lock AUDI A4 1998 B5 / 1.G AFC Engine Assembly Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1998, Model line: A4, Model: AUDI A4 1998 B5 / 1.GPages: 20, PDF Size: 0.21 MB

Page 6 of 20

10-4

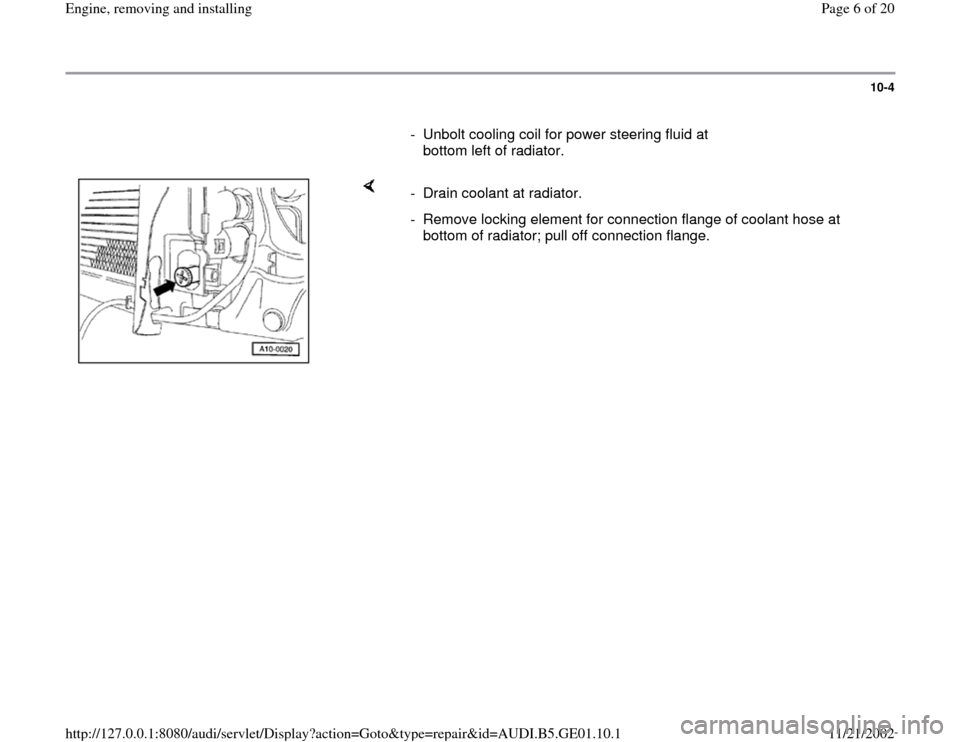

- Unbolt cooling coil for power steering fluid at

bottom left of radiator.

- Drain coolant at radiator.

- Remove locking element for connection flange of coolant hose at

bottom of radiator; pull off connection flange.

Pa

ge 6 of 20 En

gine, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.10.1

Page 12 of 20

- Remove starter, take off insulator at starter

positive (B+) connection, unbolt fixture at engine

block, disconnect ground wire from engine

support.

- Unscrew four engine mounting bolts.

Pa

ge 12 of 20 En

gine, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.10.1

Page 13 of 20

10-9

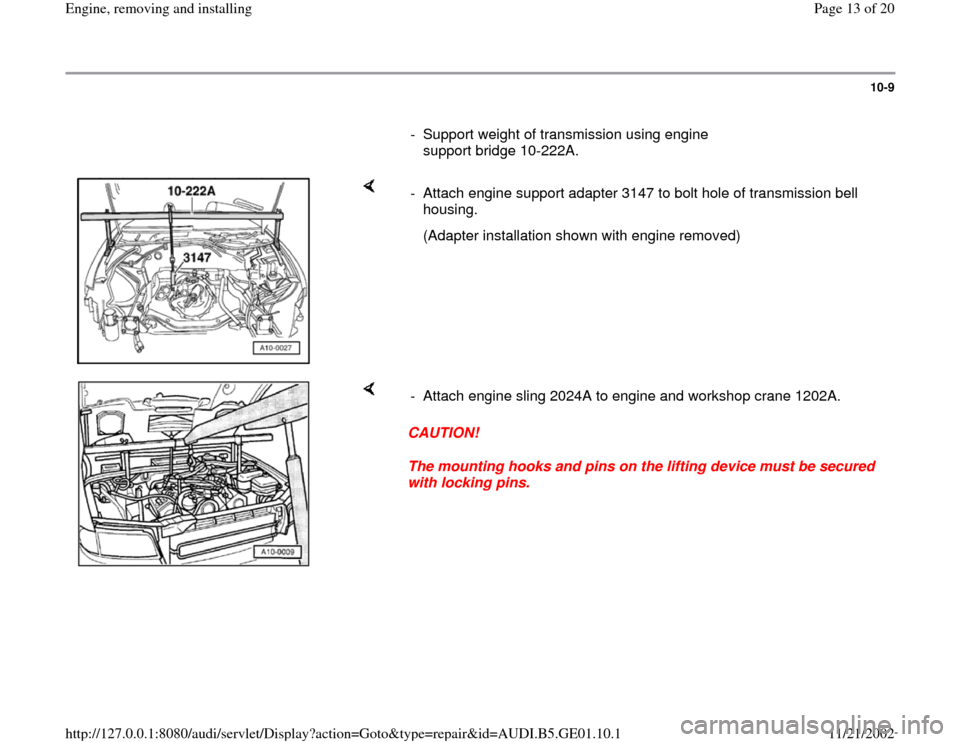

- Support weight of transmission using engine

support bridge 10-222A.

