change wheel AUDI A4 1997 B5 / 1.G AHA ATQ Engines Cylinder Block Crankshaft And Flywheel Component Service Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1997, Model line: A4, Model: AUDI A4 1997 B5 / 1.GPages: 33, PDF Size: 0.75 MB

Page 2 of 33

13-5

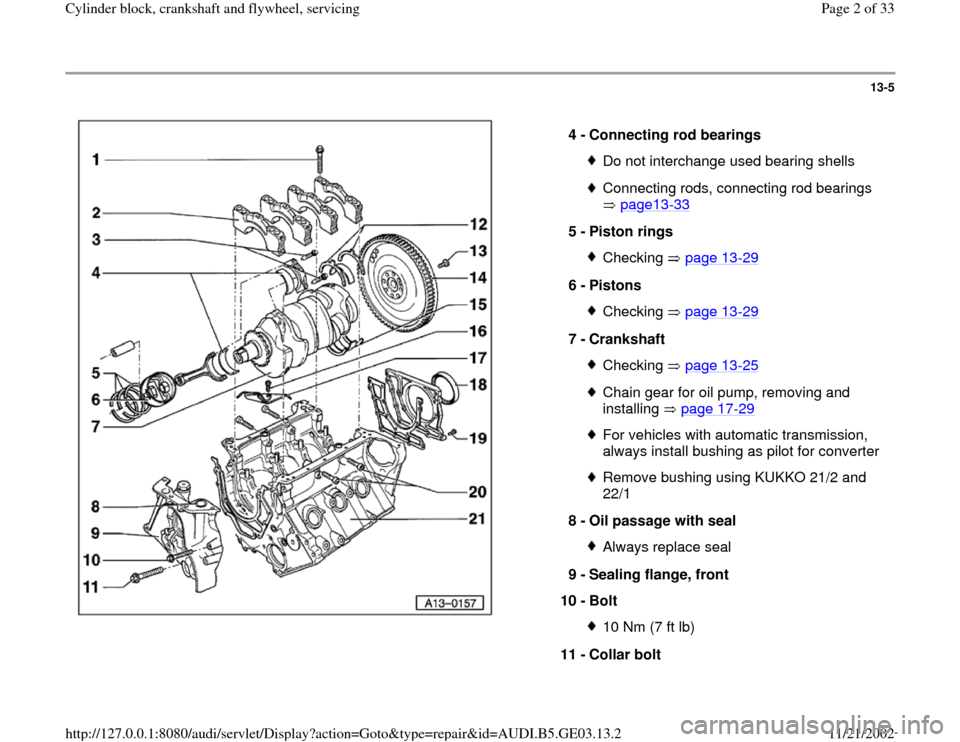

4 -

Connecting rod bearings

Do not interchange used bearing shellsConnecting rods, connecting rod bearings

page13

-33

5 -

Piston rings

Checking page 13

-29

6 -

Pistons

Checking page 13

-29

7 -

Crankshaft

Checking page 13

-25

Chain gear for oil pump, removing and

installing page 17

-29

For vehicles with automatic transmission,

always install bushing as pilot for converter Remove bushing using KUKKO 21/2 and

22/1

8 -

Oil passage with seal Always replace seal

9 -

Sealing flange, front

10 -

Bolt 10 Nm (7 ft lb)

