lock AUDI A4 1996 B5 / 1.G AFC Engine Cylinder Block Crankshaft And Flywheel Component Assembly Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1996, Model line: A4, Model: AUDI A4 1996 B5 / 1.GPages: 32, PDF Size: 0.44 MB

Page 1 of 32

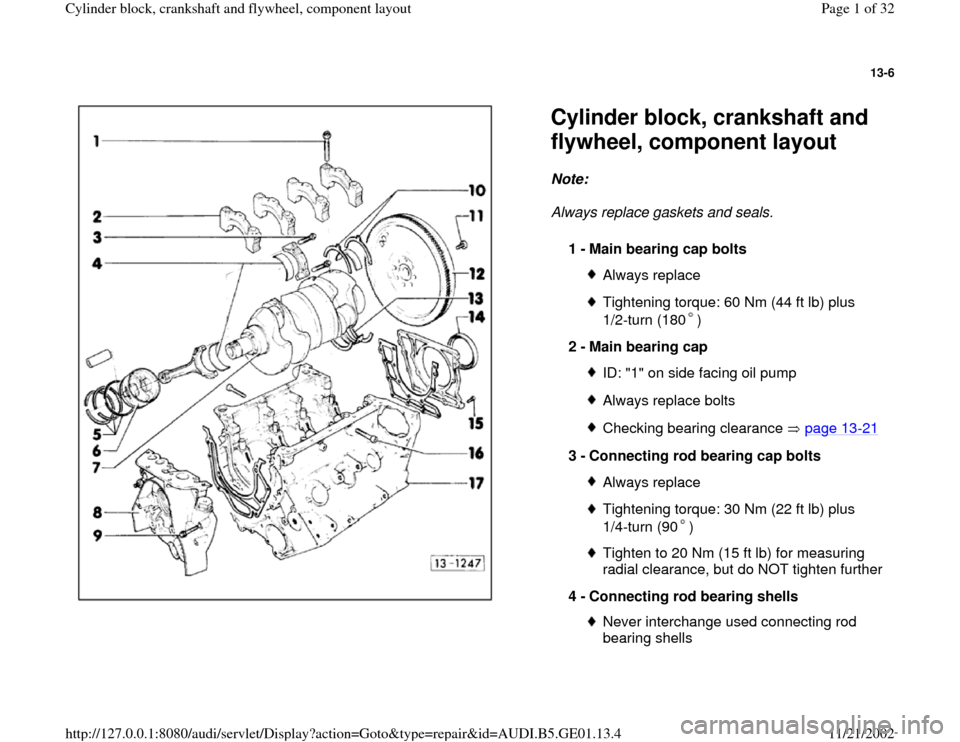

13-6

Cylinder block, crankshaft and

flywheel, component layout Note:

Always replace gaskets and seals.

1 -

Main bearing cap bolts

Always replaceTightening torque: 60 Nm (44 ft lb) plus

1/2-turn (180 )

2 -

Main bearing cap

ID: "1" on side facing oil pumpAlways replace boltsChecking bearing clearance page 13

