AUDI A3 2015 Owners Manual

Manufacturer: AUDI, Model Year: 2015, Model line: A3, Model: AUDI A3 2015Pages: 288, PDF Size: 71.46 MB

Page 251 of 288

-Make sure that passengers wait in a safe

place away from the vehicle and well

away from the road and traffic.

- To help prevent the vehicle from moving

suddenly and possibly slipping off the

jack, always fully set the parking brake

and block the wheel diagonally opposite

the whee l being changed. When one

front whee l is lifted off the gro und, plac

ing the A utomat ic Transm iss ion in P

(Park) wi ll

not prevent t he vehi cle from

moving .

- Before you change a wheel, be su re the

ground is leve l and fi rm.

If necessary,

use a st urdy board under the jack.

- Always store the vehicle tool ki t, the jack

and the replaced ti re in the l uggage com

partment¢

page 12 7 .

Changing a wheel

When you change a wheel, follow these

quence described below step-by-step and in

exactly that order.

1. Remove the d ec orative wheel cov er* . For

more deta ils see also

c:>page 249, Deco

rative wheel covers

or ¢ page 2 50,

Wheels with wheel bolt caps.

2. Loosen the wheel bolt s c:> page 250.

3. Locate the proper mount ing point for the

jack and align the jack below that point

<=> page 251.

4. Raise the car w ith the jack c:> page 251.

5. Remove the wheel with the flat tire and

then install

the spare ¢ page 252 .

6. Tighten all wheel bo lts light ly.

7 .

Low er the ve hicle with the jack.

8. Use the wheel bolt wrenc h and

firmly

tighten all whee l bolts c:> page 250.

9. Replace the decorative wheel cov er*.

A WARNING

Always read and follow all WARNINGS and

information

c:> .&. in Raising the vehicle on

page251

and ¢page 253.

What do I d o now ? 249

After changing a wheel

A wheel change is not complete without the

doing the following.

.,. Always store the vehicle tool kit, the jack*

and the replaced tire in the luggage com

partment

c:> page 127.

.,. Check the tir e pr essure on the spare whee l

immed iate ly afte r mounting i t.

.,. As soon as poss ib le, have the

tight ening

torque s

on all wheel bolts checked w ith a

torque wrench . The correct tighten ing tor

que is 90 ft lb (120 Nm).

.,. Have the flat tire

replaced as soon as possi

ble.

@ Tips

- If you notice that the wheel bo lts a re

corroded and difficult to turn while

chang ing a tire, they should be replaced

before you c heck the tightening torque.

- Drive at reduced speed until you have the tightening torques checked.

- After changing a whee l, the ti re press ure

in all four tires must be checked/correct

ed and the tire pressure monitoring indi

cator must be stored in the M MI

c:>page245.

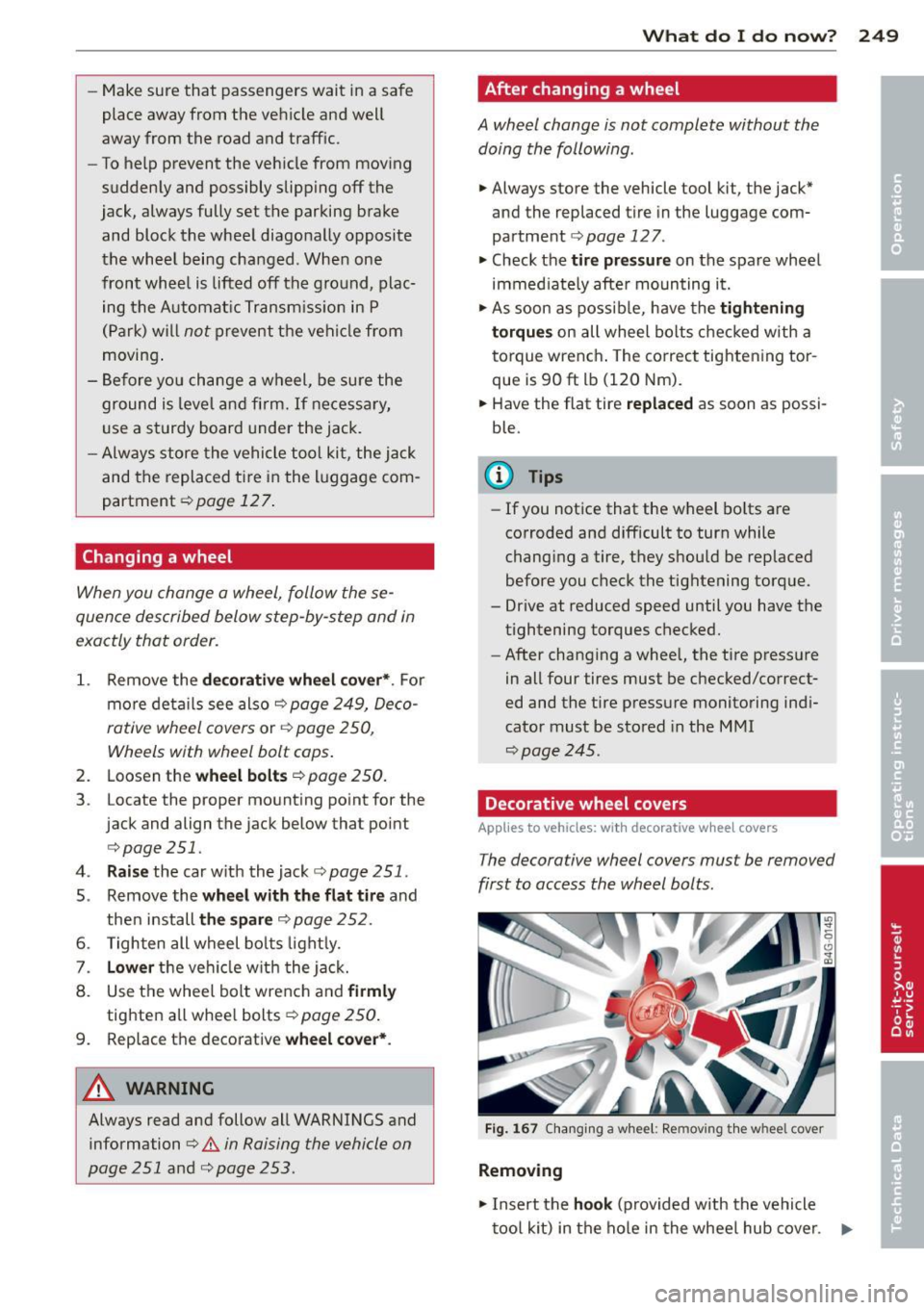

Decorative wheel covers

App lies to veh icles: w ith decorat ive w hee l cove rs

The decorative wheel covers must be removed

first to access the wheel bolts.

