engine AUDI A4 1997 B5 / 1.G AHA ATQ Engines Cylinder Block Crankshaft And Flywheel Component Service Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1997, Model line: A4, Model: AUDI A4 1997 B5 / 1.GPages: 33, PDF Size: 0.75 MB

Page 1 of 33

13-4

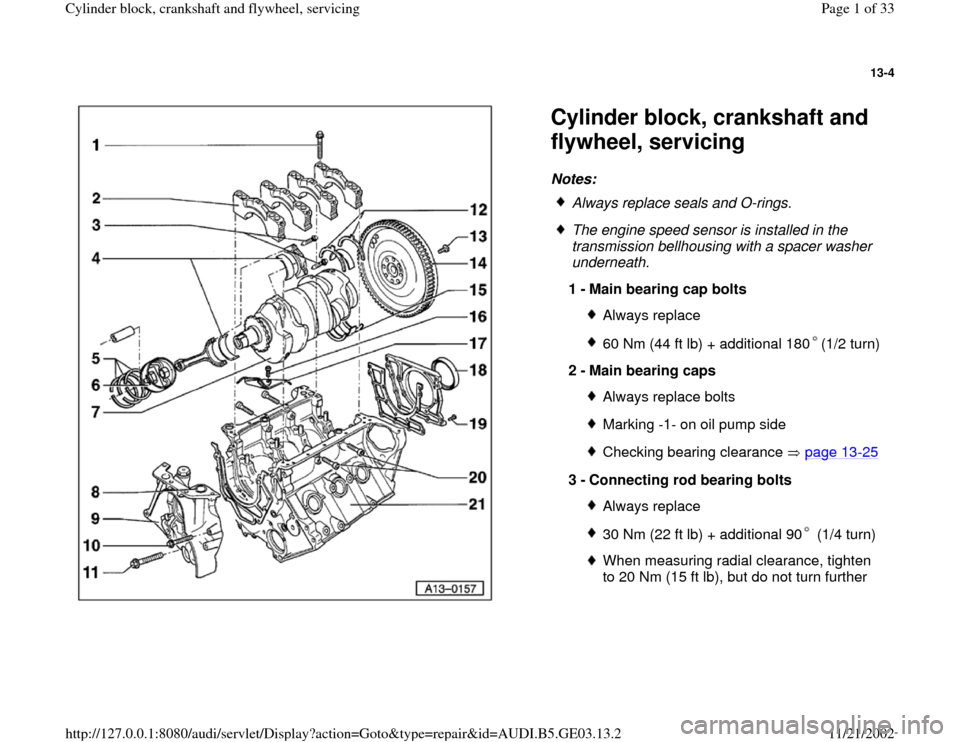

Cylinder block, crankshaft and

flywheel, servicing Notes:

Always replace seals and O-rings.

The engine speed sensor is installed in the

transmission bellhousing with a spacer washer

underneath.

1 -

Main bearing cap bolts

Always replace60 Nm (44 ft lb) + additional 180 (1/2 turn)

2 -

Main bearing caps

Always replace boltsMarking -1- on oil pump sideChecking bearing clearance page 13

-25

3 -

Connecting rod bearing bolts

Always replace30 Nm (22 ft lb) + additional 90 (1/4 turn)When measuring radial clearance, tighten

to 20 Nm (15 ft lb), but do not turn further

Pa

ge 1 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2

Page 7 of 33

13-8

Ribbed belt, removing and installing

Lock carrier in service position page 13

-1

CAUTION!

Before removing ribbed belt, note direction of

rotation with chalk or felt-tip marker.

Reversing the direction of rotation of a used

belt can destroy the belt. When installing the

ribbed belt, make sure it is seated correctly

on the pulley.

Removing

- Remove engine cover (arrows).

- Remove noise insulation panel (arrows).