-21

3 -

Connecting rod bearing cap bolts

Always replaceTightening torque: 30 Nm (22 ft lb) plus

1/4-turn (90 ) Tighten to 20 Nm (15 ft lb) for measuring

radial clearance, but do NOT tighten further

4 -

Connecting rod bearing shells Never interchange used connecting rod

bearing shells

Pa

ge 1 of 32 C

ylinder block, crankshaft and fl

ywheel, com

ponent la

yout

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.13.4

Page 2 of 32

Checking connecting rods and bearings

page 13

-31

Pa

ge 2 of 32 C

ylinder block, crankshaft and fl

ywheel, com

ponent la

yout

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.13.4

Page 3 of 32

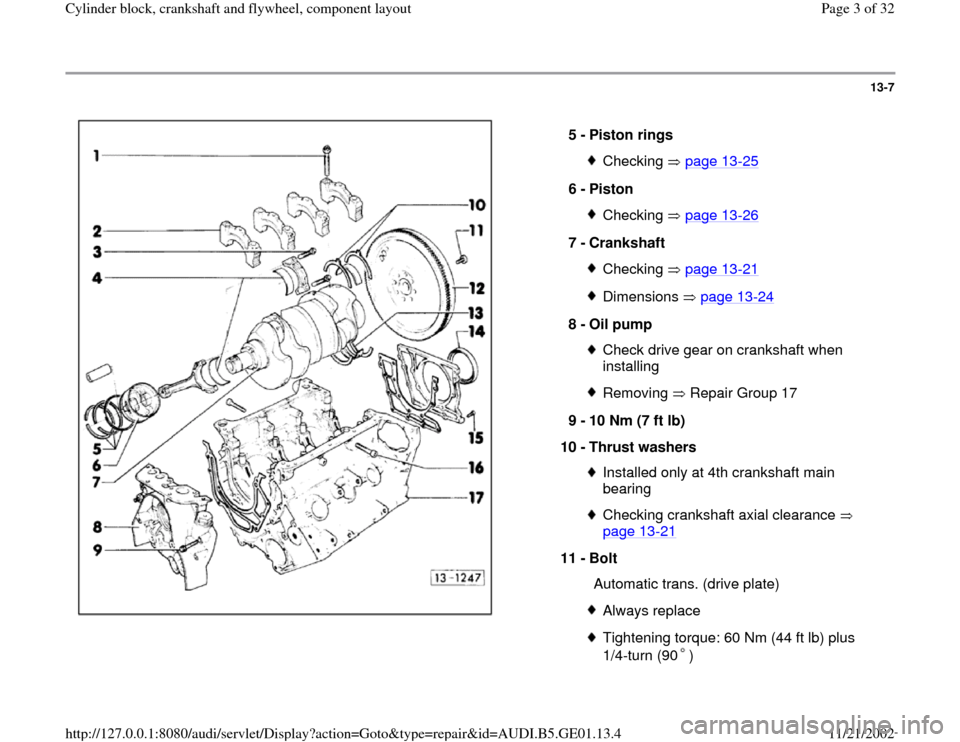

13-7

5 -

Piston rings

Checking page 13

-25

6 -

Piston

Checking page 13

-26

7 -

Crankshaft

Checking page 13

-21

Dimensions page 13

-24

8 -

Oil pump

Check drive gear on crankshaft when

installing Removing Repair Group 17

9 -

10 Nm (7 ft lb)

10 -

Thrust washers

Installed only at 4th crankshaft main

bearing Checking crankshaft axial clearance

page 13

-21

11 -

Bolt

Automatic trans. (drive plate)

Always replaceTightening torque: 60 Nm (44 ft lb) plus

1/4-turn (90 )

Pa

ge 3 of 32 C

ylinder block, crankshaft and fl

ywheel, com

ponent la

yout

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.13.4

Page 4 of 32

Manual trans. (flywheel)

Always replaceTightening torque: 40 Nm (30 ft lb) plus

1/2-turn (180 )

Pa

ge 4 of 32 C

ylinder block, crankshaft and fl

ywheel, com

ponent la

yout

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.13.4

Page 5 of 32

13-8

12 -

Dual mass flywheel or drive plate

Removing and installing, installation

dimensions page 13

-17

Removing and installing pilot needle

bearing page 13

-16

Adjusting engine speed (RPM) sensor

bracket -G28- page 13

-20

13 -

Main bearing shell

Checking radial clearance page 13

-21

14 -

Seal

Replacing page 13

-14

15 -

10 Nm (7 ft lb)

16 -

25 Nm (18 ft lb)

Thread bolts in hand-tight before tightening

crankshaft main bearing caps

17 -

Cylinder block

Pa

ge 5 of 32 C

ylinder block, crankshaft and fl

ywheel, com

ponent la

yout

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.13.4

Page 6 of 32

13-9

Ribbed belt, removing and installing

CAUTION!

Mark the direction of belt travel before

removing, using a crayon or marker.

Reinstalling a used belt in the opposite

direction could damage the belt.

Removing

- Remove engine and ribbed-belt guard.

- Loosen ribbed-belt tensioner using 17 mm

wrench and secure with locking drift 3204.

- Remove ribbed belt.

Installing

- Install ribbed belt over the crankshaft belt pulley

and guide pulley first, and then push it onto the

tensioning pulley.

- Remove locking drift 3204.

- Install engine and ribbed belt guard.