Fi g. 167 Chang ing a whee l: Removing th e w hee l cover

Removing

.,. Insert the hook (provided with the vehicle

t oo l kit) in the ho le in the whee l hub cover .

i,,.

Page 252 of 288

250 What do I do now?

• Pull off the decorative wheel cover

Q fig. 167.

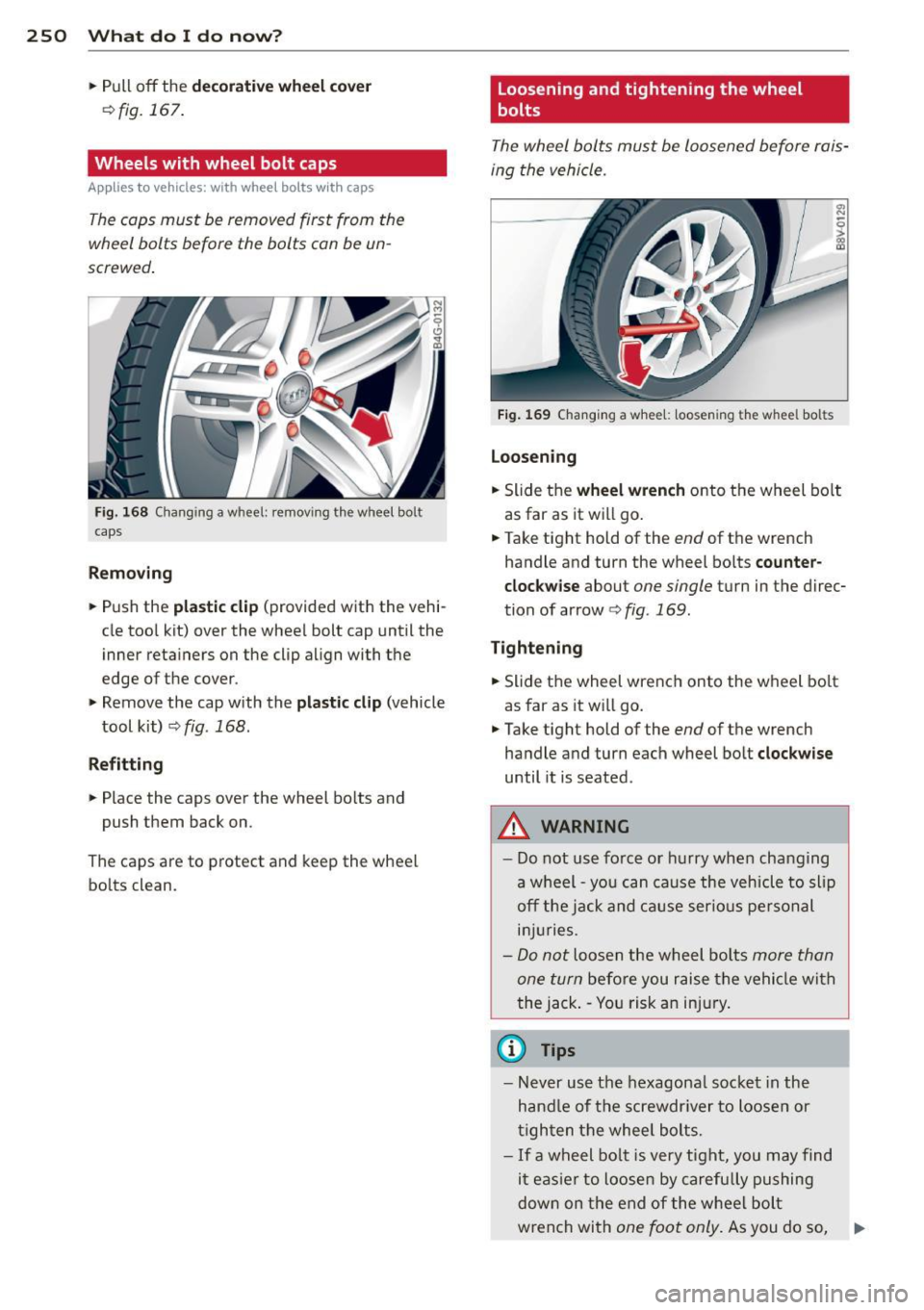

Wheels with wheel bolt caps

Applies to vehicles: with whee l bo lts wit h caps

The caps must be removed first from the

wheel bolts before the bolts con be un

screwed .

Fig. 168 Chang ing a w hee l: rem ov ing the w heel bo lt

caps

Removing

• Push the plastic clip (provided with the vehi

cle too l kit) over the whee l bolt cap until the

inner retainers on the clip align with the

edge of the cover .

• Remove the cap with the

plastic clip (vehicle

tool kit)

Q fig . 168.

Refitting

• Place the caps over the wheel bo lts and

push them back on.

The caps are to protect and keep the wheel bolts clean.

Loosening and tightening the wheel

bolts

The wheel bolts must be loosened before rais

ing the vehicle .

Fig. 1 69 Changing a whe el: loosening the w hee l bol ts

Loosening

• Slide the wheel wrench onto the wheel bolt

as far as it will go.

• Take tight hold of the

end of the wrench

handle and turn the wheel bolts

counter

clockwise

about one single turn in the direc

tion of arrow

Q fig . 169.

Tightening

• Slide t he wheel wrench onto the wheel bo lt

as far as it w ill go.

• Take tight hold of the

end of the wrench

handle and turn each wheel bolt

clockw ise

until it is seated .