Pa

ge 7 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2

Page 9 of 33

13-10

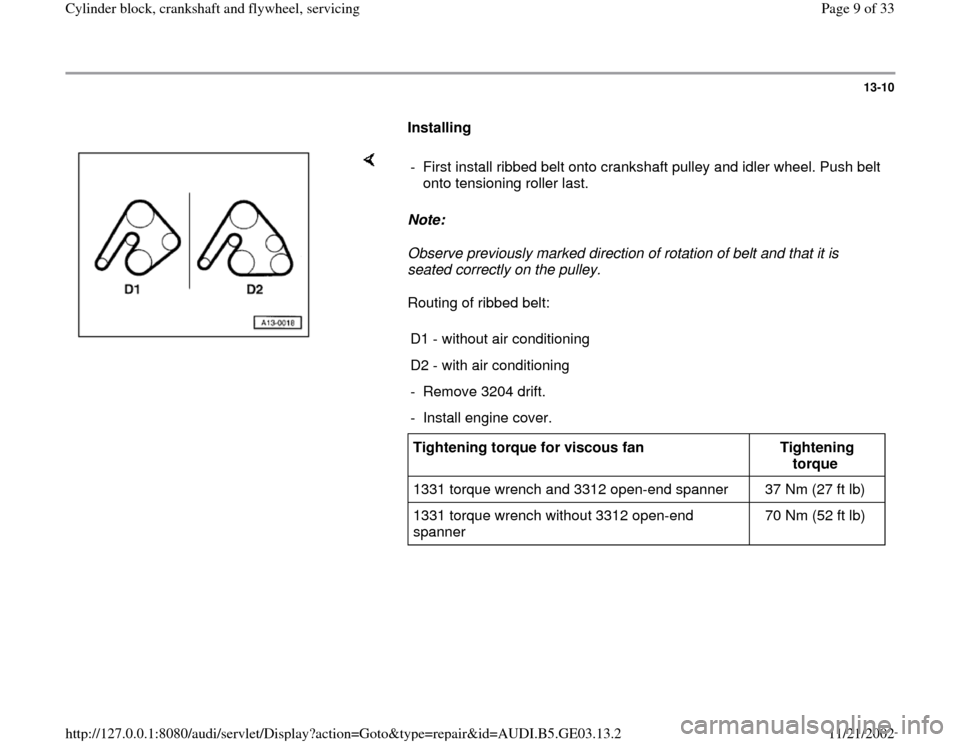

Installing

Note:

Observe previously marked direction of rotation of belt and that it is

seated correctly on the pulley.

Routing of ribbed belt: - First install ribbed belt onto crankshaft pulley and idler wheel. Push belt

onto tensioning roller last.

D1 - without air conditioning

D2 - with air conditioning

- Remove 3204 drift.

- Install engine cover.Tightening torque for viscous fan

Tightening

torque

1331 torque wrench and 3312 open-end spanner 37 Nm (27 ft lb)

1331 torque wrench without 3312 open-end

spanner 70 Nm (52 ft lb)

