lock AUDI A4 1998 B5 / 1.G AWM Engine Lubrication System Components Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1998, Model line: A4, Model: AUDI A4 1998 B5 / 1.GPages: 35, PDF Size: 0.69 MB

Page 2 of 35

17-2

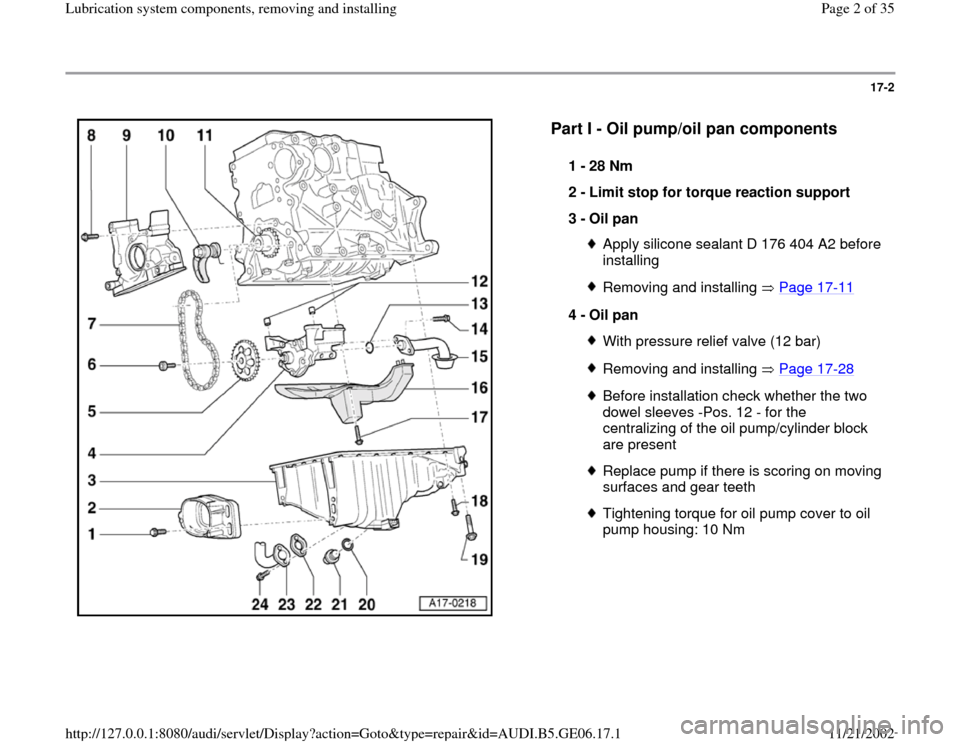

Part I - Oil pump/oil pan components

1 -

28 Nm

2 -

Limit stop for torque reaction support

3 -

Oil pan

Apply silicone sealant D 176 404 A2 before

installing Removing and installing Page 17

-11

4 -

Oil pan

With pressure relief valve (12 bar)Removing and installing Page 17

-28

Before installation check whether the two

dowel sleeves -Pos. 12 - for the

centralizing of the oil pump/cylinder block

are present Replace pump if there is scoring on moving