A WARNING

--Do not use force or hurry when changing

a wheel -you can cause the vehicle to slip

off the jack and cause serious personal

in ju ries.

-Do not loosen the wheel bolts more than

one turn

before you raise the vehicle with

the jack . - Yo u risk an inju ry.

© Tips

-Never use the hexagonal socket in the

hand le of the screwdr iver to loosen or

tighten the wheel bolts.

- If a wheel bolt is very tight, you may find

it eas ier to loosen by carefully pushing

down on the end of the wheel bolt

w rench with

one foot only. As you do so, ..,.

Page 253 of 288

hold on to the ca r to keep your ba lance

and take care not to slip.

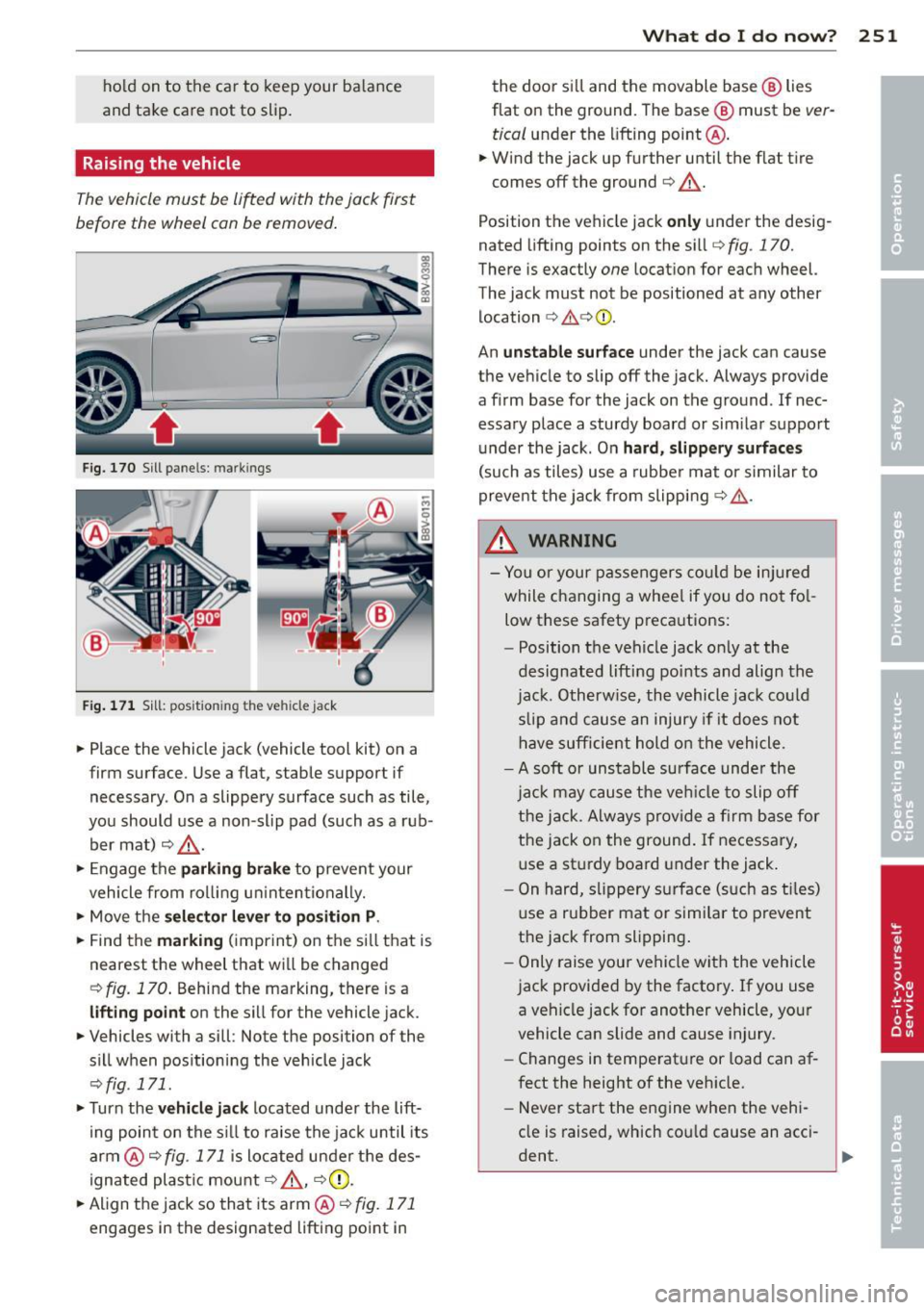

Raising the vehicle

Th e ve hicl e must be li~ed with the jack first

before the wheel can be removed.

F ig. 170 Sill p anels : m arkin gs

Fig. 171 Sill: posi tioning th e vehicle jack

.. Place the vehicle jack (vehicle tool kit) on a

firm surface . Use a flat, stable support if

necessary . On a slippery surface such as tile,

you should use a non -slip pad (such as a rub

ber mat) ¢_& .

.. Engage the

p arking brak e to prevent your

vehicle from rol ling u ninten tionally.

.. Move the

se lector leve r to pos ition P.

.. Find the marki ng (imprint) on the si ll that is

nearest the wheel that wi ll be changed

¢ fig . 170 . Behind the marking, there is a

lifting point on the si ll for the vehicle jack.

.. Vehicles with a sill : Note the position of the

s ill when pos ition ing the vehicle jack

¢ fig . 171.

.. Turn the

ve hicle jack located under the lift

ing poin t on the s ill to raise the jac k until its

arm @

Q fig. 171 is located under the des

ignated plastic mount c:::>

A, ¢(D .

.. Align the jack so that its arm @c:::> fig. 171

engages in the designated lifting point in

What do I d o now ? 251

the door si ll and the movable base ® lies

flat on the ground. The base @ must be ver

tical under the lifting point @ .

.. Wind the jack up further until the flat t ire

comes off the ground

c:::> _& .

Position the vehicle jack

onl y under the desig

nated lifting points on the si ll

c:::> fig. 170.

There is exactly one locat ion for each wheel.

The jack must not be positioned at any other location ¢ 8 ¢(1).

