warning AUDI A3 CABRIOLET 2015 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2015, Model line: A3 CABRIOLET, Model: AUDI A3 CABRIOLET 2015Pages: 302, PDF Size: 73.83 MB

Page 266 of 302

264 What do I do now?

-Always store the vehicle tool kit, the jack

and the replaced tir e in the luggage com

partment ¢

page 132.

Changing a wheel

When you change o wheel, follow these

quence described below step-by-step and in

exactly that order .

1. Remove the decorative wheel cover*. For

more details see also¢

page 264, Deco

rative wheel covers

or ¢ page 265,

Wheels with wheel bolt caps.

2 . Loosen the wheel bolts¢ page 265 .

3. Locate the proper mount ing point for the

jack and align the jack below that point

¢page 266.

4. Raise the car with the jack ¢ page 266.

5. Remove the

wheel with the flat tire and

then install

the spare ¢ page 267.

6. Tighten all wheel bolts lightly.

7 .

Lowe r the vehicle with the jack.

8 . Use the wheel bolt wrench and

firmly

tighten all whee l bolts c::> page 265.

9. Replace the decorative wheel cover*.

A WARNING

Always read and follow all WARNINGS and

information

c::> .&. in Raising the vehicle on

page

266 and c::> page 268.

After changing a wheel

A wheel change is not complete without the

doing the following .

• Always store the vehicle tool kit, the jack*

and the replaced tir e in the luggage com

partment ~

page 132 .

• Check the tire pressure on the spare wheel

i mmediately after mount ing it.

• As soon as possible, have the

tightening

torques

on a ll wheel bo lts checked with a

torque wrench. The correct tightening tor

que is 90 ft lb (120 Nm).

• Have the flat tire

replaced as soon as poss i

ble.

(D Tips

- If you notice that the wheel bolts a re

corroded and difficult to turn while

chang ing a tire, they should be rep laced

before you check the tightening torque.

- Drive at reduced speed until you have the

tightening torques checked.

- After changing a whee l, the tire pressure

in all four tires must be checked/correct

ed and the tire pressure monitoring indi

cator must be stored in the MMI

c::>page260.

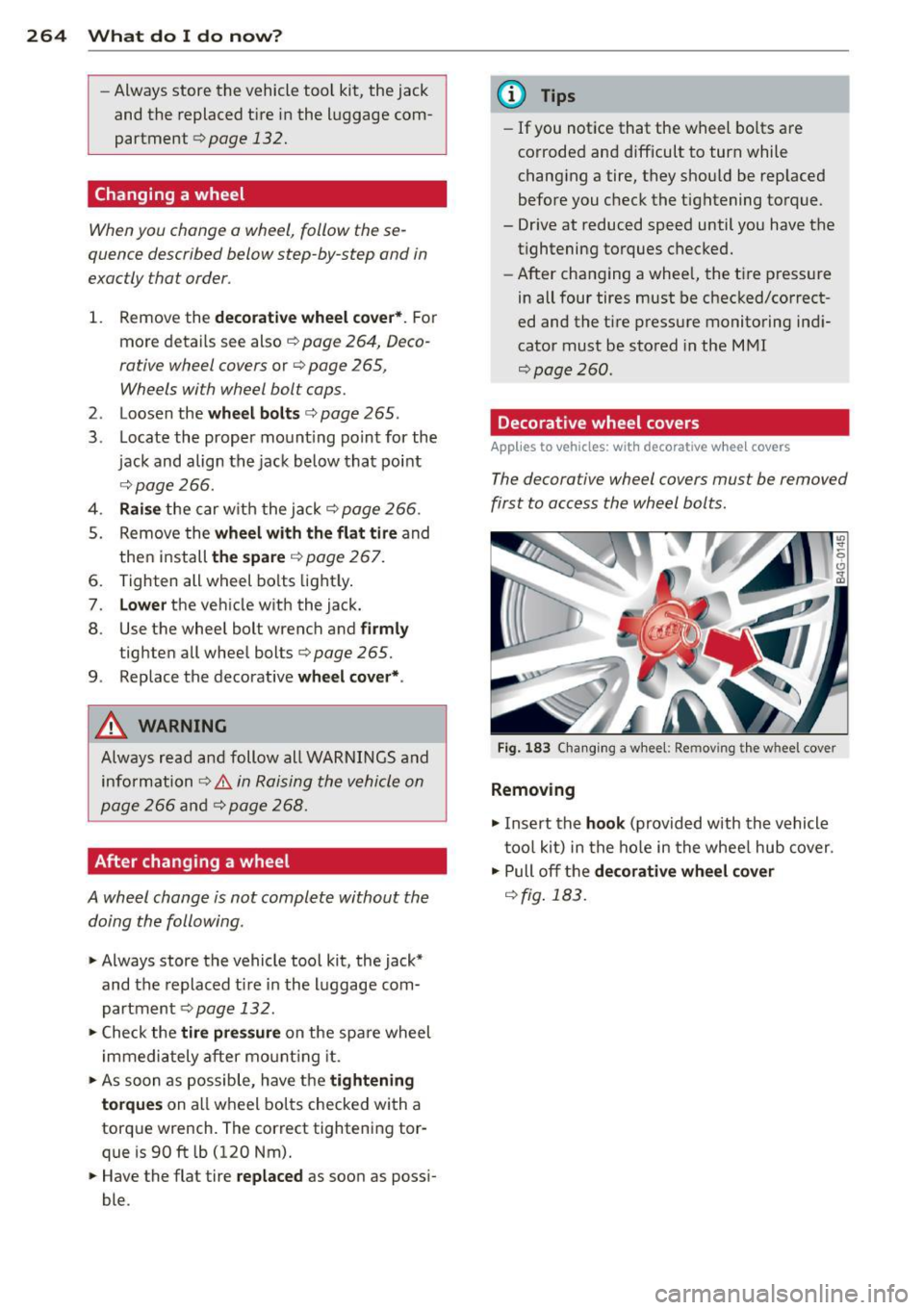

Decorative wheel covers

Applies to vehicles: wit h decorative whee l covers

The decorative wheel covers must be removed

first to access the wheel bolts .

Fig. 183 Chang ing a wheel : Remov ing th e w heel cover

Removing

.,. Insert the hook (provided with the vehicle

tool kit) in the hole in the whee l hub cover .

.,. Pull

off the decorative wheel cover

c::>fig.183.