- Attach engine support adapter 3147 to bolt hole of transmission bell

housing.

(Adapter installation shown with engine removed)

CAUTION!

The mounting hooks and pins on the lifting device must be secured

with locking pins. - Attach engine sling 2024A to engine and workshop crane 1202A.

Pa

ge 13 of 20 En

gine, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.10.1

Page 14 of 20

10-10

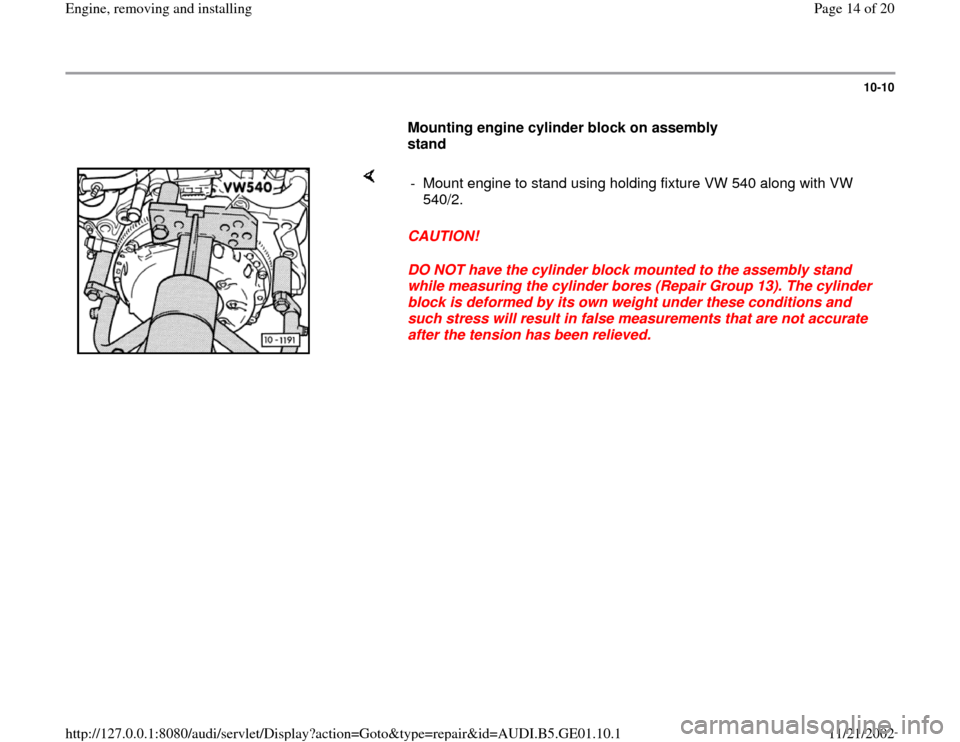

Mounting engine cylinder block on assembly

stand

CAUTION!

DO NOT have the cylinder block mounted to the assembly stand

while measuring the cylinder bores (Repair Group 13). The cylinder

block is deformed by its own weight under these conditions and

such stress will result in false measurements that are not accurate

after the tension has been relieved. - Mount engine to stand using holding fixture VW 540 along with VW

540/2.

Pa

ge 14 of 20 En

gine, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.10.1

Page 15 of 20

10-11

Installing

The engine is installed in the reverse order of

removal, with the addition of the following special

conditions and steps:

WARNING!

Do not re-use any fasteners that are worn or

deformed in normal use. Many fasteners are

designed to be used only once and become

unreliable and may fail when used a second

time. This includes, but is not limited to, nuts,

bolts, washers, self-locking nuts or bolts,

circlips and cotter pins. Always follow

recommendations given in this publication.

Always replace these fasteners with new

parts.

- Check that alignment sleeves for centering

engine and transmission are properly installed in

cylinder block. Install sleeves if necessary.

- Always install new seals and gaskets.

- Check centering of clutch disc, if necessary.

- Check clutch release bearing for wear and

replace if necessary.

Pa

ge 15 of 20 En

gine, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.10.1

Page 17 of 20

10-12

- Allow stop of torque support to move down onto

rubber block under its own weight; tighten bolts

to 45 Nm (33 ft lb).

- Align exhaust system free of stress Repair

Group 26.

- Adjust accelerator pedal cable Repair Group

20.

- Re-fill engine cooling system Repair Group

19.

- Drained coolant may only be re-used provided

the cylinder block or the cylinder head was not

replaced.

- Check oil level before starting engine.

- Short blocks are supplied without bushing in

crankshaft. For vehicles with automatic

transmission, tap bushing into place before

installing drive plate.

- Check reconditioned engines with manual

gearbox to determine whether needle bearing is

installed in crankshaft; install if necessary.

Pa

ge 17 of 20 En

gine, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.10.1