torque AUDI A4 1997 B5 / 1.G 01A Transmission Pinion Shaft Remove And Install Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1997, Model line: A4, Model: AUDI A4 1997 B5 / 1.GPages: 13, PDF Size: 0.3 MB

Page 3 of 13

39-135

3062 thrust pad

3138 drift

3253 wheel bearing assembly set with 3253/3

and 3253/4

3304 bracket

VAG1383A engine/transmission support

VAG1359/2 universal mount

Kukko 17/2 separating tool

Kukko 21/7 extractor

Kukko 22/2 support

Torque gauge 0-600 Ncm (0-53 in. lb)

32 mm socket

Pa

ge 3 of 13 Pinion shaft, removin

g, installin

g and servicin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.16

Page 4 of 13

39-136

Notes:

Observe general repair instructions Page 00

-

14

.

With the final drive installed, remove the drive

flange housing from the rear final drive Page 39

-86

.

With the final drive removed, remove the drive

flange housing from the rear final drive Page 39

-119

.

Always replace both tapered roller bearings

together as a set. If possible, use same

manufacturer.

Do not oil new tapered roller bearings for the

friction torque measurement. The bearings are

already factory treated with a special oil.

Remove differential Page 39

-114

.

Adjustments are required when replacing

components marked with "1)" List of

adjustments, Page 39

-149

.

Pa

ge 4 of 13 Pinion shaft, removin

g, installin

g and servicin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.16

Page 5 of 13

39-137

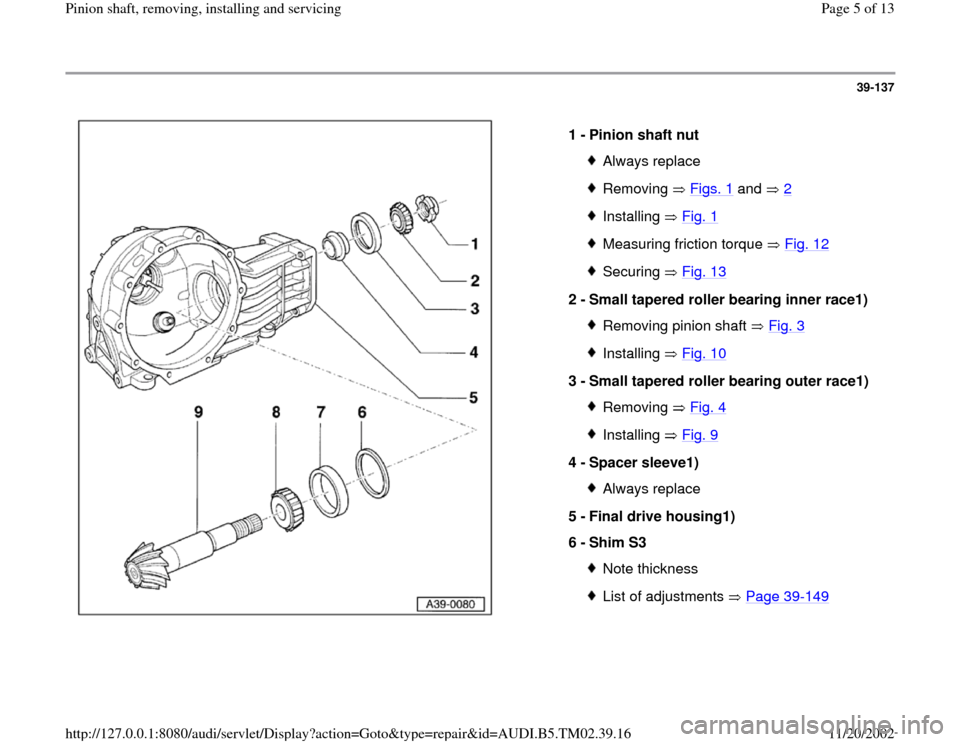

1 -

Pinion shaft nut

Always replaceRemoving Figs. 1

and 2

Installing Fig. 1Measuring friction torque Fig. 12Securing Fig. 13

2 -

Small tapered roller bearing inner race1)

Removing pinion shaft Fig. 3Installing Fig. 10

3 -

Small tapered roller bearing outer race1)

Removing Fig. 4Installing Fig. 9

4 -

Spacer sleeve1)

Always replace

5 -

Final drive housing1)

