tyre pressure ASTON MARTIN DB7 1997 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 111 of 421

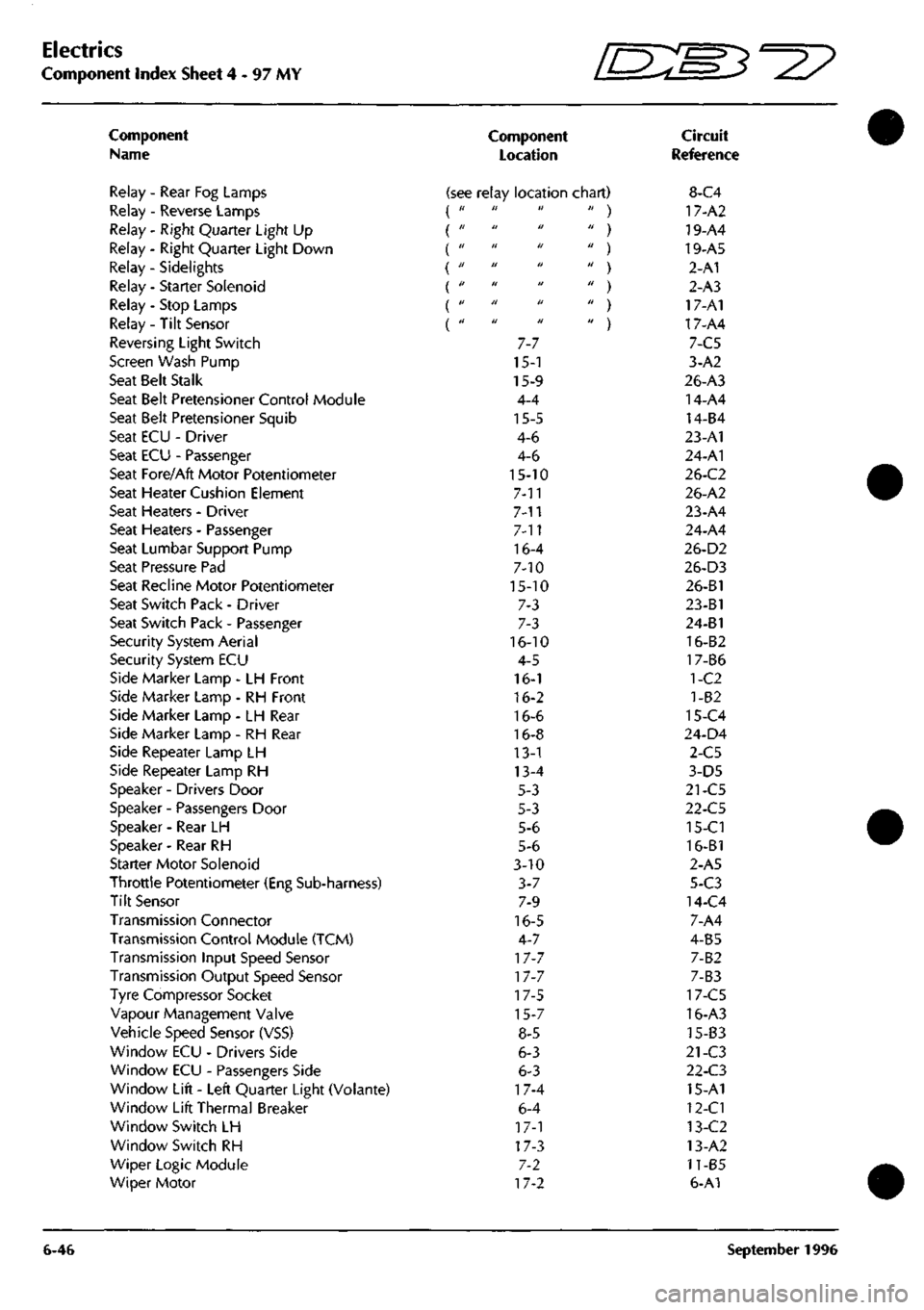

Electrics

Component Index Sheet 4-97 MY ^7

Component

Name

Relay - Rear Fog Lamps

Relay - Reverse Lamps

Relay - Right Quarter Light Up

Relay - Right Quarter Light Down

Relay - Sidelights {

Relay - Starter Solenoid

Relay - Stop Lamps

Relay- Tilt Sensor

Reversing Light Switch

Screen Wash Pump

Seat Belt Stalk

Seat Belt Pretensioner Control Module

Seat Belt Pretensioner Squib

Seat ECU - Driver

Seat ECU - Passenger

Seat Fore/Aft Motor Potentiometer

Seat Heater Cushion Element

Seat Heaters - Driver

Seat Heaters - Passenger

Seat Lumbar Support Pump

Seat Pressure Pad

Seat Recline Motor Potentiometer

Seat Switch Pack - Driver

Seat Switch Pack - Passenger

Security System Aerial

Security System ECU

Side Marker Lamp - LH Front

Side Marker Lamp - RH Front

Side Marker Lamp - LH Rear

Side Marker Lamp - RH Rear

Side Repeater Lamp LH

Side Repeater Lamp RH

Speaker - Drivers Door

Speaker - Passengers Door

Speaker - Rear LH

Speaker - Rear RH

Starter Motor Solenoid

Throttle Potentiometer (Eng Sub-harness)