surfaces and gear teeth Tightening torque for oil pump cover to oil

pump housing: 10 Nm

Pa

ge 2 of 35 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE06.17.1

Page 8 of 35

17-8

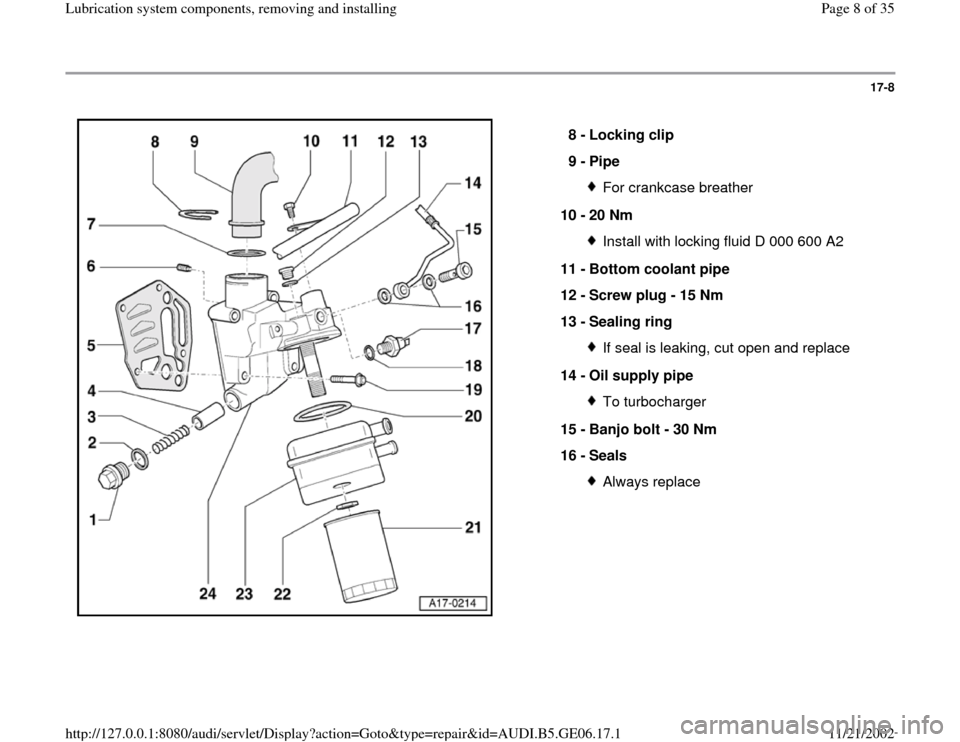

8 -

Locking clip

9 -

Pipe

For crankcase breather

10 -

20 Nm Install with locking fluid D 000 600 A2

11 -

Bottom coolant pipe

12 -

Screw plug - 15 Nm

13 -

Sealing ring If seal is leaking, cut open and replace

14 -

Oil supply pipe To turbocharger

15 -

Banjo bolt - 30 Nm

16 -

Seals Always replace

Pa

ge 8 of 35 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE06.17.1

Page 12 of 35

17-12

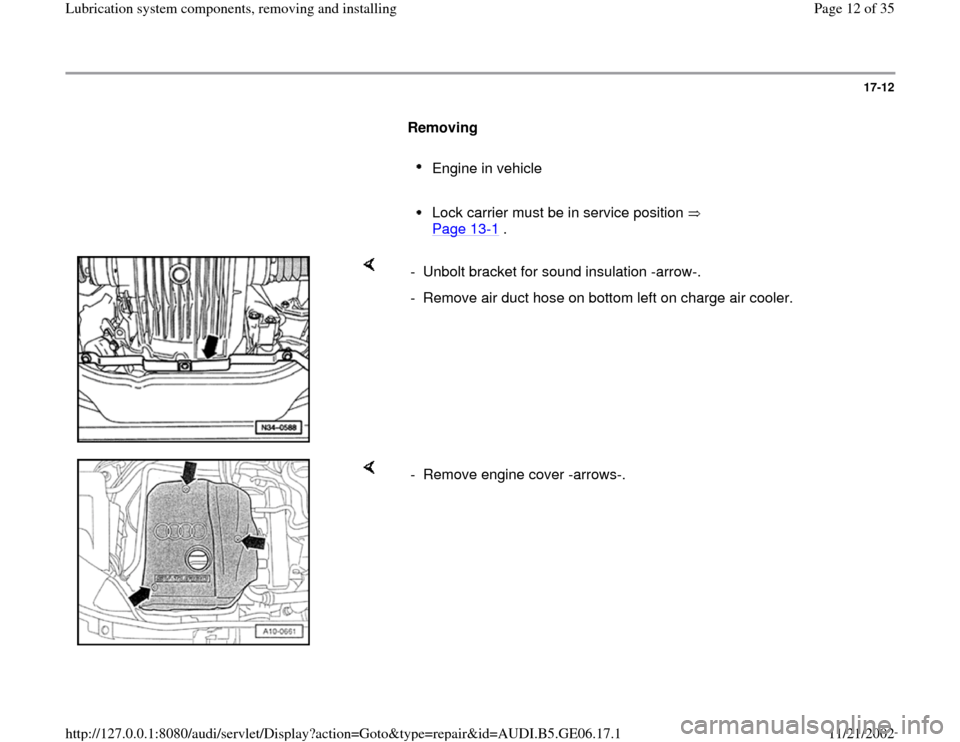

Removing

Engine in vehicle

Lock carrier must be in service position

Page 13

-1 .