Page 267 of 302

....,

N

r--. > co

rl I.O

"' rl

"' rl

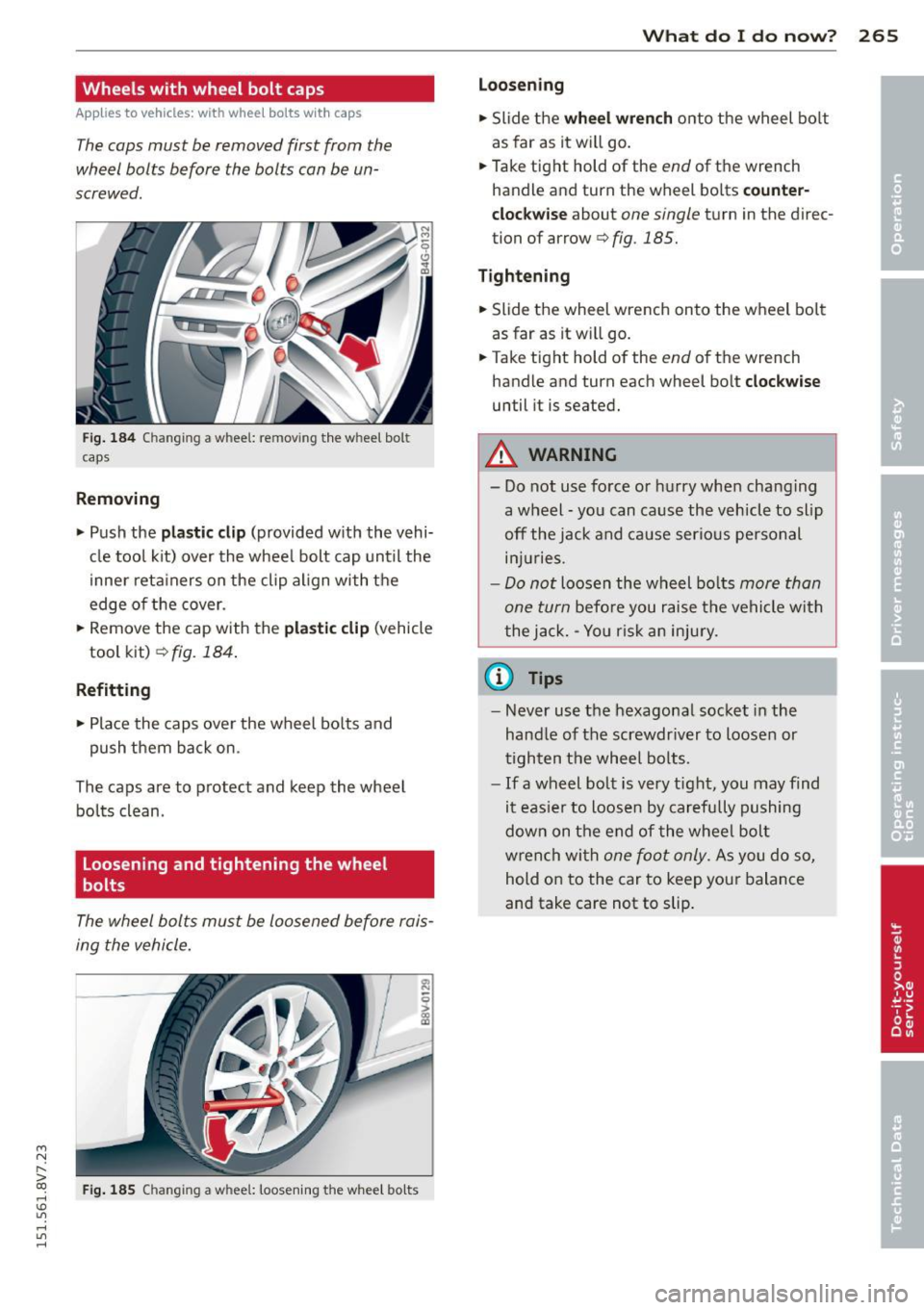

Wheels with wheel bolt caps

Applies to vehicles: with whee l bolts with caps

The caps must be removed first from the

wheel bolts before the bolts can be un

screwed.

Fig . 184 Changing a wheel: removing the wheel bolt

caps

Rem oving

• Push the pla stic clip (provided w ith the vehi

cle tool kit) over the whee l bolt cap unt il the

inner reta iners on the clip align with the

edge of the cover.

• Remove the cap w ith the

pl as tic clip (vehicle

tool kit)

¢ fig. 184 .

Refitting

• Place the caps ove r the wheel bo lts and

push them back on .

The caps are to protect and keep the wheel bol ts clean.

Loosening and tightening the wheel

bolts

The wheel bolts must be loosened before rais

ing the vehicle .