Pa

ge 9 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2

Page 11 of 33

13-12

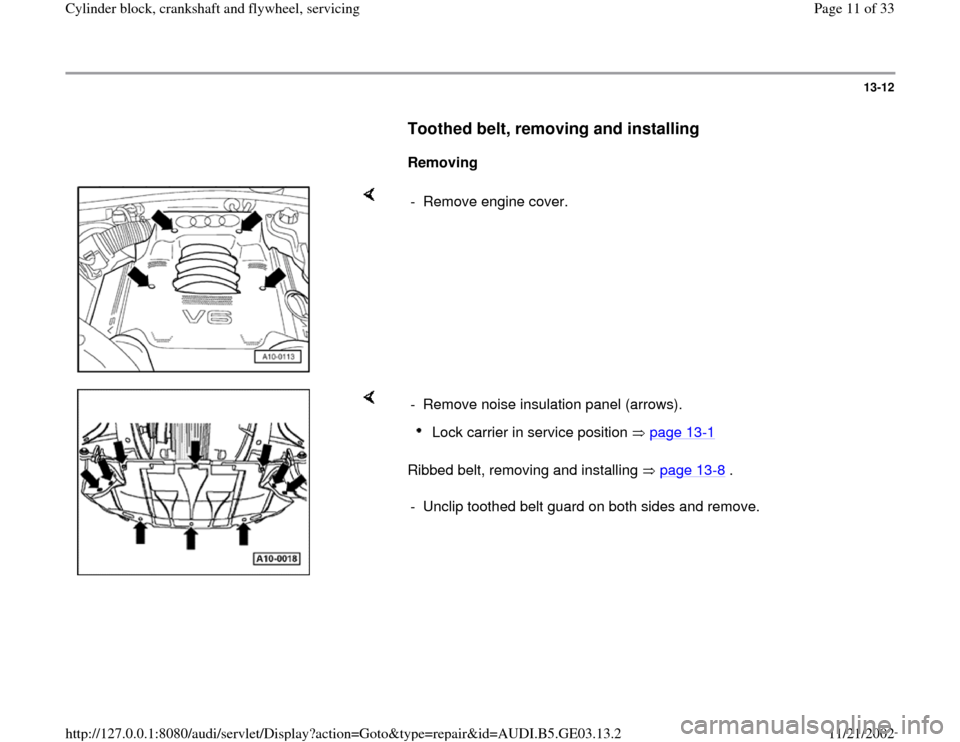

Toothed belt, removing and installing

Removing

- Remove engine cover.

Ribbed belt, removing and installing page 13

-8 . - Remove noise insulation panel (arrows).

Lock carrier in service position page 13

-1

- Unclip toothed belt guard on both sides and remove.

Pa

ge 11 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2

Page 12 of 33

13-13

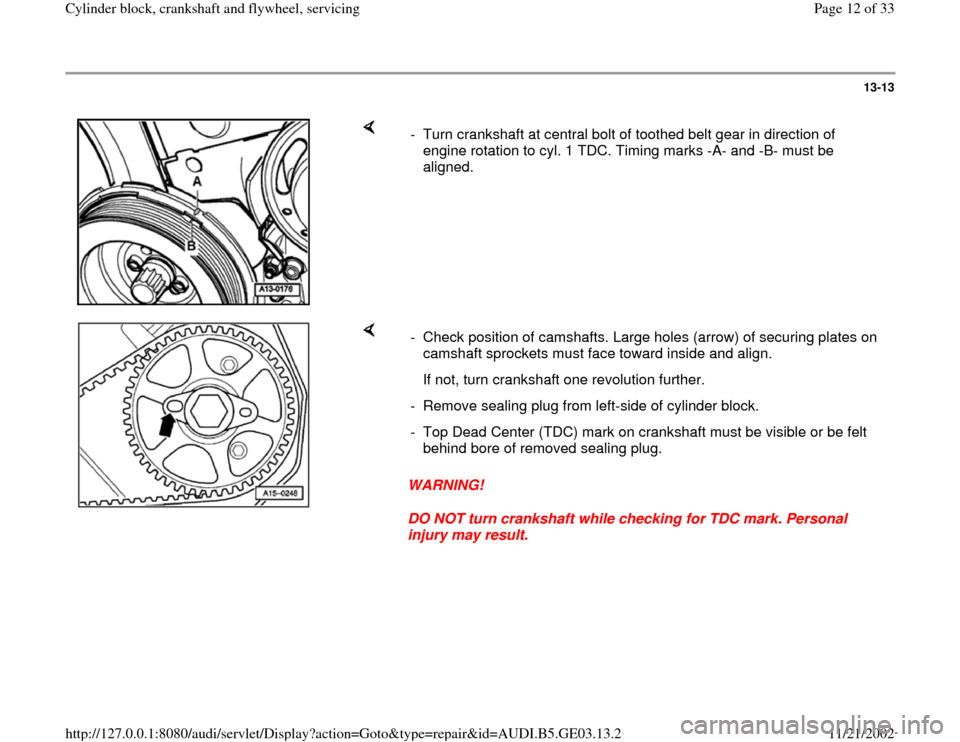

- Turn crankshaft at central bolt of toothed belt gear in direction of

engine rotation to cyl. 1 TDC. Timing marks -A- and -B- must be

aligned.

WARNING!

DO NOT turn crankshaft while checking for TDC mark. Personal

injury may result. - Check position of camshafts. Large holes (arrow) of securing plates on

camshaft sprockets must face toward inside and align.