Tilt Sensor

Transmission Connector

Transmission Control Module (TCM)

Transmission Input Speed Sensor

Transmission Output Speed Sensor

Tyre Compressor Socket

Vapour Management Valve

Vehicle Speed Sensor (VSS)

Window ECU - Drivers Side

Window ECU - Passengers Side

Window Lift - Left Quarter Light (Volante)

Window Lift Thermal Breaker

Window Switch LH

Window Switch RH

Wiper Logic Module

Wiper Motor

6-46

Component

Location

Circuit

Reference

(see relay location chart) 8-C4 it ti It

II H U

tl 11 U

a II 11

II II II

II Ji II

II II II

7-7

15-1

15-9

4-4

15-5

4-6

4-6

15-10

7-11

7-n

7-11

16-4

7-10

15-10

7-3

7-3

16-10

4-5

16-1

16-2

16-6

16-8

13-1

13-4

5-3

5-3

5-6

5-6

3-10

3-7

7-9

16-5

4-7

17-7

17-7

17-5

15-7

8-5

6-3

6-3

17-4

6-4

17-1

17-3

7-2

17-2

' ) 17-A2

' ) 19-A4

' ) 19-A5

' ) 2-A1

' ) 2-A3

' ) 17-A1

' ) 17-A4

7-C5

3-A2

26-A3

14-A4

14-B4

23-A1

24-A1

26-C2

26-A2

23-A4

24-A4

26-D2

26-D3

26-B1

23-B1

24-B1

16-B2

17-B6

1-C2

1-82

15-C4

24-D4

2-C5

3-D5

21-C5

22-C5

15-Cl

16-B1

2-A5

5-C3

14-C4

7-A4

4-B5

7-B2

7-B3

17-C5

16-A3

15-B3

21-C3

22-C3

15-A1

12-Cl

13-C2

13-A2

11-B5

6-A1

September 1996

Page 394 of 421

^?