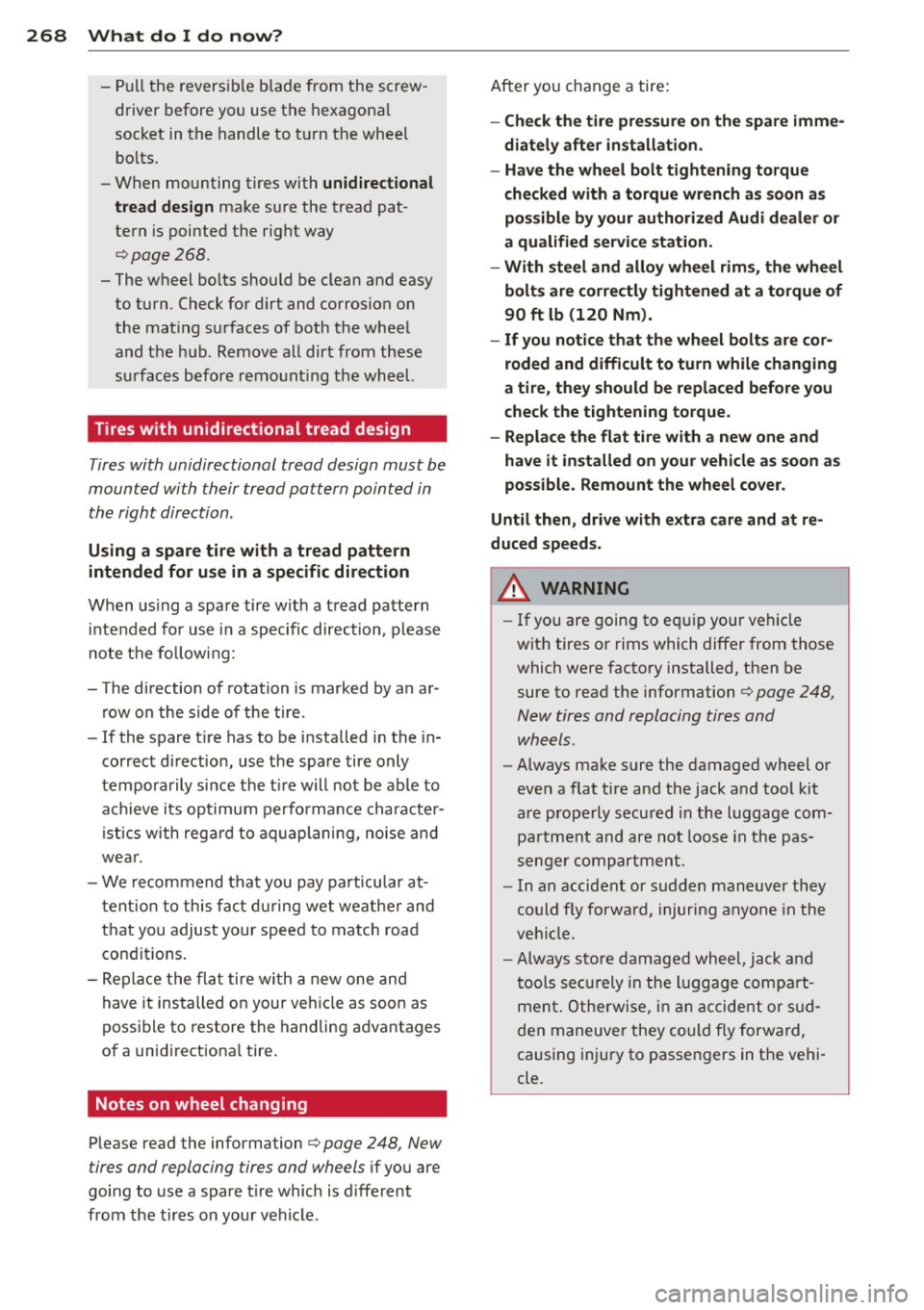

Fig . 185 Changing a wheel: loosening the whee l bo lts

What do I d o now ? 265

Loosen ing

• Slide the wheel wr en ch onto the wheel bo lt

as far as it wi ll go .

• Take tight hold of the

end of the wrench

handle and turn the wheel bo lts

c ounter ·

cloc kwi se

about one single turn in the direc

tion of arrow¢

fig. 185.

T ightening

• Slide the wheel wrench onto the wheel bolt

as far as it w ill go.

• Take tight hold of the

end of the wrench

handle and turn each wheel bolt

clo ck wis e

until it is seated.

A WARNING

- Do not use force or hurry whe n chang ing

a wheel - you can cause the vehicle to slip

off the jack and cause ser ious personal

injuries.

- Do not loosen the wheel bo lts more than

one turn

befo re you raise the vehicle with

the jack. - Yo u risk an injury.

(D Tips

- Never use the hexagona l socket in the

hand le of the screwdr iver to loosen or

t ighten the wheel bolts.

- If a wheel bolt is very tight, you may find

it eas ier to loose n by carefully pushing

down on the end of the wheel bol t

wrench wi th

one foot only. As you do so,

hold on to the car to keep you r balance

and take care not to slip .

Page 268 of 302

266 What do I do n ow ?

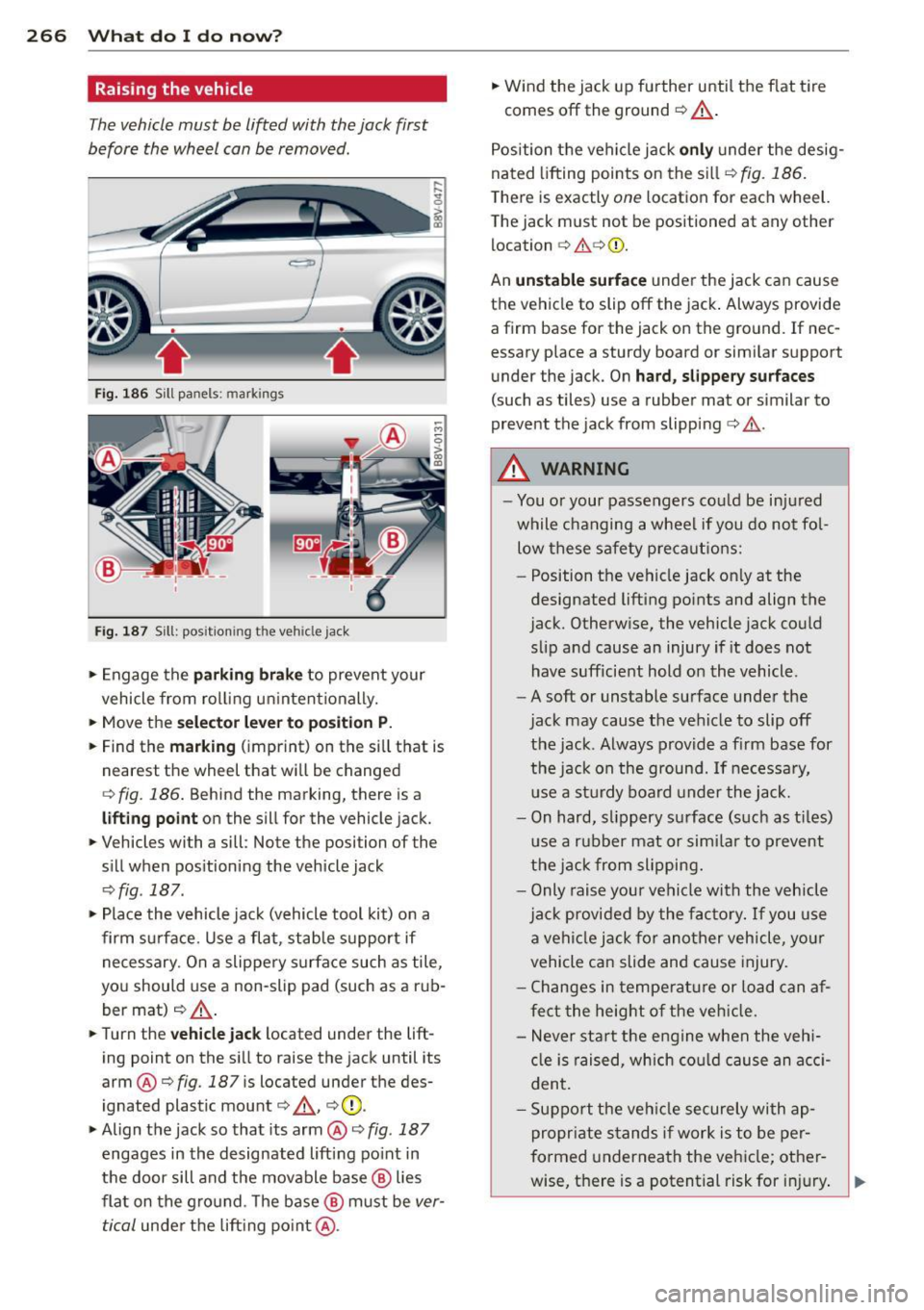

Raising the vehicle

The vehicle must be lifted with the jack first

before the wheel can be removed .

Fig. 186 Sill panels: mark ings

Fig. 187 Sill : posit ion ing the veh icle jack

., Engage the pa rkin g brak e to prevent your

vehicle from rolling un intentionally.

., Move the

se lect or l ever to po siti on P .