6 -

Shim S3 Note thicknessList of adjustments Page 39

-149

Pa

ge 5 of 13 Pinion shaft, removin

g, installin

g and servicin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.16

Page 12 of 13

39-144

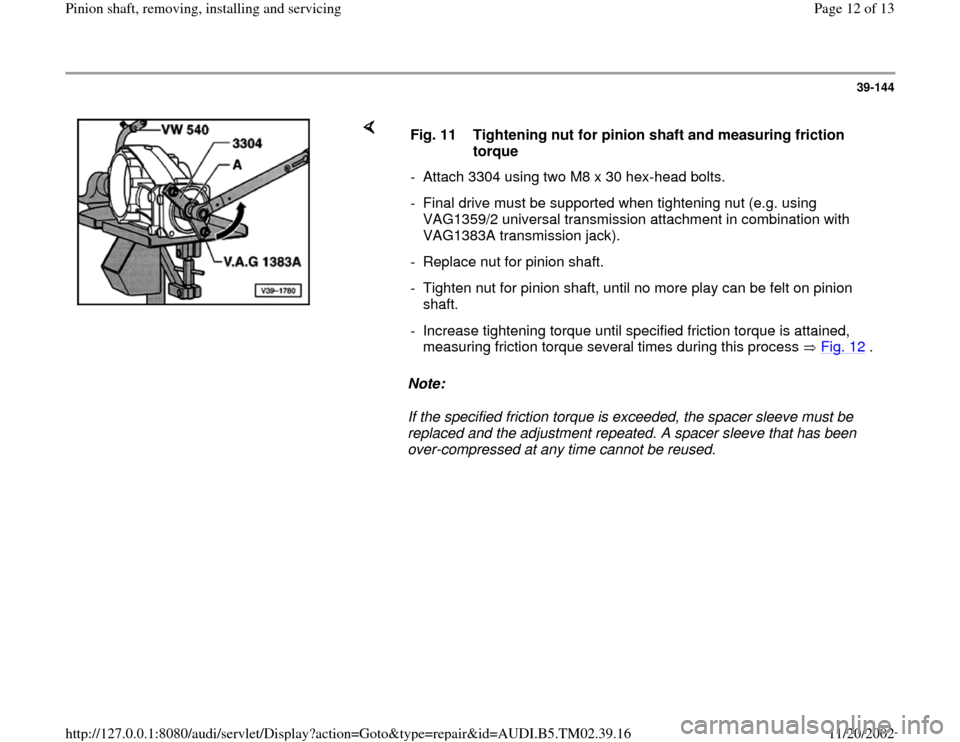

Note:

If the specified friction torque is exceeded, the spacer sleeve must be

replaced and the adjustment repeated. A spacer sleeve that has been

over-compressed at any time cannot be reused. Fig. 11 Tightening nut for pinion shaft and measuring friction

torque

- Attach 3304 using two M8 x 30 hex-head bolts.

- Final drive must be supported when tightening nut (e.g. using

VAG1359/2 universal transmission attachment in combination with

VAG1383A transmission jack).

- Replace nut for pinion shaft.

- Tighten nut for pinion shaft, until no more play can be felt on pinion

shaft.

- Increase tightening torque until specified friction torque is attained,

measuring friction torque several times during this process Fig. 12

.

Pa

ge 12 of 13 Pinion shaft, removin

g, installin

g and servicin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.16

Page 13 of 13

39-145

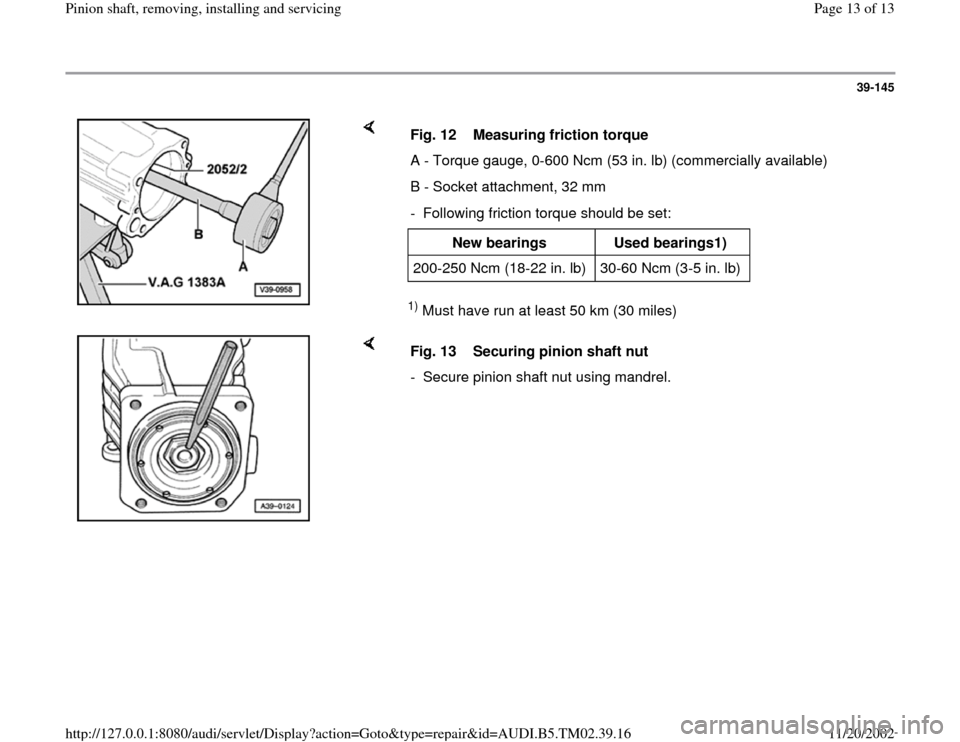

1) Must have run at least 50 km (30 miles) Fig. 12 Measuring friction torque

A - Torque gauge, 0-600 Ncm (53 in. lb) (commercially available)

B - Socket attachment, 32 mm

- Following friction torque should be set:

New bearings

Used bearings1)

200-250 Ncm (18-22 in. lb) 30-60 Ncm (3-5 in. lb)

Fig. 13 Securing pinion shaft nut

- Secure pinion shaft nut using mandrel.

Pa

ge 13 of 13 Pinion shaft, removin

g, installin

g and servicin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.16