engine AUDI A4 1996 B5 / 1.G AFC Engine Cylinder Block Crankshaft And Flywheel Component Assembly Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1996, Model line: A4, Model: AUDI A4 1996 B5 / 1.GPages: 32, PDF Size: 0.44 MB

Page 5 of 32

13-8

12 -

Dual mass flywheel or drive plate

Removing and installing, installation

dimensions page 13

-17

Removing and installing pilot needle

bearing page 13

-16

Adjusting engine speed (RPM) sensor

bracket -G28- page 13

-20

13 -

Main bearing shell

Checking radial clearance page 13

-21

14 -

Seal

Replacing page 13

-14

15 -

10 Nm (7 ft lb)

16 -

25 Nm (18 ft lb)

Thread bolts in hand-tight before tightening

crankshaft main bearing caps

17 -

Cylinder block

Pa

ge 5 of 32 C

ylinder block, crankshaft and fl

ywheel, com

ponent la

yout

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.13.4

Page 6 of 32

13-9

Ribbed belt, removing and installing

CAUTION!

Mark the direction of belt travel before

removing, using a crayon or marker.

Reinstalling a used belt in the opposite

direction could damage the belt.

Removing

- Remove engine and ribbed-belt guard.

- Loosen ribbed-belt tensioner using 17 mm

wrench and secure with locking drift 3204.

- Remove ribbed belt.

Installing

- Install ribbed belt over the crankshaft belt pulley

and guide pulley first, and then push it onto the

tensioning pulley.

- Remove locking drift 3204.

- Install engine and ribbed belt guard.

Routing of ribbed belt drive -D-

Pa

ge 6 of 32 C

ylinder block, crankshaft and fl

ywheel, com

ponent la

yout

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.13.4

Page 9 of 32

13-11

Toothed belt, removing and installing

Removing

CAUTION!

Mark the direction of belt travel before

removing, using a crayon or marker.

Reinstalling a used belt in the opposite

direction could damage the belt.

- Remove ribbed belt page 13

-9 .

- Unclip toothed belt guard on both sides.

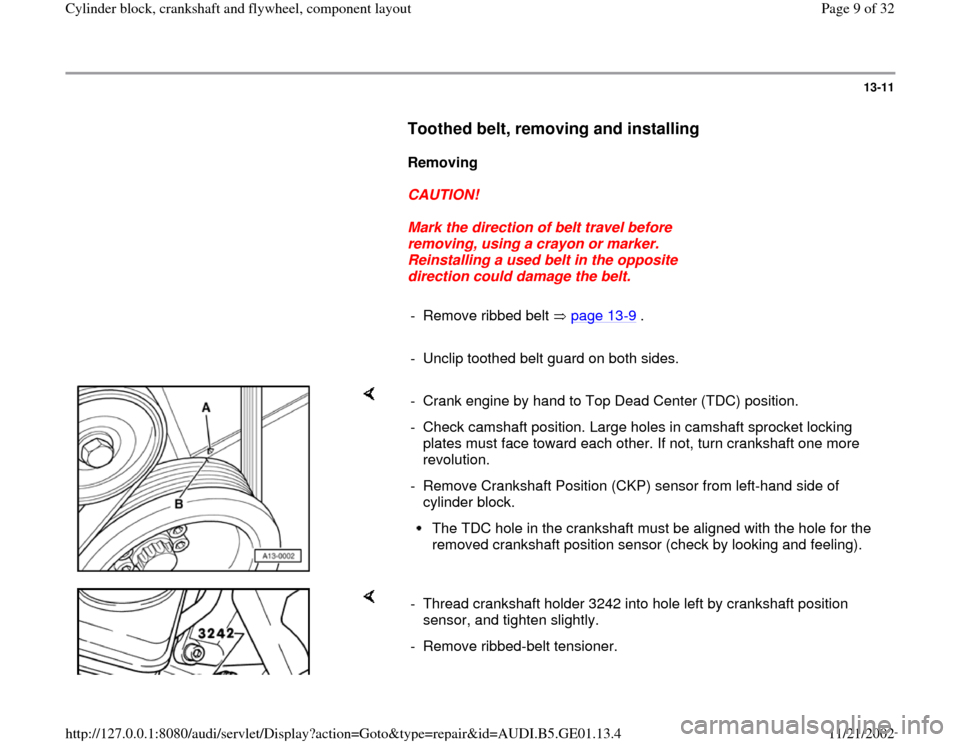

- Crank engine by hand to Top Dead Center (TDC) position.