., Find the marking (imprint) on the sill that is

nearest the wheel that wi ll be changed

r::> fig. 186. Behind the marking, there is a

lifting po int on the sill for the vehicle jack.

., Vehicles with a sill : Note the position of the

s ill when pos itioning the vehicle jack

¢ fig . 187 .

., Place the vehicle jack (vehicle tool kit) on a

firm su rface. Use a flat, stab le support if

necessary. On a slippe ry surface such as tile,

you should use a non-slip pad (such as a rub

ber mat)

c::> A .

., Turn the vehicle jack located under the lift

ing point on the sill to raise the jack until its

arm @r=>

fig. 187 is located under the des

ignated plastic mount

c> A, r=>@ .

., Align the jack so that its arm@r=> fig. 187

engages in the designated lifting point in

the door sill and the movable base @ lies

flat on the gro und . T he base @ must be

ver

tical

under the lift ing po int @ . .,

Wind the jack up fu rther until the f lat tire

comes off the ground

r=> A.

Position t he vehicle jack only under the desig

nated lifting points on the si ll

¢fig. 186.

There is exactly one location for each wheel.

The jack must not be positioned at any other

location

r=> ,&. r=>Q).

An un sta ble surf ace under the jack can cause

the vehicle to slip off the jack . Always provide

a firm base for the jack on the ground . If nec

essary place a sturdy board or similar support

under the jack. On

hard, sl ipp ery su rfaces

(such as tiles) use a rubber mat or similar to

prevent the jack from slipping

c> ,&. .

A WARNING ~

-You or your passengers could be injured

while changing a wheel if you do not fo l

low these safety preca utio ns:

- Position the vehicle jack on ly at the

designated lifting points and align the

jack. Otherwise, the vehicle jack could

slip and cause an injury if it does not

have sufficient hold on the vehicle .

- A soft or unstable surface under the

jack may cause the vehicle to slip off

the jack . Always provide a firm base for

the jack on the ground. If necessa ry,

use a stu rdy board under the jack.

- On hard, slippery surface (such as t iles)

use a rubber mat or simi lar to prevent

the jack from slipping.

- Only raise your vehicle with the vehicle

jack provided by the fac to ry.

If you use

a vehi cle jack for another vehicle, your

vehicle can slide and cause injury.

- Changes in temperat ure or load can af

fect the height o f the veh icle .

- Never start the engine when the vehi cle is raised, which co uld cause an acc i

dent.

- Suppo rt the ve hicle securely with ap

propr iate s tands if work is to be per

formed underneath the vehicle; other

wise, there is a potential risk for in jury . .,.

Page 270 of 302

268 What do I do no w?

-Pull the reversible blade from the screw

driver before you use the hexagonal

socket in the handle to t urn the whee l

bo lts.

- When mounting tires with

unid ire ctional

t re ad design

make s ure the tread pat

tern is pointed the right way

¢ page 268.

-The wheel bolts should be clean and easy

to turn. Check for d irt and corrosion on

the mat ing su rfaces of both the whee l

and the hub. Remove all dirt from these

surfaces before remount ing the wheel.

Tires with unidirectional tread design

Tires with unidirectional tread design must be

mounted with their tread pattern pointed in the right direction.

Using a spare tire with a tread pattern

int ended fo r use in a specific dir ection

When us ing a spare tire w ith a tread pattern

i ntended for use in a specific direction, please

note t he following:

- The direction of rotation is marked by an ar

row on the side of the tire .

-If the spare t ire has to be installed in the in

correct direction, use the spare tire only

temporarily since the t ire will not be able to

achieve its optimum perfo rma nce character

ist ics with rega rd to aquaplaning, noise and

wea r.

- We recommend that you pay particular at

tent ion to this fact du ring wet weat her and

that you adjust your speed to match road

condit ions .

- Replace the fla t tire w ith a new one and

have it ins talled on your veh icle as soon as

possible to restore the handling advantages

of a unidirectiona l tire .

Notes on wheel changing

Please read the information ¢ page 248, New

tires and replacing tires and wheels

i f you are

go ing to use a spare t ire which is d ifferent

from the tires on your veh icle . After you change a tire:

-

Ch eck the tire pr essure on th e spar e imm e

diatel y after in stallation .

- Hav e th e whe el bolt tight ening torque

c h ec ked with a torque wr ench as soon as

po ssible by your author ized Audi de aler or

a qu alified servic e sta tion.

- With ste el and alloy wheel r im s, the wheel

bolt s ar e c orre ctl y tightened at a torque of

9 0 ft lb (120 Nm ).

- If you notice th at the wheel b olt s ar e co r

rod ed and diffi cult to turn w hile changing

a tire , the y should be repl aced before you

check the t ightening to rque.

- Repl ace the flat tire with a new o ne and

ha ve it in stalled on your vehicle as soon a s

possible. Remount the wheel cov er.

Until then , dri ve with extra care and at re

duc ed sp eed s.

A WARNING

-

- If you are going to equip your vehicle

with tires or rims which differ from those

which were factory installed, then be sure to read the information

¢ page 248,

New tires and replacing tires and

wheels.

- Always make sure the damaged wheel or

even a flat tire and the jack and tool kit

are properly secured in the luggage com

pa rtment and are not loose in the pas

senger compartment.

- In an accident or sudden maneuver they

could fly forwa rd, injuring anyone in the

veh icle.

- Always sto re damaged wheel , jack and

too ls se curely in the luggage compart

men t. Otherwise, in an accident or s ud

den maneuve r they could f ly forwa rd,

causing injury to passengers in the vehi

cle.

Page 271 of 302

....,

N

r--. > co

rl I.O

"' rl

"' rl

Fuses and bulbs

Electrical fuses

Replacing fuses

Fuses that have blown will have metal strips

that have burned through.