11 -

Collar bolt

Pa

ge 2 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2

Page 22 of 33

13-23

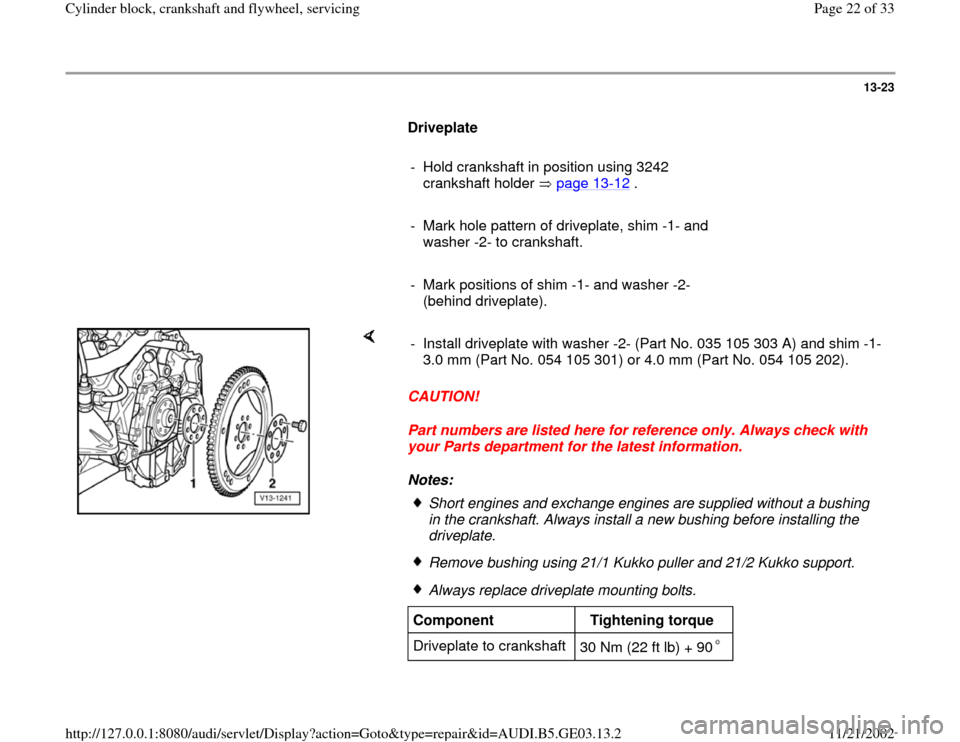

Driveplate

- Hold crankshaft in position using 3242

crankshaft holder page 13

-12

.

- Mark hole pattern of driveplate, shim -1- and

washer -2- to crankshaft.

- Mark positions of shim -1- and washer -2-

(behind driveplate).

CAUTION!

Part numbers are listed here for reference only. Always check with

your Parts department for the latest information.

Notes: - Install driveplate with washer -2- (Part No. 035 105 303 A) and shim -1-

3.0 mm (Part No. 054 105 301) or 4.0 mm (Part No. 054 105 202).

Short engines and exchange engines are supplied without a bushing

in the crankshaft. Always install a new bushing before installing the

driveplate. Remove bushing using 21/1 Kukko puller and 21/2 Kukko support.Always replace driveplate mounting bolts.

Component

Tightening torque

Driveplate to crankshaft

30 Nm (22 ft lb) + 90

Pa

ge 22 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2

Page 24 of 33

13-25

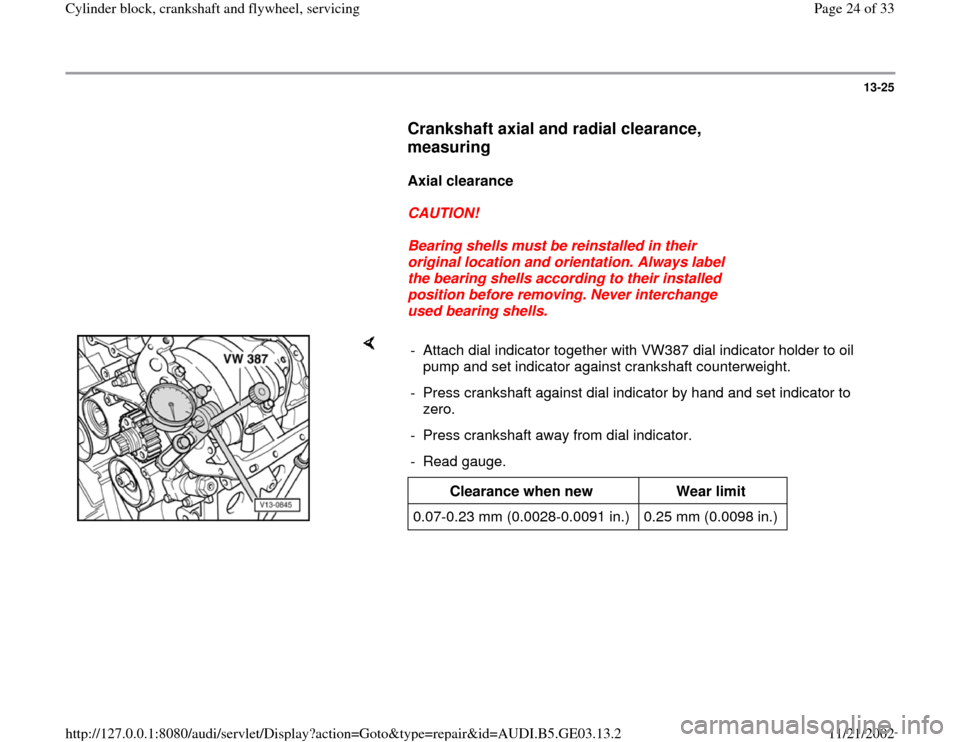

Crankshaft axial and radial clearance,

measuring

Axial clearance

CAUTION!