An

uns table surface under the jack can cause

the vehicle to slip off the jack. Always provide a firm base for the jack on the ground . If nec

essary place a sturdy board or sim ilar support

under the jack . On

hard, slippery surfaces

(such as tiles) use a rubbe r mat or similar to

prevent the jack from slipping

Q & .

_&. WARNING

-You or your passengers co uld be in ju red

while changing a wheel if you do no t fo l

low these safety preca utions:

- Position the vehicle jack on ly at the

designated lifting points and align the

j ac k. Otherw ise, the vehicle jac k co uld

slip and cause an injury if it doe s not

h ave sufficient hold on the vehicle .

- A soft or unstable su rface unde r the

ja ck may cause the ve hicle to slip off

the jack . A lw ays p rov ide a firm b ase for

the j ack on the ground . If necessary,

u se a st urdy board under the jack .

- On hard, slippery surface (such as t iles)

u se a rubber mat or similar to prevent

the jack from slipping .

- Only raise your vehicle with the vehicle

j ack provided by the factory . If you use

a veh icle jack for another vehicle, you r

vehicle can slide and cause injury .

- Changes in tempe rature or load can af

fect the height of the veh icle .

- Never sta rt the engine when the vehi

cle is raised , which cou ld cause an acci-

dent.

~

Page 254 of 288

252 What do I do n ow ?

-Support the vehicle securely with ap

propriate stands if work is to be per

formed underneath the vehicle;

otherw ise, there is a potential risk for

in Jury .

- To help preven t injury to yourself and

your passengers:

- Do not raise the vehicle u nti l you a re

sure the jack is sec urely e ngaged .

- Passengers mus t not rema in in the ve

h icle when it is jacked up .

- Ma ke sure that passengers wait in a

safe p lace away from the vehicle and

well away from the road and traffic.

- Make sure jack posi tion is co rrect, ad

just as necess ary and then contin ue to

raise the jack .

- Changes in temperature or load can af

fect the height of the vehicle .

0 Note

Do not lift the vehicle by the s ill. Pos ition

the vehicle ja ck only at the designated lift

ing poi nts on the sill. Othe rwise, your vehi

cle will be damaged .

Taking the wheel off/installing the spare

Follow these instructions s tep-by-step for

c hanging the wheel.

Fig . 172 Chang ing a w hee l: u sing th e screw driver ha n

dl e (w it h th e bla de re mov ed) to t urn the bolts

Fig. 173 Ch ang ing a wheel : alignment p in in sid e th e

t op hole

After you have loos ened all wheel bo lts and

raised the vehicle off the ground, remove and

replace the wheel as follows :

Removing the wheel

.,. Use the hexagon al so cket in th e screwdri v

er handle

to completely remove the top

most whee l bolt and set it aside on a

clean

surfac e Q fig. 172 .

.,. Screw the threaded end of the al ignme nt

p in

from the tool k it hand-t ight into t he

empty bol t hole

Q fig . 173.

.,. Then remove the other wheel bolts as de

scr ibed above .

.,. Take off the whee l leaving the a lignment pin

in the bo lt ho le

Q (J) .

Putting on the comp act sp are wheel

.,. Lift the spare whee l and carefully slide it

over the alignment p in to guide it in place

Q (J) .

.,. Use the hexagonal socket i n the screwdriver

handle to screw in and tighten a ll whee l

bolts

slightly .

.,. Remove the alignment pin and insert and

tighten the rema ining whee l bolt slightly

like the rest .

.,. Turn the jack handle counter -clockwise to

lower the vehicle until the jack is fully re

leased .

.,. Use the wheel bolt wrench to tighten all

wheel bo lts fi rmly

Q page 250 . Tighten

them

crosswise , from one bolt to the (ap

proximately) opposite one, to keep the

wheel cente red.

Page 255 of 288

(D Note

When removing or installing the wheel,

the rim could hit the bra ke rotor and dam

age the rotor . W ork carefully and have a

second person help you.

N ever use the hexa gonal s ocket in the ha n

d le of the screwdriver to loosen or t ighten

the wheel bolts .

- Pull the reversib le blade from the screw

drive r before yo u use the hexagonal

socket in t he handle to t urn the whee l

bo lts .

- When mounting tires with

unid irectional

tread design

make s ure the tread pat

te rn is poi nte d the r ight way

c:> pag e253 .

- The w heel bolts should be clea n and easy

to tu rn . Ch eck for dirt and corros ion on

the mat ing su rfaces of both the whee l

a nd th e hu b. Remove a ll dir t fro m these

s ur fa ces before remo unting the wheel.