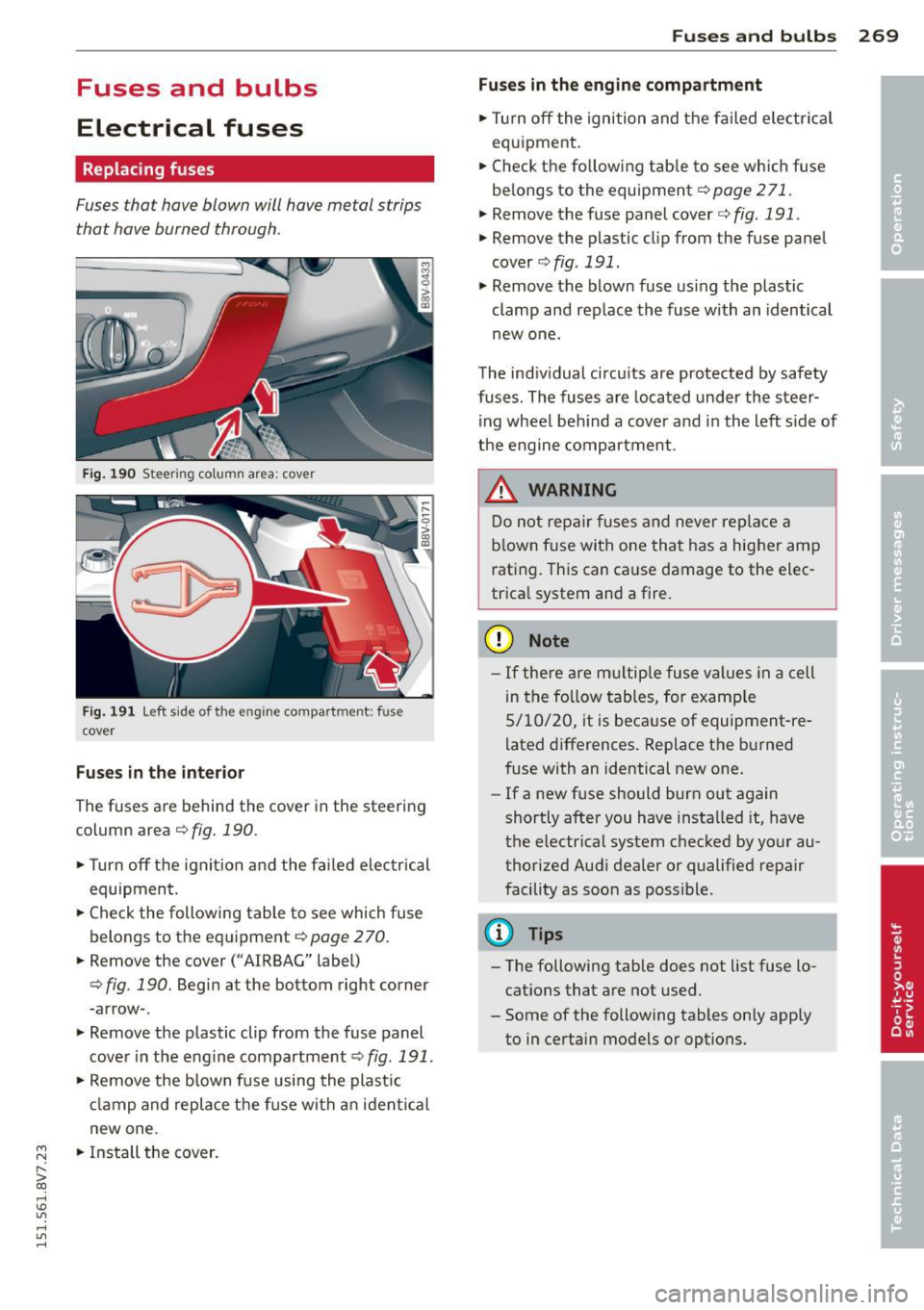

Fig. 190 Steering column area: cover

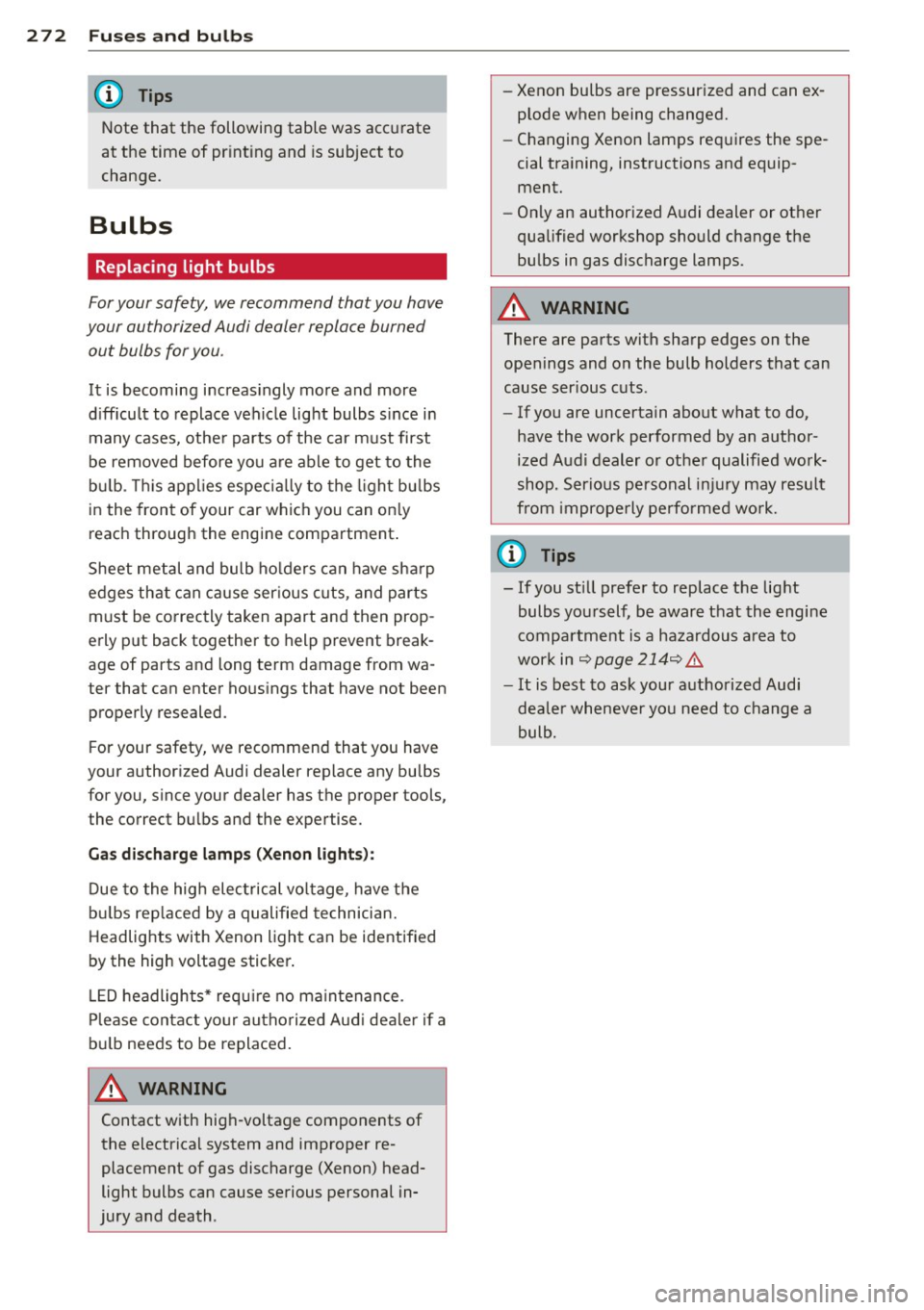

Fig. 191 Left side of the engine compartment: fuse

cover

Fuses in the interior

The fuses are behind the cover in the steering

column area¢

fig. 190.