If not, turn crankshaft one revolution further.

- Remove sealing plug from left-side of cylinder block.

- Top Dead Center (TDC) mark on crankshaft must be visible or be felt

behind bore of removed sealing plug.

Pa

ge 12 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2

Page 16 of 33

13-17

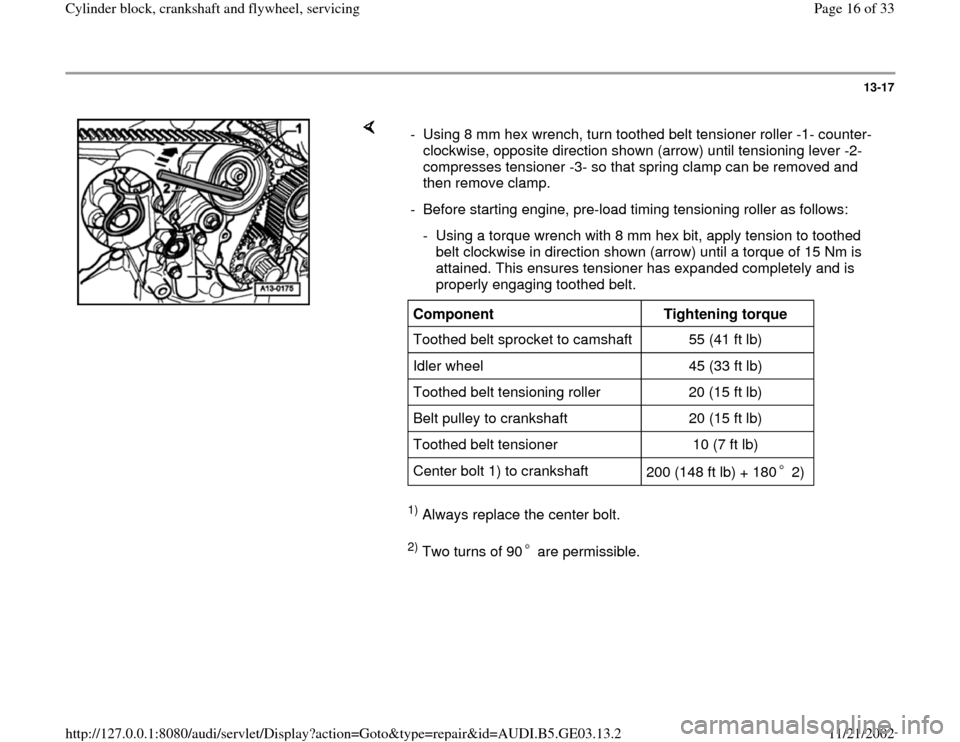

1) Always replace the center bolt. 2) Two turns of 90 are permissible. - Using 8 mm hex wrench, turn toothed belt tensioner roller -1- counter-

clockwise, opposite direction shown (arrow) until tensioning lever -2-

compresses tensioner -3- so that spring clamp can be removed and

then remove clamp.

- Before starting engine, pre-load timing tensioning roller as follows:

- Using a torque wrench with 8 mm hex bit, apply tension to toothed

belt clockwise in direction shown (arrow) until a torque of 15 Nm is

attained. This ensures tensioner has expanded completely and is

properly engaging toothed belt. Component

Tightening torque

Toothed belt sprocket to camshaft 55 (41 ft lb)

Idler wheel 45 (33 ft lb)

Toothed belt tensioning roller 20 (15 ft lb)

Belt pulley to crankshaft 20 (15 ft lb)

Toothed belt tensioner 10 (7 ft lb)

Center bolt 1) to crankshaft

200 (148 ft lb) + 180 2)