- Unbolt bracket for sound insulation -arrow-.

- Remove air duct hose on bottom left on charge air cooler.

- Remove engine cover -arrows-.

Pa

ge 12 of 35 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE06.17.1

Page 14 of 35

17-14

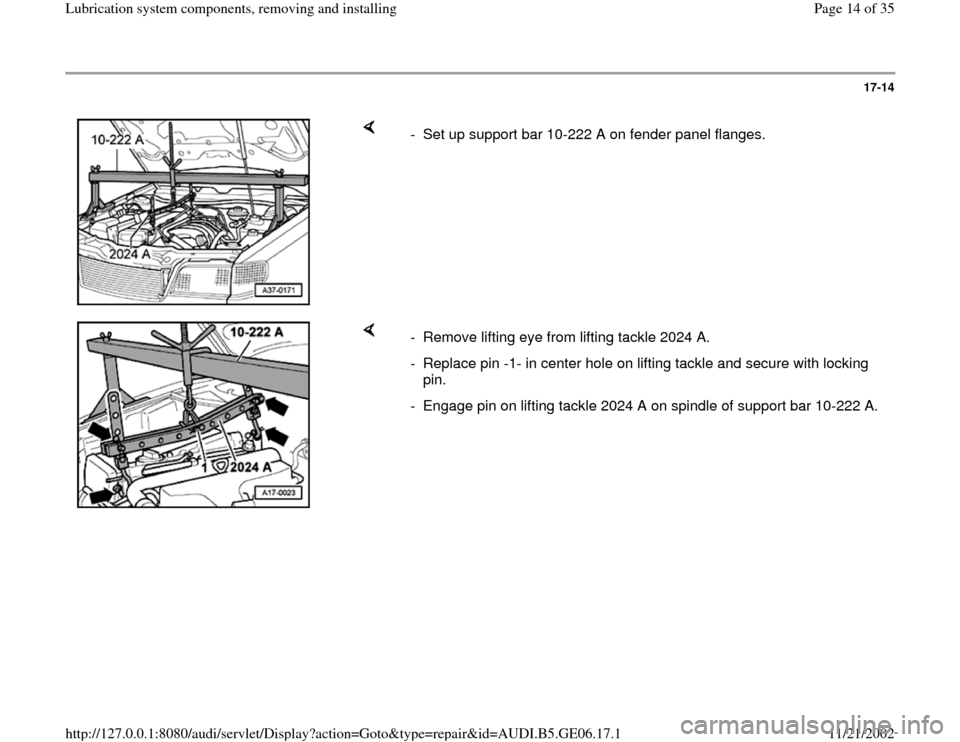

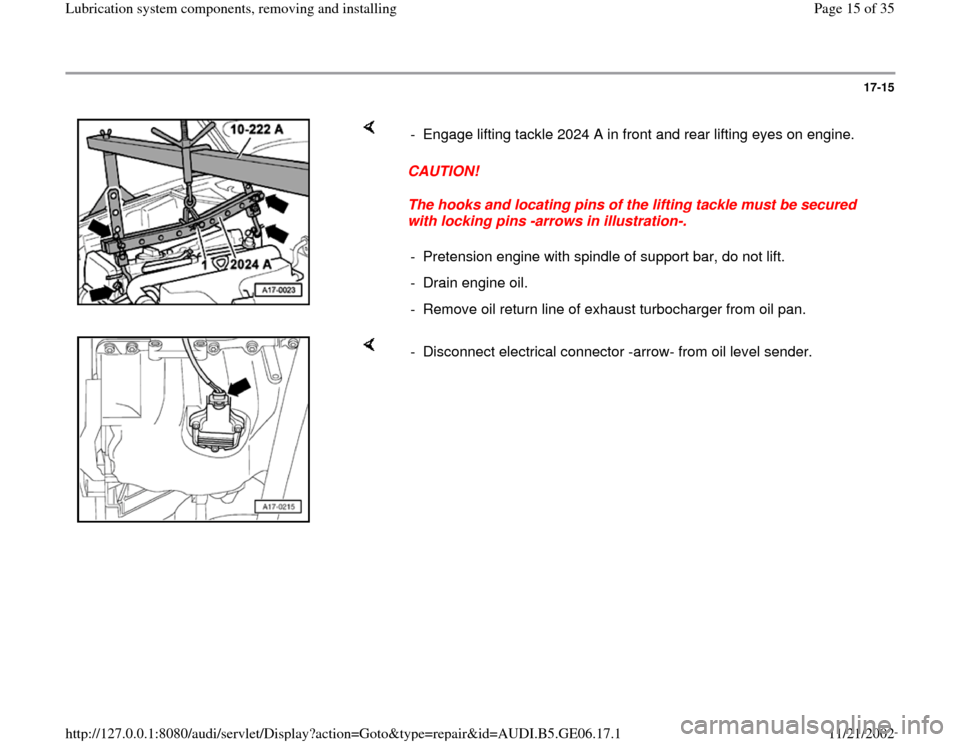

- Set up support bar 10-222 A on fender panel flanges.

- Remove lifting eye from lifting tackle 2024 A.

- Replace pin -1- in center hole on lifting tackle and secure with locking

pin.

- Engage pin on lifting tackle 2024 A on spindle of support bar 10-222 A.