- Check camshaft position. Large holes in camshaft sprocket locking

plates must face toward each other. If not, turn crankshaft one more

revolution.

- Remove Crankshaft Position (CKP) sensor from left-hand side of

cylinder block.

The TDC hole in the crankshaft must be aligned with the hole for the

removed crankshaft position sensor (check by looking and feeling).

- Thread crankshaft holder 3242 into hole left by crankshaft position

sensor, and tighten slightly.

- Remove ribbed-belt tensioner.

Pa

ge 9 of 32 C

ylinder block, crankshaft and fl

ywheel, com

ponent la

yout

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.13.4

Page 15 of 32

13-15

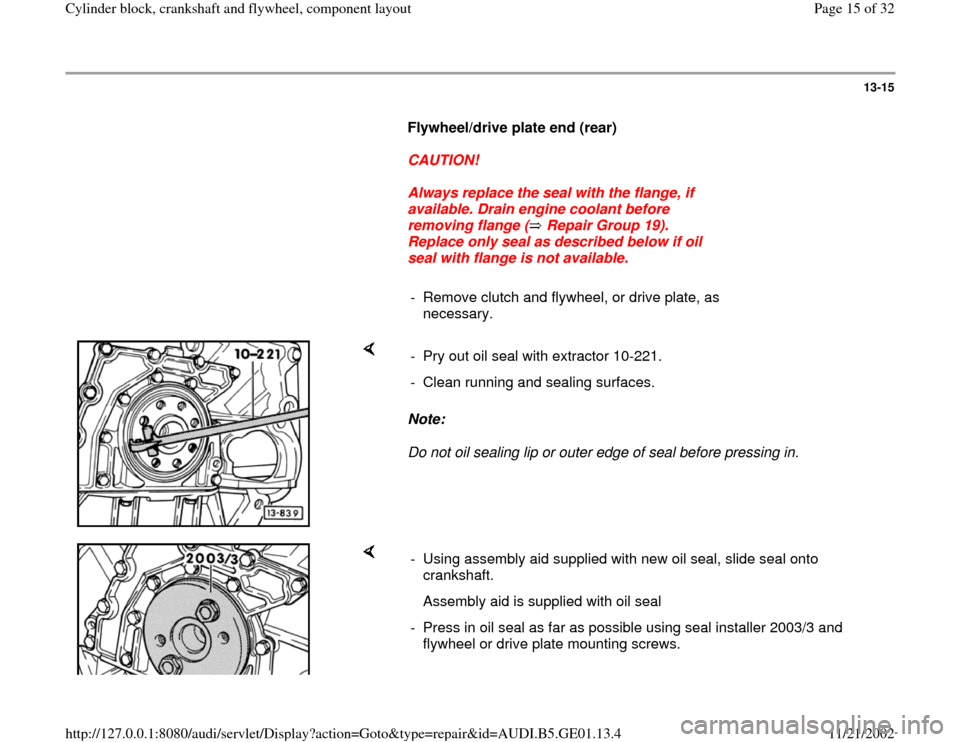

Flywheel/drive plate end (rear)

CAUTION!

Always replace the seal with the flange, if

available. Drain engine coolant before

removing flange ( Repair Group 19).

Replace only seal as described below if oil

seal with flange is not available.

- Remove clutch and flywheel, or drive plate, as

necessary.

Note:

Do not oil sealing lip or outer edge of seal before pressing in. - Pry out oil seal with extractor 10-221.

- Clean running and sealing surfaces.

- Using assembly aid supplied with new oil seal, slide seal onto

crankshaft.

Assembly aid is supplied with oil seal

- Press in oil seal as far as possible using seal installer 2003/3 and

flywheel or drive plate mounting screws.