Routing of ribbed belt drive -D-

Pa

ge 6 of 32 C

ylinder block, crankshaft and fl

ywheel, com

ponent la

yout

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.13.4

Page 7 of 32

D1 - Without air conditioner

D2 - With air conditioner

Pa

ge 7 of 32 C

ylinder block, crankshaft and fl

ywheel, com

ponent la

yout

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.13.4

Page 8 of 32

13-10

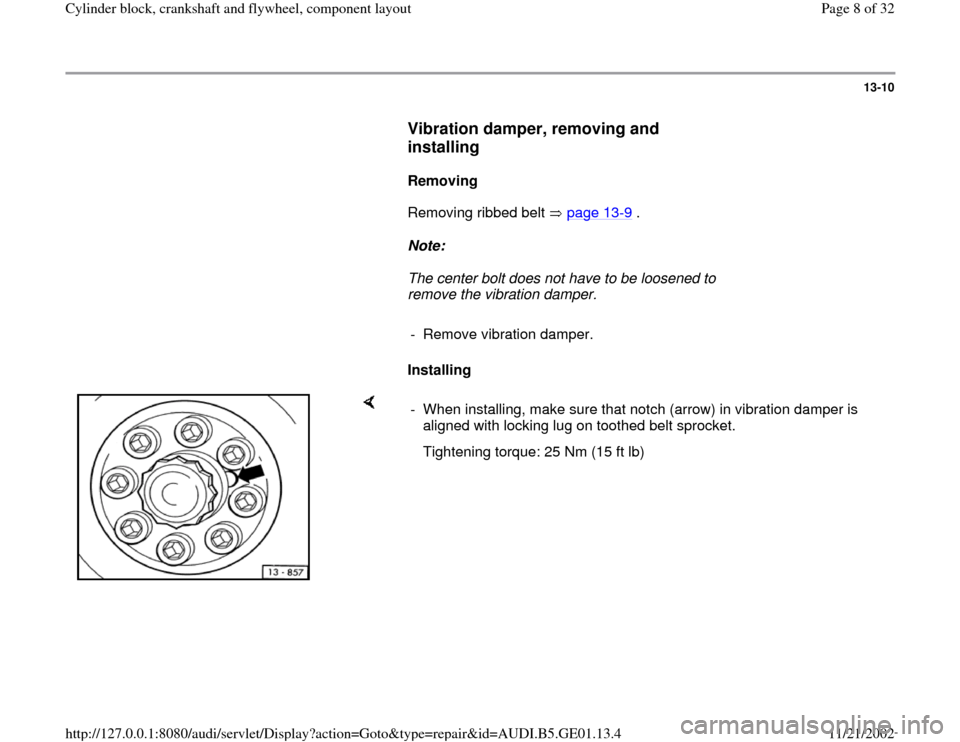

Vibration damper, removing and

installing

Removing

Removing ribbed belt page 13

-9 .

Note:

The center bolt does not have to be loosened to

remove the vibration damper.

- Remove vibration damper.

Installing

- When installing, make sure that notch (arrow) in vibration damper is

aligned with locking lug on toothed belt sprocket.

Tightening torque: 25 Nm (15 ft lb)

Pa

ge 8 of 32 C

ylinder block, crankshaft and fl

ywheel, com

ponent la

yout

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.13.4

Page 9 of 32

13-11

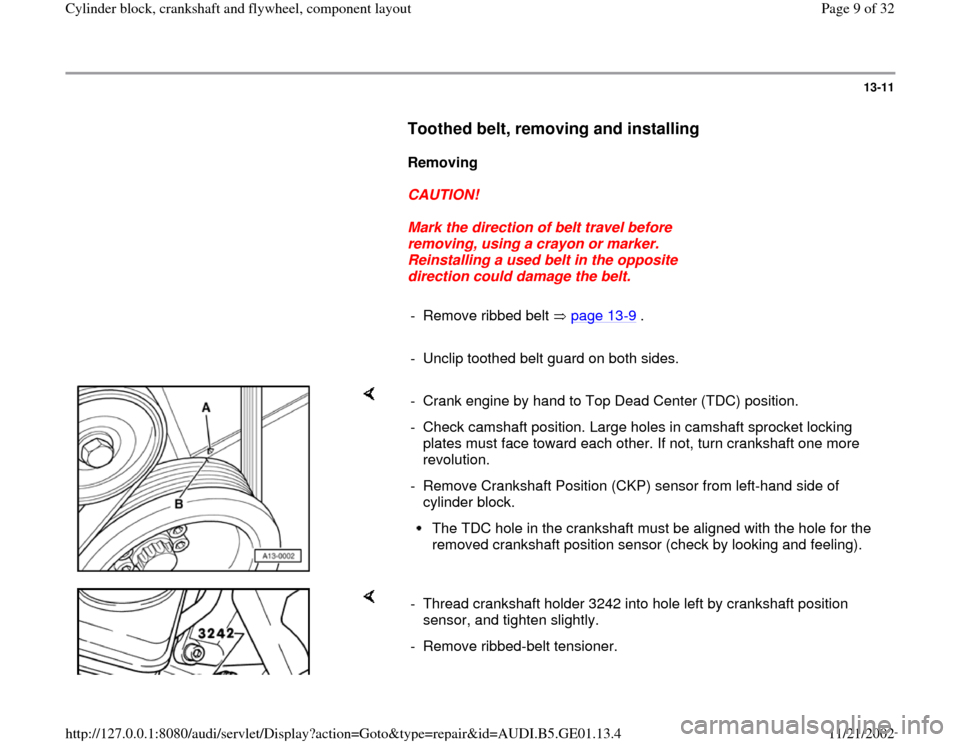

Toothed belt, removing and installing

Removing

CAUTION!