Pa

ge 14 of 35 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE06.17.1

Page 15 of 35

17-15

CAUTION!

The hooks and locating pins of the lifting tackle must be secured

with locking pins -arrows in illustration-. - Engage lifting tackle 2024 A in front and rear lifting eyes on engine.

- Pretension engine with spindle of support bar, do not lift.

- Drain engine oil.

- Remove oil return line of exhaust turbocharger from oil pan.

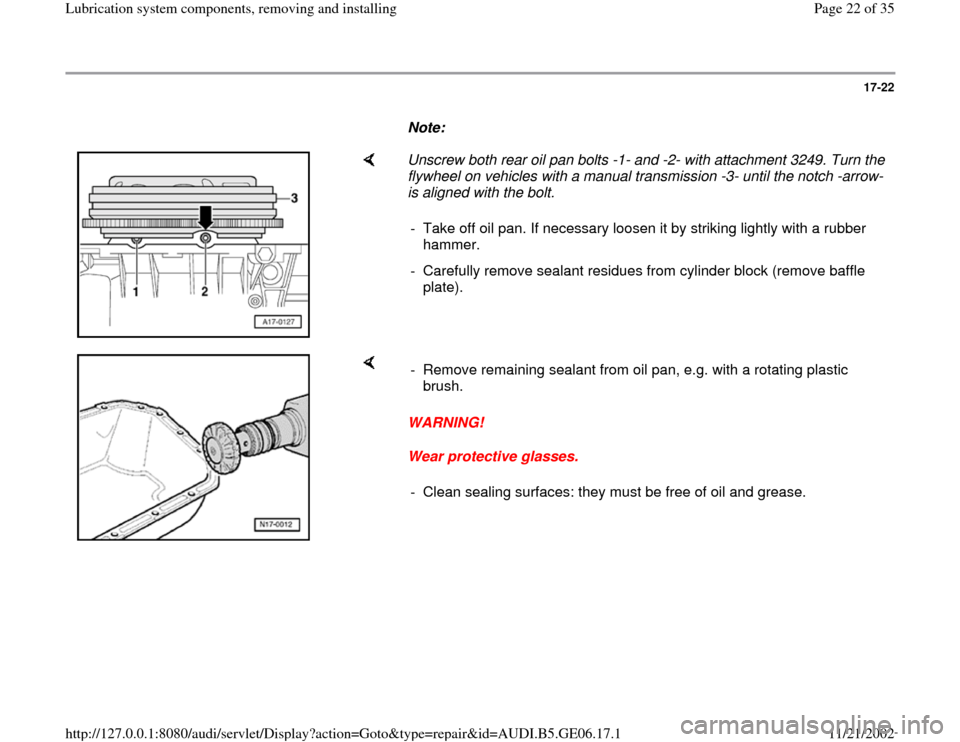

- Disconnect electrical connector -arrow- from oil level sender.