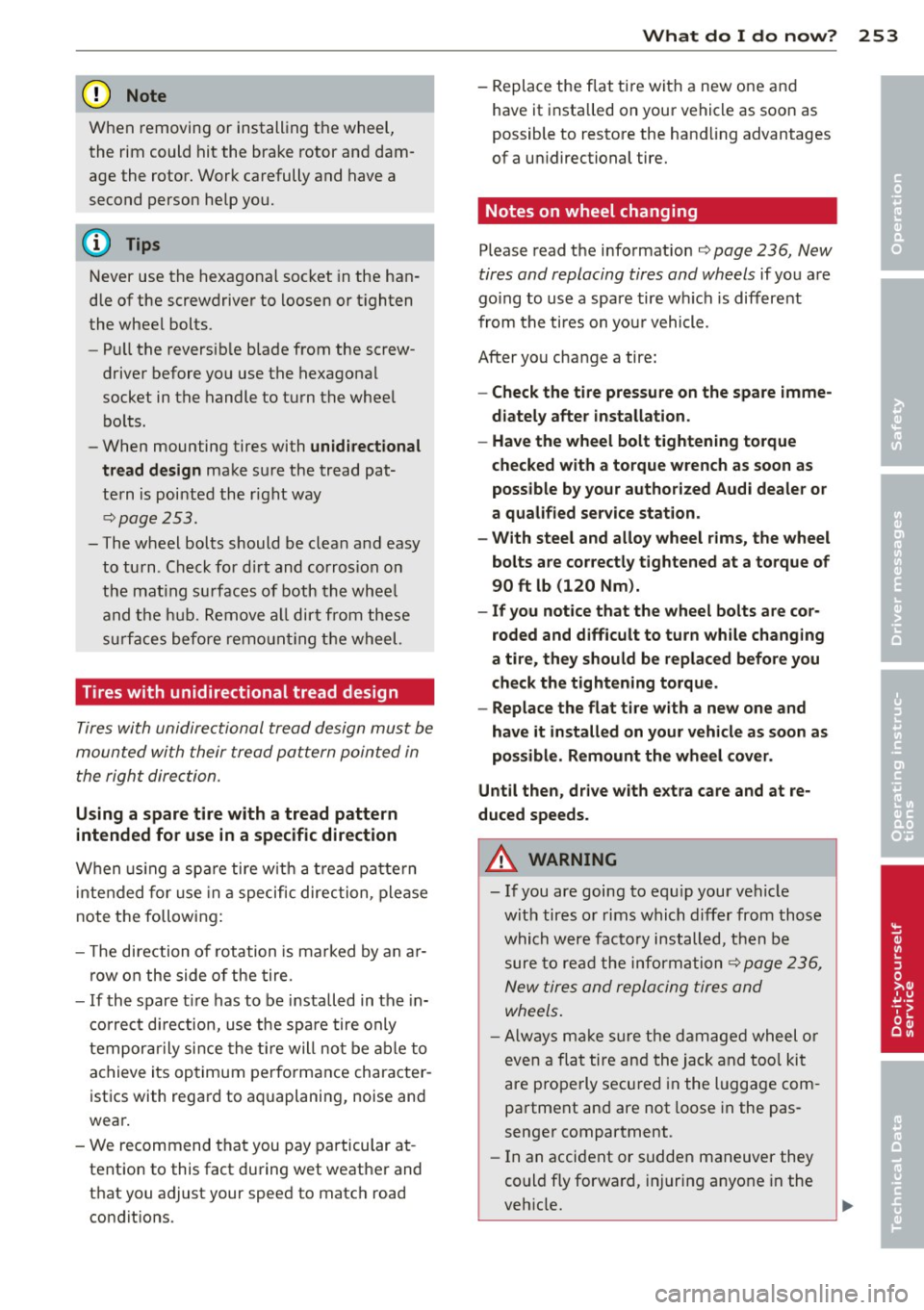

Tires with unidirectional tread design

Tires with unidirectional tread design must be

mounted with their tread pattern poin ted in

t he right direction.

Using a spare tire with a tread pattern

intended for use in a specific direction

When using a sp are tire w ith a tr ead p atte rn

i ntended fo r u se in a specific direc tion, p lease

note t he following:

- T he di rection of rotation is ma rked by an a r

r ow on the side o f the tire.

- If th e spare t i re has to be installed in the in

c orrec t direction, use the spa re tire only

tem por ari ly si nce the t ire will no t be able to

ac hieve its op timum perfo rmance character

ist ics with rega rd to aquaplani ng, noise and

wea r.

- We recommend that you pay particular at

tent io n to this fact du ring wet weat he r and

that you adjust your speed to matc h road

condit ions .

What do I do now? 253

-Replace the flat t ire with a new one and

have it installed on your vehicle as soon as

possible to restore the han dling advantages

of a un idirectional tire.

Notes on wheel changing

Please read the i nfo rmation c:> page 236, New

tires and replacing tires and wh eels

if you a re

go ing to use a spare tire wh ich is different

from the ti res on you r vehicle.

After you cha nge a tire :

-Check the tire pressure on the spare imme

diately after installation .

- Have the wheel bolt tightening torque

checked with a torque wrench as soon as

possible by your authorized Audi dealer o r

a qualified service station.

- With steel and alloy wheel r ims, the wheel

bolts are correctly tightened at a torque of

90 ft lb (120 Nm ).

- If you notice that the wheel bolts are cor

roded and diff icult to turn while changing

a tire, they should be replaced before you

check the tightening torque.

- Replace the flat tire w ith a new one and

have it installed on your vehicle as soon as

possible. Remount the whee l cover.

Until then , dr ive with e xtra care and at re

duced speeds.

A WARNING

-

- I f you are going to e quip your ve hicle

wit h tires o r rims which differ from those

which were fac to ry inst alled, t hen be

s ure to read t he informa tion

c:> p age 2 36,

New tire s and repla cing tires a nd

wheels .

-Always make s ure th e d am age d wheel o r

eve n a fla t tire an d the jack an d too l ki t

are p rope rly secu red in the luggage com

pa rtment an d are not loose in the pas

senger compartment .

- In an accident or sudden maneuver they

co uld f ly forwa rd, inj uring a nyone in the

veh icle.

•

•

•

Page 256 of 288

254 What do I do now?

-Always store damaged wheel, jac k and

tools secure ly in the luggage compart

ment. Otherw ise, in an acc ident or sud

den maneuver they cou ld fly forward,

causing injury to passenge rs in the vehi

cle .

Page 257 of 288

Fuses and bulbs

Electrical fuses

Replacing fuses

Fuses that have blown will have metal strips

that have burned through.