•Turnoff the ignition and the fai led e lectrical

equipment.

• Check the following table to see which fuse

belongs to the eq uipment

¢page 270.

• Remove the cover(" AIRBAG" label)

¢ fig . 190. Begin at the bottom right corner

-arrow-.

• Remove the plastic clip from the fuse panel

cover in the eng ine compartment ¢

fig. 191.

• Remove the blown fuse using the plastic

clamp and replace the f use with an ident ica l

new one .

• Install the cover .

Fuses and bulbs 269

Fuses in the engine compartment

•Tu rnoff the ignition and the failed electrical

equipment.

• Check the fo llowing tab le to see which fuse

be longs to the equipment¢

page 271.

• Remove the fuse panel cover¢ fig. 191.

• Remove the plastic clip from the fuse pane l

cover

¢ fig. 191.

• Remove the blown fuse using the plastic

clamp and replace the fuse with an identical

new one.

The indiv idual circuits are protected by safety

fuses. The fuses are located under the steer

ing wheel beh ind a cover and in the left side of

the engine compartment .

_&. WARNING

-

Do not repair fuses and never replace a

blown fuse with one that has a higher amp

rat ing. This can ca use damage to the elec

trica l system and a fire .

(D Note

-If there are multip le fuse values in a cell

in the follo w tables, for example

5/10/20, it is because of equipment-re

lated differences. Replace the burned

fuse with an identical new one.

- If a new fuse should burn out again

shortly after you have insta lled it, have

the electrical system checked by your au

thorized Audi dealer or qualified repair

facility as soon as possible.

(D Tips

- The following table does not list fuse lo

cat ions that are not used.

- Some of the following tables only apply

to in certain models or options.

Page 274 of 302

272 Fuses and bulb s

Note that the following table was accurate

at the time of print ing and is subject to

change.

Bulbs

Replacing light bulbs

For your safety, we recommend that you have

your authorized Audi dealer replace burned out bulbs for you.

It is becoming increas ingly more and more

d iff icu lt to replace vehicle light bulbs s ince in

many cases, other parts of the car must first

be removed before you are able to get to the

bu lb . Thi s appl ies especia lly to the light bu lbs

in the front of your car which you can on ly

reach through the engine compartment .

Sheet metal and bulb ho lders can have sha rp

edges that can cause ser ious cuts, and parts

must be co rrectly taken apart and then prop

erly put back together to help prevent break

age of parts and long term damage from wa

ter that can enter housings that have not been

properly resealed.

For your safety, we recommend that you have

your authorized Audi dealer replace any bulbs

for you, since your dealer has the proper tools, the correct bulbs and the expertise.

Gas discharge lamps (Xenon lights):

Due to the high electrical vo ltage, have the

bu lbs rep laced by a qualified technician.

Headlights with Xenon light can be identified

by the high voltage sticker.

LE D headlights* require no ma intenance .

Please contact your authorized Aud i dealer if a

bu lb needs to be replaced.

A WARNING

Contact with high-voltage components of

the electrical system and improper re

placement of gas discharge (Xenon) head

light bulbs can cause serious personal in

jury and death . -

Xenon bulbs are pressurized and can ex

plode when being changed.

- Changing Xenon lamps requires the spe

cial training, instructions and equip

ment.

- Only an authorized Audi dealer or other

qualified workshop should change the

bulbs in gas discharge lamps.

A WARNING

--

There are parts with sharp edges on the

openings and on the bulb holders that can

cause ser ious cuts .

- If you are uncertain about what to do,

have the work performed by an author

ized Audi dealer or other qualified work

shop. Serious personal injury may result

from improperly performed work.

(D Tips

- If you st ill prefer to replace the light

bulbs yourself, be aware that the engine

compartment is a hazardous area to

work in

~ page 214~ &

-It is best to ask your authorized Audi

dealer whenever you need to change a

bulb.

Page 275 of 302

M N

" > co ,...., \!) ..,.,

,...., ..,., ,....,

Emergency situations

General

This chapter is intended for trained emer

gency crews and working personnel who have the necessary tools and equipment to

perform these operations.

Starting by pushing or

towing

(D Note

Vehicles with an automatic transmission

cannot be started by pushing or towing.

Starting with jumper

cables

If necessary, the engine can be started by

connecting it to the battery of another vehi

cle.

If the engine should fail to start because of a

discharged or weak battery, the battery can be

connected to the battery of

another vehicle,

using a

pair of jumper cables to start the en

gine.

Jumper cables

Use only jumper cables of sufficiently large

cross section to carry the starter current safe

ly. Refer to the manufacturer's specifications.

Use only jumper cables with

insulated termi

nal clamps which are distinctly marked :

plus(+) cable in most cases colored red

minus(-) cable

in most cases colored black.

A WARNING

Batteries contain electricity, acid, and gas.

Any of these can cause very serious or fatal

injury. Follow the instructions below for

safe handling of your vehicle's battery.

- Always shield your eyes and avoid lean

ing over the battery whenever possible.

- A discharged battery can freeze at tem

peratures just below 32 °F (0 °C). Before

Emergency situations 273

connecting a jumper cable, you must

thaw the frozen battery completely, oth

erwise it could explode.

- Do not allow battery acid to contact eyes

or skin. Flush any contacted area with

water immediately .

- Improper use of a booster battery to start a vehicle may cause an explosion.

- Vehicle batteries generate explosive gas

es. Keep sparks, flame and lighted ciga

rettes away from batteries.

- Do not try to jump start any vehicle with a low acid level in the battery.

- The voltage of the booster battery must

also have a 12-volt rating. The capacity

(Ah) of the booster battery should not be

lower than that of the discharged bat

tery . Use of batteries of different voltage

or substantially different "Ah" rating

may cause an explosion and personal in

JU ry.

- Never charge a frozen battery. Gas trap

ped in the ice may cause an explosion.

-Never charge or use a battery that has

been frozen. The battery case may have

be weakened.

- Use of batteries of different voltage or

substantially different capacity (Ah) rat

ing may cause an explosion and injury.

The capacity (Ah) of the booster battery

should not be lower than that of the dis

charged battery.

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS ¢

page 214.

(D Note

-Applying a higher voltage booster bat

tery will cause expensive damage to sen

sitive electronic components, such as

control units, relays, radio, etc.

- There must be no electrical contact be

tween the vehicles as otherwise current

could already start to flow as soon as the

positive(+) terminals are connected. ..,. •

•

•

Page 277 of 302

M N ,....

> co ,...., \!) 1.1'1 ,...., 1.1'1 ,....,

installed. Make sure the cables do not get

caught in moving engine components .

11. Sw itch the heater fan and rear window de-

froster off.

12. Close the battery cover.

The battery is vented to the outside so that not gases enter the passenger compartment.

