Removal/Service Instructions

WARNING: In the event of a vehicle impact where the

airbags and the seatbeltpretensioner (if fitted) are

deployed, the following actions MUST be

performed:

Check the condition of the seatbelts, steering

wheel,

steering column, all connections to airbags,

and the column switchgear connectors for integrity

and damage. If in any

doubt,

replace suspected

parts for new parts.

Replace both crash

sensors,

the

safing sensor

and

the seatbelt pretensioner module (if fitted).

On completion of all repair procedures, switch on

the ignition and check that the

Airbag/SRS

warning

light comes on when the ignition is switched on

and extinguishes after approximately six seconds

indicating satisfactory completion of the airbag

and pretensioner

system

self

tests.

WARNING: Before starting

work,

ensure

that the ignition

switch is in position 'O' and the ignition key is

removed.

Disconnect the battery negative lead

within 12 seconds of switching off the ignition to

prevent the alarm system triggering.

As the airbag control module is equipped with a

back-up power source and due to the risk of the

airbag being inadvertently deployed, wait one

minute or longer after disconnecting the battery

before starting work on the airbag module.

• Disconnectingthe battery negative cable cancels

the memory for the 'one-touch' window down

system and stops the vehicle clock. Reset the

window memory and the clock when work is

completed.

• Never use airbags from other vehicles, always

use new parts.

• After work is completed, reconnect the battery

and perform the airbag warning light check

• Never use electrical probes to check voltage or

electrical resistance of the airbag modules.

• Disconnect the airbag before carrying out any

work on, or in the vicinity of the module, or

when using electric welding equipment.

• Always ensure that the battery negative lead has

been disconnected for at least one minute before

commencing any removal procedure.

September 1996 6-71

Page 194 of 421

Electrics

Airbag System '=2?

Airbag System Diagnostics

System Description

The airbag system installation comprises:

Airbag Diagnostic Module

Driver and passenger airbag modules

Two front impact (crash) sensors

One 'safing' sensor

Dedicated wiring harness

SRS indicator/warning lamp

The system is designed to provide protection for

both driver and front seat passenger by automatical ly

deploying airbags in the event of

a

collision during

forward travel.

In the event of a collision, the crash and safing

sensors will operate, completing the firing circuit

and causing the airbags to inflate within 32

milliseconds. At least one crash sensor and the

safing sensor must operate to fire the airbags.

Any faults in system components, installation or

wiring will be indicated by a flashing code on the

SRS/AIRBAG warning lamp. Fault code information

may also be monitored using the PDU or scan

tool.

Component Descriptions

Airbag Diagnostic Module

The airbag diagnostic module is mounted on top of

the passenger airbag mountingcage.Thediagnostic

module contains the microprocessor which is

connected to the complete airbag system. The state

of the three system sensors, the two airbag modules

and the wiring harness is constantly monitored by

the microprocessor for faults and for sensor

activation (crash) conditions.

The diagnostic module also confirms correct supply

voltage by comparing

a

direct battery voltage input

with a similar input via the ignition switch.

The diagnostic module contains a reserve power

supply, enabling the airbags to fire even if the

supply voltage is lost due to collision damage. The

reserve power charge will be retained for

approximately one minute if the positive battery

supply is lost in a collision. An auxiliary internal

circuit known as the 'dwell enhancer' provides a

temporary ground if normal system ground was lost

in a collision.

Wiring Harness

A dedicated electrical wiring harness is used to

connect all system components to the bulkhead

harness. To allow free movement of the steering

mechanism, a cable reel cassette is used to connect

the drivers airbag in the steering wheel to the airbag

harness on the steering column.

Airbag Modules

The two airbag modules contain achargeof sodium

azide/copper oxide which wi

11

generate

a

sufficient

volume of nitrogen gas to fully inflate the airbag

when ignited by an electrical impulse. The volume

of gas is greater in the passenger side airbag due to

its larger size.

Both airbag modules, including the surrounding

trim of the drivers airbag, are non-serviceable and

once deployed, must be renewed as a complete

assembly.