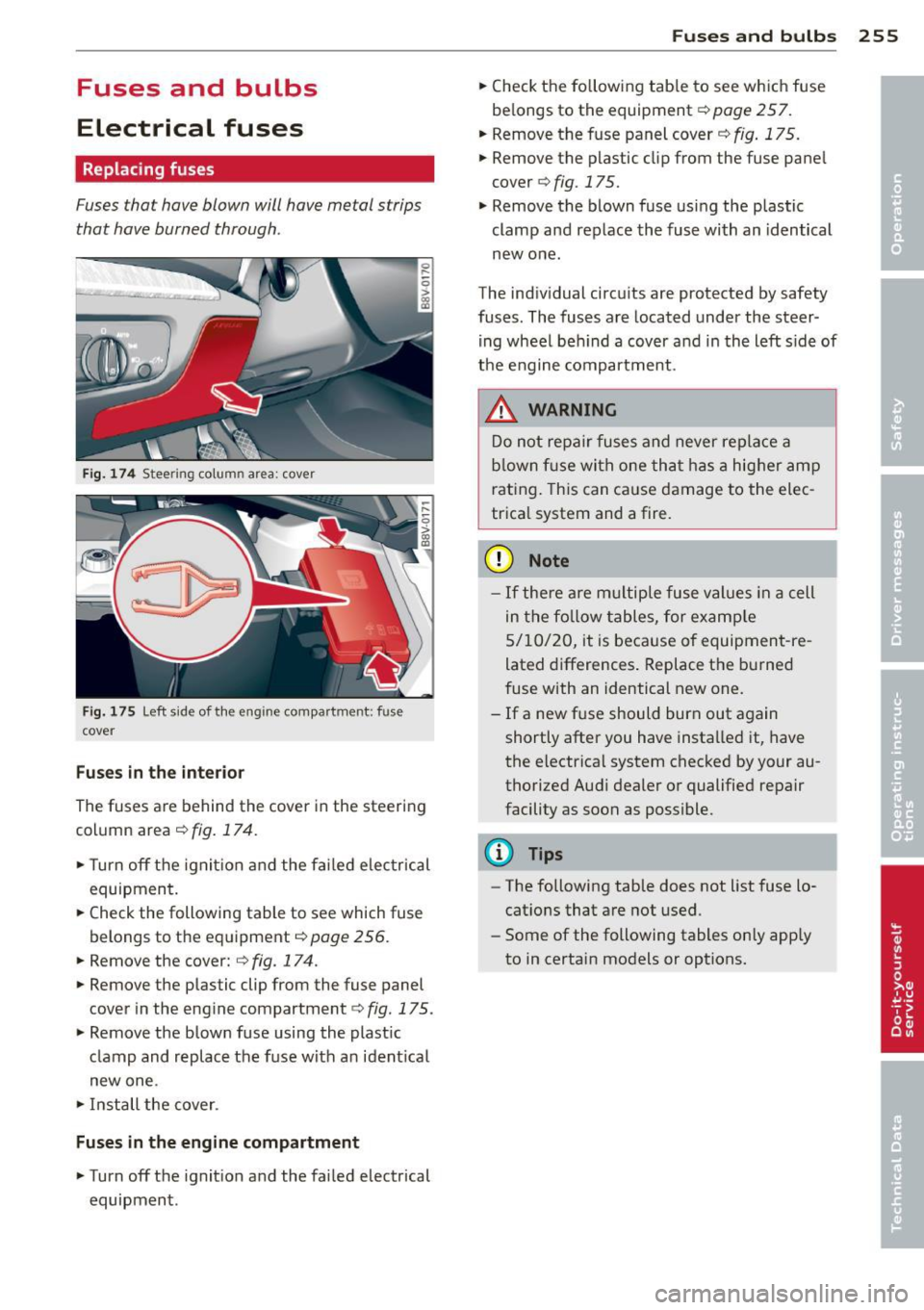

Fig. 17 4 Steering column area: cover

Fig. 175 Left side of the engine compartment: fuse

cover

Fuses i n the interio r

The fuses are behind the cover in the steering

column area

¢fig. 174.

•Turnoff the ignition and the fai led e lectrical

equipment.

• Check the following table to see which fuse

belongs to the equipment¢

page 256.

• Remove the cover: ¢ fig. 174.

• Remove the plastic clip from the fuse panel

cover in the eng ine compartment

c;, fig. 175.

• Remove the blown fuse using the plast ic

clamp and replace the fuse with an ident ica l

new one.

• Install the cover .

Fuse s in th e en gine compar tmen t

•Turnoff the ignition and the failed electrical

equipment .

Fuse s and bulb s 255

• Check the fo llowing tab le to see which fuse

be longs to the equipment

c:;, page 257.

• Remove the fuse panel cover¢ fig. 175.

• Remove the plastic clip from the fuse pane l

cover

c;, fig. 175.

• Remove the blown fuse using the plastic

clamp and replace the fuse with an identical

new one .

The indiv idual circu its are protected by safety

fuses . The fuses are located under the steer

ing wheel beh ind a cover and in the left s ide of

the engine compartment .

.&_ WARNING

-

Do not repair fuses and never replace a

blown f use with one that has a hig her amp

rating. Th is can cause damage to the elec

trica l system and a fire .

(D Note

-If there a re multiple fuse values in a cell

in the fo llow tables, for examp le

5/10/20, it is because of equipment -re

lated differences . Replace the burned

fuse with an identical new one.

- If a new f use should burn out again

shortly after you have installed it, have

the electrical system checked by your au

thorized Aud i dealer or qualified repair

facility as soon as possible.

(!) Tips

- The following tab le does not list fuse lo

cations that are not used .

- Some of the following tables on ly app ly

to in certain models or options.