Make sure that the connected positive termi

nal clamps on the jump start cable have suff i

cient contact with metal.

A WARNING

Follow the warn ings and instructions from

the jump start cable manufacturer to re duce the risk of serious injuries and vehicle

damage .

If you are uns ure abo ut anything,

call roadside assistance.

- T he jump start cables must be long

enough so that the vehicles do not

touch.

- Route the jump sta rt cab les so they can

not get ca ught in the moving parts in the

engine compartment .

- Always read and follow the warnings be

fore checking anything in the engine

compartment <=>

page 214.

(D Note

Correctly jump start cables incorre ctly can

destroy the a lternator .

- Always connect the positive term inal(+)

to the positive terminal( +) and the neg

ative termina l (-) to the negative termi

nal(-) on the body ground point, but not

the negative termina l on the battery.

- Make sure the screw plugs on the batte ry

ce lls are insta lled securely. If not, tight

en the plugs before connecting the

clamps to the negat ive termina l on the

battery.

- P lease note that the connecting process

described be low for the jump start ca

bles is intended for when your vehicle is

being jump started. If you are jump

starting another vehicle, do not connect

the negat ive cab le to the negative termi

nal(·) on the drained battery, but rathe r

Emerg en cy si tuation s 275

connect it to a large metal component

that is bolted securely to the engine

bloc k, or to the engine block itsel f. If the

battery in the vehicle being jump started

is not vented to the outside, there is a

r isk of explosion due to hydrogen gas.

- Make sure that the connected positive

terminal clamps have sufficient contact

with metal.

- Do not use the battery negat ive terminal

for jump start ing or a malfunct ion could

occur in the vehicle electrical system.

Emergency towing

with commercial tow

truck

General hints

Your Audi requires special handling for tow

ing .

The following information is to be used by

commerc ial tow truck operators who know

how to operat e th eir equipment safely.

- Never to w you r Aud i. Towing will cause

damage to the engine and tran smission.

- Nev er wra p the s afety ch ains or wi nch ca

bles a round the brake li nes.

- To p revent unnece ssary dam age , your Aud i

must be t ranspo rted with a flat bed truck.

- To load the vehicle on to the fl at bed , us e

the towing loop fo und in the vehicle tool s

and attach to the front o r rear anchorage

<=> page 2 76 and <=> page 2 76.

A WARNING

A vehicle being towed is not safe for pas

sengers. Neve r allow anyone to ride in a

vehicle be ing towed, fo r any reason.

-

•

•

•

Page 278 of 302

2 76 Emergency situations

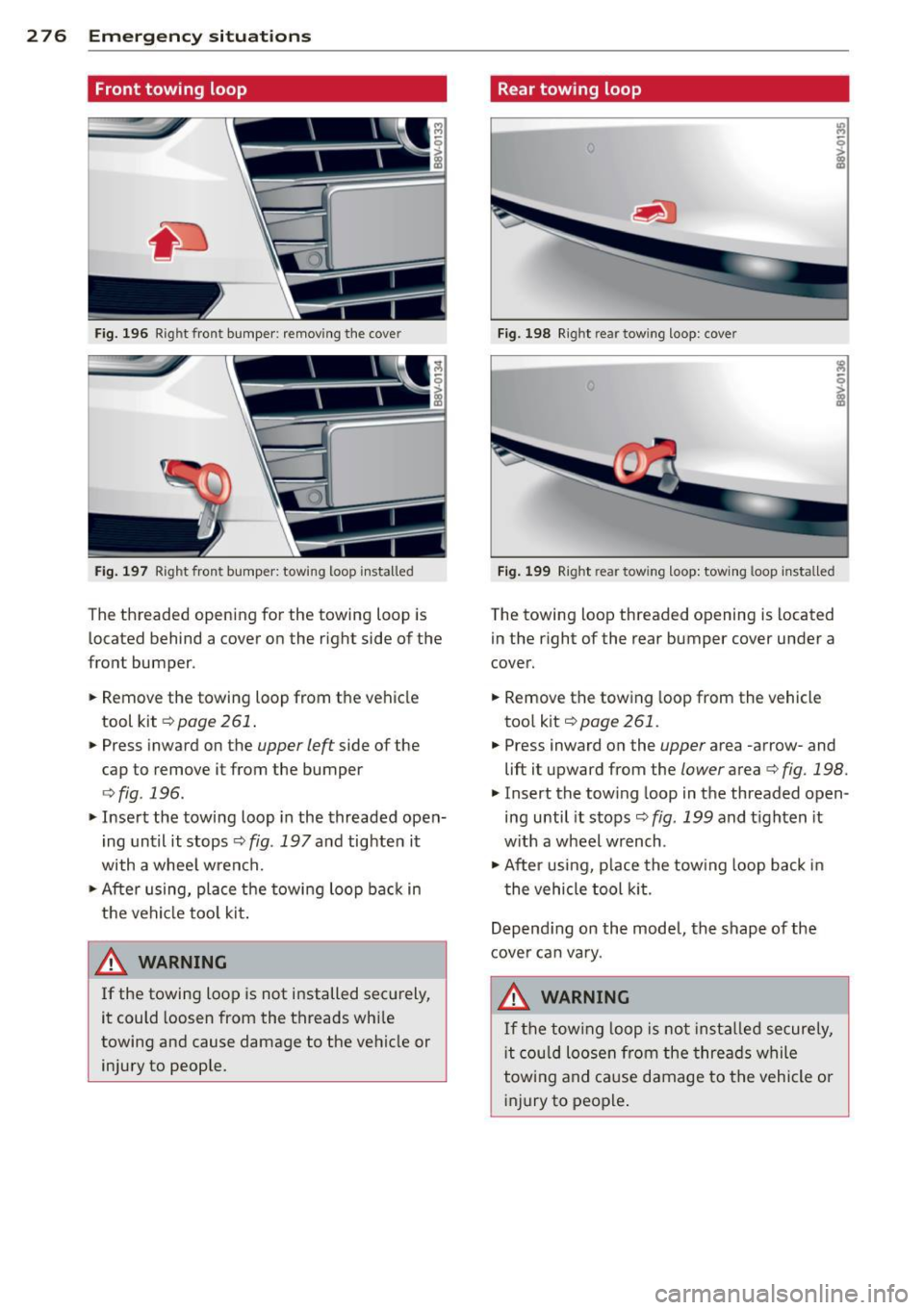

Front towing loop

Fig. 196 Right front bumper: removing the cove r

Fig. 197 Right front bumper: towing loop installed

The threaded opening for the towing loop is

located behind a cover on the right side of the

front bumper.

• Remov e the towing loop from the vehicle

tool kit¢

page 261 .

• Press inward on the upper le~ side of the

cap to remove it from the bumper

¢fig . 196.

• Insert the towing loop in the threaded open

ing until it stops¢

fig. 197 and tighten it

with a whee l wrench.