Pa

ge 15 of 35 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE06.17.1

Page 22 of 35

17-22

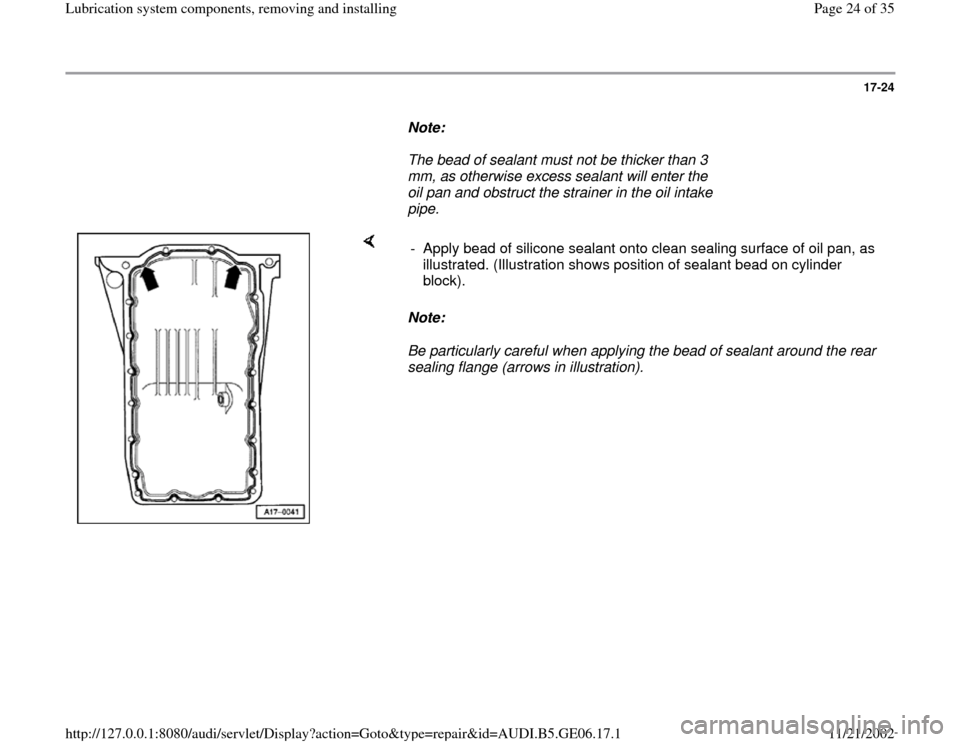

Note:

Unscrew both rear oil pan bolts -1- and -2- with attachment 3249. Turn the

flywheel on vehicles with a manual transmission -3- until the notch -arrow-

is aligned with the bolt.

- Take off oil pan. If necessary loosen it by striking lightly with a rubber

hammer.

- Carefully remove sealant residues from cylinder block (remove baffle

plate).

WARNING!

Wear protective glasses. - Remove remaining sealant from oil pan, e.g. with a rotating plastic

brush.

- Clean sealing surfaces: they must be free of oil and grease.