Pa

ge 16 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2

Page 21 of 33

13-22

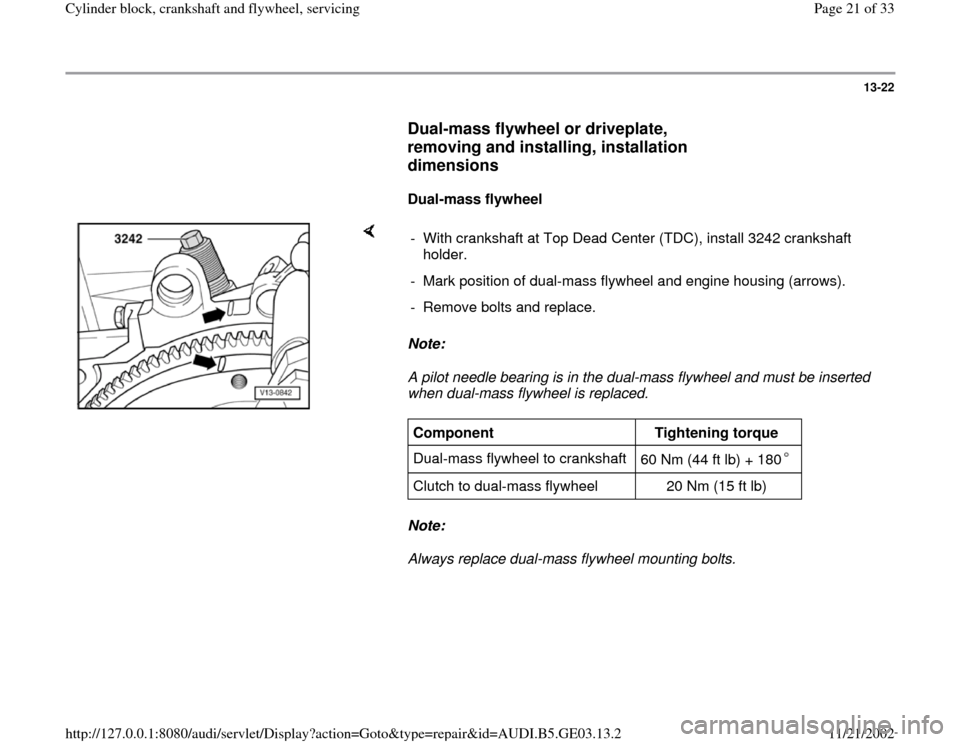

Dual-mass flywheel or driveplate,

removing and installing, installation

dimensions

Dual-mass flywheel

Note:

A pilot needle bearing is in the dual-mass flywheel and must be inserted

when dual-mass flywheel is replaced.

Note:

Always replace dual-mass flywheel mounting bolts. - With crankshaft at Top Dead Center (TDC), install 3242 crankshaft

holder.

- Mark position of dual-mass flywheel and engine housing (arrows).