Pa

ge 15 of 32 C

ylinder block, crankshaft and fl

ywheel, com

ponent la

yout

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.13.4

Page 17 of 32

13-17

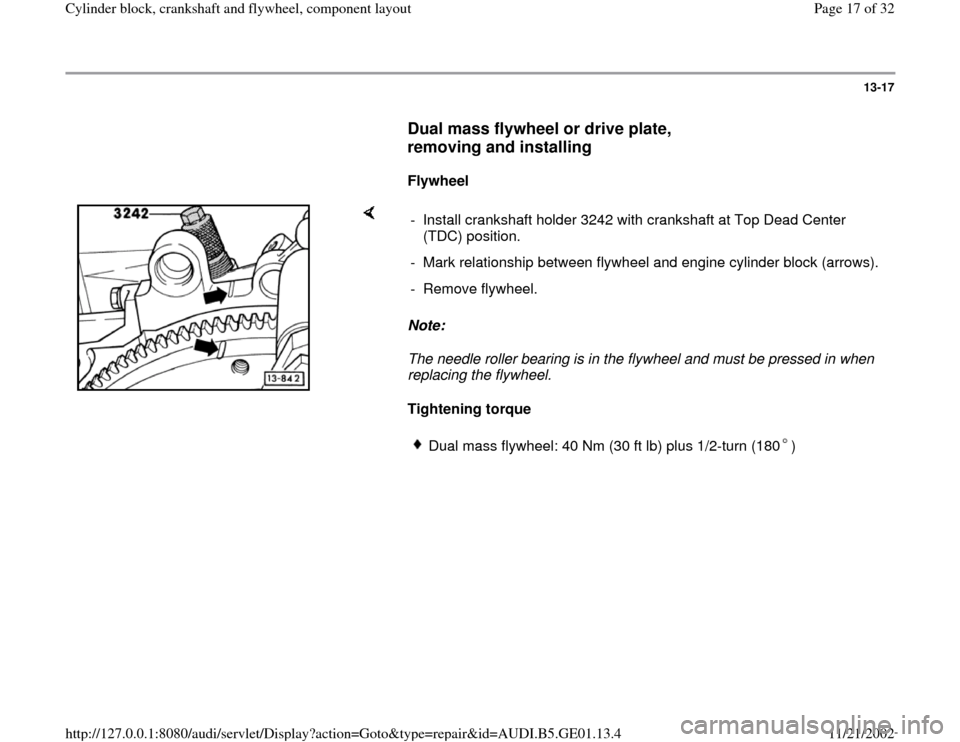

Dual mass flywheel or drive plate,

removing and installing

Flywheel

Note:

The needle roller bearing is in the flywheel and must be pressed in when

replacing the flywheel.

Tightening torque - Install crankshaft holder 3242 with crankshaft at Top Dead Center

(TDC) position.

- Mark relationship between flywheel and engine cylinder block (arrows).

- Remove flywheel.

Dual mass flywheel: 40 Nm (30 ft lb) plus 1/2-turn (180 )