Pa

ge 22 of 35 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE06.17.1

Page 24 of 35

17-24

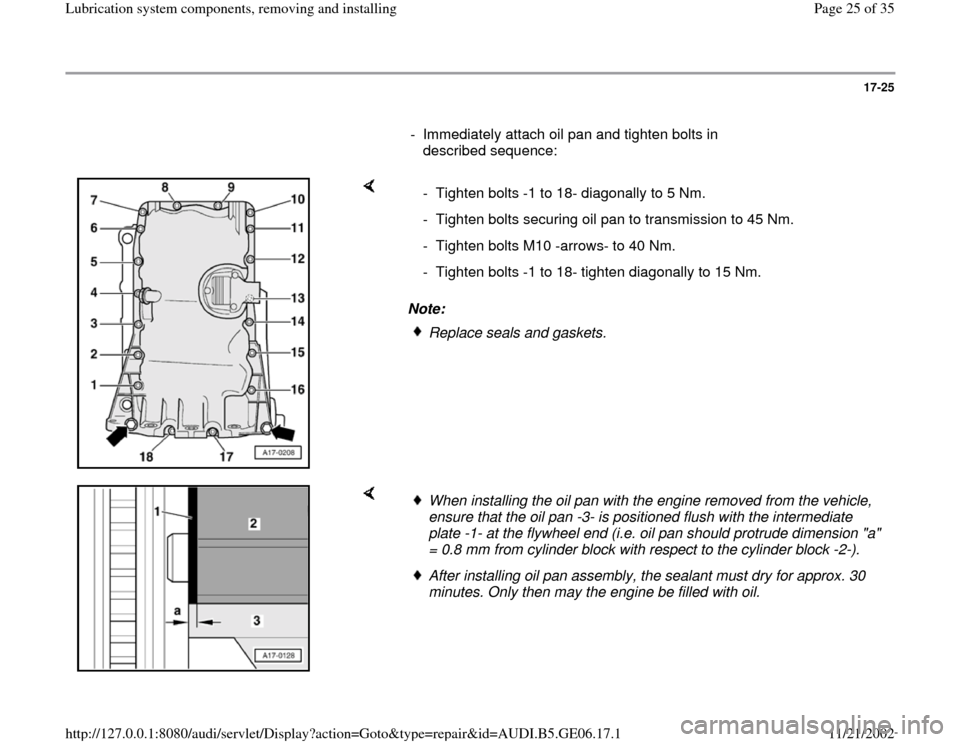

Note:

The bead of sealant must not be thicker than 3

mm, as otherwise excess sealant will enter the

oil pan and obstruct the strainer in the oil intake

pipe.

Note:

Be particularly careful when applying the bead of sealant around the rear

sealing flange (arrows in illustration). - Apply bead of silicone sealant onto clean sealing surface of oil pan, as

illustrated. (Illustration shows position of sealant bead on cylinder

block).

Pa

ge 24 of 35 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE06.17.1

Page 25 of 35

17-25

- Immediately attach oil pan and tighten bolts in

described sequence:

Note: - Tighten bolts -1 to 18- diagonally to 5 Nm.

- Tighten bolts securing oil pan to transmission to 45 Nm.

- Tighten bolts M10 -arrows- to 40 Nm.

- Tighten bolts -1 to 18- tighten diagonally to 15 Nm.

Replace seals and gaskets.

When installing the oil pan with the engine removed from the vehicle,

ensure that the oil pan -3- is positioned flush with the intermediate

plate -1- at the flywheel end (i.e. oil pan should protrude dimension "a"

= 0.8 mm from cylinder block with respect to the cylinder block -2-). After installing oil pan assembly, the sealant must dry for approx. 30

minutes. Only then may the engine be filled with oil.