- Remove bolts and replace.Component

Tightening torque

Dual-mass flywheel to crankshaft

60 Nm (44 ft lb) + 180 Clutch to dual-mass flywheel 20 Nm (15 ft lb)

Pa

ge 21 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2

Page 22 of 33

13-23

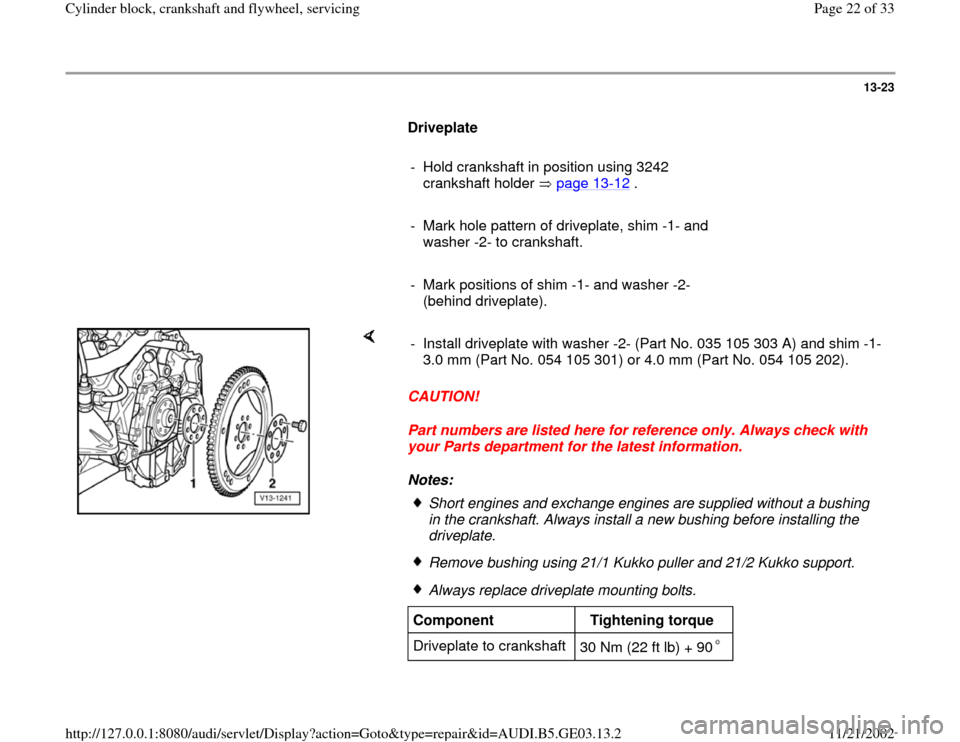

Driveplate

- Hold crankshaft in position using 3242

crankshaft holder page 13

-12

.

- Mark hole pattern of driveplate, shim -1- and

washer -2- to crankshaft.

- Mark positions of shim -1- and washer -2-

(behind driveplate).

CAUTION!

Part numbers are listed here for reference only. Always check with

your Parts department for the latest information.

Notes: - Install driveplate with washer -2- (Part No. 035 105 303 A) and shim -1-

3.0 mm (Part No. 054 105 301) or 4.0 mm (Part No. 054 105 202).

Short engines and exchange engines are supplied without a bushing

in the crankshaft. Always install a new bushing before installing the

driveplate. Remove bushing using 21/1 Kukko puller and 21/2 Kukko support.Always replace driveplate mounting bolts.

Component

Tightening torque

Driveplate to crankshaft

30 Nm (22 ft lb) + 90

Pa

ge 22 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2

Page 23 of 33

13-24

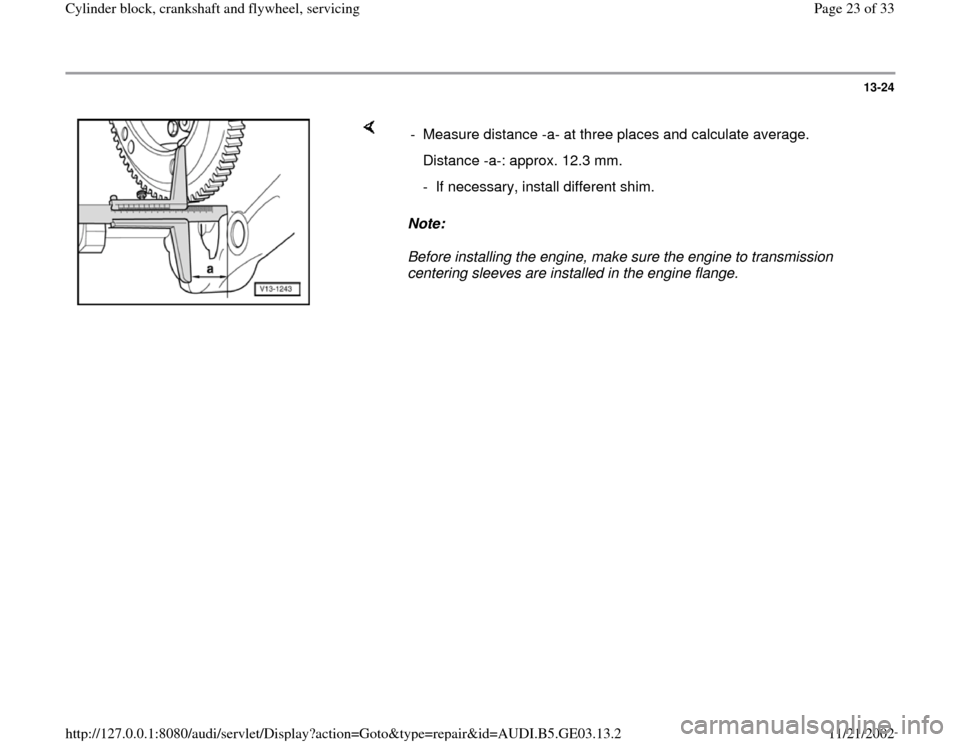

Note:

Before installing the engine, make sure the engine to transmission

centering sleeves are installed in the engine flange. - Measure distance -a- at three places and calculate average.