Crash and Safing Sensors

The two crash sensors are mounted one at either

side of the bumper mounting cross member, outside

of the bonnet hinges.

The safing sensor is mounted in the base of the

drivers side 'A' post.

The two crash sensors and the safing sensor

determine when airbag deployment is necessary in

a crash condition.

The sensor contacts will only close when the vehicle

suffers a forward impact of sufficient force. At least

one crash sensor and the safing sensor contacts

must close before the airbags will deploy. The

doubletrigger strategy

is

used to prevent deployment

during trivial impacts such as contacts during

parking.

6-78 September 1996

Page 196 of 421

Electrics

Airbag System ^2?

6.4.21.4

Airbag Disarming/Arming

Procedures

WARNINGS AND CAUTIONS:

WARNINGS:

Disarm the airbags by disconnecting the battery

ground (black)

lead,

waiting one minute and then

removing the airbag modules before servicing of

any airbag or steering column component.

After disconnecting the battery ground

lead,

allow

a minimum of one minute delay for the back-up

power supply to discharge before servicing the

airbag system.

The system components are non-serviceable, if

faults are

suspected,

change components for new

items

only.

Failure to observe the above procedures may

result in accidental deployment of the airbags.

Always wear safety

glasses

when working on airbag

equipped vehicles.

Personnel carrying an airbag module must ensure

that the module and trim cover are pointing away

from the

body.

When positioning on a bench or

work surface, ensure that the airbag module and

trim cover face upwards to limit motion on

accidental deployment.

Always wear

gloves

when handling deployed airbag

modules. Deposits of sodium hydroxide may be

presenton the module surface. If sodium hydroxide

contacts any area of the skin, wash the affected

area immediately with mild soap and

water.

Dispose of the deployed airbag using the correct

procedures referred to in this section.

Cautions:

When scrapping vehicles,

ensure

that the

airbags

have

been deployed (see

Scrapping Vehicles

with Live

Airbags).

If a component

has been

renewed and the fault

does

not

clear,

refit the original item and repeat the diagnostic

procedure.

After

servicing,

repeatthe diagnostic

procedures

to ensure

correct

system

operation.

Renew

the airbag module if the surrounding trim

panels

are

damaged.

Do not attempt to repaint trim covers as

paint may

damage

cover material.

Disarming the Airbags

3.

4.

WARNING: Carry out the following disarming

procedure before attempting any work on the

vehicles electrical

systems.

Note: The battery ground (black) lead must be

disconnected within 12 seconds of switching off the

ignition to avoid the alarm siren sounding.

Disconnect the battery ground

lead.

Allow a

minimum of one minute delay for the back-up

power supply to discharge.

Remove the drivers side airbag module and replace

it with an airbag simulatorfrom the simulator kit (Pt

No.

43.27028).

Remove the passengers airbag module and replace

it with an airbag simulator from the simulator kit.

Reconnect the battery ground.

Rearming the Airbags

WARNING: Carry out the following procedure to

rearm and check the airbags after completing all

work on the vehicles electrical

systems.

Note: The vehicle battery

must be

disconnected within

12

seconds

of switching off

the

ignition

to

avoid the alarm

siren sounding.

^. Disconnect the battery ground

lead.

Allow a

minimum of one minute delay for the back-up

power supply to discharge.

2.

Removethedriverssideairbagsimulatorand replace

it with the drivers airbag module. Secure the airbag

module with the two captive torx screws.

3. Remove the passengers side airbag simulator and

replace it with the passenger side airbag module.

Secure the module with four nuts and washers.

Close the passenger side airbag door.

4.

Reconnect the battery ground.

5. Switch on the ignition and check for correct

indications from the SRS/AIRBAG warning light.

TheSRS/AIRBAC lamp should come on after

a

brief

delay and remain on for approximately six seconds

during the airbag system self check. The lamp will

extinguish upon satisfactory completion of the self

check, or will flash a diagnostic code if an airbag

system fault is detected. Continuous illumination of

the warning lamp may indicate a seatbelt

pretensioner fault

Note:

Reset the

clock and window

ECUs

on completion.

6-80 September 1996