The Aston Martin Lagonda Diagnostic System

Users Guide

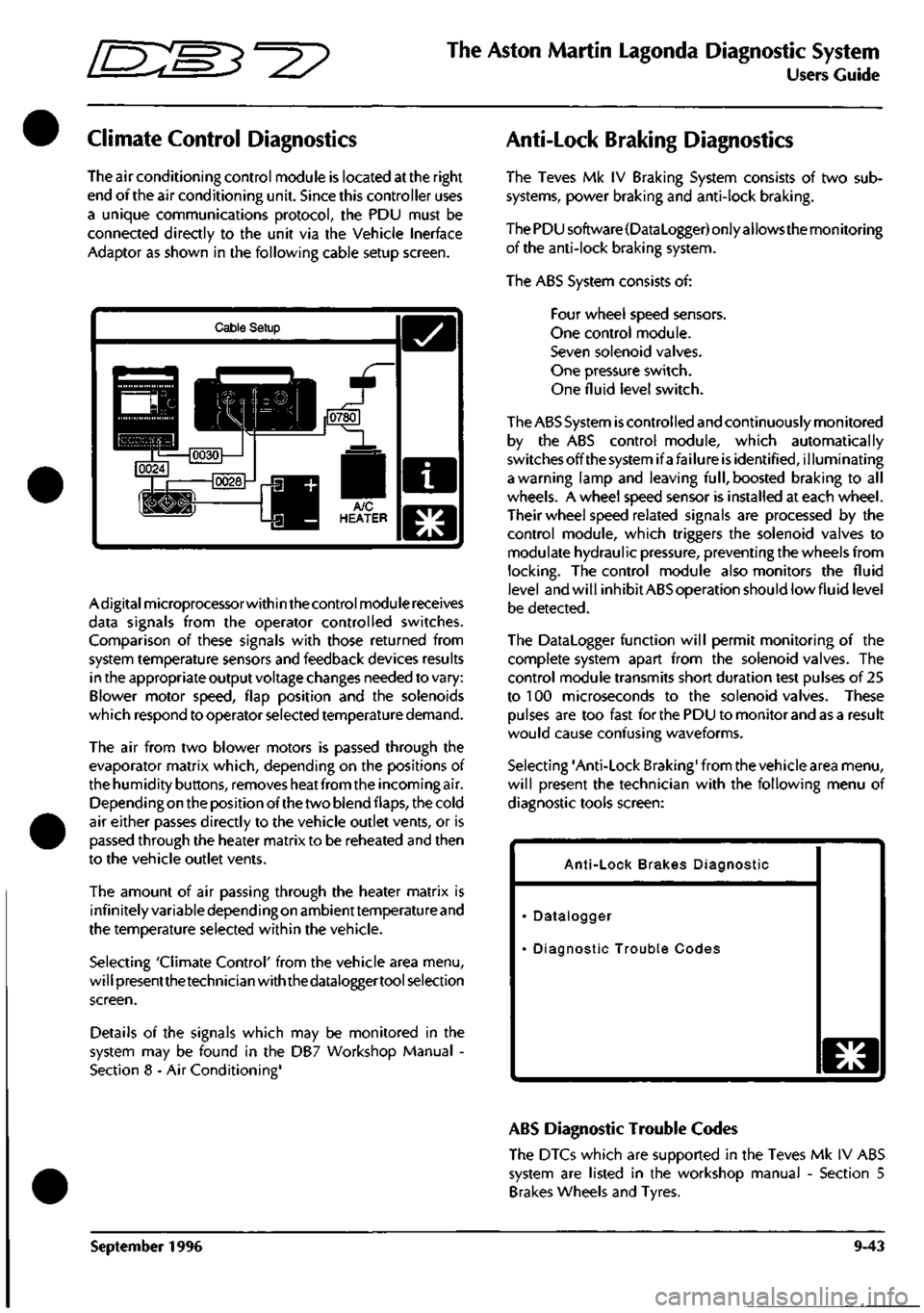

Climate Control Diagnostics

The air conditioning control module is located at the right

end of the air conditioning unit. Since this controller uses

a unique communications protocol, the PDU must be

connected directly to the unit via the Vehicle Inerface

Adaptor as shown in the following cable setup screen.

Cable Setup

Adigitalmicroprocessorwithin the control module receives

data signals from the operator controlled switches.

Comparison of these signals with those returned from

system temperature sensors and feedback devices results

in the appropriate output voltage changes needed to vary:

Blower motor speed, flap position and the solenoids

which respond to operator selected temperature demand.

The air from two blower motors is passed through the

evaporator matrix which, depending on the positions of

the humidity buttons, removes heat from the incoming air.

Dependingon the position of the two blend flaps, the cold

air either passes directly to the vehicle outlet vents, or is

passed through the heater matrix to be reheated and then

to the vehicle outlet vents.

The amount of air passing through the heater matrix is

infinitely variable depending on ambienttemperature and

the temperature selected within the vehicle.

Selecting 'Climate Control' from the vehicle area menu,

will presentthetechnician with the dataloggertool selection

screen.

Details of the signals which may be monitored in the

system may be found in the DB7 Workshop Manual -

Section 8 - Air Conditioning'

Anti-Lock Braking Diagnostics

The Teves Mk IV Braking System consists of two sub

systems, power braking and anti-lock braking.

The PDU software(DataLogger) only allows the monitoring

of the anti-lock braking system.

The ABS System consists of:

Four wheel speed sensors.

One control module.

Seven solenoid valves.

One pressure switch.

One fluid level switch.

The ABS System

is

controlled and continuously monitored

by the ABS control module, which automatically

switchesoffthesystemifafailure is identified, illuminating

a warning lamp and leaving

full,

boosted braking to all

wheels. A wheel speed sensor is installed at each wheel.

Their wheel speed related signals are processed by the

control module, which triggers the solenoid valves to

modulate hydraulic pressure, preventing the wheels from

locking.

The control module also monitors the fluid

level and will inhibit ABS operation should lowfluid level

be detected.

The Datalogger function will permit monitoring of the

complete system apart from the solenoid valves. The

control module transmits short duration test pulses of 25

to 100 microseconds to the solenoid valves. These

pulses are too fast for the PDU to monitor and as a result

would cause confusing waveforms.

Selecting 'Anti-Lock Braking' from the vehicle area menu,

will present the technician with the following menu of

diagnostic tools screen:

Anti-Lock Brakes Diagnostic

Datalogger

Diagnostic Trouble Codes

o

ABS Diagnostic Trouble Codes

The DTCs which are supported in the Teves Mk IV ABS

system are listed in the workshop manual - Section 5

Brakes Wheels and Tyres.

September 1996 9-43