Page 258 of 288

256 Fuses and bulbs

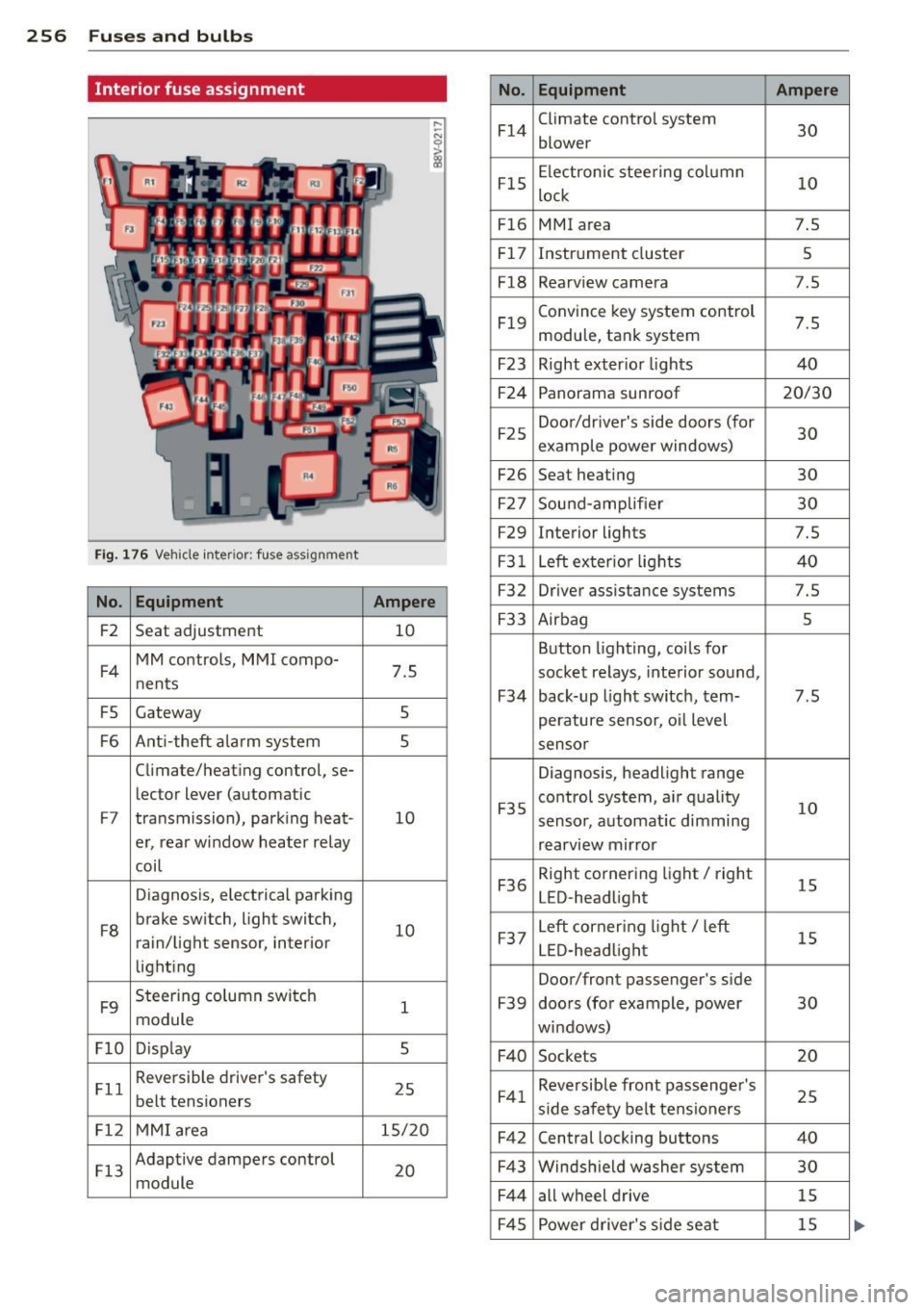

Interior fuse assignment

No. Equipment Ampere

F14

Climate control system

30 blower

F15

Electronic steering column

10 lock

F16 MMI area 7.5

F17

Instrument cluster 5

F18

Rearv iew camera 7 .5

F19

Convince key system control

7.5 module, tank system

F23 Right exter ior lights 40

F24

Panorama sunroof 20/30

F25

Door/driver's side doors (for

30 example power windows)

F26 Seat heating 30

F27

Sound-amp lifier 30

F29

Interior lights 7.5

Fig. 176 Vehicle inte ri or : fuse assignment F31 Left exter ior lights 40

No . Equipment Ampere F32 Driver assista nce systems 7.5

F2

Seat adjustment 10 F33 Airbag 5

F4

MM controls, MMI compo-

7.5 nents

F5 Gateway 5

Button lighting, coils for

socket relays, interior sound,

F34 back-up light switch, tern-7.5

perature sensor, o il level

F6 Ant i-theft alarm system 5 sensor

Climate/heating control, se-

Diagnosis, headlight range

le ctor lever (automatic

F7 transmission), parking heat -10 F35

control system, air quality

10 sensor,

automat ic dimming

er, rear window heater relay

rearview mirror

coil

Diagnosis, electrical parking

F36

Right cornering light/ right

15 LED-headlight

F8

brake switch, light switch,

10 rain/light sensor, interior

lighting

F9

Steering column switch

1 module

F37

Left corner ing light/ left

15 LED-headlight

Door/front passenger's side

F39 doors (for example, power 30

windows)

Fl0 D isp lay 5

F40 Sockets 20

Fll

Reversible driver's safety

25 belt tensioners F41 Reversible front passenger 's

25 side safety belt tensioners

Fl2 MMI area 15/20

F42 Central locking buttons 40

Fl3

Adaptive dampers control

20 module

F43 Windsh ield washer system 30

F44

all wheel drive 15

F45

Power driver's side seat 15

Page 259 of 288

No. Equ ipment Ampere

F49 Starter, clutch sensor

5

FS3 Rear window defogger 30

The power seats* are protected v ia

circ uit

br ea ker s

that automatically sw itch on after a

few seconds after the overload has been re

d uced.

(D Tips

Note that the following table was accurate

at the time of pr int ing and is subject to

change.