Mark the direction of belt travel before

removing, using a crayon or marker.

Reinstalling a used belt in the opposite

direction could damage the belt.

- Remove ribbed belt page 13

-9 .

- Unclip toothed belt guard on both sides.

- Crank engine by hand to Top Dead Center (TDC) position.

- Check camshaft position. Large holes in camshaft sprocket locking

plates must face toward each other. If not, turn crankshaft one more

revolution.

- Remove Crankshaft Position (CKP) sensor from left-hand side of

cylinder block.

The TDC hole in the crankshaft must be aligned with the hole for the

removed crankshaft position sensor (check by looking and feeling).

- Thread crankshaft holder 3242 into hole left by crankshaft position

sensor, and tighten slightly.

- Remove ribbed-belt tensioner.

Pa

ge 9 of 32 C

ylinder block, crankshaft and fl

ywheel, com

ponent la

yout

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.13.4

Page 10 of 32

13-12

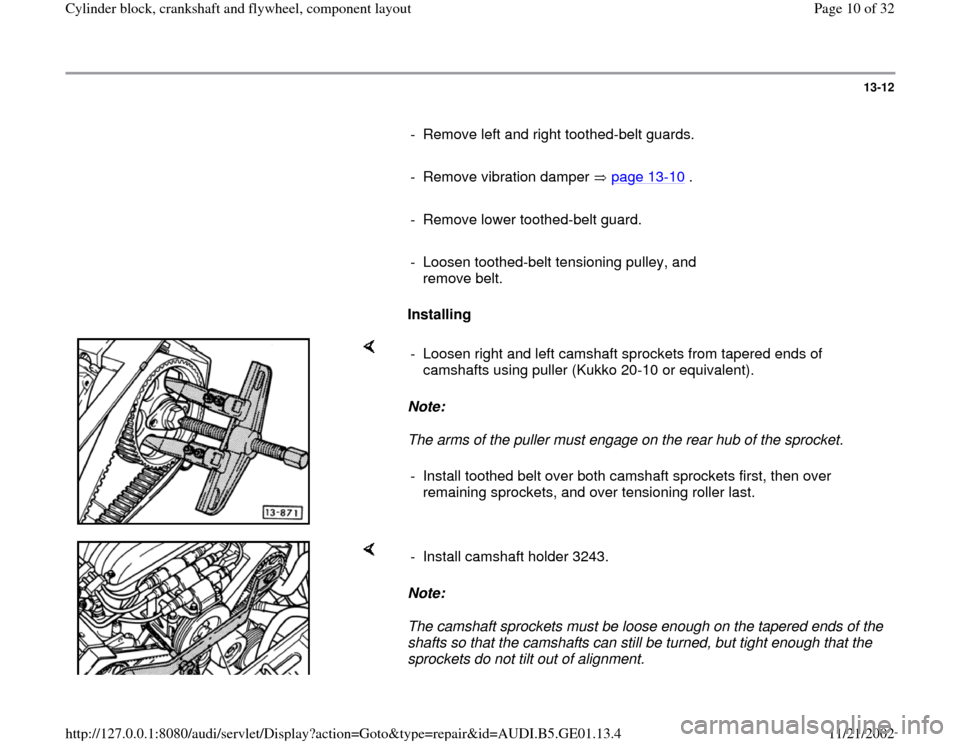

- Remove left and right toothed-belt guards.

- Remove vibration damper page 13

-10

.

- Remove lower toothed-belt guard.

- Loosen toothed-belt tensioning pulley, and

remove belt.

Installing

Note:

The arms of the puller must engage on the rear hub of the sprocket. - Loosen right and left camshaft sprockets from tapered ends of

camshafts using puller (Kukko 20-10 or equivalent).

- Install toothed belt over both camshaft sprockets first, then over

remaining sprockets, and over tensioning roller last.

Note:

The camshaft sprockets must be loose enough on the tapered ends of the

shafts so that the camshafts can still be turned, but tight enough that the

sprockets do not tilt out of alignment. - Install camshaft holder 3243.

Pa

ge 10 of 32 C

ylinder block, crankshaft and fl

ywheel, com

ponent la

yout

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.13.4