Bearing shells must be reinstalled in their

original location and orientation. Always label

the bearing shells according to their installed

position before removing. Never interchange

used bearing shells.

- Attach dial indicator together with VW387 dial indicator holder to oil

pump and set indicator against crankshaft counterweight.

- Press crankshaft against dial indicator by hand and set indicator to

zero.

- Press crankshaft away from dial indicator.

- Read gauge.

Clearance when new

Wear limit

0.07-0.23 mm (0.0028-0.0091 in.) 0.25 mm (0.0098 in.)

Pa

ge 24 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2

Page 32 of 33

13-33

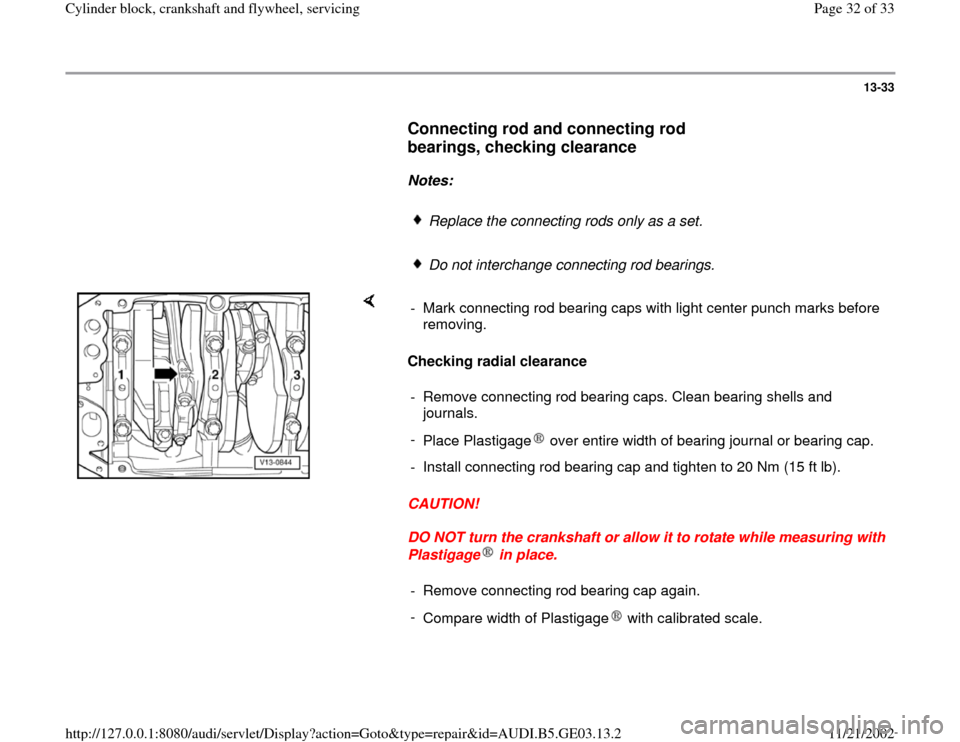

Connecting rod and connecting rod

bearings, checking clearance

Notes:

Replace the connecting rods only as a set.

Do not interchange connecting rod bearings.

Checking radial clearance

CAUTION!

DO NOT turn the crankshaft or allow it to rotate while measuring with

Plastigage in place. - Mark connecting rod bearing caps with light center punch marks before

removing.

- Remove connecting rod bearing caps. Clean bearing shells and

journals.

-

Place Plastigage over entire width of bearing journal or bearing cap.- Install connecting rod bearing cap and tighten to 20 Nm (15 ft lb).- Remove connecting rod bearing cap again.

-

Compare width of Plastigage with calibrated scale.

Pa

ge 32 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2