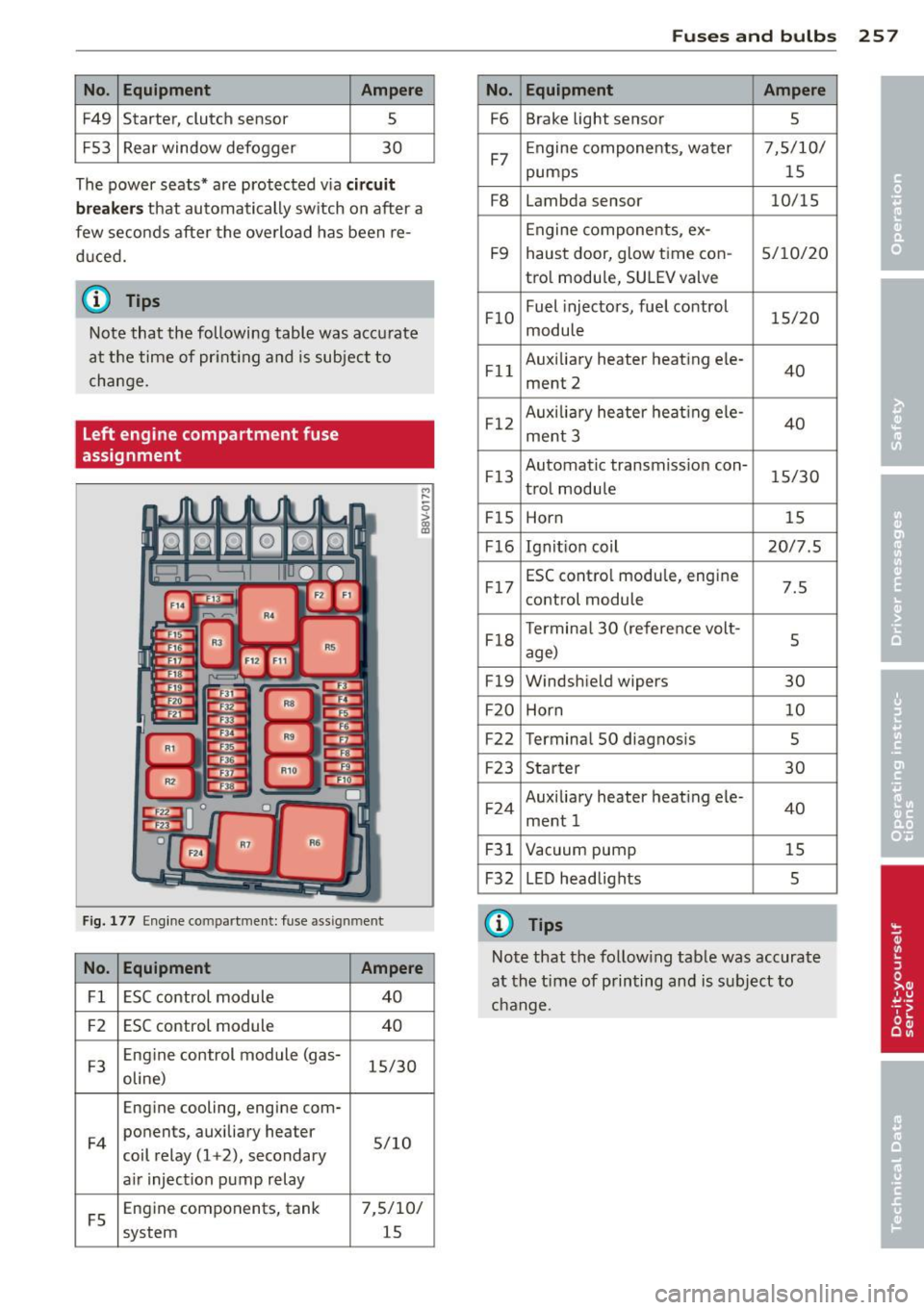

Left engine compartment fuse

assignment

F ig. 177 Eng ine compartment: fuse assignment

M ,.._

-0

!

No. Equ ipment Ampere

Fl ESC control module 40

F2 ESC control module

40

F3 Eng

ine control module (gas-

15/30

oline)

Engine cooling, engine com-

F 4 ponents, auxiliary heater

5/10

coil relay (1 +2), secondary

a ir injection pump relay

FS Eng

ine components, tank

7,5/10/

system 15

Fuse s and bulb s 257

No. Equipment Ampere

F6 Brake light sensor

5

F7 Engine components, water 7,5/10/

pumps

15

F8 Lambda sensor 10/15

Engine components, ex-

F9 haust door, glow time con-

5/10/20

tro l module, SU LEV valve

FlO Fuel

injectors, fuel control

15/20

module

Fl l Auxiliary heater heating ele

-

40

ment 2

F12 Auxilia

ry heater heat ing ele-

40

ment 3

F13 Automatic transmiss

ion con-

15/30

trol module

FIS Horn 15

F16 Ignit ion coil 20/7.5

F17 ESC contro

l modu le, engine

7.5

control module

F18 T

ermina l 30 (reference volt-

5

age)

F19 Windshield wipers

30

F20 Horn 10

F22 Termina

l SO diagnosis

5

F23 Starter 30

F24 Auxiliary heater heating ele-

ment 1 40

F31 Vacuum pump 15

F32 L ED head lights

5

(i} Tips

Note that the follow ing tab le was accurate

at the time of printing and is subject to

change.

Page 260 of 288

258 Fuses a nd bul bs

Bulbs

Replacing light bulbs

For your safety, we recommend that you have

your authorized Audi dealer replace burned

out bulbs for you .

It is becoming increasingly more and more

difficult to replace vehicle light bulbs since in

many cases, other parts of the car must first

be removed before you are able to get to the

bu lb . T his appl ies especia lly to the l ight bu lbs

in the front of your car which you can on ly

reach through the engine compartment .

Sheet metal and bulb ho lders can have sharp

edges that can cause ser ious cuts, and parts

must be correctly taken apart and then prop

e rly put back together to help prevent break

age of parts and long term damage from wa

ter that can enter housings that have not been properly resealed.

F or your safety, we recommend that you have

your authorized Audi dealer replace any bulbs

for you, since your dealer has the proper tools,

the correct bu lbs and the expertise.

Gas disc harg e lam ps (X enon lig ht s):

Due to the high electrical vo ltage, have the

bu lbs rep laced by a qualified technician.

H eadlights with Xenon light can be identified

by the high voltage sticker.

LED headlights* require no ma intenance .

P lease contact your authorized Aud i dealer if a

bu lb needs to be replaced.

A WARNING

Contact with high-voltage components of

the electrical system and improper re placement of gas discharge (Xenon) head

light bulbs can cause serious personal in

jury and death .

- Xenon bulbs are pressurized and can ex

plode when being changed.

- Changing Xenon lamps requires the spe

cial training, instruct ions and equ ip

ment. -

On ly an authorized A udi dealer or other

qualified workshop should change the

bulbs in gas discharge lamps .

A WARNING

There are parts with sharp edges on the

openings and on the bulb holders that can

cause serious cuts.

- If you are uncertain about what to do,

have the work performed by an author

ized Audi dealer or other qualified work

shop. Serious personal injury may result

from imprope rly performed work.

(D Tips

- If you st ill prefer to replace the light

bulbs yourself, be aware that the engine

compartment is a hazardous area to

work in

~ page 21 a ~ .11::..

- It is best to ask your authorized Audi

dea ler whenever you need to change a

bulb.

-