• After using, place the towing loop back in

the vehicle tool kit.

A WARNING

If the towing loop is not installed securely,

it could loosen from the threads while

towing and cause damage to the vehicle or

injury to people.

Rear towing loop

Fig. 198 Righ t rea r towing loop: cover

Fig. 199 Right rea r towing loop: towing loop installed

The towing loop threaded opening is located

in the right of the rear bumper cover under a

cover.

• Remove the towing loop from the vehicle

tool kit¢

page 261 .

• Press inward on the upper area -arrow-and

lift it upward from the

lower area¢ fig. 198.

• Insert the towing loop in the threaded open

ing until it stops ¢

fig. 199 and tighten it

w ith a wheel wrench .

• After using, p lace the towing loop back in

the vehicle tool kit.

Depending on the model, the shape of the

cover can vary .

.&_ WARNING

If the towing loop is not installed securely,

it could loosen from the threads while

towing and cause damage to the vehicle or

injury to people .

Page 279 of 302

....,

N

r--. > co

rl I.O

"' rl

"' rl

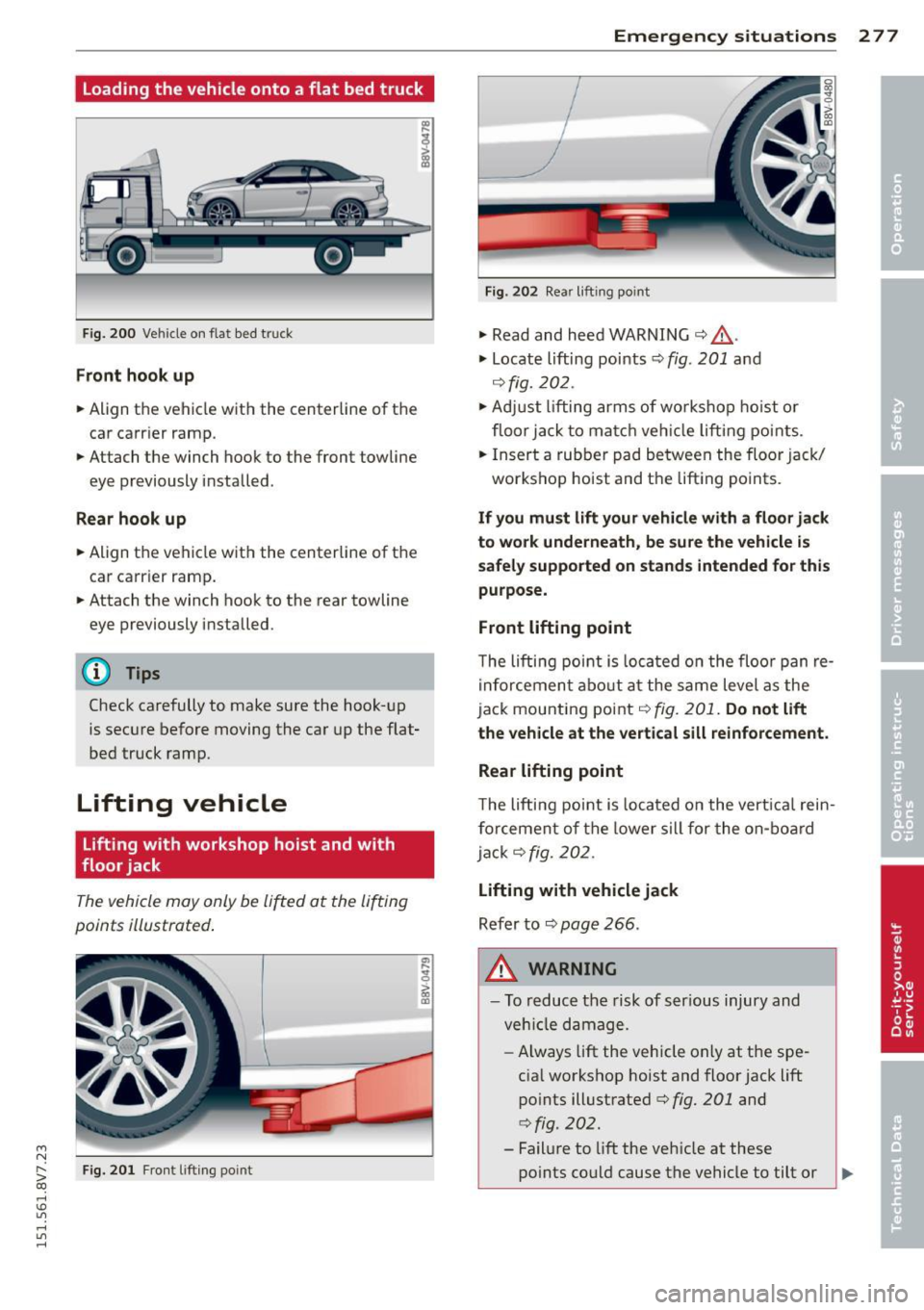

Loading the vehicle onto a flat bed truck

Fig. 200 Veh icle on flat bed truck

Front hook up

.. Align the vehicle with the centerline of the

car carr ier ramp.

.. Attach the winch hook to the front towline

eye previously installed .

Rear hook up

.. Align the vehicle with the centerline of the

car carrier ramp.

.. Attach the winch hook to the rear towline

eye previously installed.

(D} Tips

Check carefully to make sure the hook-up

is secure before moving the car up the flat

bed truck ramp.

Lifting vehicle

Lifting with workshop hoist and with

floor jack

The vehicle may only be lifted at the lifting

points illustrated .

Fig. 201 Front l ifting point

Emergency situations 2 77

Fig. 202 Rea r liftin g po int

.,. Read and heed WARNING c::> .&, .

.,. Locate lifting points c::> fig. 201 and

¢ fig. 202 .

.,. Adju st lifting arms of workshop hoist or

floor jack to match veh icle lifting points.

.. Insert a rubber pad between the floor jack/

workshop hoist and the lift ing points.

If you must lift your vehicle with a floor jack

to work underneath, be sure the vehicle is

safely supported on stands intended for this

purpose .

Front lifting point

T he lifti ng point is loca ted on the floo r pan re

info rcemen t about at the same level as the

jack mounting point

c::>fig. 201. Do not lift

the vehicle at the vertical sill reinforcement.

Rear lifting point

The lifting point is located o n the vert ica l rein

forcement of the lower sill for the on-board

jack

c::> fig. 202 .

Lifting with vehicle jack

Refer to c:;, page 266.

A WARNING

-To reduce the risk of ser ious injury and

vehicle damage .

- Always lift the vehicle only at the spe

cia l workshop hoist and floor jack lift

points illustrated

c:;, fig. 201 and

c:;, fig. 202.

- Failure to lift the veh icle at these

-

points could cause the vehicle to tilt or ..,.