Pa

ge 25 of 35 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE06.17.1

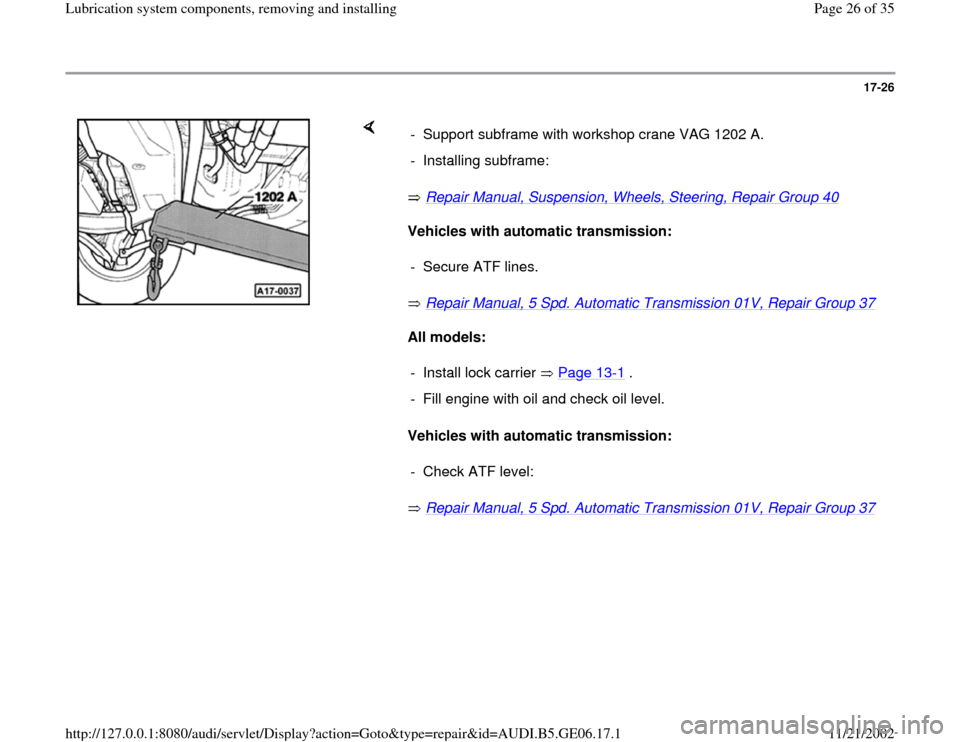

Page 26 of 35

17-26

Repair Manual, Suspension, Wheels, Steering, Repair Group 40

Vehicles with automatic transmission:

Repair Manual, 5 Spd. Automatic Transmission 01V, Repair Group 37

All models:

Vehicles with automatic transmission:

Repair Manual, 5 Spd. Automatic Transmission 01V, Repair Group 37 - Support subframe with workshop crane VAG 1202 A.

- Installing subframe:

- Secure ATF lines.- Install lock carrier Page 13

-1 .

- Fill engine with oil and check oil level.

- Check ATF level:

Pa

ge 26 of 35 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE06.17.1

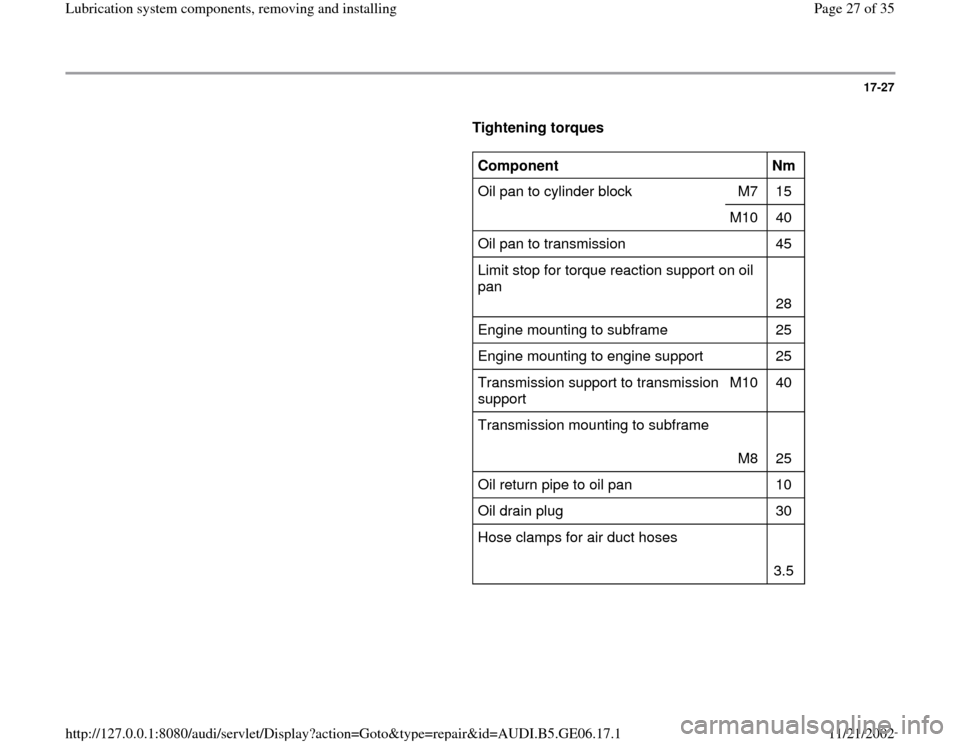

Page 27 of 35

17-27

Tightening torques

Component

Nm

Oil pan to cylinder block M7 15

M10 40

Oil pan to transmission 45

Limit stop for torque reaction support on oil

pan

28

Engine mounting to subframe 25

Engine mounting to engine support 25

Transmission support to transmission

support M10 40

Transmission mounting to subframe

M8

25

Oil return pipe to oil pan 10

Oil drain plug 30

Hose clamps for air duct hoses

3.5

Pa

ge 27 of 35 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE06.17.1