Distance -a-: approx. 12.3 mm.

- If necessary, install different shim.

Pa

ge 23 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2

Page 27 of 33

13-28

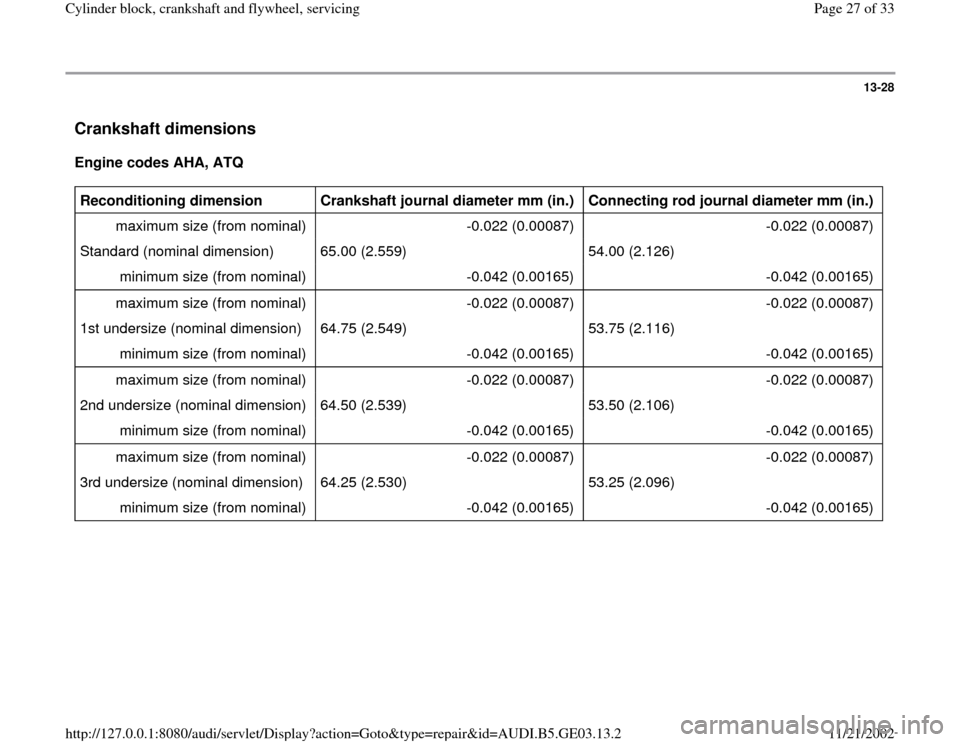

Crankshaft dimensions

Engine codes AHA, ATQ

Reconditioning dimension

Crankshaft journal diameter mm (in.)

Connecting rod journal diameter mm (in.)

maximum size (from nominal) -0.022 (0.00087) -0.022 (0.00087)

Standard (nominal dimension) 65.00 (2.559) 54.00 (2.126)

minimum size (from nominal) -0.042 (0.00165) -0.042 (0.00165)

maximum size (from nominal) -0.022 (0.00087) -0.022 (0.00087)

1st undersize (nominal dimension) 64.75 (2.549) 53.75 (2.116)

minimum size (from nominal) -0.042 (0.00165) -0.042 (0.00165)

maximum size (from nominal) -0.022 (0.00087) -0.022 (0.00087)

2nd undersize (nominal dimension) 64.50 (2.539) 53.50 (2.106)

minimum size (from nominal) -0.042 (0.00165) -0.042 (0.00165)

maximum size (from nominal) -0.022 (0.00087) -0.022 (0.00087)

3rd undersize (nominal dimension) 64.25 (2.530) 53.25 (2.096)

minimum size (from nominal) -0.042 (0.00165) -0.042 (0.00165)

Pa

ge 27 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2