Pa

ge 17 of 32 C

ylinder block, crankshaft and fl

ywheel, com

ponent la

yout

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.13.4

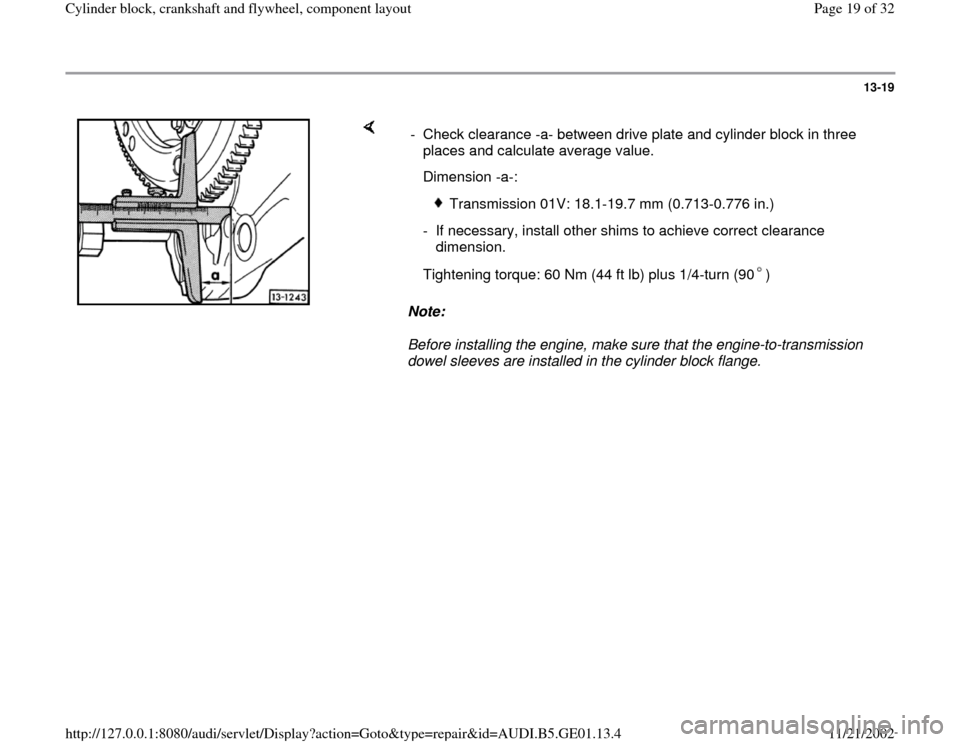

Page 19 of 32

13-19

Note:

Before installing the engine, make sure that the engine-to-transmission

dowel sleeves are installed in the cylinder block flange. - Check clearance -a- between drive plate and cylinder block in three

places and calculate average value.

Dimension -a-:

Transmission 01V: 18.1-19.7 mm (0.713-0.776 in.)

- If necessary, install other shims to achieve correct clearance

dimension.

Tightening torque: 60 Nm (44 ft lb) plus 1/4-turn (90 )

Pa

ge 19 of 32 C

ylinder block, crankshaft and fl

ywheel, com

ponent la

yout

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.13.4

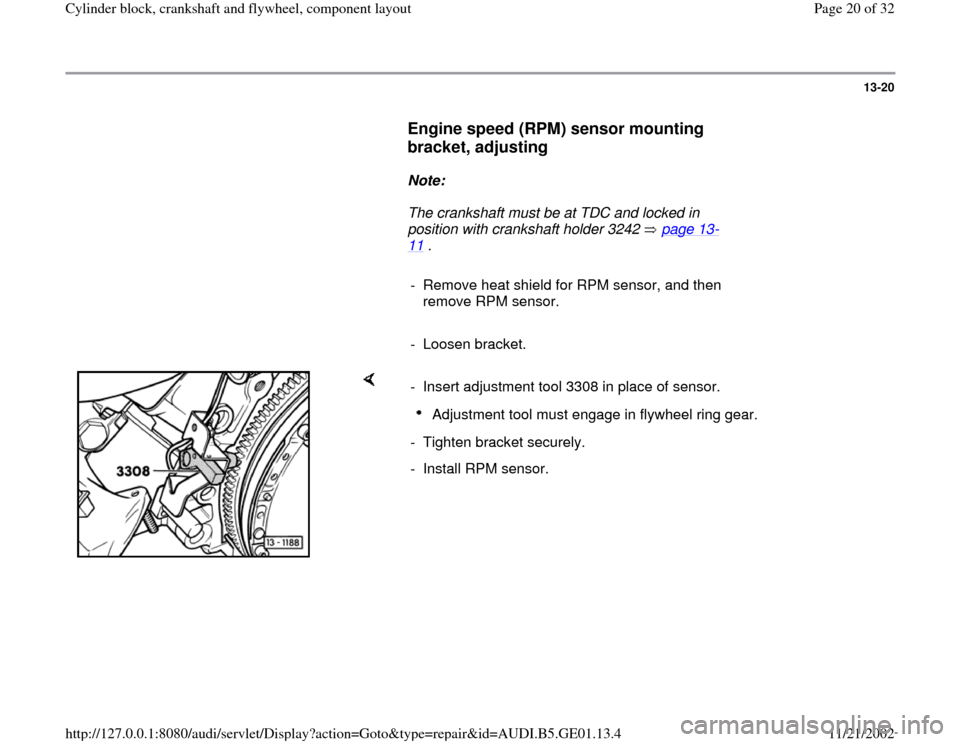

Page 20 of 32

13-20

Engine speed (RPM) sensor mounting

bracket, adjusting

Note:

The crankshaft must be at TDC and locked in

position with crankshaft holder 3242 page 13

-

11

.

- Remove heat shield for RPM sensor, and then

remove RPM sensor.

- Loosen bracket.

- Insert adjustment tool 3308 in place of sensor.

Adjustment tool must engage in flywheel ring gear.

- Tighten bracket securely.

- Install RPM sensor.

Pa

ge 20 of 32 C

ylinder block, crankshaft and fl

ywheel, com

ponent la

yout

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.13.4